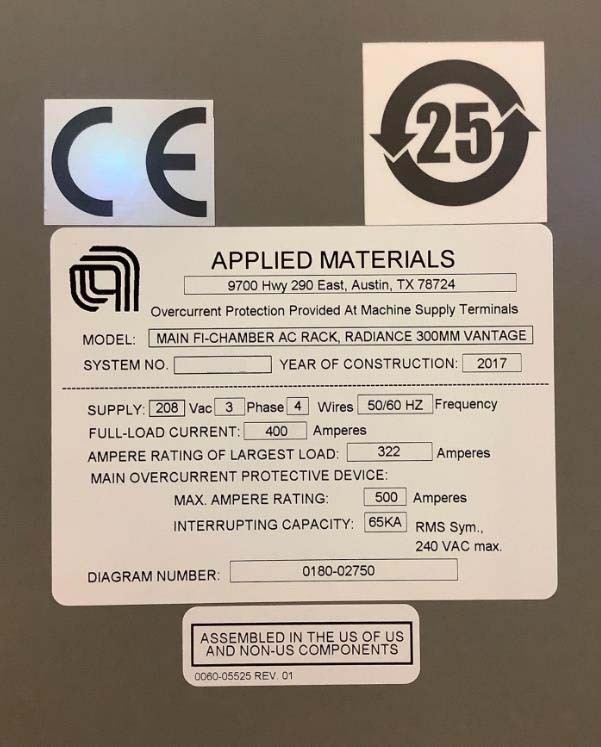

Used AMAT / APPLIED MATERIALS Vantage Radiance #293587166 for sale

URL successfully copied!

Tap to zoom

ID: 293587166

Rapid Thermal Processing (RTP) system, 12"

Process: RadOx

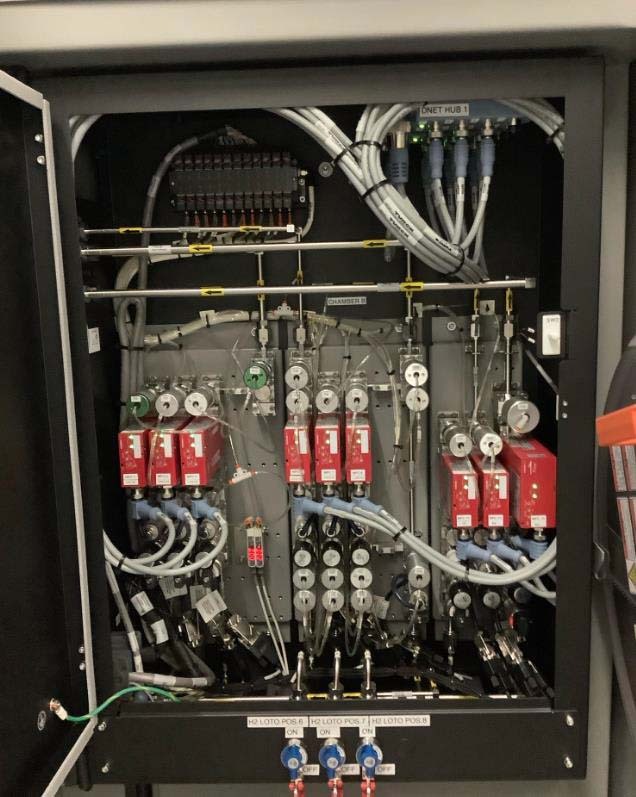

(2) Chambers

Wafer type: SNNF

Platform type: Vantage 3.X

Position A and B: (V352) RadOx2

Chamber A and B process: Toxic RP

OHT WIP Delivery

Dual 2-slot active cool down station

E99 Docked reading capability

Load port: SELOP 7

Load port operator interface: Standard (8) lights

Configurable colored lights

Top air intake system

Upper E84 interface enabled OHT

Upper E84 PIO sensors and cables

E99 Carrier ID: TIRIS With RF

Operator access switch

4-Color configurable light towers

Interface A option

eDiagnostic

Out the back connection type: RP

Out the back connection H2

(2) Water cooling chambers

RP Integration hardware: Chamber A and B

Standard RAGB rear light tower

Vantage skin: (2) Toxic chambers

IPUP Transfer pump

Open loop tuner

MFC Type: STEC

Core anneal and RTO

Monitor 1: Flat panel with keyboard on stand, 17"

Monitor 2: Flat panel on stand, 17"

Monitor 1 and 2 cables: 25 ft with 16 feet effective

SEMI F47

Semi S2 compliance

RTP Chamber type: Radiance RadOx2, 12"

Technology option: Open loop tuner

MFC Type: STEC

Core anneal and RTO

Rotation type: WRLD Toxic

Low flow O2: 5 SLM

High flow O2: 50 SLM

Oxygen analyzer

H2:

High flow

Low flow

Side inject

No process N2 for flammable MNFLD

Gas pallet type: TOXIC RP Common gas pallet

No MWBC improvement kit

Chamber integration lines: RadOx2

RP Pump cable: 81 Feet

Base ring: RadOx2 base ring

Line 1 / N2 (N/O), 50 SLM

Line 2 / O2, 50 SLM

Line 3 / O2, 5 SLM

Line 6 / H2, 15 SLM, Side inject high flow

Line 7 / H2, 22 SLM, High flow

Line 8 / H2, 2 SLM, Low flow

Line 10 / N2 (P/P), 30 SLM Restrictor

Line 11 / He, 30 SLM

Line 12 / N2 (BP), 50 SLM

Line 13 / N2 (Maglev), 100 SLM

Docking station FST install kit

Does not include Hard Disk Drive (HDD)

2017 vintage.

AMAT / APPLIED MATERIALS Vantage Radiance is a high-performance, advanced rapid thermal processor that applies innovative technologies to improve process stability, enable high-temperature transitions, and maximize the quality of chip manufacturing while significantly reducing process times. AMAT Vantage Radiance has the capability of achieving high-temperature transitions up to 2000°C, in a matter of seconds. This extremely high-performanceRTP also allows for precise temperature control. APPLIED MATERIALS Vantage Radiance has an improved temperature uniformity across the heated area and a faster transient thermal response time. It also offers a wide operating window, allowing for a larger process temperature range, thus providing process flexibility. Vantage Radiance features an efficient process control that enables the equipment to monitor the temperature distribution, with adjustable time and temperature safety margins for enhanced system control. Its automation capabilities help reduce cycle time, improve repeatability, and simplify unit setup and control. Its innovative radiative heating and convective cooling abilities help maintain a uniform temperature distribution with a high degree of temporal stability. This helps to improve thermal stability and reduce the likelihood of temperature fluctuations due to thermal shock. The multi-zone temperature control and full automation capabilities of AMAT / APPLIED MATERIALS Vantage Radiance help to maintain the highest level of quality and consistency in the process. This machine also integrates a variety of advanced safety features, ensuring the safety of personnel and devices. With its innovative technologies, AMAT Vantage Radiance accurately and quickly processes at temperatures required in modern IC manufacturing, helping to reduce cycle times while maintaining process quality. Overall, APPLIED MATERIALS Vantage Radiance is a high-performance and advanced rapid thermal processor, featuring innovative heating technologies, comprehensive automation capabilities, and advanced safety features. It is designed to provide a high degree of temperature uniformity and stability while helping to maximize the quality and efficiency of chip manufacturing.

There are no reviews yet