Used AIXTRON 2400 G2 #9018984 for sale

URL successfully copied!

Tap to zoom

ID: 9018984

GaAr/InP Planetary reactor systems

Set up to run Red LED's

Configured for 8x3"(15x2") wafers

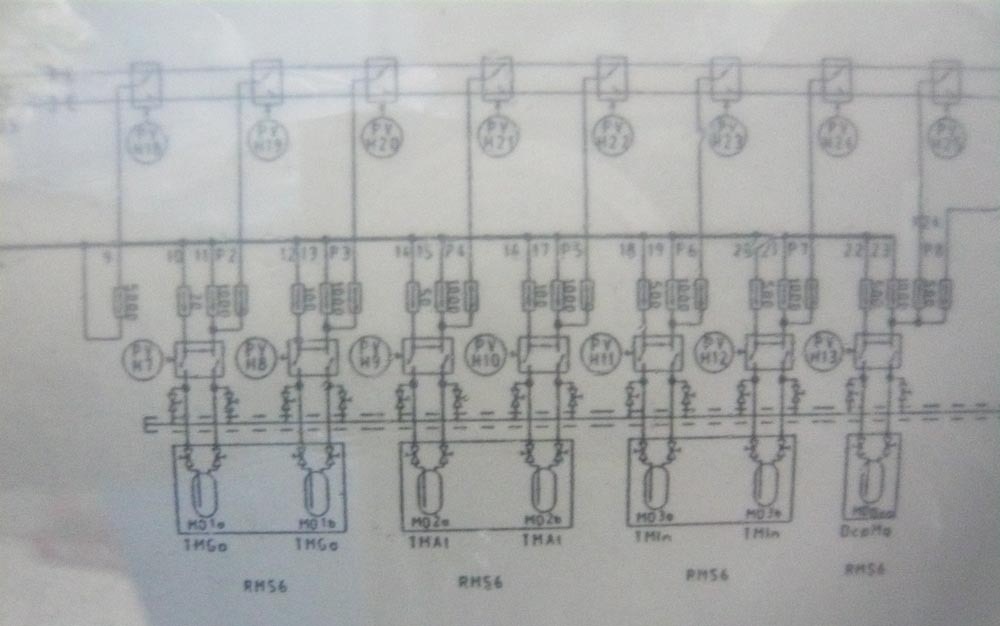

Source configuration:

TMGa-1, TMGa-2, TMAl-1, TMAl-2, TMIn-1, TMIn-2,Cp2Mg-1

Currently deinstalled

1998 vintage.

AIXTRON 2400 G2 is a chemical vapor deposition (CVD) reactor designed for the production of graphene, semiconducting materials, and other nanomaterials. It is a single-wafer reactor and operates at temperatures ranging from 800°C to 1300°C. 2400 G2 consists of a main chamber, which is heated up to a selected temperature. This chamber is enclosed by a vacuum vessel which is connected to a vacuum pump. The chamber is made up of two sources of reactant gas, which is pumped into the chamber along with the reactants and their precursors. Inside the chamber, the reactants will react with the substrate (material to be coated) under the controlled temperature and pressure conditions. AIXTRON 2400 G2 is equipped with an electrical feeding equipment and has a built-in Pulsed Plasma Deposition System (PPDS), where the material is encouraged to grow with plasma energy. This helps to achieve a uniform deposition of the material. Additionally, the unit has the capability of controlling the deposition rates of the reactant gases for different kinds of materials. The chamber is fully automated, with temperature and pressure sensors that monitor and maintain the gas and substrate temperatures, the pressure inside the chamber, and the volume of gas used for the deposition process. The machine is also designed with safety features, such as automated shut-off mechanisms and over-pressure protection, to ensure that no hazardous events can occur during deposition. Finally, 2400 G2 is equipped with an efficient control tool, which utilizes dedicated algorithms and graphical user interfaces. It has a built-in data logging capability and can be operated with different level of automation. Additionally, the asset includes software-based analysis tools such as optical emission spectroscopy (OES) to analyze the deposited material. This helps in obtaining precise and repeatable results for the user.

There are no reviews yet