Used AIXTRON Crius 30 X 2" #9032566 for sale

URL successfully copied!

Tap to zoom

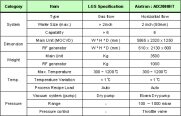

ID: 9032566

Vintage: 2007

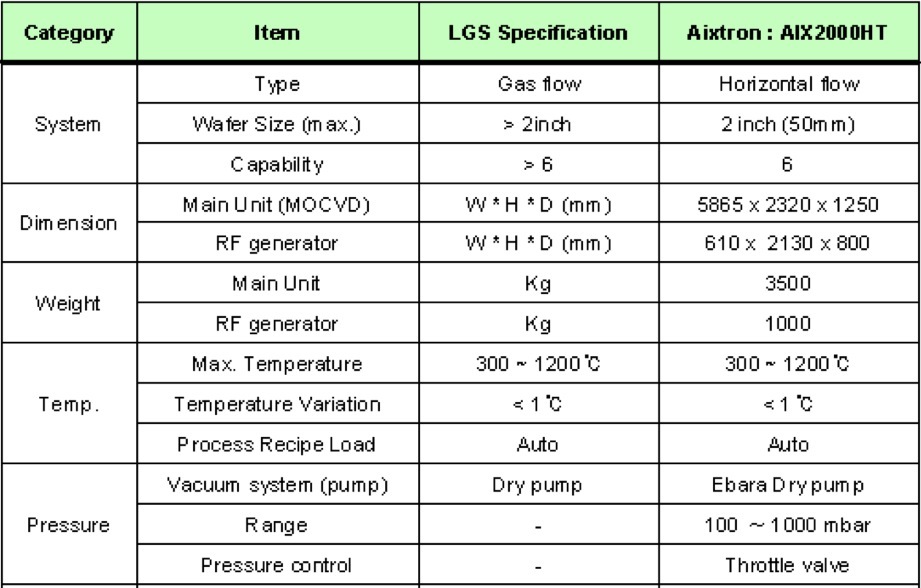

CCS/IC MOCVD GaN system

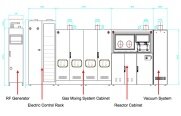

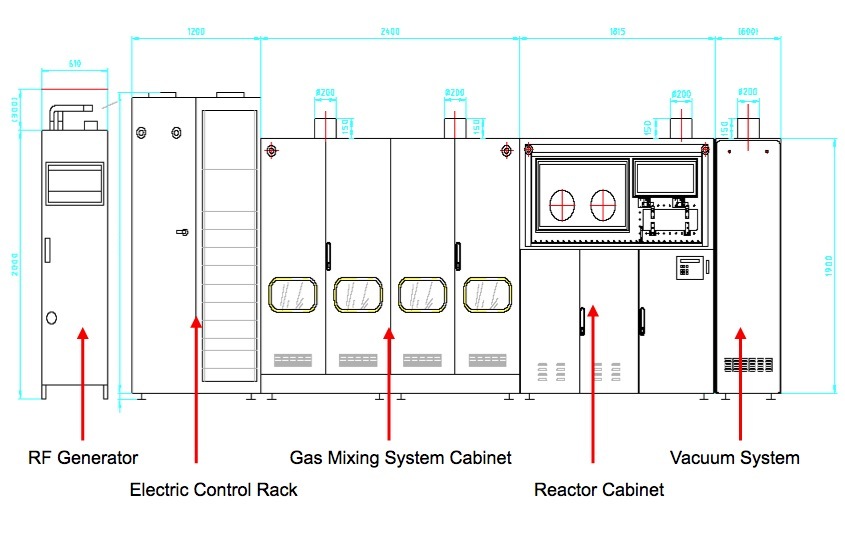

Electrical cabinet

Gas mixing cabinet

Reactor cabinet

Glove box cabinet

Heater power supply unit

Heat exchanger

Vacuum system

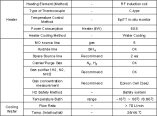

Temperature range: Storage: 10º-50º C; During condition: 15º-25º C

Relative humidity: Storage: 30-80%; 45-80%

Voltage: 400 V +/- 5% (3/N/PE); 208 V +/- 5% (3/N/PE)

Frequency: 50 Hz +/- 1% for 400 V; 60 Hz +/- 1% 208 V

Power consumption: Approx. 28 kVA for system; approx. 110 kVA for power supply, cabinet

Max power consumption: 110 kVA

Gas mixing cabinet/electrical cabinet: 2 ventilation ducts, ∅250mm

=> 750 m3/h each

Process gases:

Type of gas: e.g. NH3, HCl

Purity: ≥ 5.0 N (free of condensate)

Inlet pressure range: 3, 3.5 bar

Pneumatic supply:

Quality: Clean, dry 5 um filtered

Pressure: 5,7 bar

Temperature: Approx. 20º C

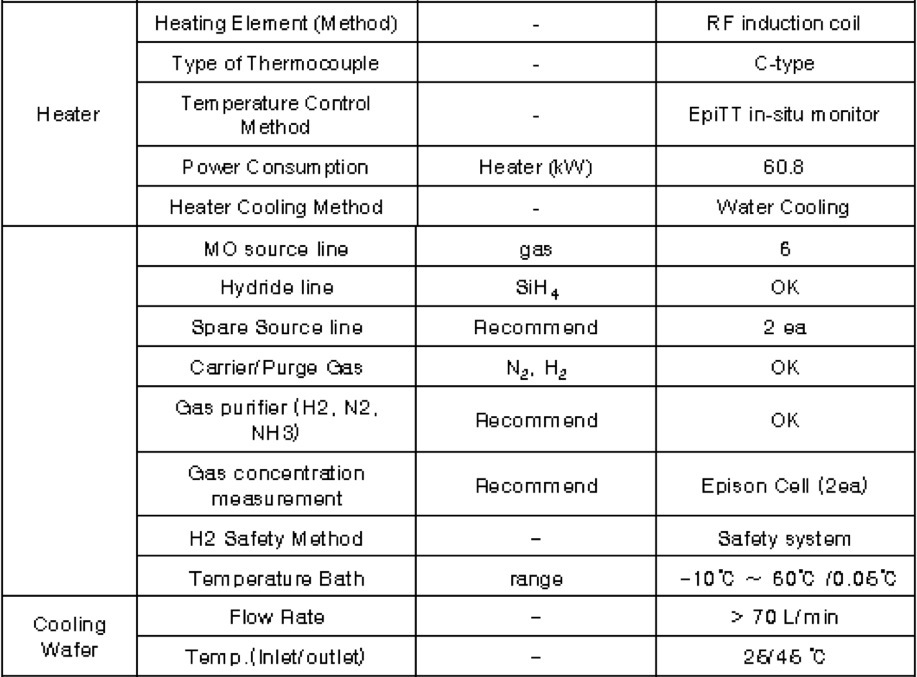

Cooling water:

Inlet temperature: 17-25º C

Temperature stability: +/- 1º C

Inlet pressure (max): 6.5 bar

Outlet pressure (max): 2.5 bar

Pressure difference inlet/out: > 4 bar

Minimum total flow: 50 l/min

RF generator board is nonfunctional

2007 vintage.

AIXTRON Crius 30 X 2 is a two-platen, plasma-enhanced chemical vapor deposition (PECVD) reactor. It is used for the deposition of high quality thin films, such as oxides and nitrides, onto a variety of substrates including silicon, metals, dielectrics, and polymers. Its two platen design enables larger diameter and area substrates to be processed compared to single-platen PECVD systems. The Crius 30 X 2 has a 30 cm process chamber, which is designed for uniform, controlled deposition of thin films by using plasma-enhanced CVD along with computer-controlled process variables such as pressure, substrate temperature, and gas flows. It also has adjustable work chamber homogeneity zones, allowing users to distribute their process conditions over specific areas of the substrate. The PECVD process is powered by a patented 1.8 kW radio frequency (RF) power generator that operates at 13.56 MHz. It is designed to provide tunable RF power for both platen electrodes and substrate bias. The system allows up to 100 Watts of RF power per platen. The machine includes an advanced software and control system that provides easy user interface, enhanced process control, and automated quality monitoring. The deposition rates on the Crius 30 X 2 are adjustable between 0.1 and 10 microns/minute. Deposition rates depend on the type of substrate and the gases used. The maximum temperature is limited to 350°C, but can be lower for certain substrates. Additionally, the PECVD process can be used to deposit multicomponent, multilayer thin films with excellent reproducibility. The Crius 30 X 2 is also highly reliable, as it is designed with structural parts that are connected by precise alignment pins to ensure superior bed flatness and repeatability. Its modular design makes maintenance and service relatively easy, and it is suitable for industrial production lines. In conclusion, AIXTRON Crius 30 X 2 is an advanced PECVD system for the deposition of quality thin films that is designed with reliability and accuracy in mind. Its two platen design enables larger and more precise substrate processing than single-platen systems, and its adjustable work chamber homogeneity zones allow for more accurate process control. Its advanced RF power generator and software make it suitable for both industrial production lines and laboratory research.

There are no reviews yet