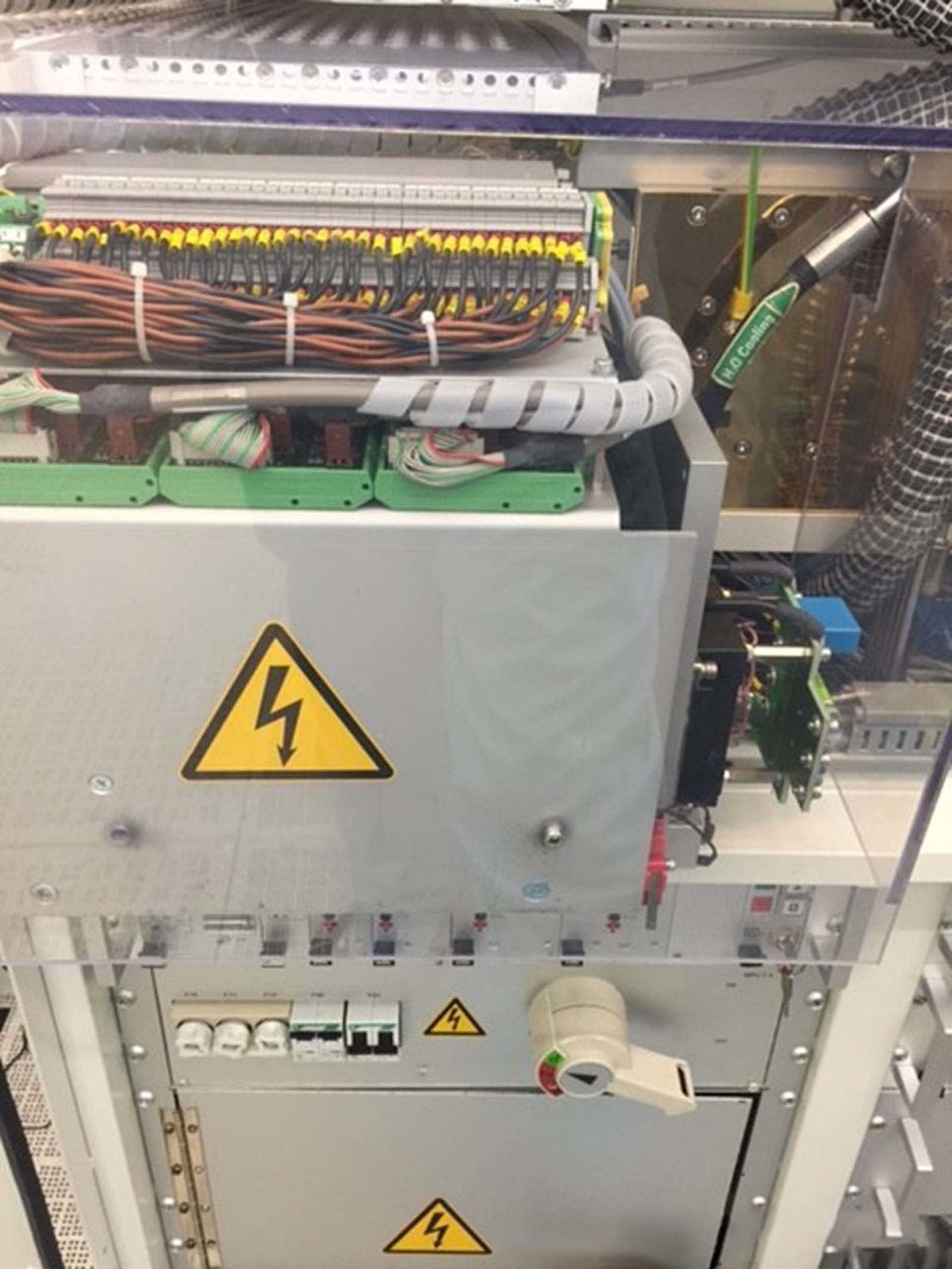

Used STEAG / MATTSON / AST 2800 #9205415 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9205415

Wafer Size: 8"

RTP System, 8"

Configuration:

Dual load lock single chamber RTP

General configuration:

30L N2 High:

50psi / 2Bar / Tool, dynamic (Full N2 flow)

60psi / 2.8Bar / Tool, static (No N2 flow)

10L O2 High:

40psi / 2Bar / Tool, dynamic (Full O2 flow)

42psi / 2.5Bar / Tool, static (No O2 flow)

O2 Low:

40psi / 2Bar / Tool, dynamic (Full O2 flow)

42psi / 2.5Bar / Tool, static (No O2 flow)

10L Ar:

40psi / 2Bar / Tool, dynamic (Full Ar flow)

43psi / 2.5Bar / Tool, static (No Ar flow)

CDA:

90psi

Tool: 5.5bar

Chamber high cool:

Bottom: 17/18 m³/h

Top: 26/27 m³/h

Chamber H20 cooling: 6.8LPM

TC Amplifier test

With Omega meter

O2 Sensor final testing:

3ppm O2: 30L N2 Flow in chamber in 30 second

4-5ppm O2: 5L N2 Flow in chamber in 60 seconds

Robot atation names:

A: Primary sender

I: Secondary receiver

F: Furnace

D: Cooling station 0

Cooling station 1 (No cooling station 1, used for dummy station)

C: Dummy wafer station

Pyrometer calibration:

Un-calibrated pyrometer check: Pyro 878C output at 1080TC

With emis 1300

Calibration recipe: TOMCAL.2

Calibration file: TRCAL0923

Network setup:

Network ID / Machine name: 03AST

Facility name:

Serial gemSecs used

Expansion board: COM8

AST 01 and 02 RTP:

Physical dummy wafer station: No

Cooling station: Dummy wafer station C

Gas panel: TYLAN MFC's

Robot:

Equipe 307

No swivel cassette stations

Install connections: 03AST

Gasbox above rear of tool: Supplies MFCs

N2

O2

H2 Mix

Ar

Connections at bottom rear tool:

CDA: 1/4" Swagelok / 90- 120psi

PCWS: 1/2" Swagelok / 8slpm

PCWR: 1/2" Swagelok / 60 - 120PSI

PCWS: 1/2" Swagelok

PCWR: 1/2" Swagelok

HiFlow N2: 1/2" Swagelok / >90PSI in operation

Cooling N2: 1/4Inch Swagelok / 10 - 30 slpm

Vent1: 3/8" Swagelok / Acid exhaust

Vent2: 3/8" Swagelok / Acid exhaust

11/2" Exhaust / 11/2" / Tube acid exhaust

Middle bottom of tool:

Blower output / 4" Tube / Heat exhaust

Front tool:

House vacuum / 1/4" Swagelok / 600 mbar

Power supply: 43KVA / 208VAC / 3 Phase / 125amps / 125 Max fusable.

STEAG / MATTSON / AST 2800 Rapid Thermal Processor is a tool used for high-speed processing of thick films for semiconductor material. It allows for thermal processing of films in an efficient thermal environment, giving a fast ramp rate and eliminating thermal gradients. The processor has built-in air recirculation technology that ensures uniform temperatures during surface heating. The processor's temperature sensors eliminate the effects of thermal gradients and make it more reliable. The high temperature ranges of up to 900°C and 1350°C enable the rapid thermal processing of thick films. It also has a low-pressure oxidation, reduction and nitridation zone, allowing for further fabrication and applications of material during processing. The processor has a variable cooling source with a controller and an additional cooling source for temperature control. It also offers a variety of forced-gas cooling systems including air and nitrogen. The user can select the amount of cooling depending on the application. An additional feature of AST 2800 is its built-in multi-zone programmable software. This allows for the processing of different film thicknesses at different temperatures with each zone having its own controller. A user may also use pre-installed programs for fast setup times and for coordinating multiple recipes with different temperature processes. The processor offers adjustable wafer cassette holders to assure flat and uniform processing. It is also capable of priming, debonding and frontside lecturing processes. The Robot Interface allows full-facet wafer transfer and unloading. STEAG AST2800 is a valuable tool that benefits a variety of industries, such as compound and organic semiconductors. It is used for the rapid thermal processing of materials such as dielectrics and metals, allowing for the fabrication and applications of new semi-conducting materials. The ease of use and accuracy enables increased production and efficiency in a variety of industries.

There are no reviews yet