Used STEAG / MATTSON / AST SHS 10MA #9188335 for sale

URL successfully copied!

Tap to zoom

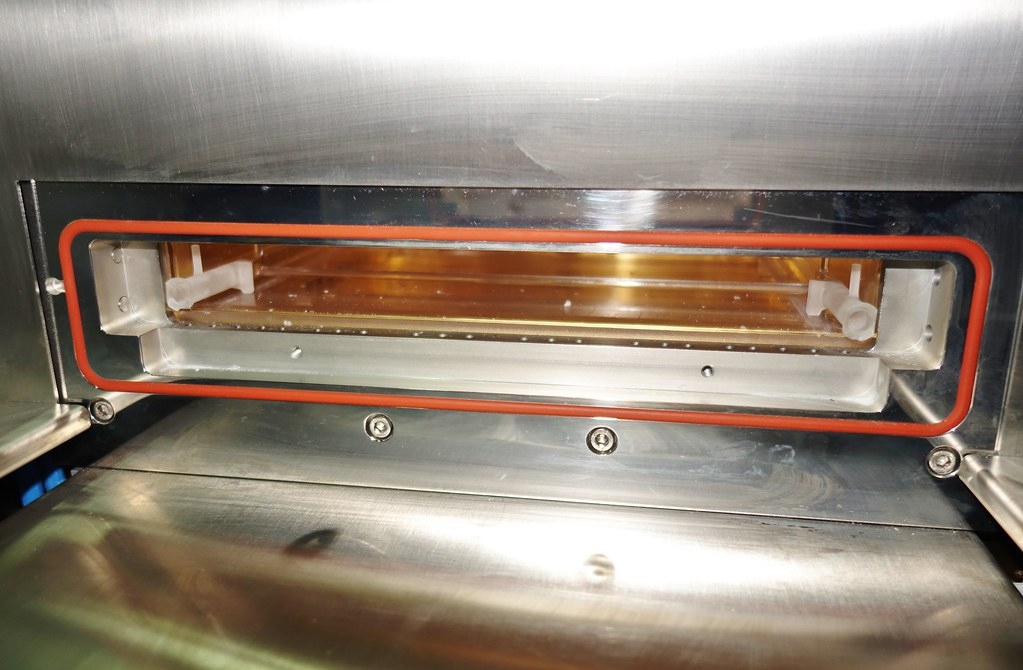

STEAG / MATTSON / AST SHS 10MA is a rapid thermal processor that offers advanced processing capabilities for a wide range of applications in the electronics industry. This equipment offers fast thermal processing with a throughput rate of up to 10 per second, allowing for maximum throughput and high accuracy. AST SHS 10MA uses an advanced thermal processor with precision and temperature control for rapid thermal processing with excellent repeatability. The built-in sensing and feedback systems can continuously monitor and adjust the temperature of the entire system, ensuring reliable and precise processing. STEAG SHS 10MA employs both stationary and rotary processes to convey product through the unit quickly and accurately. Its unique design allows for high temperatures up to 500° Celsius to be achieved and maintained at different processing zones, with temperature zones being accurately maintained and adjustable as needed. The machine also uses radiative thermal infrared radiation to further control the temperature of the thermal processor with complex programming capabilities for maximum temperature accuracy. The tool features an advanced safety asset with thermal protection systems, alarmed interlocks, and an emergency shutoff feature. This ensures the safety of operators and other personnel from exposure to dangerous thermal radiation. An advanced control model allows easy setting of temperature profiles for different processes and product heights, as well as the monitoring of temperature and process conditions. SHS 10MA also offers state-of-the art diagnostics so operators can identify and address issues quickly and accurately. Furthermore, it includes a FTP protocol for easy network connection and remote control. The latest user interface and graphical display allows intuitive troubleshooting and improved visualization of the thermal process. MATTSON SHS 10MA is suited for a variety of industrial processes, such as high temperature bonding, chip on board assembly, and soldering, as well as other types of joining processes that require accurate and repeatable thermal processing. This equipment can be used in a wide range of operations, from prototyping to production, and provides an efficient, cost-effective, and highly reliable solution for thermal processing.

There are no reviews yet