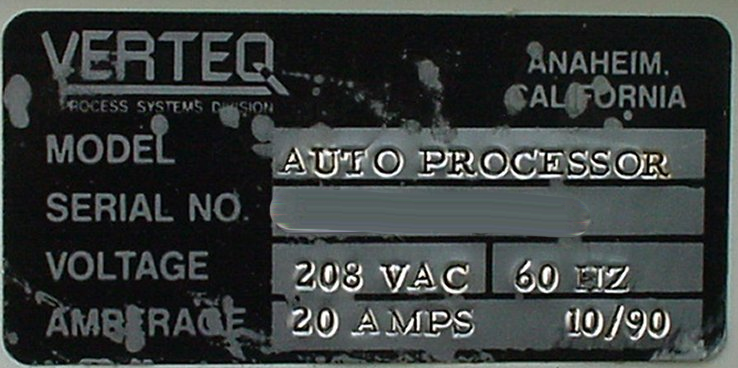

Used VERTEQ Auto Processor #142256 for sale

URL successfully copied!

Tap to zoom

VERTEQ Auto Processor is a revolutionary photoresist equipment designed to enable the production of photoresist patterns with high accuracy, repeatability, and speed. The system uses high-precision, state-of-the-art technology for its photoresist production. It is designed for use with all types of photoresist materials, including standard dry-film and dry electro-photoretic photoresist systems. The unit utilizes several key subsystems in order to achieve its capabilities. The first is a stepper motor with a built-in control machine that enables the accurate and repeatable delivery of photoresist materials onto a substrate. The motor is compatible with a range of motion control systems, allowing the tool to be easily integrated into existing manufacturing processes. The second is the substrate cleaning and pre-treatment asset. This model enables the substrate to be prepared in a way that optimizes photoresist pattern formation on it. The equipment also includes an advanced and versatile metering system for photoresist coating. This unit features a servo-controlled metering plate, which precisely measures and places photoresist material onto the substrate. The addition of the servo-controlled metering plate helps to minimize the possibility of errors that can occur during the coating process. The process of photoresist application is performed by an advanced laser machine, which ensures uniform and finely detailed patterns on the substrate. This laser tool can also be used to print a line or a matrix of photoresist material onto the substrate. Finally, the asset includes an integrated post-processing unit, which helps to ensure that all photoresist patterns on the substrate are firmly and securely attached to its surface. Auto Processor is built to meet the highest performance, reliability and efficiency standards, making it ideal for use in the production of small to large photoresist patterns. It is suitable for both large and small substrate sizes, and can be easily and quickly integrated into existing manufacturing processes. Additionally, it is capable of printing with various photoresist materials, allowing for a wide range of applications.

There are no reviews yet