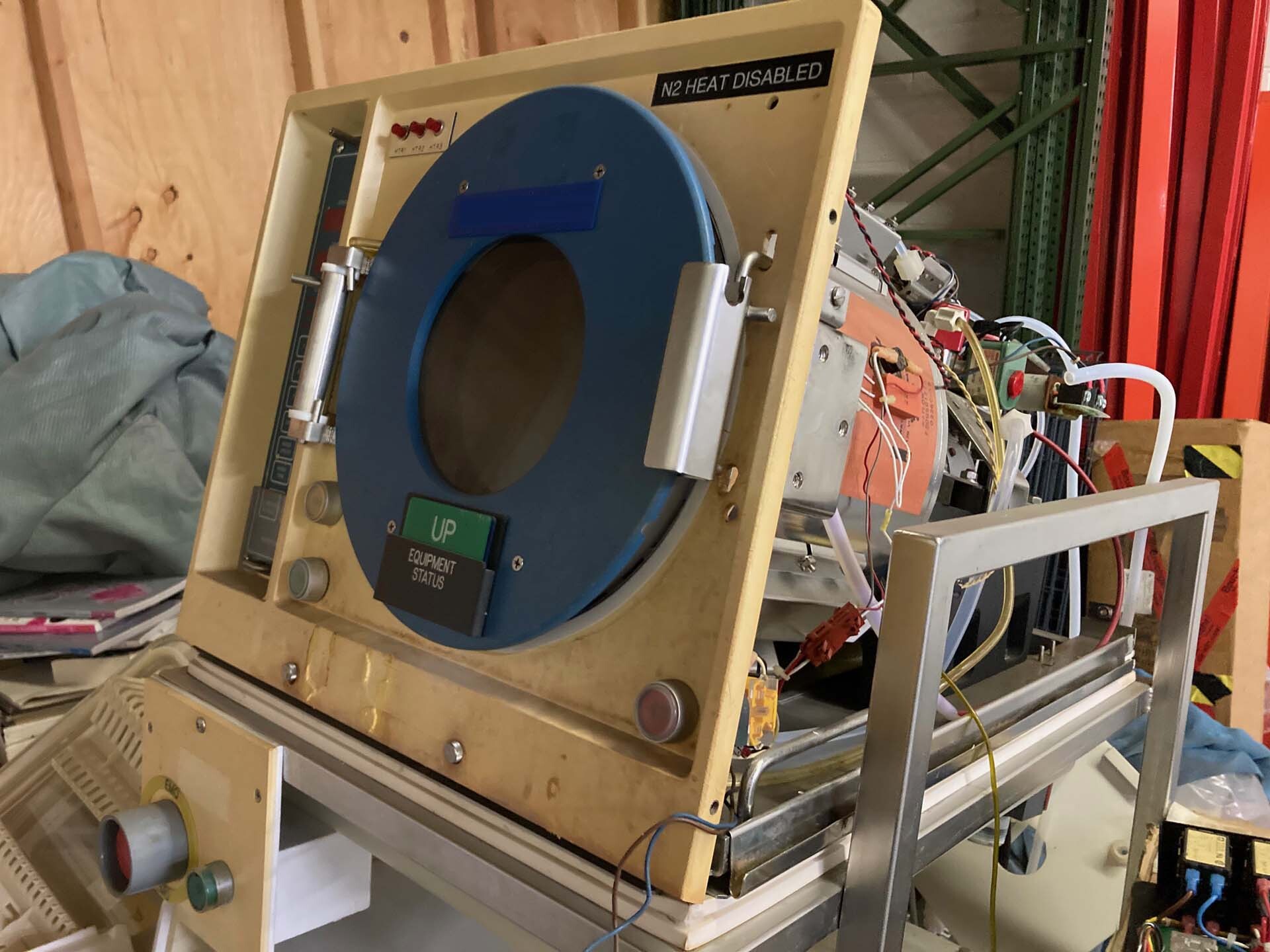

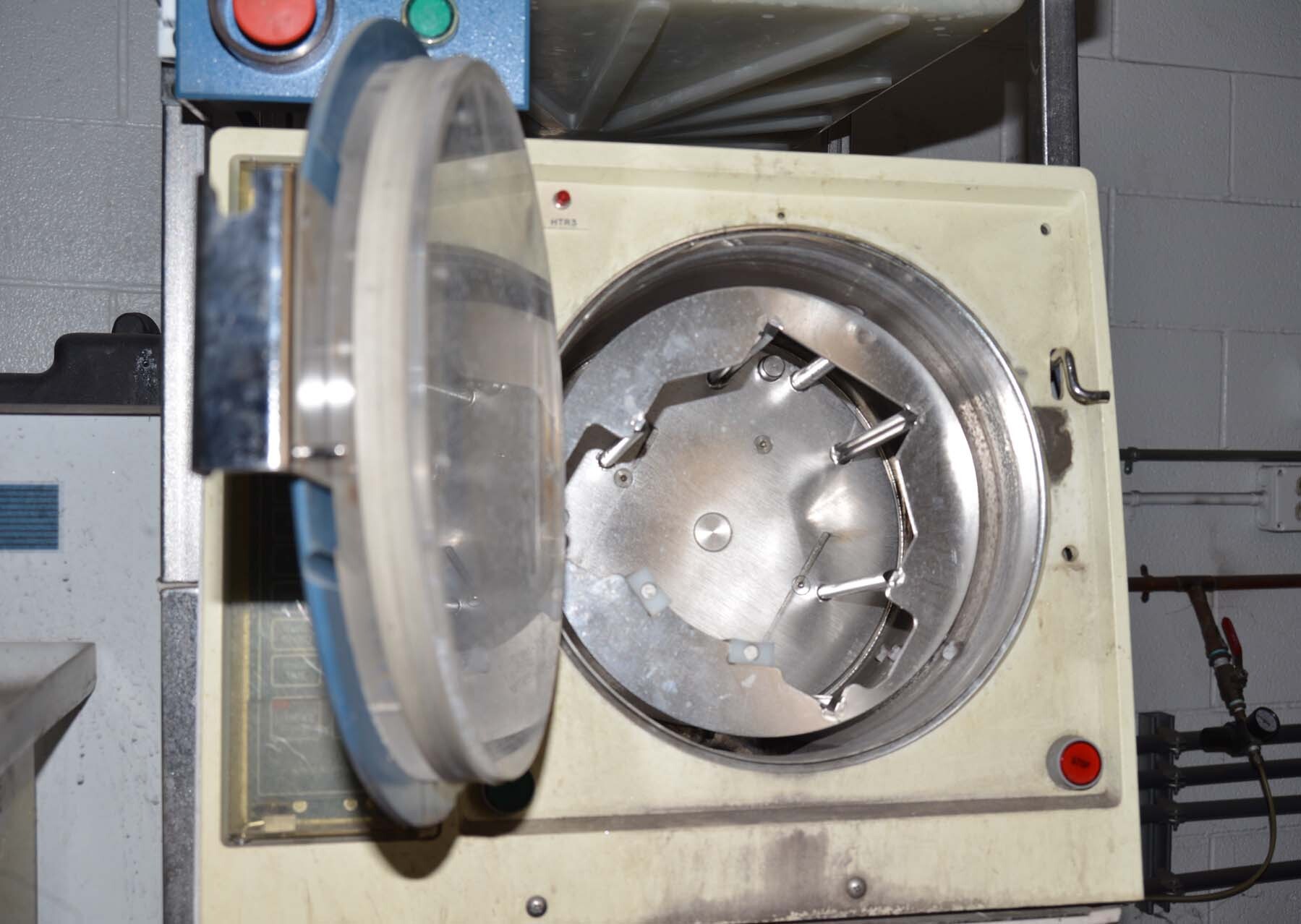

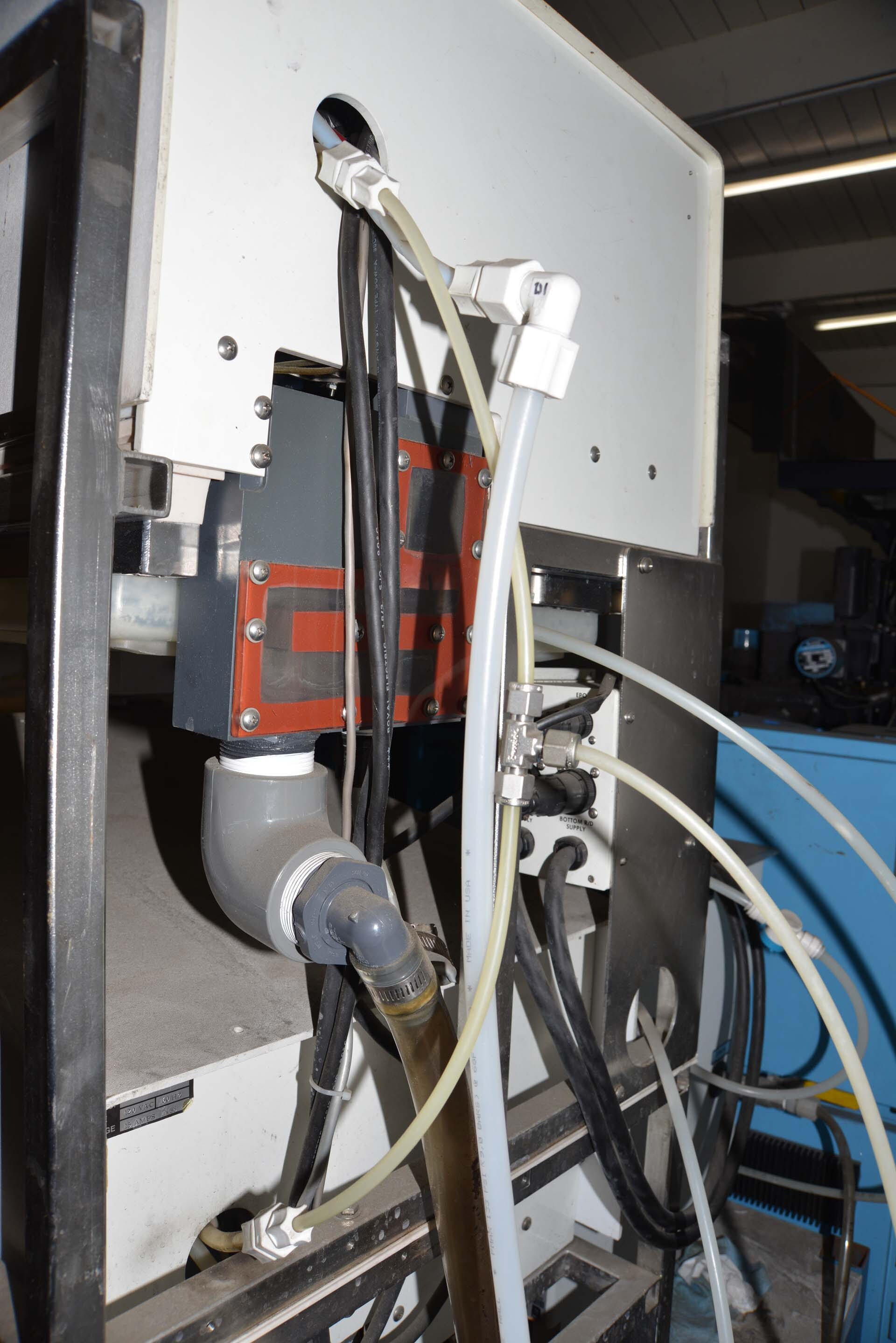

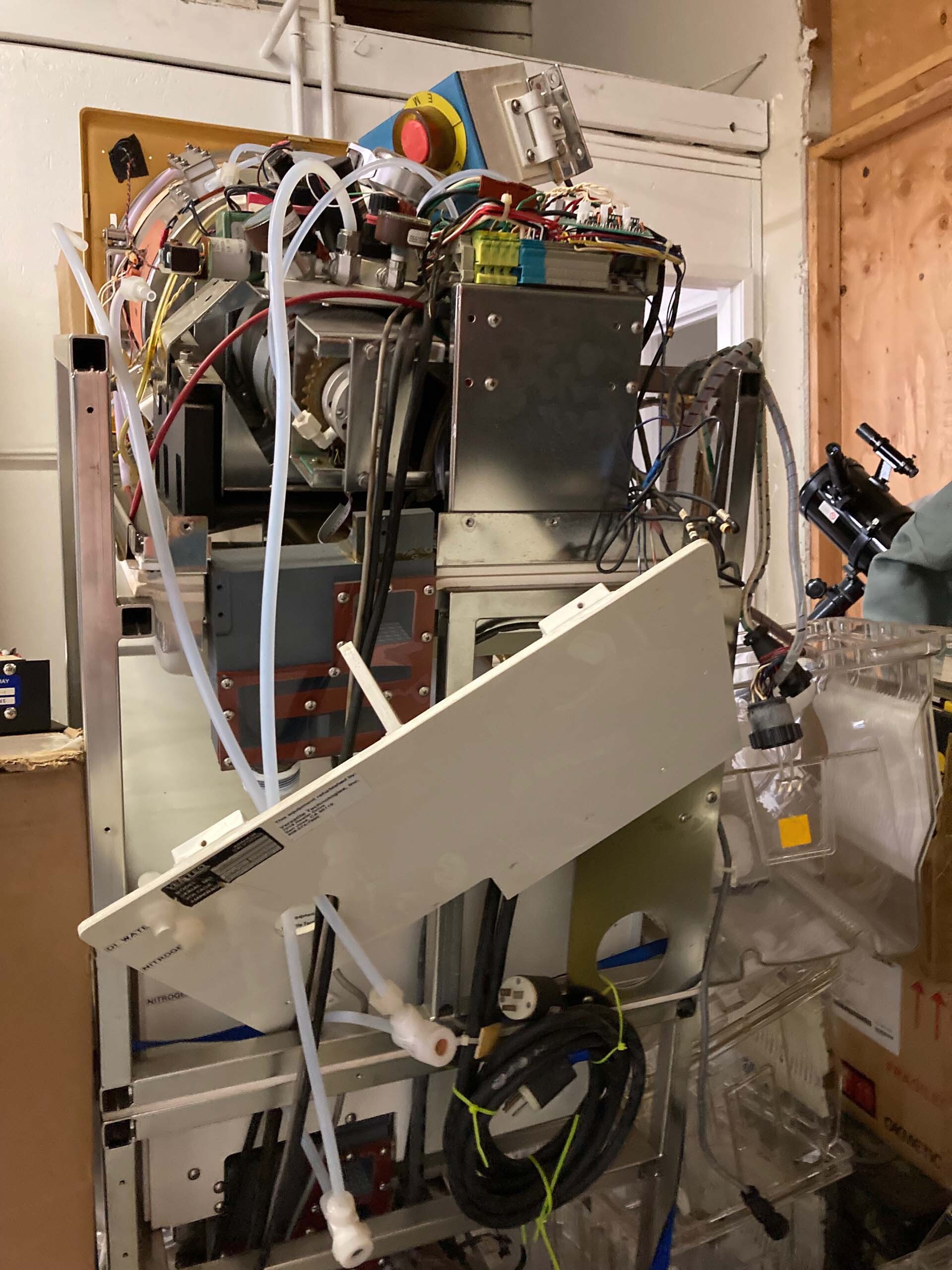

Used VERTEQ SC1600-3 #293592052 for sale

URL successfully copied!

Tap to zoom

VERTEQ SC1600-3 is a photoresist equipment commonly used for the manufacture and thin film deposition of optical components. It has a state-of-the-art optical projection system with high power and uniformity in order to apply accurate and precise patterns on a wide variety of substrates. SC1600-3 photoresist unit includes a high-resolution scanning traverse head and precision optics as well as a software package allowing users to handle complex vector and raster designs. The machine provides 1800 watt of power with three step pulser tool to ensure uniform shifting of the photoresist layer. The top layer of the asset is a plate equipped with up to 8 linear scanning axes that can be controlled individually. The Wafer-Moving Model (WMS) ensures accurate substrate positioning, even with large wafers. It has an integrated shutter mechanism and cooling equipment to prevent overheating. VERTEQ SC1600-3 has a high accuracy stage feed that can be used for multiple substrates with a throughput of up to 450 um/s with repeatable accuracy of 30 um. It also includes a fast-focus optimization feature that lets users quickly adjust the projection optics for optimal focus in between exposures. Thanks to the adjustable photomask holder and motorized light source, users can switch between different photomasks quickly and easily. Additionally, the system can be operated manually or automatically via a comprehensive set of digital process control functions, as well as an array of tool-specific features including autofocus, registration, alignment and scanning. SC1600-3 also features a wide range of process control functions, allowing users to customize their processes for each substrate type and material. These include reticle loading, photoresist application, exposure control, alignment and registration control, etching and development. It also supports a wide range of resist materials and thicknesses for various substrate types, including polyimide, quartz and indium tin oxide (ITO). In order to ensure the highest quality of the end-products, VERTEQ SC1600-3 also includes various diagnostic and monitoring functions, such as uniformity mapping, critical dimension analysis and transmittance. Its software interface allows users to program customized recipes and to generate reports in real time. Altogether, SC1600-3 is the ideal tool for high-precision, high-density photoresist processing. Its robust design, versatile digital process control capabilities and fast processing speed make it an ideal choice for the manufacture and thin film deposition of optical components.

There are no reviews yet