Used STEAG / MATTSON / AST 2800 #9038290 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9038290

Vintage: 1996

Rapid thermal processor, 2" - 8"

Includes:

(3) Cool down stations

(1) Dummy load station

(1) Touch screen

Automatic doors, foot control

Software: NT Windows

Mass Flow Controllers:

Brooks 5964 / 10 SLPM / N20

Brooks 5964 / 10 SLPM / Argon

Unit 8160 / 30L / N2

Brooks 5964 / 10 SLPM / Oxygen

Gas Plumbed: N2 – Argon – N2 – O2

Controller: EEOCU / BLCU / delta U1 / delta U1 / delta U1, 2 & 3 / delta U1 / MCU

Control rack extension board: LCCU / LCL / LCL / TCA

Pneumatic board: WCU / WCU / PCU / PDCU / PIO / PDU / PSU / PVC / PVU / PVU / WVU / DVU

PMW Generator: Delta V 1-4 / PWM 1 & 2 / POD / INT / CB / MIB / GPC 486 Connections / SEC

Heating unit: PWD

PRI Robot: ATM-305010S & PRI Controller ESC-200

Brooks Pre Aligner PRE 201

EMO Front & Rear

Optical Pyrometry

Vent pressure monitoring

DC Stabilization

Single lamp control

Open loop control

Thru the wall

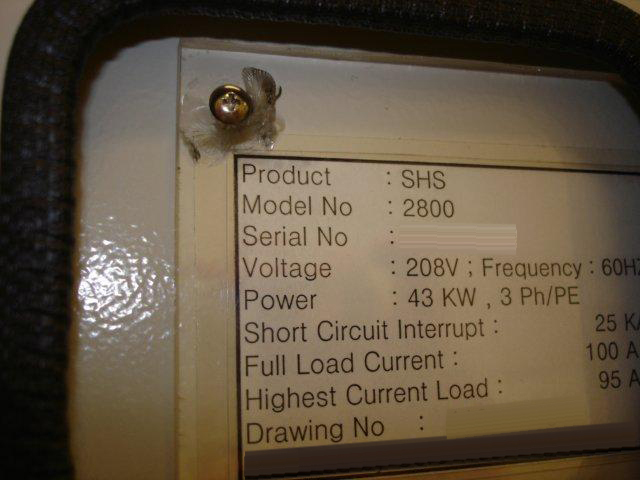

208 V / 60 Hz / 3 Ph / 43 kW

1996 vintage.

STEAG / MATTSON / AST 2800 is a rapid thermal processor (RTP) designed for research, development, and wafer production. It is a multi-mode tool, capable of carrying out several thermal processes such as oxidation, annealing, diffusion, and sputtering. AST 2800 utilizes two process chambers, one containing an induction coil and the other an infrared source - each independently controlled. The main feature of STEAG AST2800 is its high temperature and fast processing capabilities. The coil and infrared sources are capable of raising the temperature of the wafer or substrate up to 1000°C and 1500°C respectively using rapid thermal processing. The high processing temperature allows for quick and precise substrate modifications such as silicidation and phase transformation. MATTSON 2800 is also equipped with advanced control systems. It is designed with Vacuumschmelze advanced microprocessor technology, which allows for precise temperature and time control with minimal operator intervention. The advanced control system also helps to maintain uniformity of temperatures throughout the process and thus ensures uniformity of the final product. Moreover, STEAG / MATTSON / AST AST2800 is a multi-functional system capable of performing several processes at once. It has a dual rapid thermal zone where two processes can take place simultaneously. This feature allows for efficient utilization of time and resources as the processing throughput can be increased drastically by performing multiple processes at the same time. AST AST2800 also comes with a comprehensive software platform that enables easy operation. The software platform provides real-time process control data, detailed wafer history tracking, recipes, and process archives. This ensures smooth wafer processing and better control over the parameters of each process. Overall, AST2800 is a reliable and highly advanced rapid thermal processor that provides excellent precision, temperature repeatability, and throughput. It is extremely useful for a variety of applications and processes due to its high temperature, fast-cycle, and thorough process control functionality.

There are no reviews yet