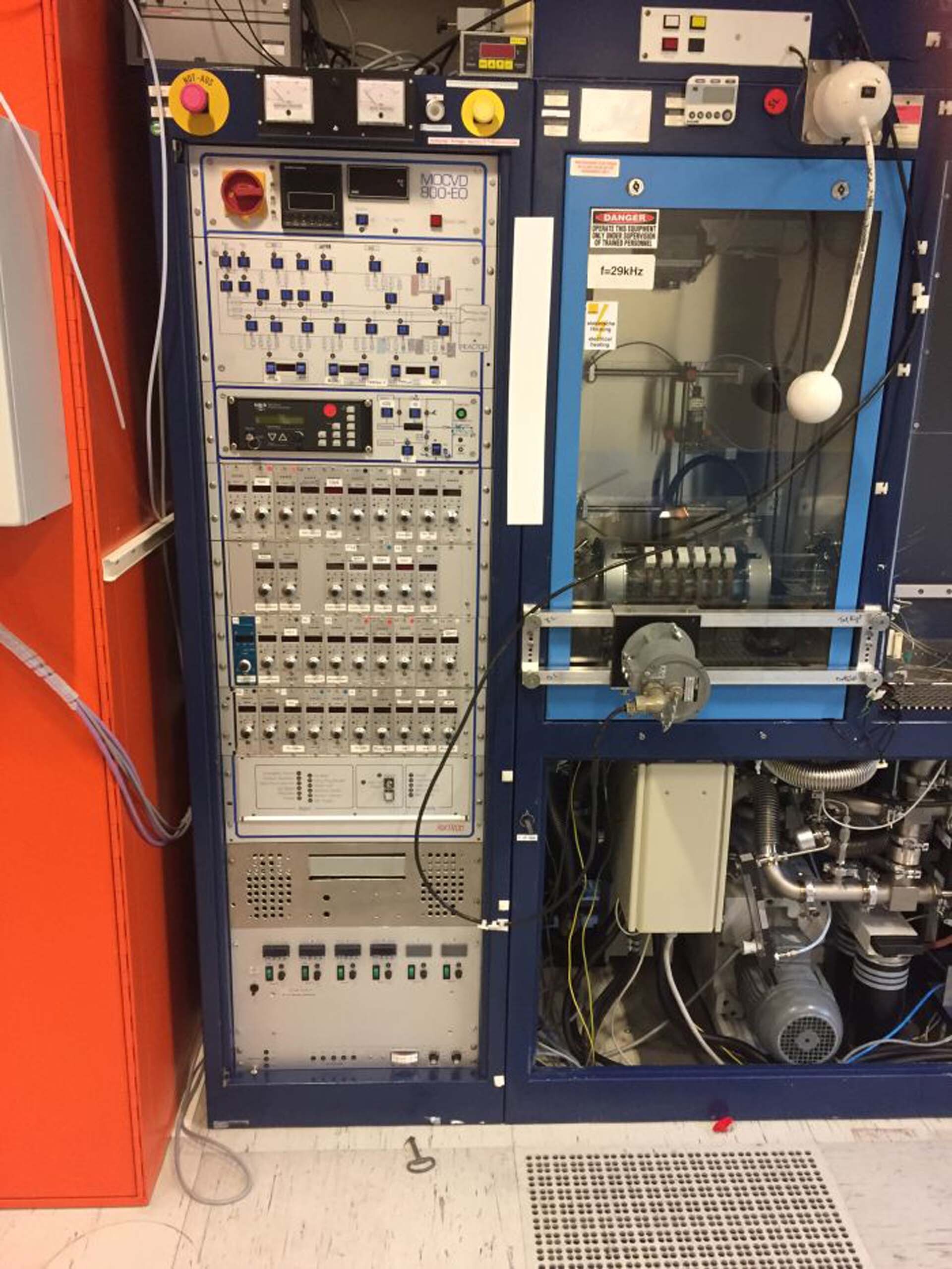

Used AIXTRON AIX 200 #9359469 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9359469

MOCVD System, 2"

RF Coil heater

With FILMETRICS in-situ reflectometry system

GaN and Water-cooled quartz reactor

With inner quartz liner, 2"

SiC Coated graphite susceptor: GaN, AlN, InGaN, AlGaN

Gas foil rotation MO sources: (2) TMGa, TEGa, TMIn, TMAl, Cp2Mg (6 MO Channels)

(3) Gas precursor lines and NH3

H2 and N2 Carrier gases

Spare parts included.

AIXTRON AIX 200 is a multi-wafer batch type deposition equipment designed to be used for the growth of device grade high quality crystalline material layers on a variety of substrates. This system is capable of producing high-resolution and high-quality layers of up to 200 mm in diameter. It is designed to deposit material onto up to eight substrates in small batches, making it an ideal choice for prototyping and research purposes. AIX 200 features a single zone planar magnetron sputtering unit with standard silicon target sources, enabling the growth of materials such as silicon, silicon oxide, and silicon nitride. It offers a high degree of automation and ease-of-use, allowing precise control over layer deposition parameters such as thickness, grain structure, and uniformity of topography. The machine is also equipped with a multi-wavelength optical monitor and pH/Density/Thermal Measurement tool, enabling the user to monitor the quality of layers throughout the entire deposition process. AIXTRON AIX 200 is equipped with a number of control systems, including a direct current (DC) power supply, DC bias, and heating/cooling systems. This allows precise temperature control, ensuring excellent layer uniformity and consistent quality of layer growth. AIX 200 also features advanced pressure control, allowing users to regulate gas influx during deposition and achieve precise control over the desired reaction. AIXTRON AIX 200 also features a number of safety features, ensuring safe operation of the asset. A number of external safety features are included, such as explosion proof seals, as well as a set of integrated tools designed to monitor, control, and secure the model. In addition, AIX 200 has an integrated monitoring equipment designed to ensure a safe environment for personnel operation. Overall, AIXTRON AIX 200 offers a reliable, cost-effective solution for the growth of device grade high quality crystalline material layers on a variety of substrates. It is capable of producing high-resolution and high-quality layers at up to 200 mm in diameter, making it ideal for prototyping and research purposes. It is also equipped with a number of safety features, ensuring a secure environment for personnel operation.

There are no reviews yet