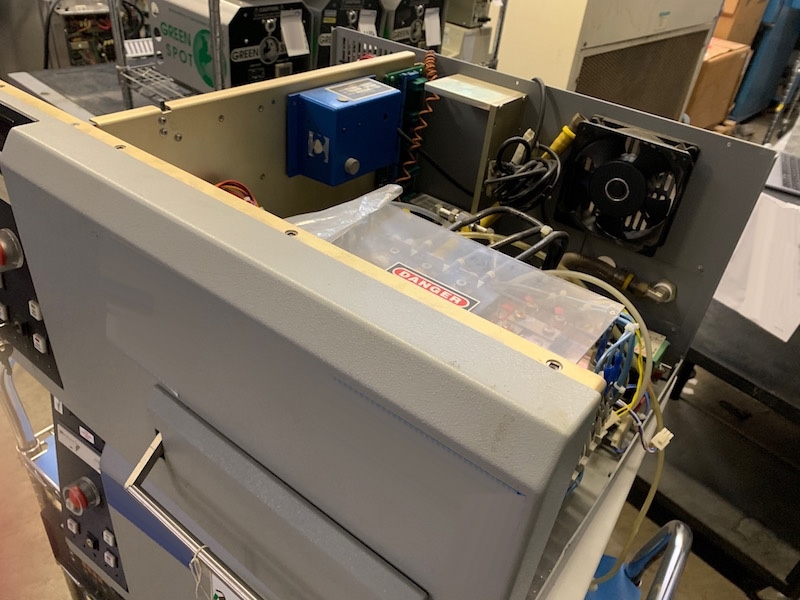

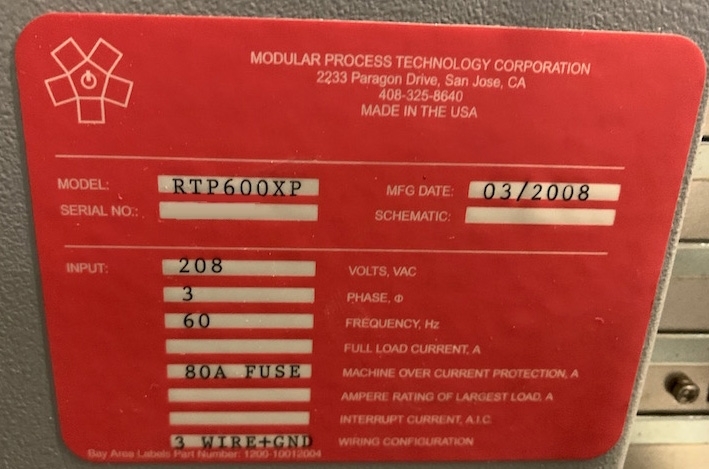

Used MODULAR PROCESS TECHNOLOGY / MPTC RTP-600XP #9262681 for sale

URL successfully copied!

Tap to zoom

MPTC/MPT MODULAR PROCESS TECHNOLOGY / MPTC RTP-600XP is a rapid thermal processor that is used for the uniform heating and cooling of processed wafer samples. It uses a combination of halogen lamp and a Peltier effect to quickly heat, cool and anneal device substrates. These rapid thermal processes are used in a variety of applications such as rapid thermal oxidation, rapid thermal annealing, rapid thermal nitridation, rapid thermal diffusion and rapid thermal laser-ablation. MPTC RTP-600XP is designed for maximum precision and repeatability in temperature control. Its proprietary Edge Energy Control Plate technology provides precise and uniform power distribution around the circumference of the wafer, with an extremely low thermal gradient. MODULAR PROCESS TECHNOLOGY RTP-600XP is capable of rapidly ramping up to substrate temperatures up to 600°C, and also offers support for single wafer and parallel configurations, making it suitable for a variety of applications. Additionally, RTP-600XP is equipped with high-performance security and safety systems that protect it from damage and keep it running optimally. These include a power monitor circuit with sign and over temperature protection, and hardware protective sheaths to protect the optics of the system. Additionally, the system includes a high-efficient, low-noise fans to ensure effective cooling of the system and the samples, as well as cooling of the optics. MODULAR PROCESS TECHNOLOGY / MPTC RTP-600XP is simple to operate, and offers versatile data logging capabilities and customizable wafer recipes. It can also be integrated with automation equipment and application-specific software to enable fully automated processing. Additionally, its small footprint and mobile design makes it well-suited for use in research and quality assurance applications. Overall, MODULAR PROCESS TECHNOLOGY/MPT MPTC RTP-600XP is an ideal rapid thermal processor for a variety of wafer processing types. It is precise, efficient, and designed for maximum safety and repeatability. It also offers a range of useful features that make it suitable for a variety of applications, while its small design and mobile capabilities make it suitable for use in smaller laboratories and facilities.

There are no reviews yet