Used AMAT / APPLIED MATERIALS Vantage Radiance #293586616 for sale

URL successfully copied!

Tap to zoom

ID: 293586616

Rapid Thermal Processing (RTP) system, 12"

Process: RadOx

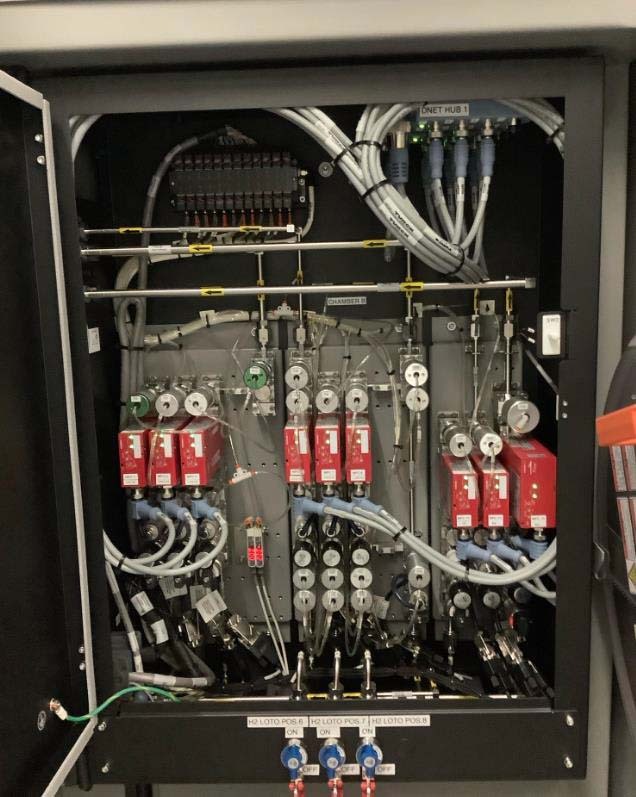

(2) Chambers

Wafer type: SNNF

Platform type: Vantage 3.X

Position A and B: (V352) RadOx2

Chamber A and B process: Toxic RP

OHT WIP Delivery

Dual 2-slot active cool down station

E99 Docked reading capability

Load port: SELOP 7

Load port operator interface: Standard (8) lights

Configurable colored lights

Top air intake system

Upper E84 interface enabled OHT

Upper E84 PIO sensors and cables

E99 Carrier ID: TIRIS With RF

Operator access switch

4-Color configurable light towers

Interface A option

Out the back connection type: RP

Out the back connection H2

(2) Water cooling chambers

RP Integration hardware: Chamber A and B

Standard RAGB rear light tower

Vantage skin: (2) Toxic chambers

IPUP Transfer pump

Open loop tuner

MFC type: STEC

Core anneal and RTO

Monitor 1: Flat panel with keyboard on stand, 17"

Monitor 2: Flat panel on stand, 17"

Monitor 1 & 2 cables: 25 ft with 16 feet effective

No RTP Abatement Unit

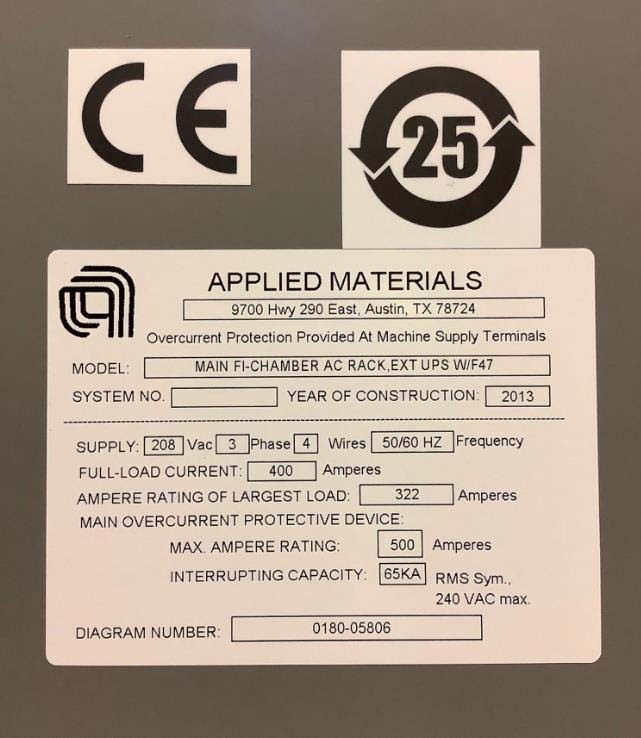

SEMI F47

Semi S2 compliance

RTP Chamber type: Radiance RadOx 2, 12"

Technology option: Open loop tuner

MFC Type: STEC

Core anneal and RTO

Rotation type: WRLD Toxic

Low flow O2: 5 SLM

High flow O2: 50 SLM

Oxygen analyzer

H2:

High flow

Low flow

Side inject

No process N2 for flammable MNFLD

Gas pallet type: TOXIC RP Common gas pallet

No MWBC improvement kit

Chamber integration lines: RadOx2

RP Pump cable: 81 Feet

Base ring: RadOx2 base ring

Line 1 / N2 (N/O), 50 SLM

Line 2 / O2, 50 SLM

Line 3 / O2, 5 SLM

Line 6 / H2, 15 SLM - side inject high flow

Line 7 / H2, 22 SLM - high flow

Line 8 / H2, 2 SLM - low flow

Line 10 / N2 (P/P), 30 SLM Restrictor

Line 11 / He, 30 SLM

Line 12 / N2 (BP), 50 SLM

Line 13 / N2 (Maglev), 100 SLM

Docking station FST install kit

Does not include Hard Disk Drive (HDD)

2013 vintage.

AMAT / APPLIED MATERIALS Vantage Radiance is a rapid thermal processor (RTP) used for semiconductor device fabrication. It produces rapid heating and cooling cycles that are critical for the commercial production of wafer-level devices. The RTP is a single-wafer rapid thermal annealing system that features a large quartz tube, an infrared lamp array and associated optics, and an adjustable platform for controlling the uniformity of the lamps' heating of the semiconductor layer. It has an effective process temperature range of 0°C to 900°C, a process time of 5-60 seconds, and a uniformity of +/-1°C across the wafer surface. AMAT Vantage Radiance uses sophisticated computer control and a hot-wall vacuum chamber to ensure temperature accuracy and environmental integrity. Its infrared lamps offer high intensity and uniform spatial and temporal irradiance, enabling excellent wafer-level uniformity. Its hot-wall vacuum design ensures a clean and contaminant-free environment, eliminating the need for nitrogen or helium atmosphere during processing, thus providing low cost-of-ownership and high efficiency. The RTP is designed to deliver high speed and repeatable annealing results with uniform temperature distribution, excellent wafer-level uniformity, and a wide range of process temperatures. It features advanced clean chamber technology, which provides improved process fidelity, repeatability, and performance for high-speed process optimization—including high-precision spectral matching for process optimization. APPLIED MATERIALS Vantage Radiance is also equipped with a broad array of diagnostic and control systems, providing real-time data regarding temperature, process time, and energy consumption. It includes features such as automated sample loading and wafer exchange, process and thermal cycle scheduling, and process verification. In addition, a unique diagnostic system provides process feedback and can be securely accessed remotely to oversee system performance and adjust the process parameters remotely. Vantage Radiance is a compact and rugged RTP designed for reliable production of high-performance semiconductor devices. Its low cost-of-ownership, high precision, and easy automation make it an ideal tool for semiconductor device production.

There are no reviews yet