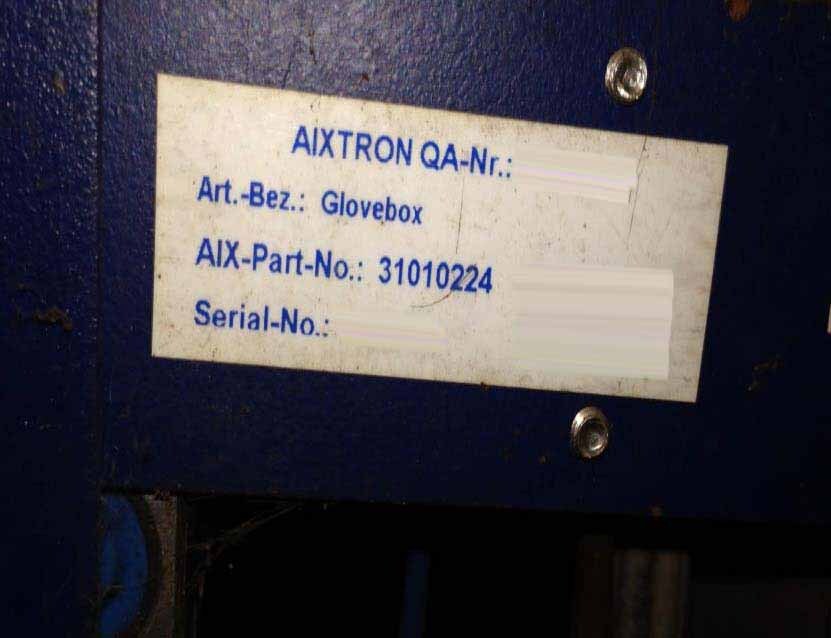

Used AIXTRON 3000 #9121782 for sale

URL successfully copied!

Tap to zoom

ID: 9121782

Planetary reactor system

P/N: 31010224

(95) Hi volume reactors, 2"

MO-IR3000 Heating unit

MOE-3000 Growth cabinet

MO-V300 Low pressure system

MO-EO Control cabinet

MO-GO Gas blending cabinet

Process materials:

Trimethylaluminum: (ch3)3al

Trimethylgallium: (ch3)3ga

Trimethylindium: (ch3)3in

Dimethylzinc: (ch3)2zn

Phosphine: ph3

Arsine: ash3

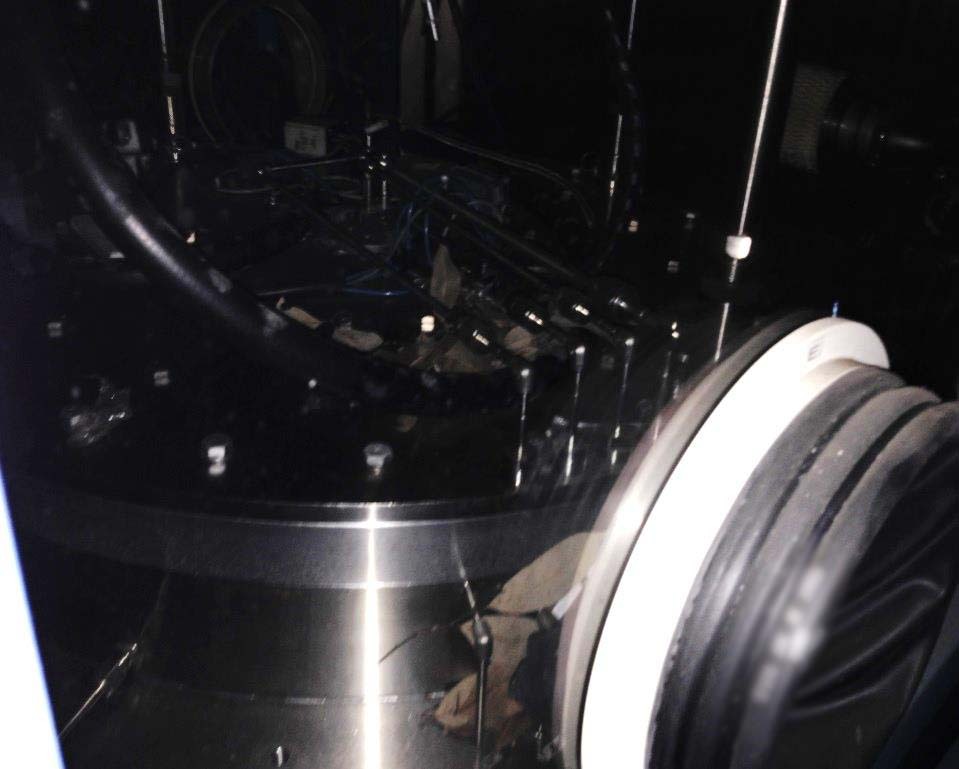

MO-R3000 AIX MOCVD Reactor:

Integrated in stainless steel glovebox

Water cooled stainless steel

Aluminum reactor

Quartz plate

Gas distributor

Exhaust gas collector

Hydraulic lift for reactor lid

Double O-ring system

LEYBOLD d1.6 pump

Graphite susceptor:

Current configuration: (95) 2" Wafers

Supply: (4) 8" Wafers

Tools for handling transfer system unit

Mo-IR3000 AIX 3000 infrared heating unit:

(30) IR Stripe heaters

Power control unit (thyristor system)

Current distribution

Fused

Individual control

Electronic control system

Water cooling system

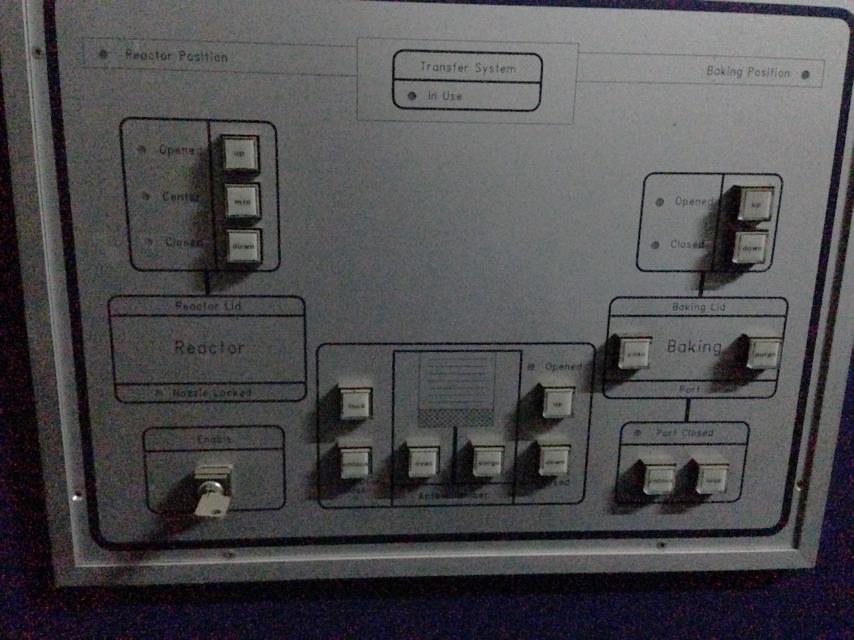

MOE-3000 Growth cabinet:

Glove box with automatic pressure control containing:

Planetary reactor AIX 3000

Inert gas purification system for glove box

Achievable gas purity 1 ppm H2O and O2

Filters regenerative

Control panel for glove box

Low pressure operating unit MO-V3000 AIX 3000

Transfer chamber for reactor parts

Wafer transfer chamber

N2 Blow off gun

Hydraulic system for reactor lid operation

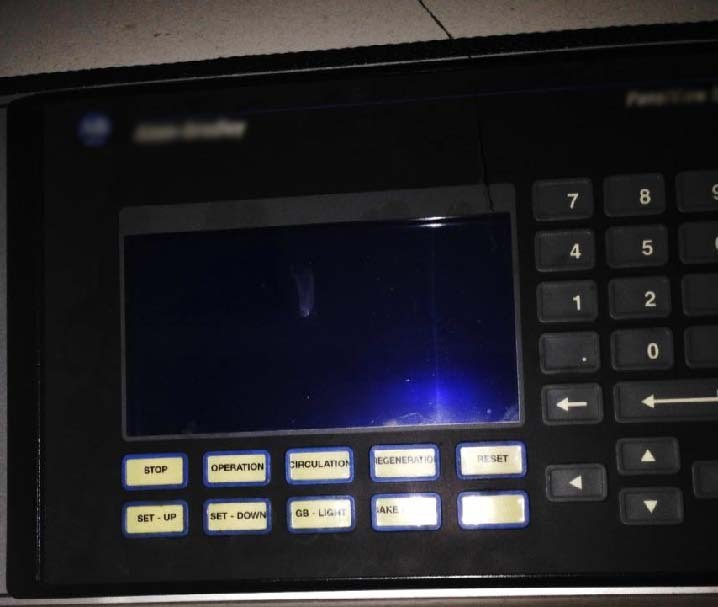

MO-V3000 Low pressure system:

High capacity particulate filter

Pressure sensor

Throttle valve

Pressure control

(2) IF 100 Particle traps

Vacuum valves

Vacuum tweezers

N2 Purge of pump

Dual port MKS pressure readout

PIS Indication system

MO-EO Control cabinet:

Ventilated steel cabinet for electronic control units

Power supplies for reactor heater and electronics

Control panel for reactor temperature with EUROTHERM 818s pid

Control panel for reactor pressure regulation with MKS 652

Control panel for pneumatic valves in gas blending system

Control panel for reactor cooling

Control panel for double O-ring leak monitoring

Control panel for moisture sensor

Safety control:

Hard-wired

Pal programmable logic

Computer control console

Printer

Emergency power off button

Power distribution

Signal distribution

Mo-go gas blending cabinet:

Exhausted steel cabinet

Metalorganic

Hydride sources

Controlled temperature baths

Integrated N2H2 distribution manifold

Asec pressure regulators

Run and vent lines

Auxiliary lines for reactor

Gas foil rotation

Particle filters

Check valves in all gas supply lines

Pneumatic distribution panel

Signal distribution panel

Integrated pd-diffuser.

AIXTRON 3000 is a chemical vapor deposition (CVD) reactor dedicated to the production of ultra-high quality semiconductor materials, used in the production of advanced electronic devices. Its modular design and unique patented features make it ideal for use in both laboratory environments and in larger production operations. 3000 is comprised of a deposition chamber, containing a single source electron beam gun and two target electrodes. The energy source is a 650ºC isolated electron beam, which is optimized for production of quality material. Inside the vacuum-tight chamber, energetic electrons from the gun interact with the gaseous reactant material to create a deposition of material on the target substrate. The resulting response is highly uniform and repeatable, providing the basis for a controlled production process. AIXTRON 3000 is engineered to deliver an unmatched degree of control over the deposition environment, allowing parameters such as pressure, temperature and rate of deposition to be precisely monitored and adjusted at will. Additional features include a state-of-the-art automated gas supply system and advanced wafer handling robots for quick and efficient substrate transfers. AILTRON 3000 materials come in a variety of options, including group IV, III-V and II-VI compounds. These compounds are specially formulated to provide uniformity and repeatability of the deposition process, and to ensure the highest possible quality of device production. The reactor also has the capability to incorporate a range of substrates, including silicon oxide, aluminum oxide and nitride. AIXTRON 3000 has a wide range of applications in the production of advanced electronic devices. Notable uses include high-efficiency infrared detectors, optical data storage devices, advanced ultra-thin films, and transfer-less lithography. It has also been used for the successful fabrication of graphene-based materials, for applications in biotechnology and nanoelectronics.

There are no reviews yet