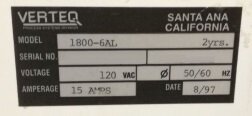

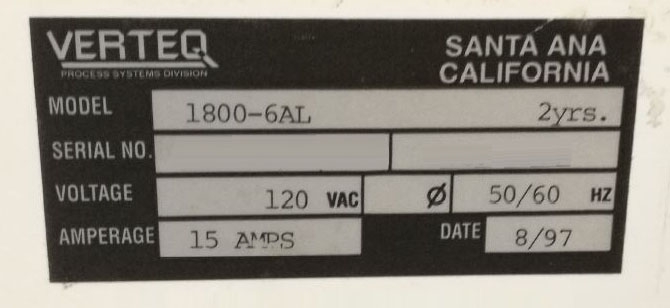

Used VERTEQ 1800-6AL #9255522 for sale

URL successfully copied!

Tap to zoom

ID: 9255522

Vintage: 1997

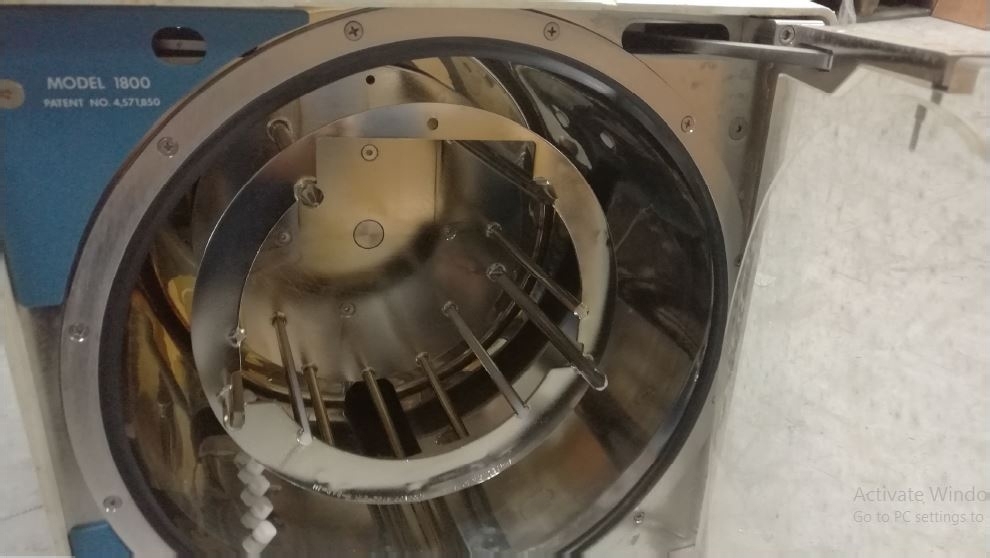

Spin Rinse Dryer (SRD)

Without controller and cables

1997 vintage.

VERTEQ 1800-6AL is a photoresist equipment, designed to provide an accurate and efficient patterning of substrates. The system utilizes a low-voltage, high-speed, laser-technology based exposure unit with precision pattern alignment. The exposure machine is capable of producing resolution of between 0.25 and 1.5 microns, with exposure up to 6 UV wavelengths for multi-x technology. The laser exposure is capable of exposure of 20 and 50 watt laser power, and also has polarizing effects for exposure of alignment layers. The tool also offers a high-speed Maskless Array Illumination (MAI) exposure with aberration-free resolution, as well as high speed axis synchronous exposure technology and a passive thermal management asset. The model features a x,y,z measurement and exposure automation and a monitoring equipment, allowing for accurate and repeatable patterns. 1800-6AL also includes a multi-stage cassette exposure station and an exposure arm stabilization system. Both of these features contribute to improved process stability and performance, and enable efficient and continuous operation of the unit. VERTEQ 1800-6AL is ideal for traditional photoresist processes such as direct write lithography and imprint lithography, as well as supporting a variety of other process steps, including wet processing and nanoparticle deposition. The machine can be used to pattern a wide range of substrates, such as liquid-epitaxial-grown device layers, metals, ceramics, polymers and glass. In terms of safety, the tool is CE compliant, with emergency stop and emergency access features enabling quick shut off in hazardous scenarios. Additionally, the asset is capable of automatically monitoring substrate profiles and the alignment of the patterned structures, making sure that all process steps adhere to the tightest tolerances. 1800-6AL is a sophisticated and reliable photoresist model, providing excellent resolution, improved process stability and safety. Its multi-x laser exposure technology and automatic monitoring equipment provide consistent and accurate results, making this system ideal for a range of photoresist processes.

There are no reviews yet