Used WAFER PROCESS SYSTEMS 1222-327 19/21 #9216432 for sale

URL successfully copied!

Tap to zoom

ID: 9216432

Vintage: 2003

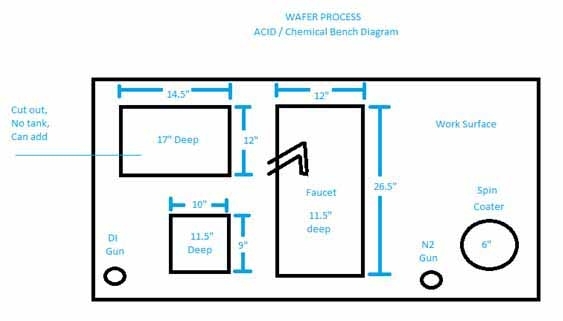

Acid bench

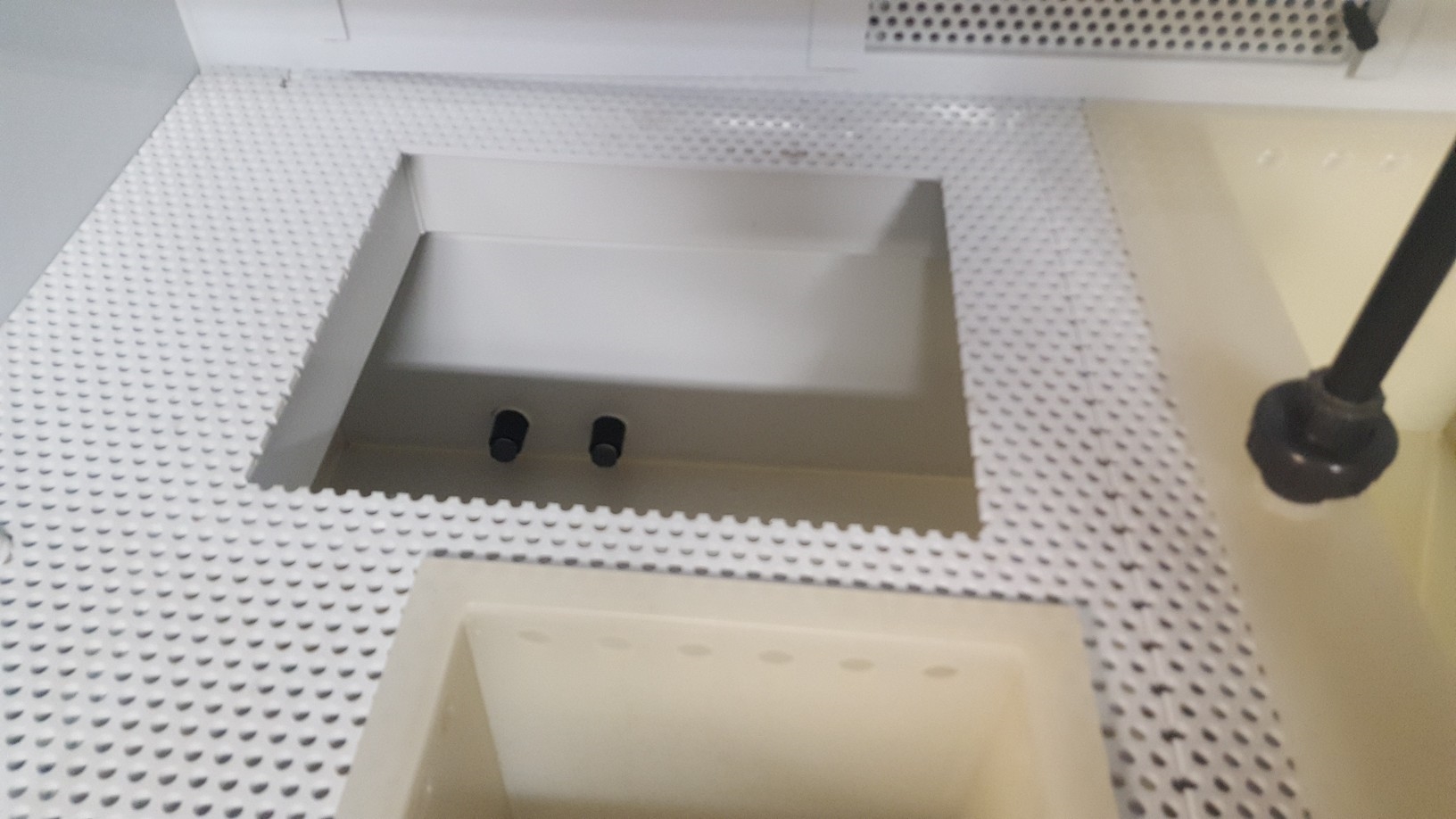

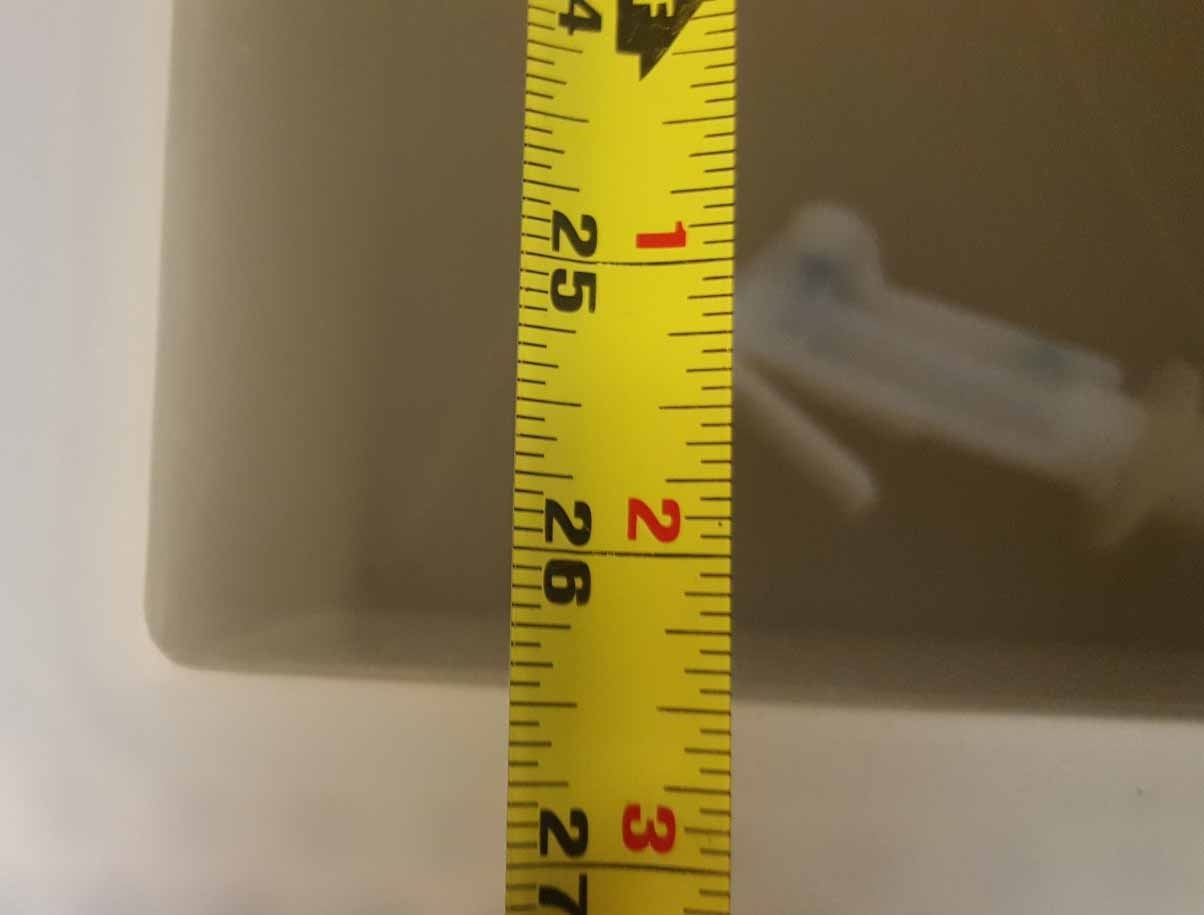

Sink with faucet: 12" x 26.5"

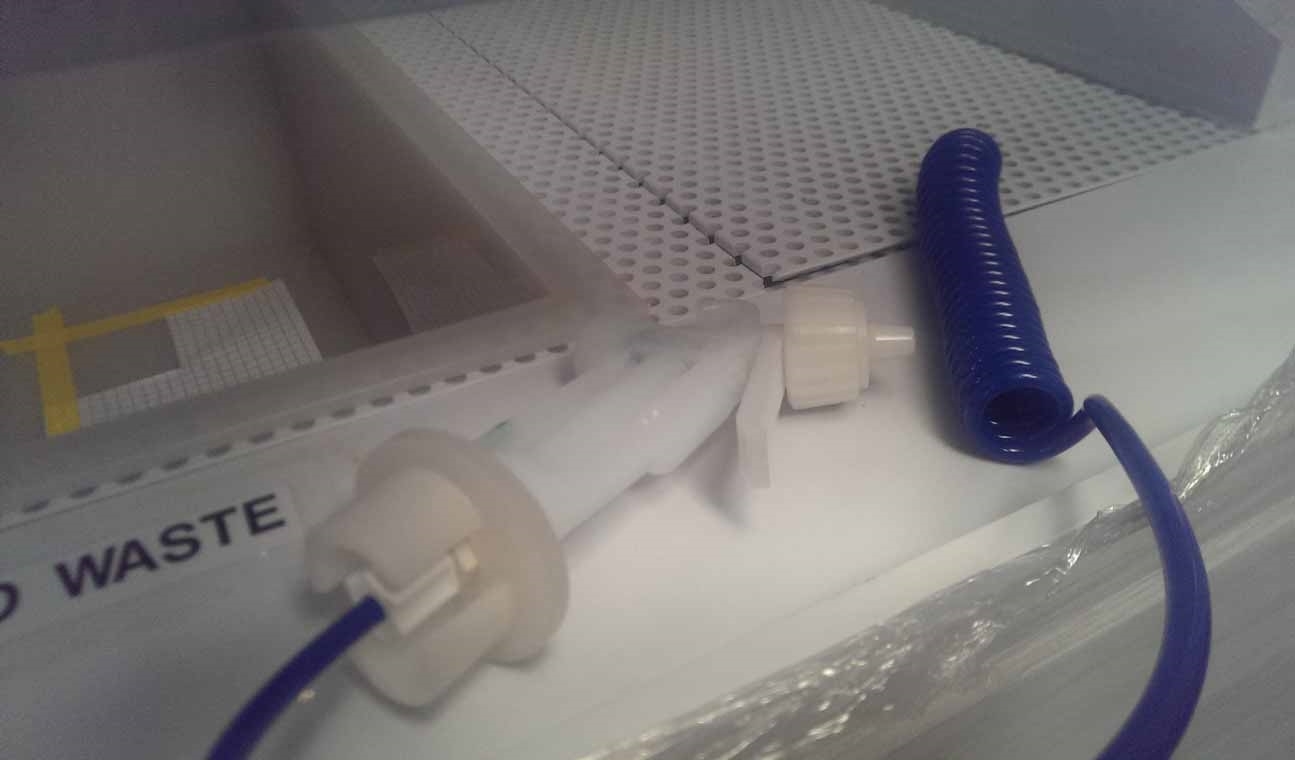

Chemical bath: 10" x 9"

Holding tank: 15" x 12"

Work surface area: 14" x 30"

EPO-100 Controller

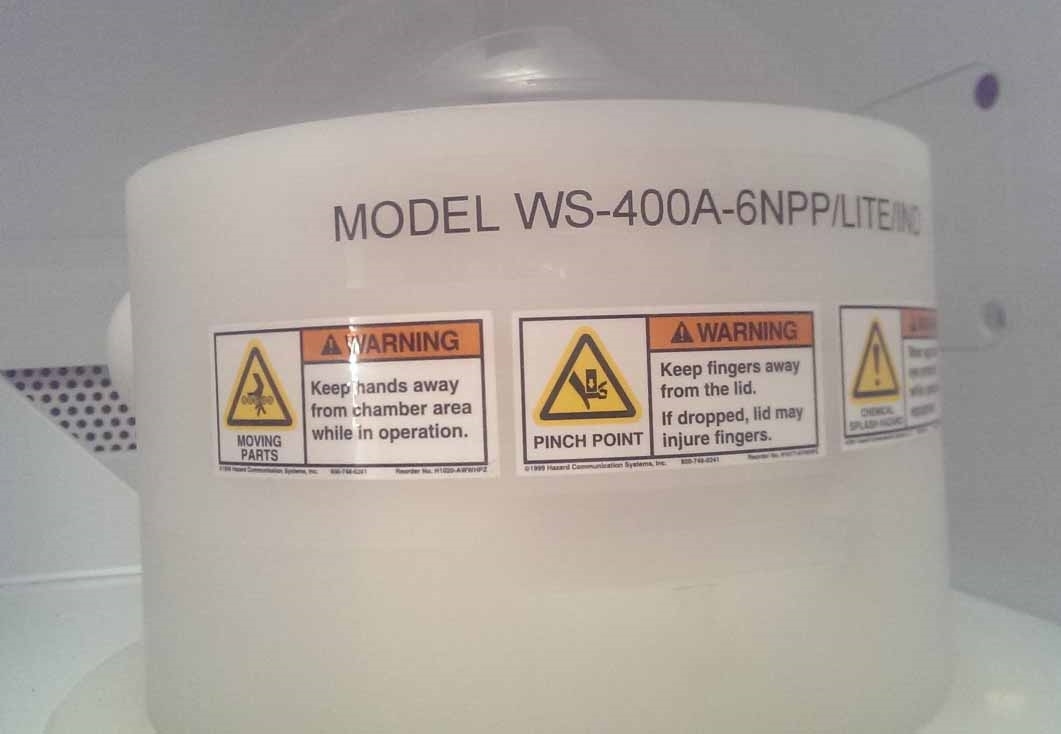

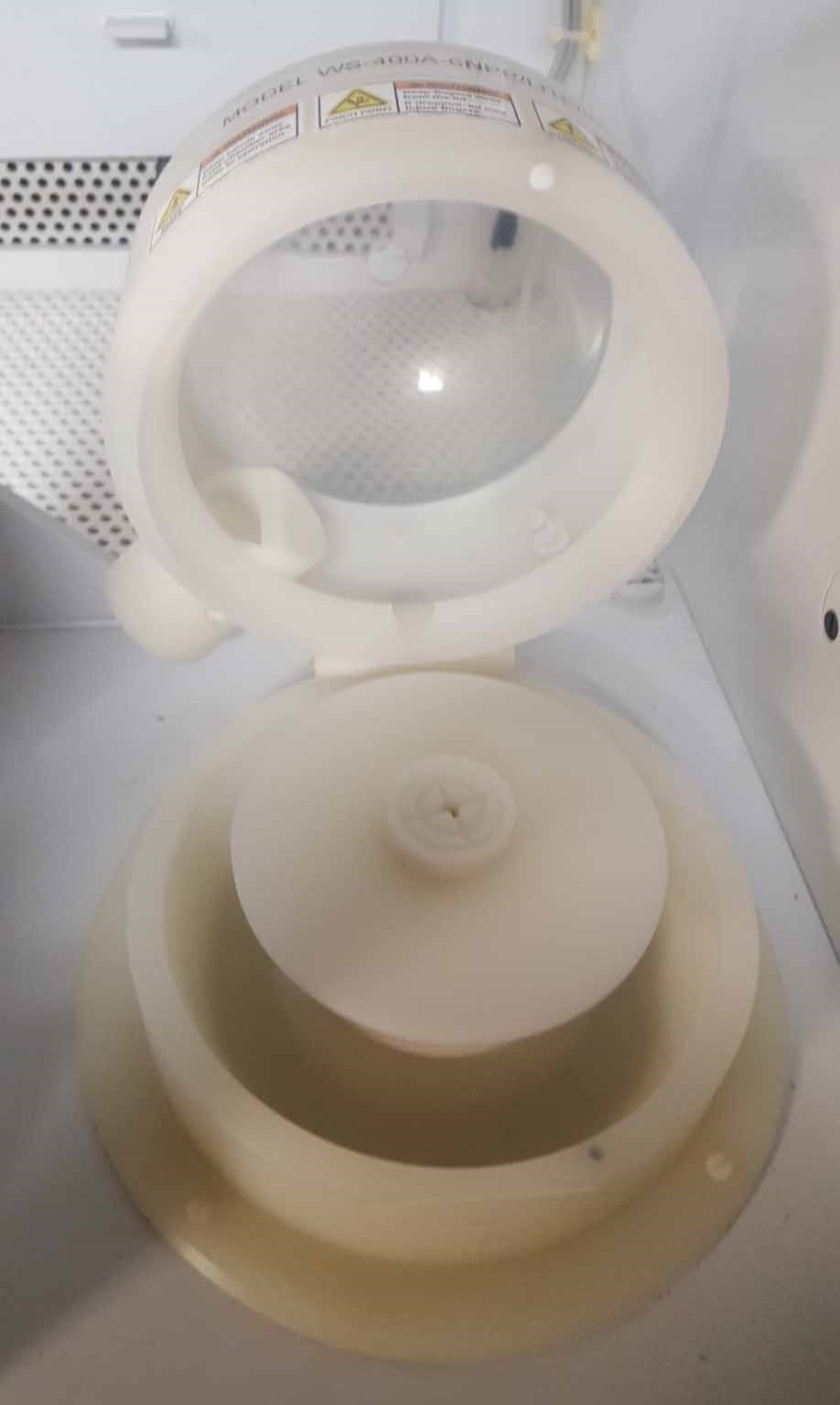

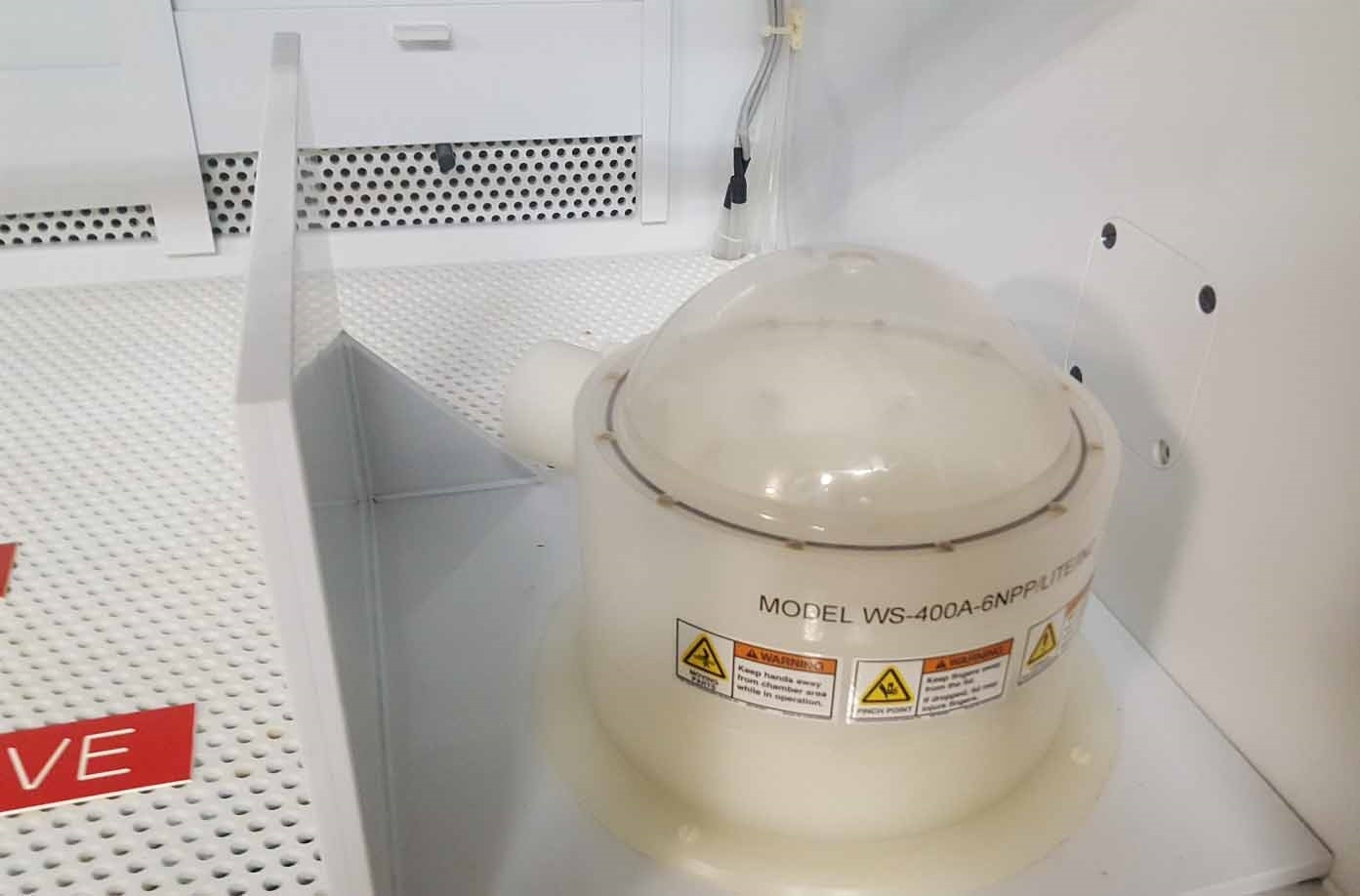

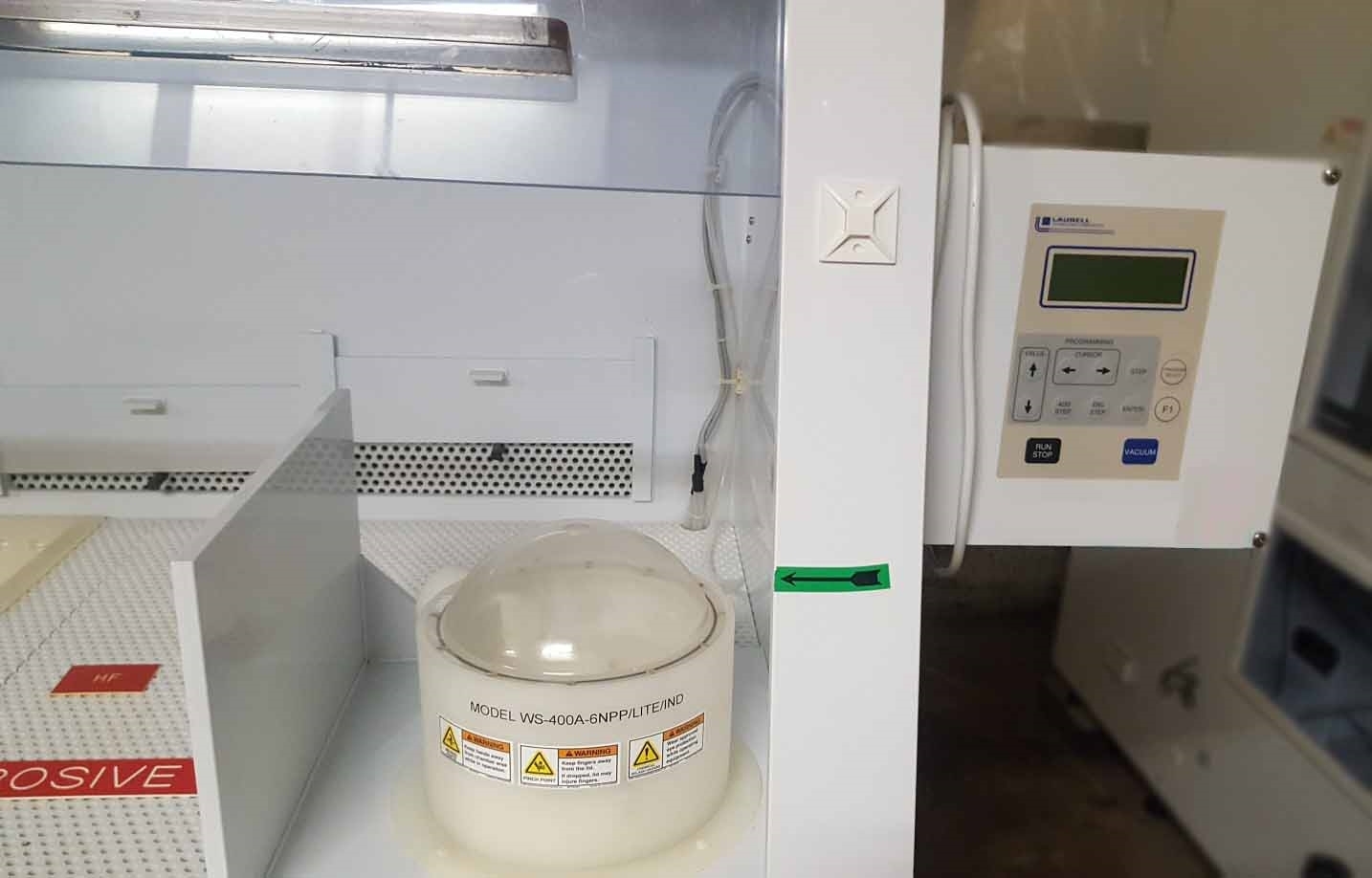

Spin coater module WS-400A-6NPP/LITE/IND

With LAURELL controller

DI Bubble controller

Holding tank alarm monitor controller

Hot plate timer

Hot plate stirrer & temperature controller

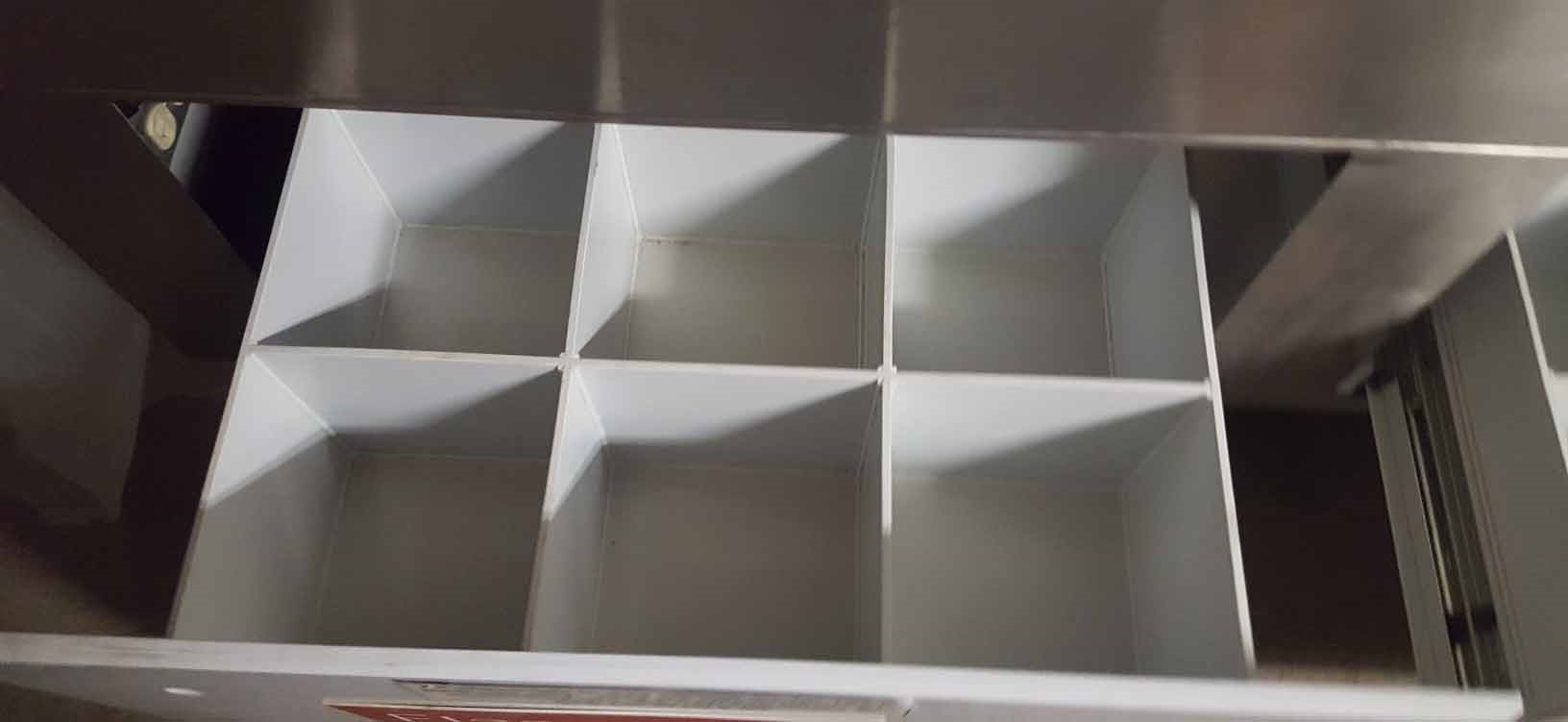

(2) Bottom drawer storages for chemicals and supplies

2003 vintage.

A WAFER PROCESS SYSTEMS 1222-327 19/21 photoresist equipment is a semi-automated tool for processing silicon wafers. This system is able to perform a variety of processes from directional etching and plasma etching, to lithography. It provides a repeatable, accurate, and economic way of creating multiple layers of semiconductor devices on a single silicon wafer. The 1222-327 19/21 includes a production stage that is used to apply photoresist to the positively charged wafers. Photoresist is a chemical substance that is applied to the surface of a silicon wafer in order to produce photochemical effects. It is generally light-sensitive and becomes insoluble when exposed to light, allowing for specific yields to be achieved. Once the photoresist has been applied to the wafers and exposed to the light source, the wafer is either transferred to an oscillating spray cabinet that uses a spray of high-pressure water to wash away unwanted areas of resist, or to a vacuum pump machian that uses vacuum to remove residual resist. Following the wash process, the wafers are then stripped of their resist using a solvents containing benzene that are applied in an automated spin. Sometimes thermal processes are used during the wafer processing stage. This consists of placing the wafer in an oven or furnace to temper it. This is done for a variety of reasons, such as to make it more resistant to stress or to modify the electrical characteristics. Once the photoresist and removal processes are complete, an additional layer of photoresist is applied to the wafer using a thin film deposition machine. This process will generally form a protective coating that enables many additional steps of procedures to be undertaken. The 1222-327 19/21 unit makes use of highly sophisticated programming and operators must be able to monitor each process as it occurs. In order to ensure high-quality results, the machine performs a series of tests including tool tests, inspection tests, and electrical tests. By conducting these tests, any problems are quickly spotted and resolved. WAFER PROCESS SYSTEMS 1222-327 19/21 is an essential tool for any semiconductor manufacturing facility. It is capable of creating multiple layers of devices in an accurate and repeatable manner. Furthermore, the asset adheres to strict production processes in order to ensure that the highest levels of product quality are achieved.

There are no reviews yet