Used VON ARDENNE WM70H / C #9172921 for sale

URL successfully copied!

Tap to zoom

ID: 9172921

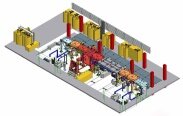

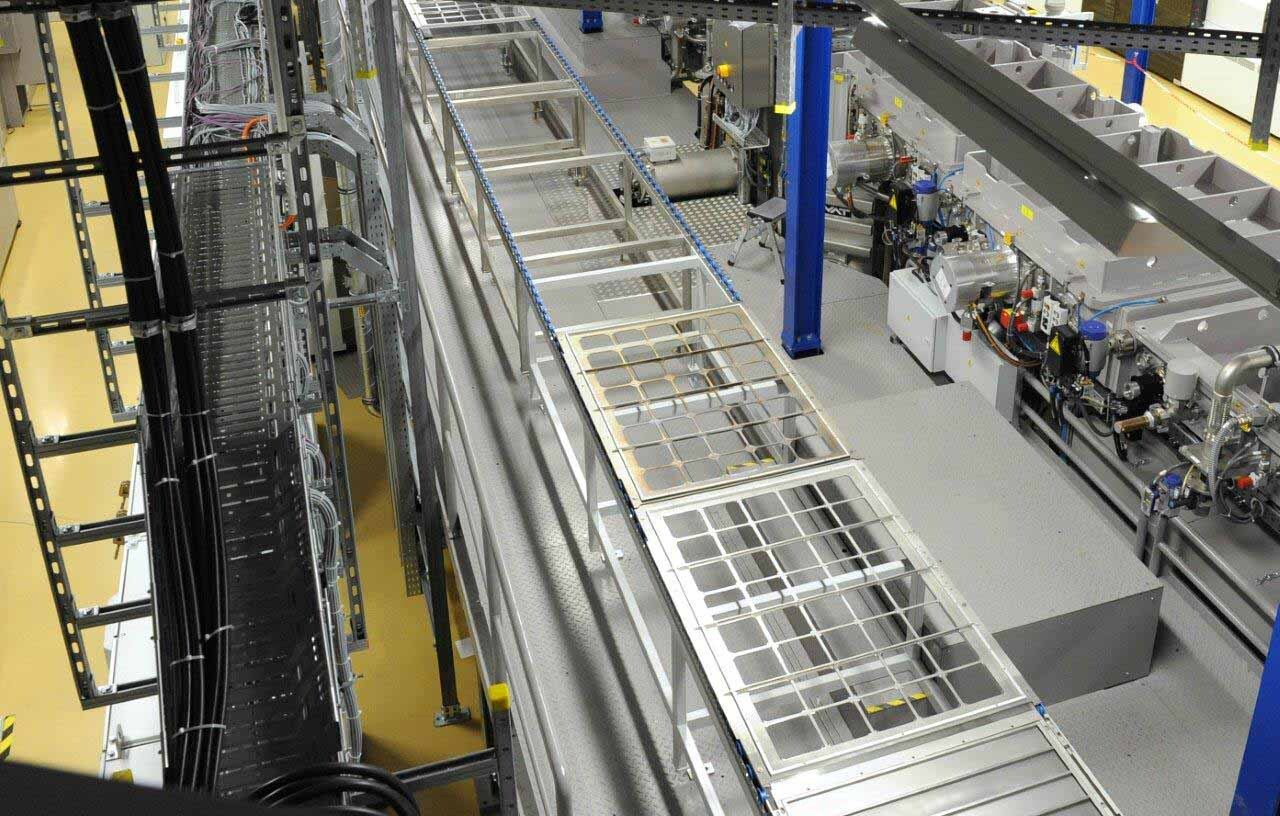

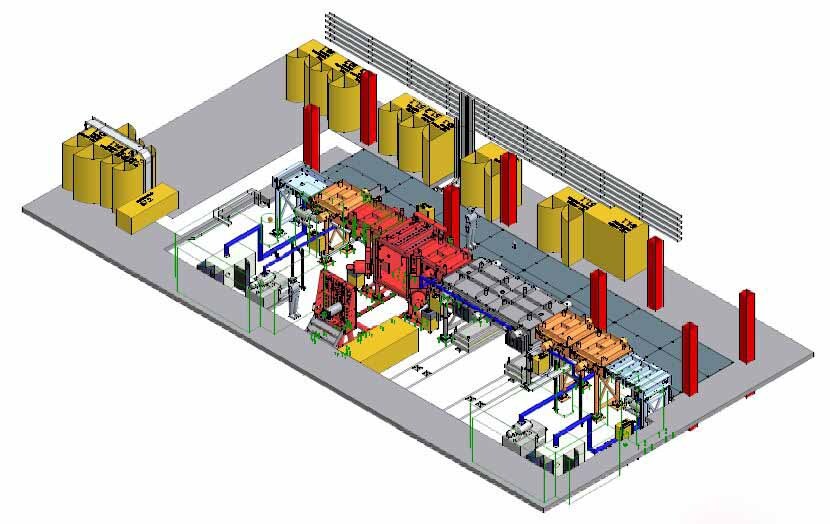

High end coating line

Wafer metallizer

In-line complete system for coating wafers

Back coating of silicon wafers with an aluminum layer

Coating of nickel, silver and aluminum by electron beam evaporation

(35) Cells can be coated per tray

Productivity:

4,000 Wafers (5") per hour

2,600 Wafers (6") per hour

Cycle time: 50s

Technical parameters:

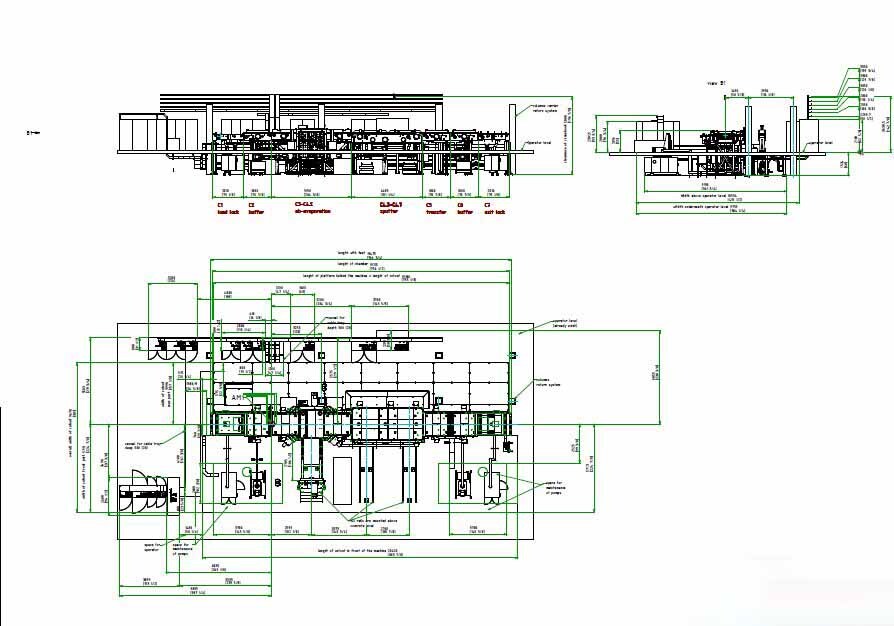

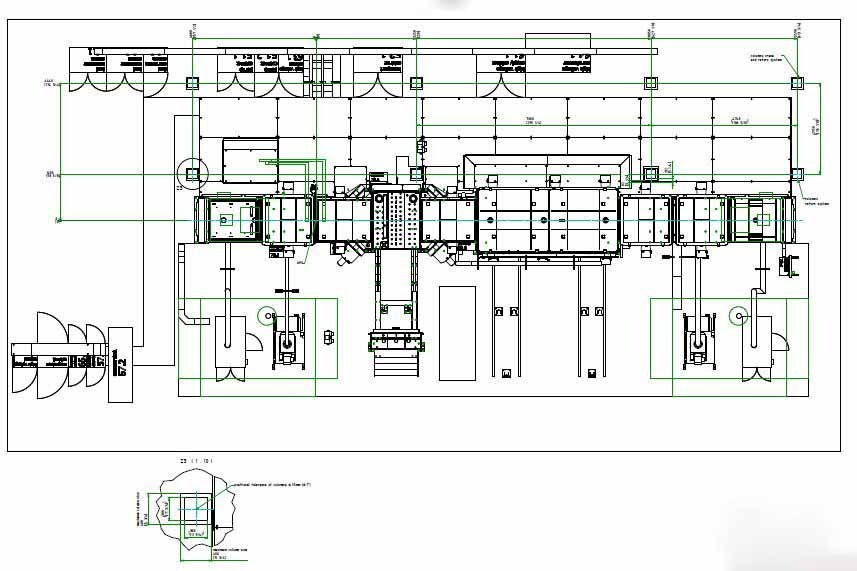

System dimensions:

Length: 19 m

Area: 20 x 7 m

Height: ~3 m

Drive:

Carrier speed max: 5 m/min

Carrier speed during vapor deposition: 1.5 - 2.0 m/min

Substrate temperature:

Max. temperature: 300°C / 572°F

Carrier dimensions:

Length: ~1,450 mm

Width: 925 mm

(60) Wafers (5") per carrier

(40) Wafers (6") per carrier

Ambient conditions:

Ambient temperature:

+15 to 35 °C

+59 to 95 °F

Relative humidity at 30°C / 86°F: < 70 %

Dust: < 10 mg/m3

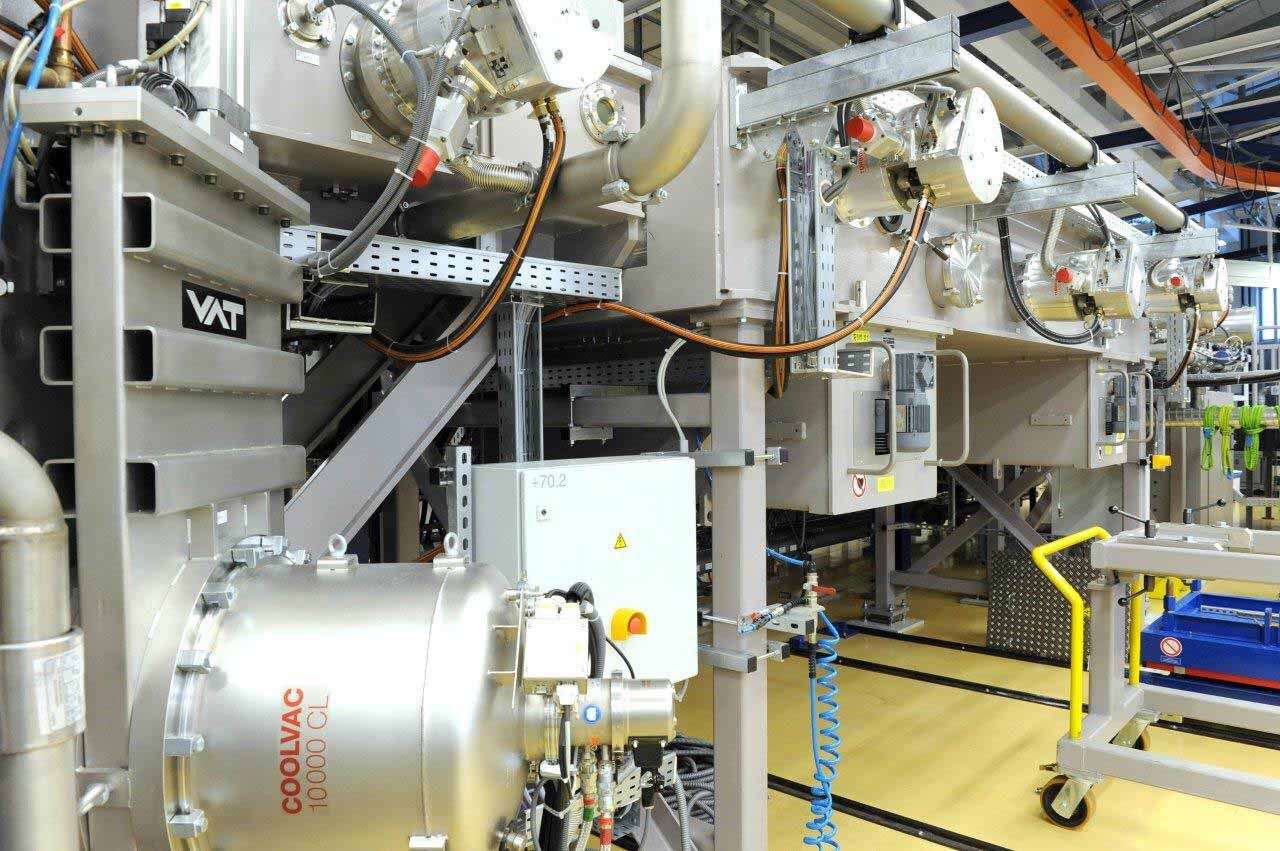

Sluice chambers C1 and C7

Buffer chambers C2 and C6

Transfer chamber C5

Process chamber C4:

EB Chamber C3 / C4.1 / C4.2

Sputter chambers

(5) Sections (C4.3 to C4.7)

Vacuum

Working pressure:

C2 - Buffer chamber 2 to 5 x 10-3 mbar

C4.1 - EB chamber 5 to 9 x 10-5 mbar

C4.2 - Intermediate chamber 2 to 5 x 10-4 mbar

C4.3 - Intermediate chamber 2 to 5 x 10-3 mbar

C4.4 - Sputter chamber 2 to 5 x 10-3 mbar

C4.5 - Pump chamber 2 to 5 x 10-3 mbar

C4.6 - Sputter chamber 2 to 5 x 10-3 mbar

C4.7 - Intermediate chamber 2 to 5 x 10-3 mbar

C5 - Transfer chamber 2 to 5 x 10-3 mbar

C6 - Buffer chamber 2 to 5 x 10-3 mbar

Leak rate: < 1 x 10-2 mbar l/s-1

Layer thickness / Properties:

AI with copper:

Thickness: 2 μm

Wafer thickness: > 200 μm

Temperature: 400°C / 752°F

Purity: 99.98%

AI with ceramic:

Thickness: 3 μm

Wafer thickness: 150 to 250 μm

Temperature: 300°C / 572°F

Purity: 99.5%

Ag: Thickness: < 300 nm

Sn: Thickness: < 300 nm

NiCr: Thickness: < 40 nm

Uniformity: ± 10%

Evaporation:

Production cycle: 120 h

Power of electron beam

Copper crucible: 100 to 200 kW

Ceramic crucible: 20 kW

Target material per cycle: 90 to 150 kg

Vapor utilization: 48 to 50 %

Target-substrate distance: 600 mm

Carrier frequency: 60s

Sputtering:

Target material: Ag

Target utilization: ~70%

Target life: 240 h

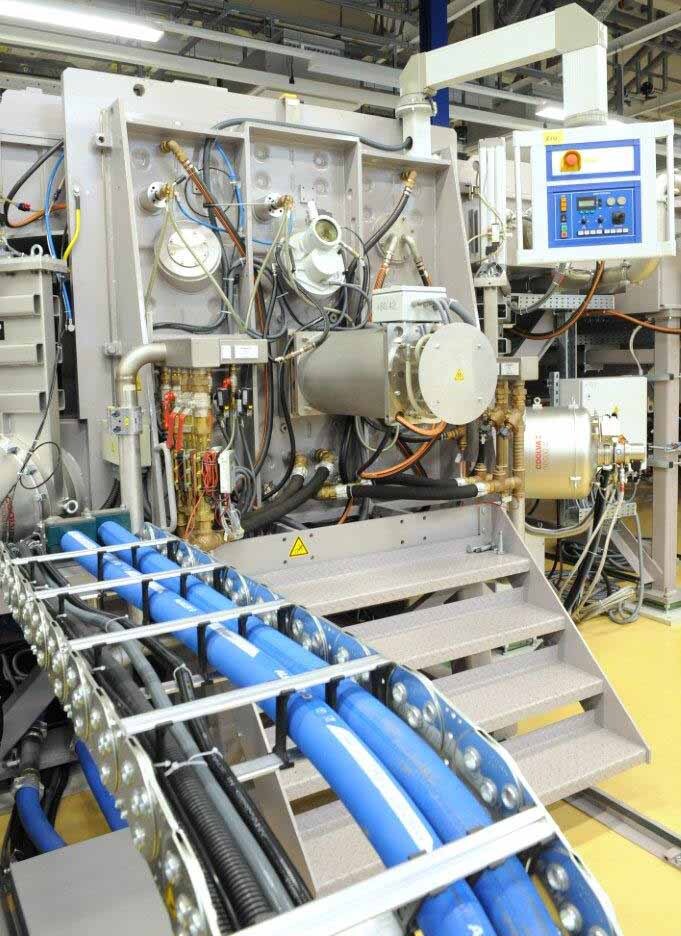

Cooling water:

Particle size: ~50 mg/l

pH Value: (8.0 to 9.0)

Electrical conductivity: (150 to 250) μS/cm

Acid capacity, Ks 4.3: (0.5 to 2.0) mmol/l

Filterable substances: < 50 mg/l

Chloride: < 10 mg/l

Sulfate: < 30 mg/l

Ammonium: < 0.5 mg/l

Nitrate: < 10 mg/l

Colony count (CFU): ~ 1,000 ml-1

TOC (total organic carbon): < 1.5 mg/l

Inlet temperature:

21 to 25°C

69.8 to 77°F

Differential pressure: 2 bar

Absolute pressure max: 8 bar

Water circuit 1 chambers:

Volume flow: TBD m3/h

Temperature: 25°C / 77°F

Required pressure: 6 - 8 bar

Cooling capacity: TBD kW

Electrical system:

3 Phases, 3 AC 480 V

Tolerance: -10/+6 %

Frequency: 59 to 61 Hz

Grounding resistance: <2 Ohm

Connected load max: 400 kVA

Function:

Wafers are coated on one side with (2) metal layers.

VON ARDENNE WM70H / C is an advanced Photoresist equipment capable of producing high-quality thin-film images and patterns. The system is designed to create sizes down to 70 nm in width and 100 nm in height with an accuracy of 2 nm. The unit comprises of several components such as photomasks, a lithography machine, numerous fluidic components, a gas dispenser, and a resist source. The photomasks, which are used to pattern the wafer's surface, are first loaded into the lithography machine. Then, the fluidic components rapidly dispense the resist (a chemical mixture) onto the photomask and the wafer and help to spread it uniformly. The resist is then exposed to light from a flood source to create a resist pattern that functions as a template into which the surface details will be formed. A gas dispenser precisely applies a protective fluorocarbon film over the resist surface to handle the gas flow and insure emulsion consistency. The resist is then stripped, rinsed, and dried, and the wafer is then ready to undergo a further etching process and for the resist to be stripped. TheWM70H/C machine features the most cutting-edge components in the market and provides a superior image placement accuracy, precision pattern definition, and high-fidelity film structuring for semiconductor lithography processes between 70-100 nm. When used in combination with a post-etch harmonic imaging tool, WM70H / C provides clear, detailed features, with an accuracy of 2 nm. Furthermore, its wide range of parameters and automated operations guarantee minimal setup time, which results in significant productivity gains. It is ideal for high-volume production environments of advanced semiconductor processes.

There are no reviews yet