Used VERTEQ Etch Processor #142255 for sale

URL successfully copied!

Tap to zoom

ID: 142255

Vintage: 1990

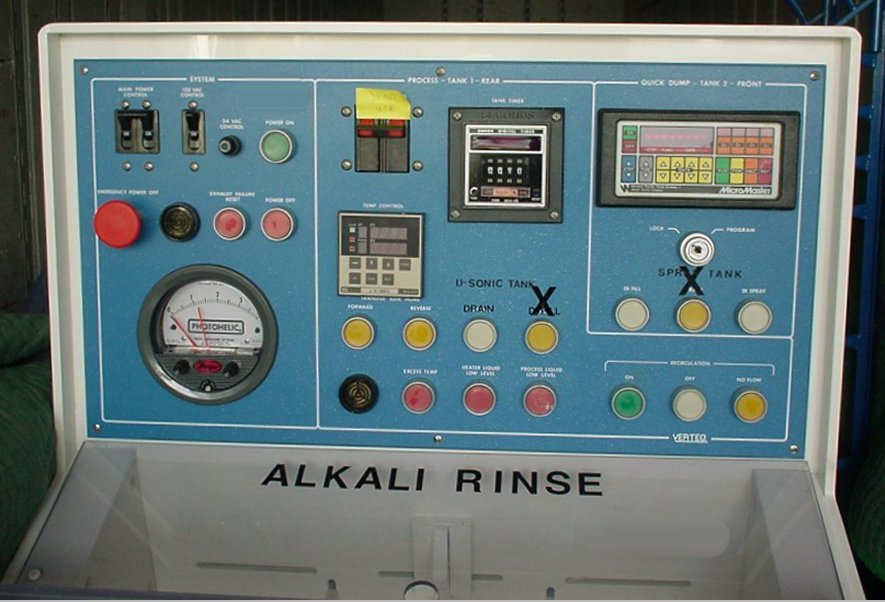

Automatic processor, wet sink

208 Vac, 60 Hz, 20 Amp

1990 vintage.

VERTEQ Etch Processor is a photoresist equipment used for precise etching and engraving on hard substrates, such as metals and hard plastics. The robust and efficient design of the system enables it to work at temperatures up to 90°C and with a range of suitable materials up to T6 in strength. It also includes a unique layer formation technology which offers uniform etching on very thin substrates and low-k dielectric materials. Etch Processor consists of three main components: an electrolytic discharge unit, an optical path unit, and an anodic etching unit. The electrolytic discharge unit is used to generate an electric current in the bath surrounding the substrate. This current is then used to activate the photoresist material, where the exposed portions become conductive and the unexposed portions retain their insulating properties. The optical path unit is responsible for separating the illumination source from the substrate and focusing the light onto the resist material in a controlled pattern. This allows for precise light patterning and etch patterning in the target material. Finally, the anodic etching unit is responsible for the actual etching of the substrate material, as the applied current levels cause an oxidation reaction in the material. VERTEQ Etch Processor also includes temperature control, pressure control, and humidity control units to ensure that etching parameters are kept within the specified range. In addition, the unit includes a closed loop feedback machine which continuously monitors the etching process and adjusts anodic current levels accordingly. Tool safety features such as short-circuit protection and a break-in circuit monitoring asset are also in place. The total package of tools and mechanism makes Etch Processor an ideal tool for electronics packaging, dye sensing, and ferroelectric applications. This reliable and efficient micro-etching model can be used to etch complex and intricate shapes onto a variety of hard substrates with excellent features and industry-leading precision.

There are no reviews yet