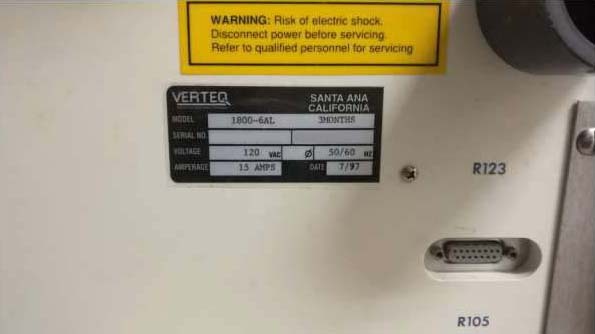

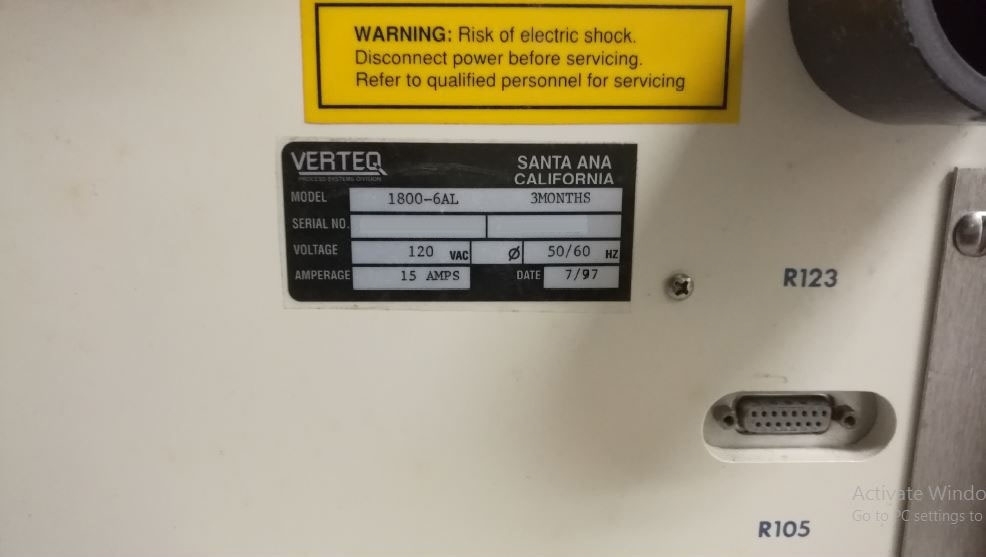

Used VERTEQ 1800-6AL #9255509 for sale

URL successfully copied!

Tap to zoom

ID: 9255509

Wafer Size: 6"

Vintage: 1997

Spin Rinse Dryer (SRD), 6"

Does not include controller and cables

1997 vintage.

VERTEQ 1800-6AL photoresist equipment is a high-precision, automated, and flexible PECVD system used in the fabrication and processing of semiconductor, optoelectronic, and biomedical components. With the use of an advanced tube-level heating chamber, the unit allows precise control over the photoresist chemistry, deposition rates, and overall performance of the machine. 1800-6AL tool utilizes a variety of vapor deposition techniques to deposit conformal thin films of photoresist with excellent film uniformity and thickness control with reproducibility. It operates using a multi-partite asset with an AC source, magnetron sputtering, and a high-pressure PECVD chamber, allowing for optimized operation for processing desired film structures. The AC source is used to create a voltage-controlled electric field in the discharge chamber to magnetically excite the high-pressure process gases. A high-power magnetron sputtering source is used as an anode to generate a controlled flux of energetic vaporized droplets of photoresist material that react with the process gases in the reaction chamber. The reaction of the process gases in the plasma decomposes the droplets into photoresist, depositing it onto the substrate in the form of a thin film. VERTEQ 1800-6AL model is exceptionally easy to operate, with a dedicated controller that allows the user to adjust the flow rate, pressure, and temperature of the process gases, as well as monitor the deposition rate for the target film thickness. The temperature of the substrate can also be precisely controlled using dedicated heaters. With these highly advanced and configurable features, the equipment has the ability to accurately and reliably deposit photoresist films of consistent thickness, grain size, and uniformity with minimal post-processing. 1800-6AL also features an auto-leveling convenience, enabling the operator to have quicker substrate changeover times and faster turnaround times between projects. This feature is especially useful for larger photoresist substrates, allowing for the automated level adjustment and substrate alignment of the deposition plate, reducing manual handling. This significantly reduces the risk of human error and streamlines the production process; ultimately allowing for faster throughputs and increased productivity. In summation, VERTEQ 1800-6AL is an advanced PECVD system offering high-precision automated control of photoresist deposition with excellent film uniformity and precision. With its automated level setting feature, monitored substrate temperature, and precision pressure and temperature control, the unit is a robust tool widely used in the semiconductor, optoelectronic and biomedical device fabrication and processing industry.

There are no reviews yet