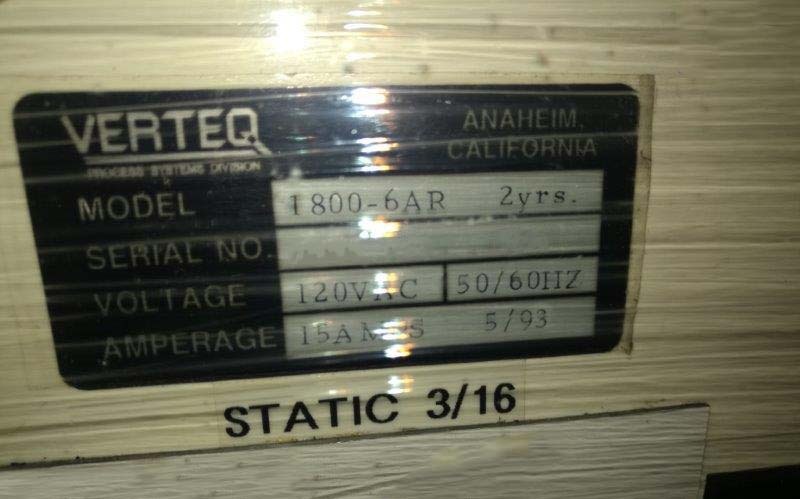

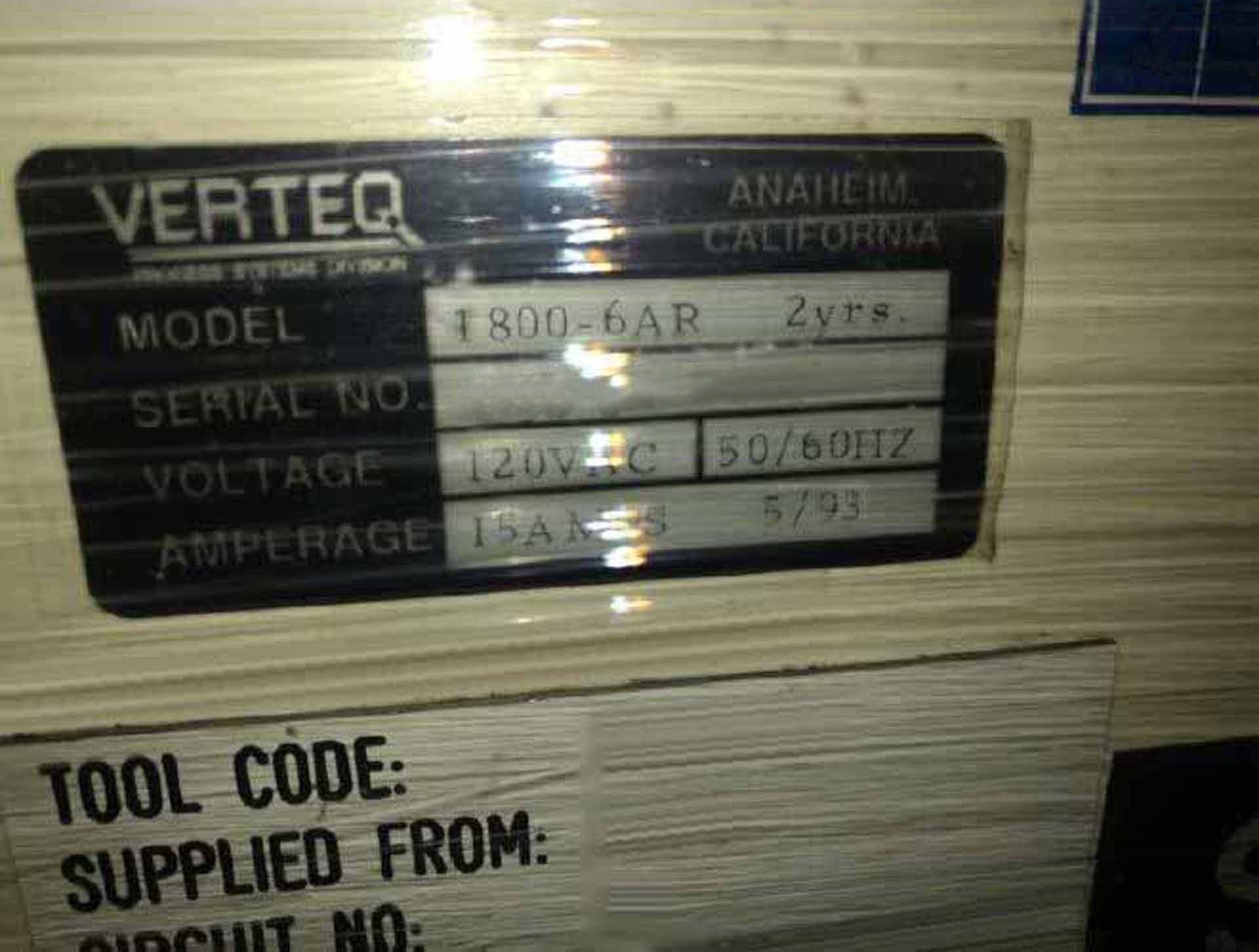

Used VERTEQ 1800-6AR #9228771 for sale

URL successfully copied!

Tap to zoom

VERTEQ 1800-6AR is a photoresist equipment specifically designed for microfabrication. It is a vacuum-capable machine that uses a multi-column configuration to make the most precise photoresist patterns. This system is especially advantageous when working with highly sensitive substrates like III-V materials, because it increases pattern accuracy and precision. At the heart of this unit is its rotary stage, which allows the substrate to be moved in all six directions of XYZ. This motion, coupled with the 6-axis robotic arm, provides the highest degree of accuracy for placing thin film resist layers. The robotic arm also serves as a carrier for a pair of photon energy source panels, which generate the UV light used in the photolithography process. In 1800-6AR machine, both the robotic arm and the rotation stage are driven by two high-performance servo motors, which enable a wide range of motion and high repeatability. In addition, the tool is also equipped with a programmable temperature control tool that keeps the working environment and the substrate at a constant and consistent heat level, so that the most accurate patterns can be achieved. In order to make perfect and accurate patterns, the asset is equipped with an integrated laser and optical alignment model. This makes sure that accurate exposure is achieved, while allowing the substrate to be exposed in a point-by-point manner. This ensures a uniform patterning experience with no deviation. VERTEQ 1800-6AR equipment is also equipped with advanced data processing and communication solutions. The robotic arm is able to transmit data from its measurement systems directly to the computer, where programmers and engineers can quickly adjust routings, pressures, and temperatures. This gives the system the fastest response and greatest flexibility in the microfabrication process. The high-precision control capabilities, coupled with excellent sub-nanometer accuracy, makes the unit ideal for creating patterns with extreme accuracy and resolution. In addition, the machine offers integrated yet quite detailed error-tracking systems, along with an intelligent machine logic feature that helps detect errors and provide automatic corrections. This ensures a flawless production output. Overall, 1800-6AR is an extremely precise photoresist tool with a wide range of features and capabilities to assist in the microfabrication process. This asset offers the highest level of accuracy while minimizing human-interaction risks as much as possible. The model's ability to double as both an automated robot and a photolithography engine allows it to keep up with modern technological advances and provide precision in the most demanding microfabrication environments.

There are no reviews yet