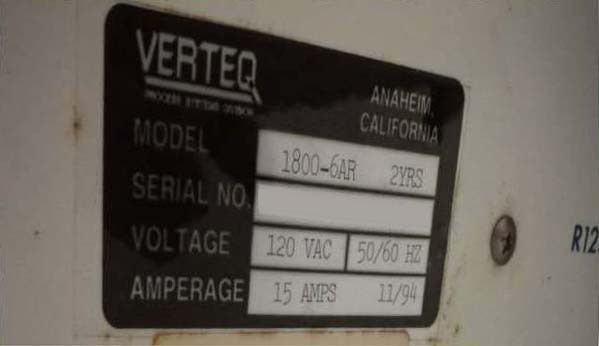

Used VERTEQ 1800-6AR #9255510 for sale

URL successfully copied!

Tap to zoom

ID: 9255510

Wafer Size: 6"

Vintage: 1994

Spin Rinse Dryer (SRD), 6"

Doe not include controller and cables

1994 vintage.

VERTEQ 1800-6AR is a professional photoresist equipment designed to process photoresist and other related materials in the most efficient manner. Photoresist is a crucial material in many microelectronics processes such as lithography, etching, and deposition. 1800-6AR offers advanced features to enable users to work quickly and accurately in these processes. VERTEQ 1800-6AR employs a state-of-the-art 6-axis robot arm for accurately and quickly transferring substrates and materials. It is a completely automated photoresist system that is capable of moving - and filling - microfabrication materials through multiple lines and even catalyst off-gassing. This allows complex processing operations to be completed with utmost accuracy and precision. The 6-axis robot arm of 1800-6AR has a working range of 1200 mm in X and Y axes and 450 mm in Z axis, allowing it to process substrates of different sizes with utmost accuracy. It is also equipped with a sophisticated vision unit that provides real-time feedback of the photoresist-processing steps. This helps users to monitor and adjust processes for optimal performance. VERTEQ 1800-6AR also has the capability to quickly transfer small amounts of photoresist for development and sampling, making it very suitable for research and development purposes. The transport and filling capabilities of this machine also make it an ideal choice for prototype manufacturing. The clear, touchscreen interface of 1800-6AR allows users to adjust the tool quickly, even in complex operations. It offers an intuitive interface and a vast library of presets, and also enables remote programming of the asset. All of this helps users to enjoy maximum control of the process and increase its efficiency. Overall, VERTEQ 1800-6AR is an advanced photoresist model offering robust features that maximize accuracy and efficiency in photoresist processing operations. Its 6-axis robot arm, sophisticated vision equipment, intuitive touchscreen interface, and remote programming capability make it an ideal choice for quick and accurate feedback processes.

There are no reviews yet