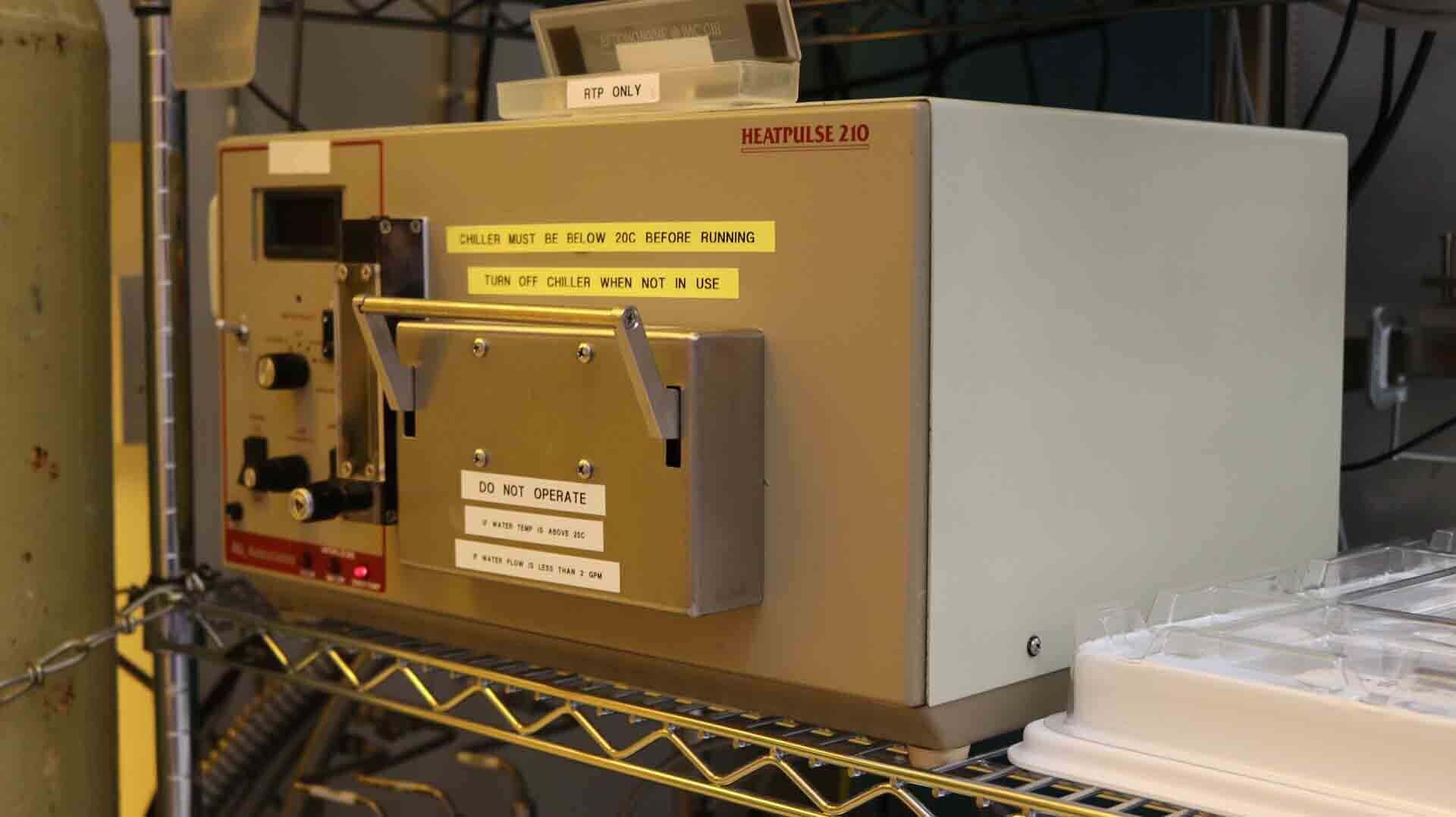

Used AG ASSOCIATES Heatpulse 210 #293627701 for sale

URL successfully copied!

Tap to zoom

AG ASSOCIATES Heatpulse 210 is a rapid thermal processing equipment that has been designed to provide repeatable, temperature-controlled processes for a wide variety of wafer substrates. The system operates in a pulsed and rapid thermal cycling mode for optimal process control, resulting in products with highly uniform properties and superior repeatability. The unit features a modular construction, making it easy to configure for a variety of applications. It is designed to be easy to maintain, allowing fast and easy setup and operation. At its base configuration, the machine comes with an RTP (Rapid Thermal Processor) station, an annealing station, and a furnace wi th an 8 inch quartz quartz susceptor. It is designed to operate in a dual-region configuration, providing two separate process chambers to facilitate multiple simultaneous processes. The standard features of the tool include a precise temperature control asset, controlled by an onboard embedded controller to provide precise thermal cycle management, including precise automatic temperature ramping, accurate temperature sampling and control, and precise thermal measurements. Additionally, the model includes a comprehensive data logging equipment, which provides valuable data for analysis and process optimization. The system also includes a web-based graphical user interface for easy set-up, calibration and control. Additionally, the unit is capable of supporting complex processes involving precise pump down, multiple levels of vacuum pumping, and time-sensitive processes. It also has manufacturing capability for multiple types of processes, ranging from single duty-cycle operations to continuous, uniform batch process runs. Overall, Heatpulse 210 is a powerful rapid thermal processing machine that is designed for precise, repeatable temperature control and precise process optimization. With its modular design, it can be easily configured to meet the needs of any particular application. By combining the features of both an RTP station and a furnace station, it is capable of supporting many types of processes, including precise pump down, multiple levels of vacuum pumping, uniform batch process runs, and time-sensitive operation.

There are no reviews yet