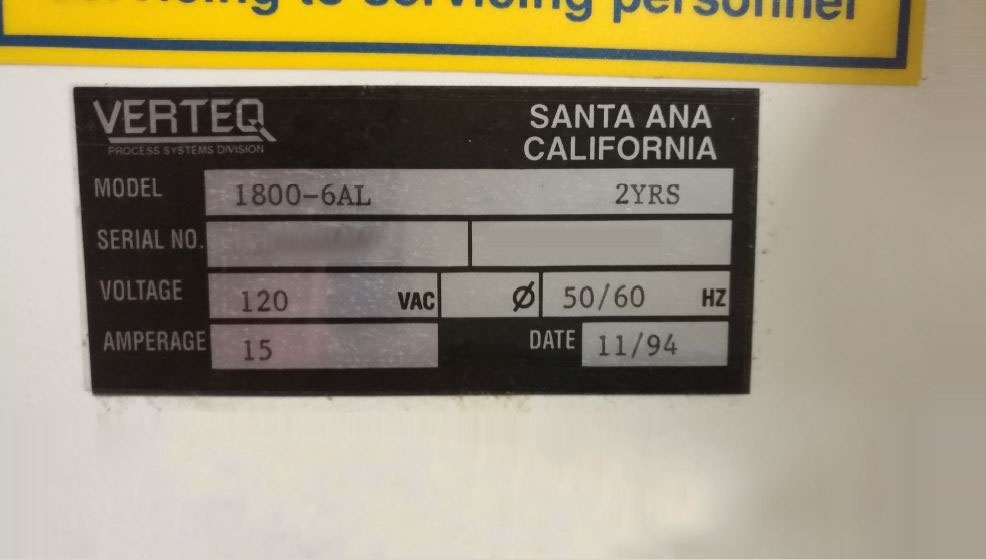

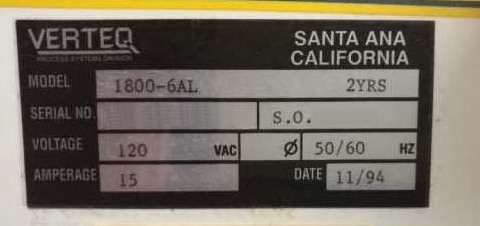

Used VERTEQ 1800-6AL #9255500 for sale

URL successfully copied!

Tap to zoom

ID: 9255500

Wafer Size: 6"

Vintage: 1994

Spin Rinse Dryer (SRD), 6"

Does not include controller and cables

1994 vintage.

VERTEQ 1800-6AL is a fully automated chemical mechanical polishing (CMP) equipment designed for photoresist materials used in semiconductor device fabrication. The system features an integrated control console and automated feed unit that can accommodate a wide range of wafer sizes and process specifications. Its design for photoresist planarization provides a more uniform surface finish across the entire wafer, resulting in improved yields and device performance. The CMP machine uses chemical mechanical polishing (CMP) techniques to achieve precise surface planarization on photoresist wafers. It uses a two-phase process which begins with a chemical etch to reduce the surface roughness of the photoresist layers, followed by a physical polish to level the photoresist surface. The tool is equipped with a platen configuration that allows for varying belt tensions to provide precision control over the contact pressure on the wafer surface. The feedback loop on the asset ensures a uniform polish rate across the whole wafer for improved process uniformity. 1800-6AL uses an integrated control console to manage the CMP process. It has an automated feed model to feed and reload wafers as needed during processing, and it is equipped with automated polishing parameters that can be easily adjusted for different types of photoresist wafers and desired processes. The equipment also features a built-in end point control system which monitors the endpoint of the CMP process and adjusts the process parameters as needed. The unit has been specifically designed for use with photoresist wafers in semiconductor device fabrication. It is highly reliable, easy to use, and comes with a range of automated safety features such as interlocks and alarms to protect the operator as well as the equipment. It is a cost-effective solution for planarizing photoresist layers on wafers, and its uniform finish reduces yield loss and improves device performance.

There are no reviews yet