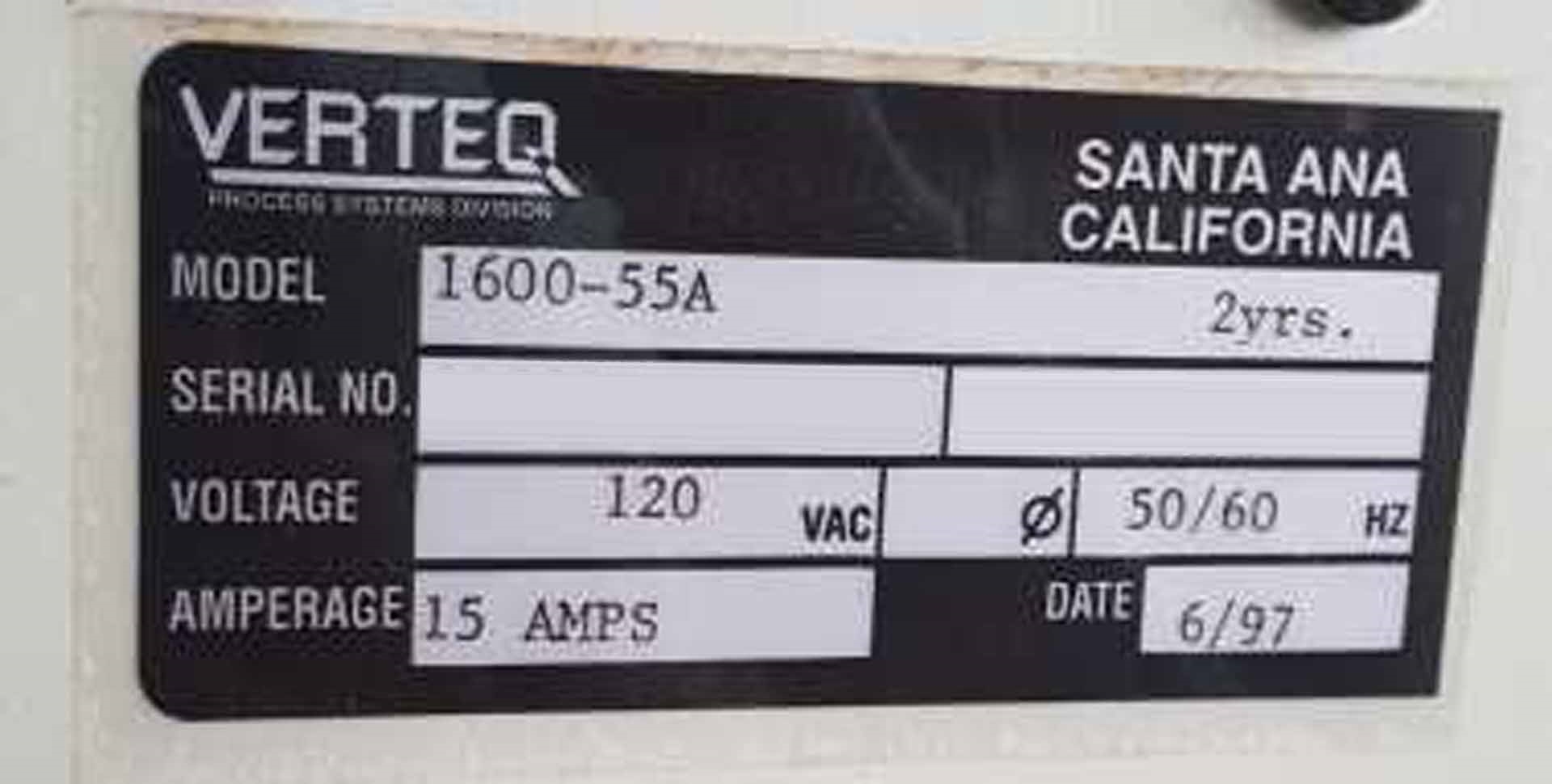

Used VERTEQ 1600-55A #9219682 for sale

URL successfully copied!

Tap to zoom

VERTEQ 1600-55A is a state-of-the-art photoresist equipment used for the production of high precision integrated circuitry. It enables the production of intricate vias and contactholes and provides dynamic and uniform patterning with consistent results. This system is ideal for the mass production of integrated circuit components which require reliable, consistent, and precise patterning. The unit is composed of a three-axis resist coating stage, an auto-spin table for quick substrate-to-substrate exchanges, and a five-axis laser exposure machine. It utilizes a combination of laser scanning and projection functions to provide multi-beam and single-beam exposures. The multi-beam laser exposure allows for microscopic patterns by focusing multiple laser beams and projecting them onto the target. The single beam laser exposure projects only one focused laser beam onto the target, resulting in larger and more covering patterns. The tool is designed with four process control parameters. The parameters are beam width, beam height, beam intensity, and time. The beam width defines how wide the pattern will be, while the beam height, determines how tall the pattern will be. The beam intensity and time settings, can be adjusted to produce an array of different patterns. This flexibility allows for better results and higher precision designs. 1600-55A also provides an auto-adjustment feature which allows for the laser to adjust to different substrates, ensuring consistent coating accuracy. Additionally, it features an automatic substrate exchanged feature that allows for a quick exchange of substrates, saving time and labor. In conclusion, VERTEQ 1600-55A Photoresist Asset is an ideal tool for the mass production of integrated circuitry with intricate features and complex patterns. Through its cutting-edge laser scanning and projection technologies, the model is capable of producing reliable, consistent, and precise results. By incorporating process control parameters and the auto-adjustment feature, the equipment provides users with the flexibility for customizing their designs and the ability to quickly exchange substrates for expeditious production.

There are no reviews yet