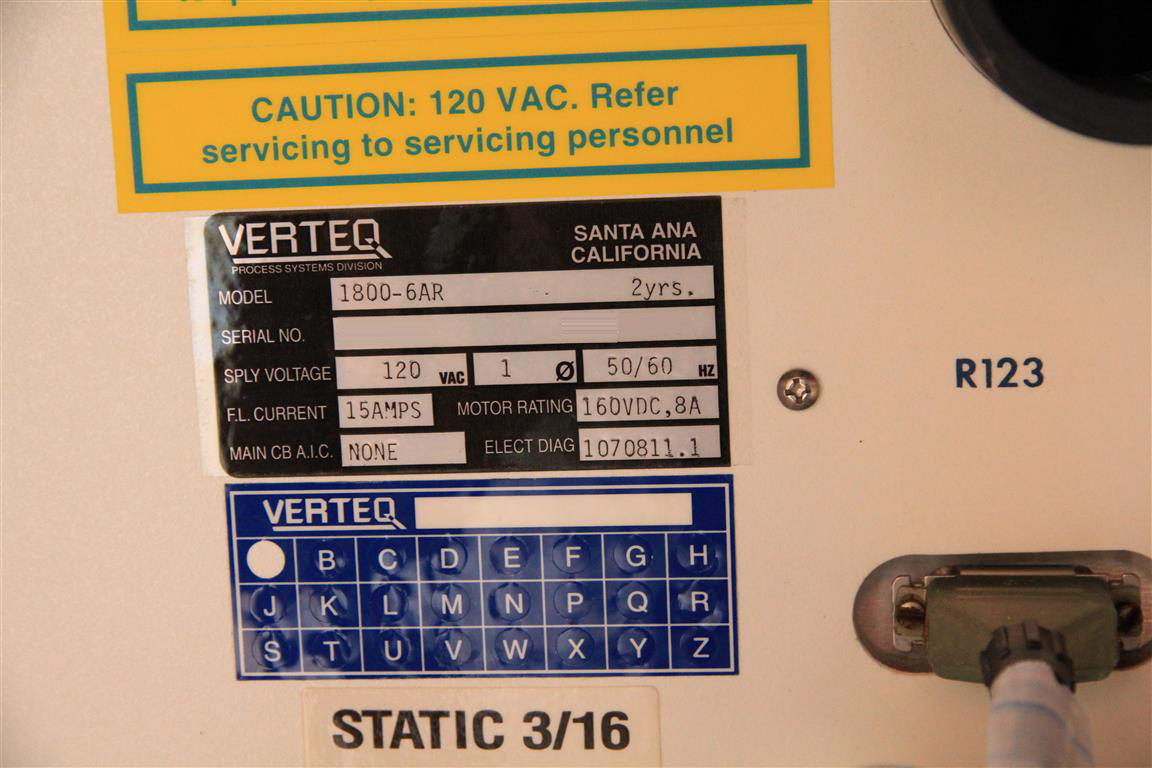

Used VERTEQ 1800-6AR #9070694 for sale

URL successfully copied!

Tap to zoom

ID: 9070694

Spin rinse dryer, (SRD), 8"

Single chamber

Connections: CDA/N2, DI In, N2 In, DI Out

Currently warehoused.

VERTEQ 1800-6AR photoresist equipment is a critical component to many production processes around the world. The system is a highly capable and sophisticated unit that gives users the ability to build, clean, and repair substrates using a variety of methods and material source material. The machine consists of a photo-mask aligner with a built-in light source and a precision resist spinner. The photomask aligner is used to divide the substrate into particular shapes using a series of predetermined masks. An optical alignment tool then aligns the layer of exposed material accordingly. After the layer is exposed, the resist spinner then applies the photoresist material to the substrate. Different photoresist materials can be used to ensure susceptibility to laser radiation while still retaining-sensitive areas. The precision resist spinner is capable of spinning the substrate at speeds up to 18,000 RPM to ensure accurate and exact layer deposition. At its highest settings, the spinner applies a uniform thickness to the substrate with a minimal amount of deviation that allows for accurate layer placement. It also features low torque levels that make it easy for operators to keep a constant spinning speed as they move the substrate through the process. The spinner also includes a leak-proof air support asset to ensure safety and air-sensitive materials are not contaminated. This model features temperature controllers that keep the air over the substrate at a constant level of purity. The equipment is charge-neutral, which eliminates the need for additional power supplies or direct current sources to bind the resist layer to the substrate. This feature further reduces contamination and simplifies the process while enhancing the accuracy of the layer placement. 1800-6AR photoresist system is a highly advanced and intuitive unit with all the features required to consistently build components with tight tolerances. This machine was designed for commercial vendors and end users alike.

There are no reviews yet