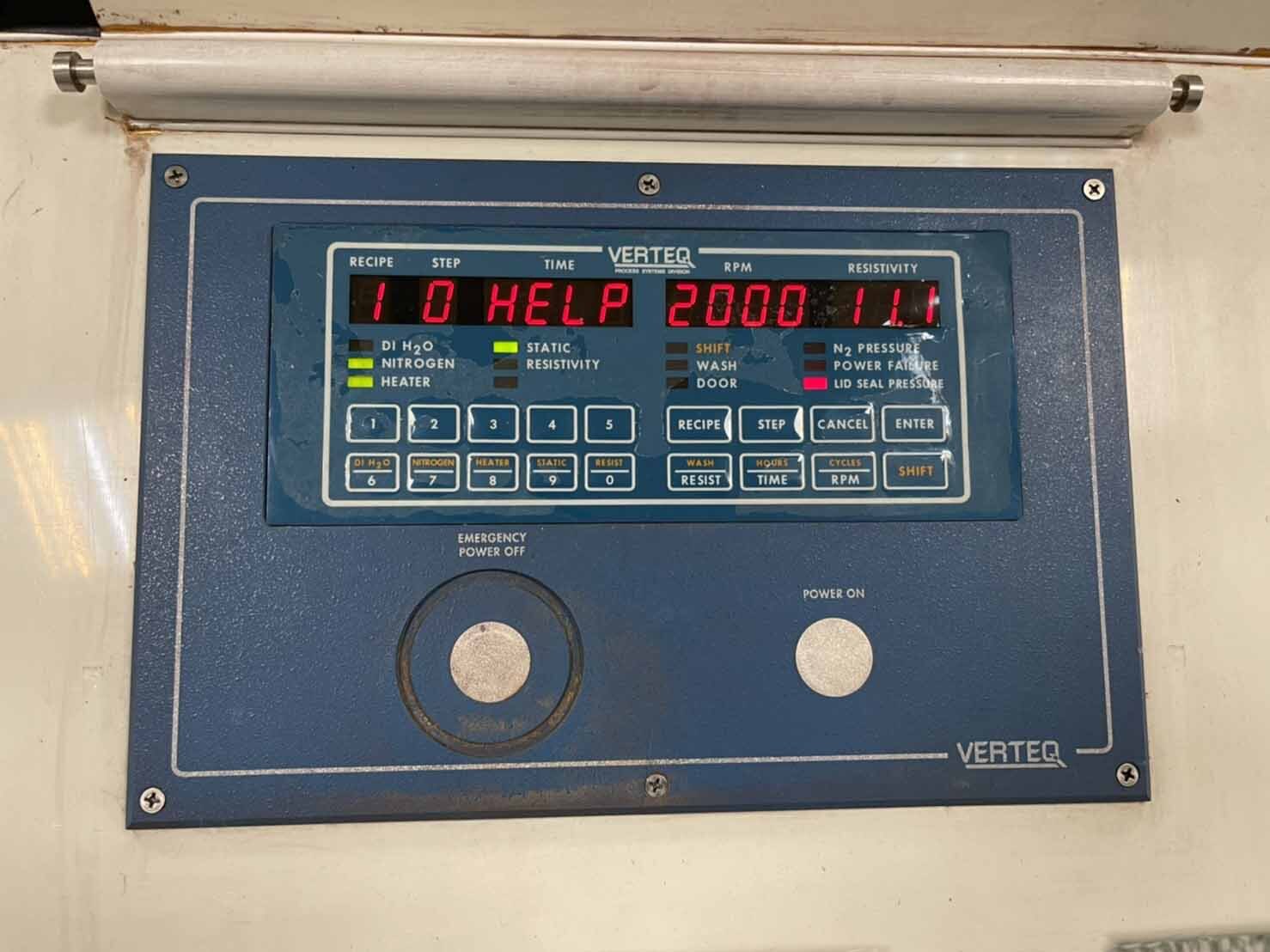

Used VERTEQ 1800-5M #9401930 for sale

URL successfully copied!

Tap to zoom

ID: 9401930

Vintage: 1997

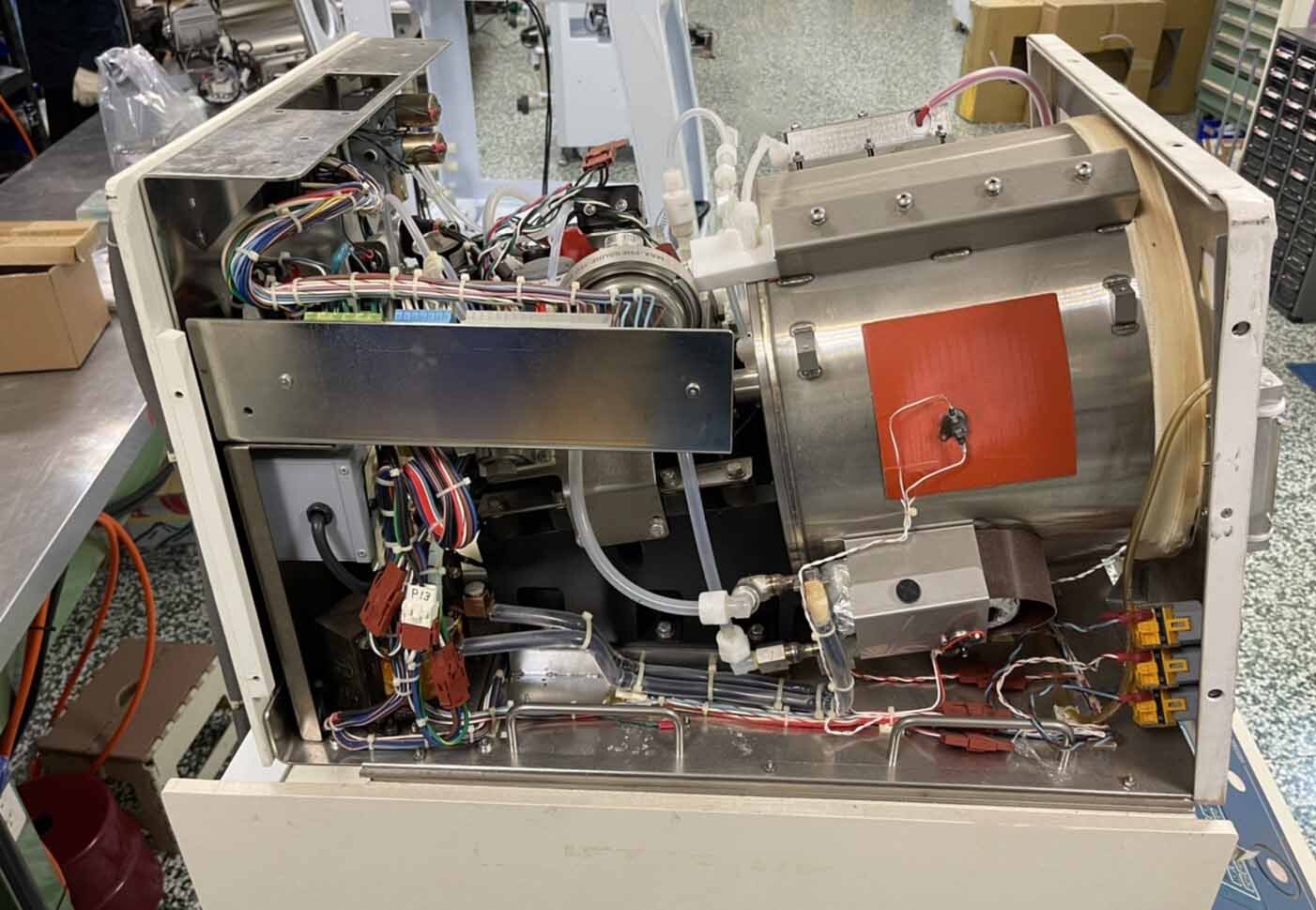

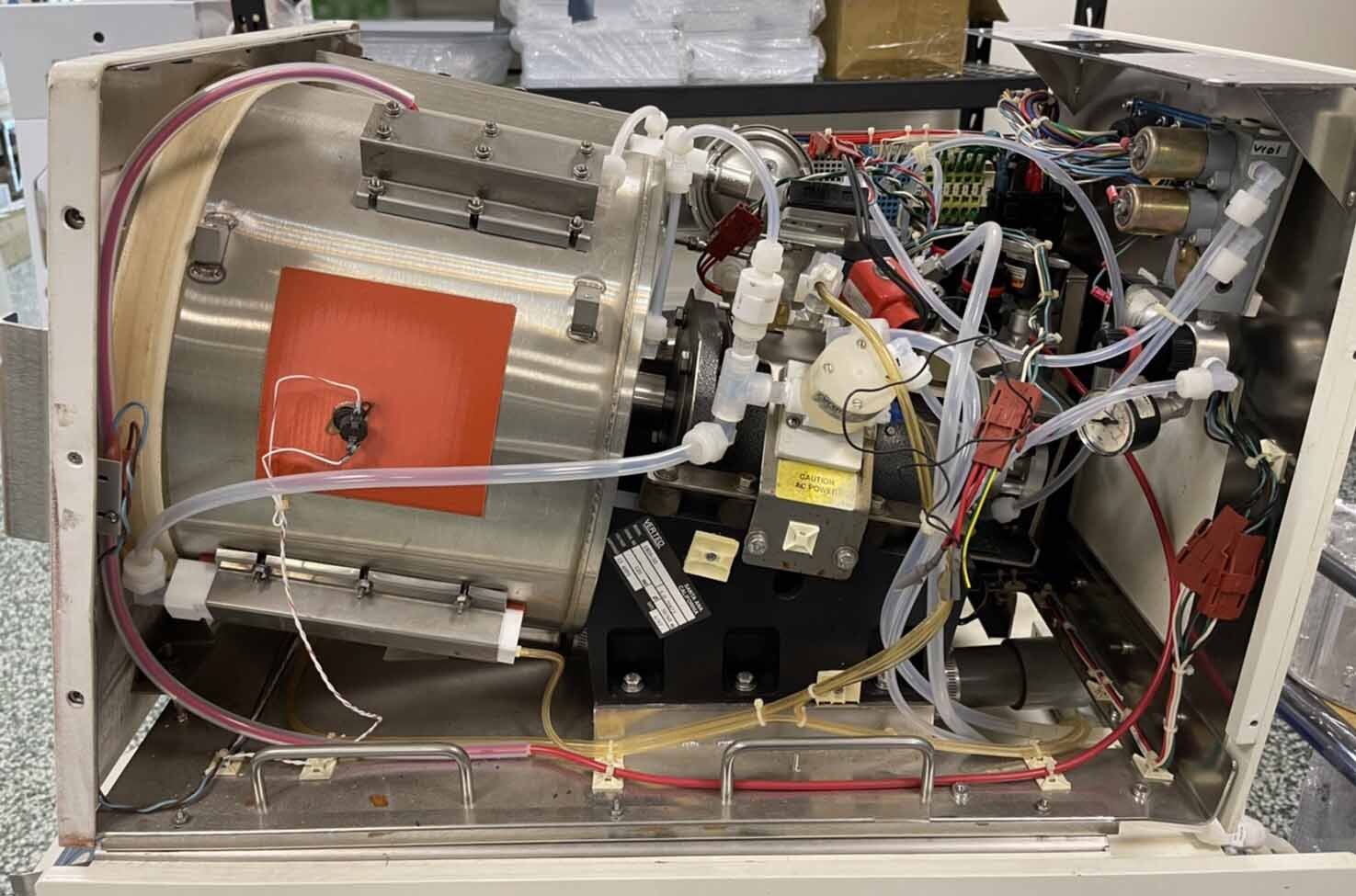

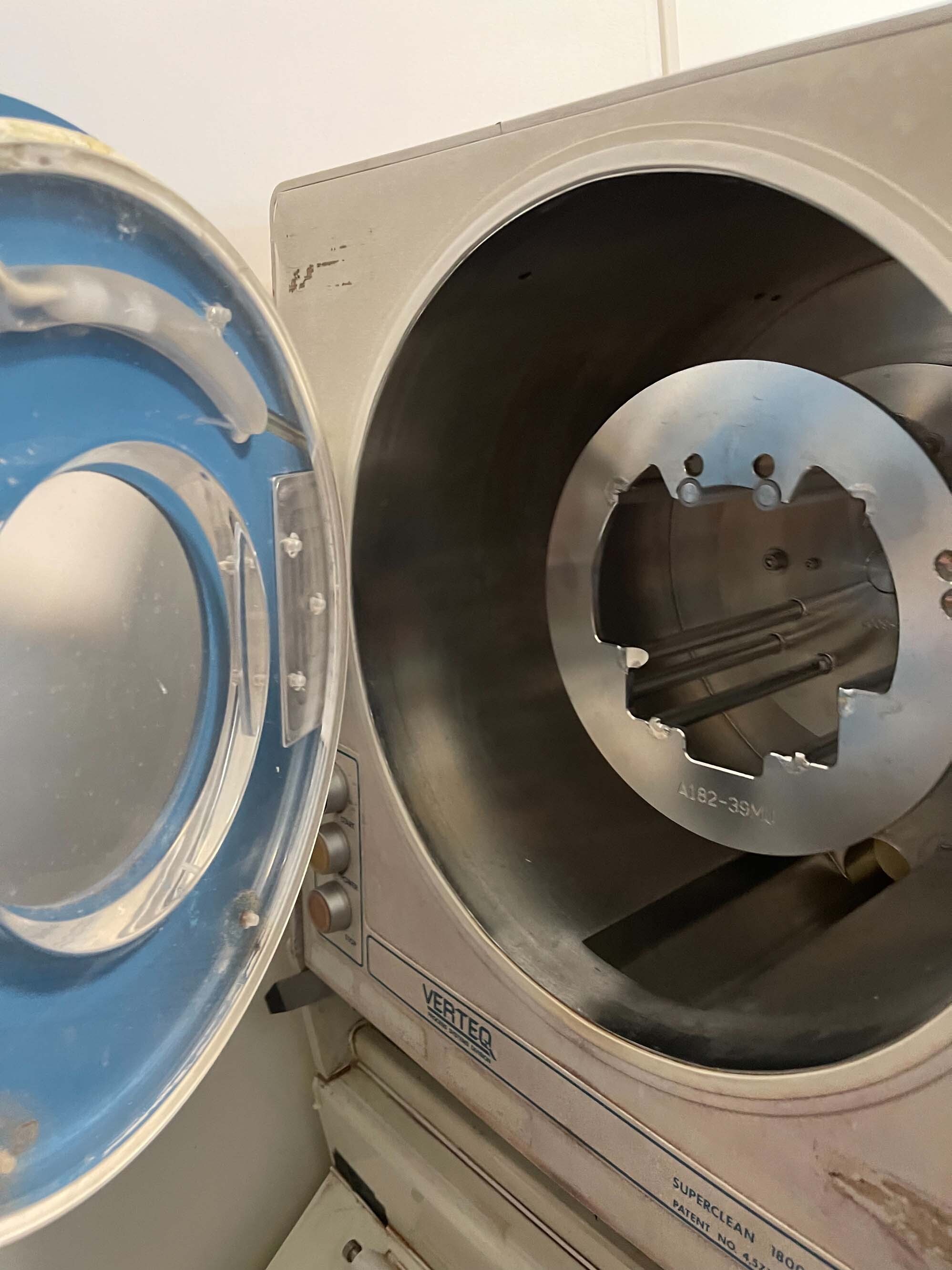

Spin Rinse Dryer (SRD), 8"

Power supply: 120 VAC, 50/60 Hz, 15 A

1997 vintage.

VERTEQ 1800-5M is an advanced photoresist equipment designed for use in the semiconductor manufacturing industry. It offers a comprehensive suite of features and capabilities to meet the needs of today's production process. 1800-5M is designed to build, align and treat wafers of various sizes and shapes. It features an advanced alignment system, allowing for precise alignment of the wafer to a high degree of accuracy. Additionally, it is also equipped with sophisticated software for controlling the temperature, gas and pressure needed for each step in the wafer processing cycle. The unit also features a microprocessor-controlled drop detector, which is designed to detect any small droplets of liquid which may be present on the wafer surface and ensure that the correct photoresist is used for the job. VERTEQ 1800-5M also offers a user-friendly integrated interface which makes it easy to program and control the machine. The intuitive interface allows for easy calibration and adjustment of tool parameters, as well as providing real-time insights into the asset's performance. 1800-5M includes multiple autonomous platform modules, allowing for simultaneous photoresist processing. This enables high-precision, high-speed operation and production. Additionally, direct connection to external suppliers facilitates quick and easy access to photoresist and other materials. VERTEQ 1800-5M is also equipped with a variety of safety features built into the model to protect the user, particularly during high-temperature operations. This includes a number of safeguards, such as automatic shutoff and fail-safe operations, which help to minimize the risk of damage to the equipment and its components. Overall, 1800-5M is an advanced photoresist system designed for use in the semiconductor manufacturing industry. It offers a comprehensive suite of features and capabilities to meet the needs of today's production process, providing users with a reliable, high-performing unit that is capable of delivering high-precision results quickly and efficiently.

There are no reviews yet