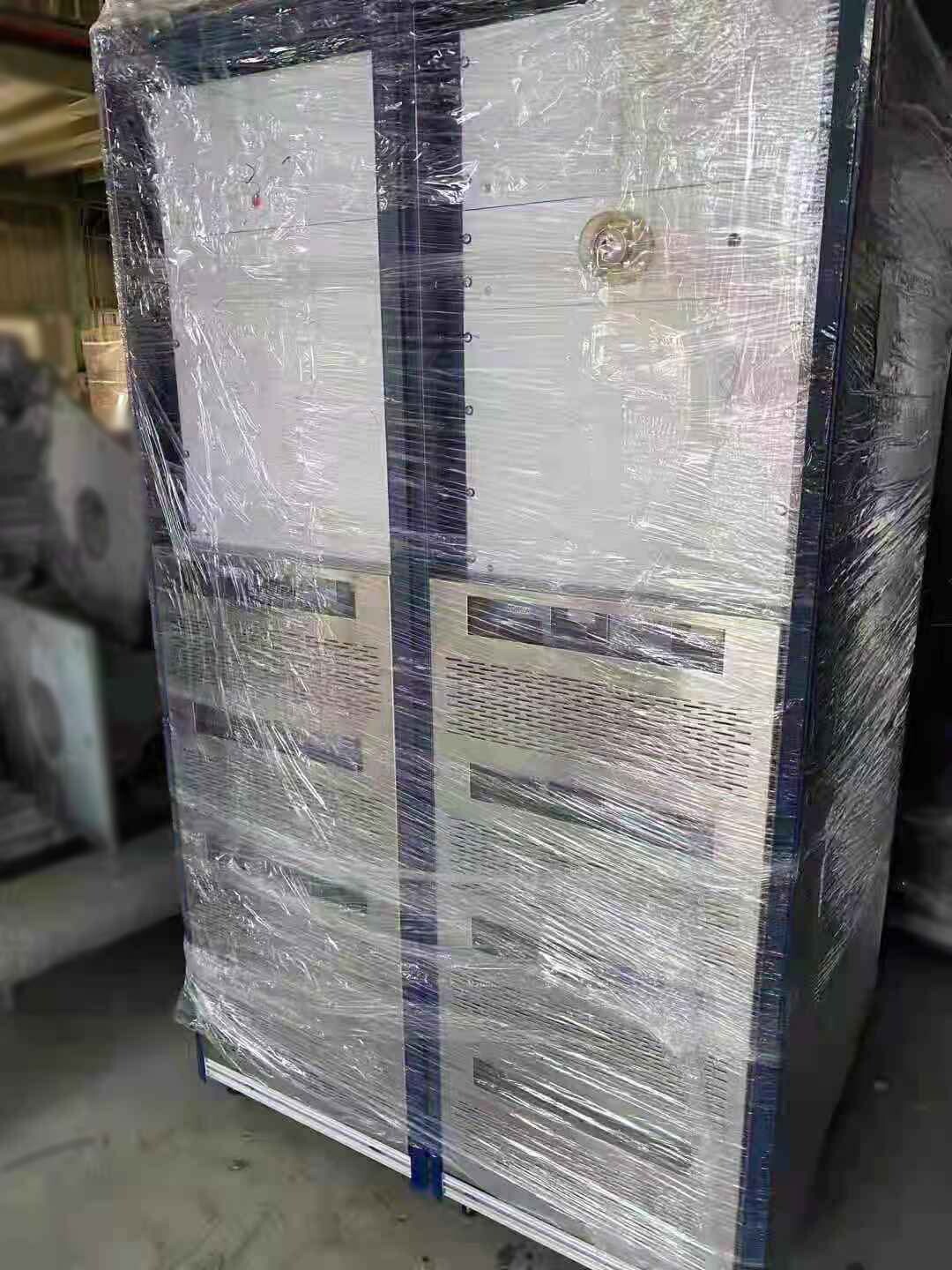

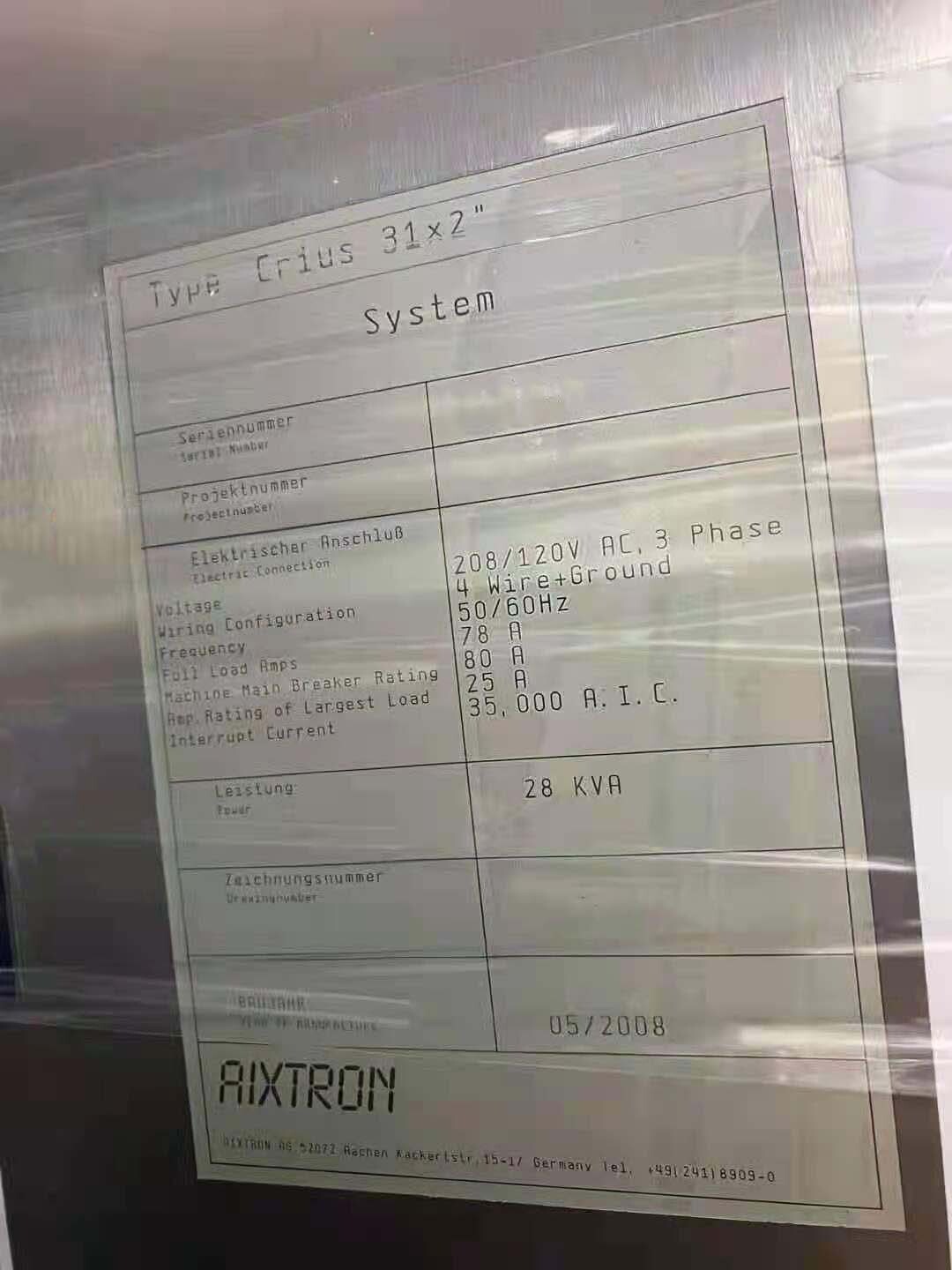

Used AIXTRON Crius 31x2" #9383394 for sale

URL successfully copied!

Tap to zoom

ID: 9383394

Vintage: 2008

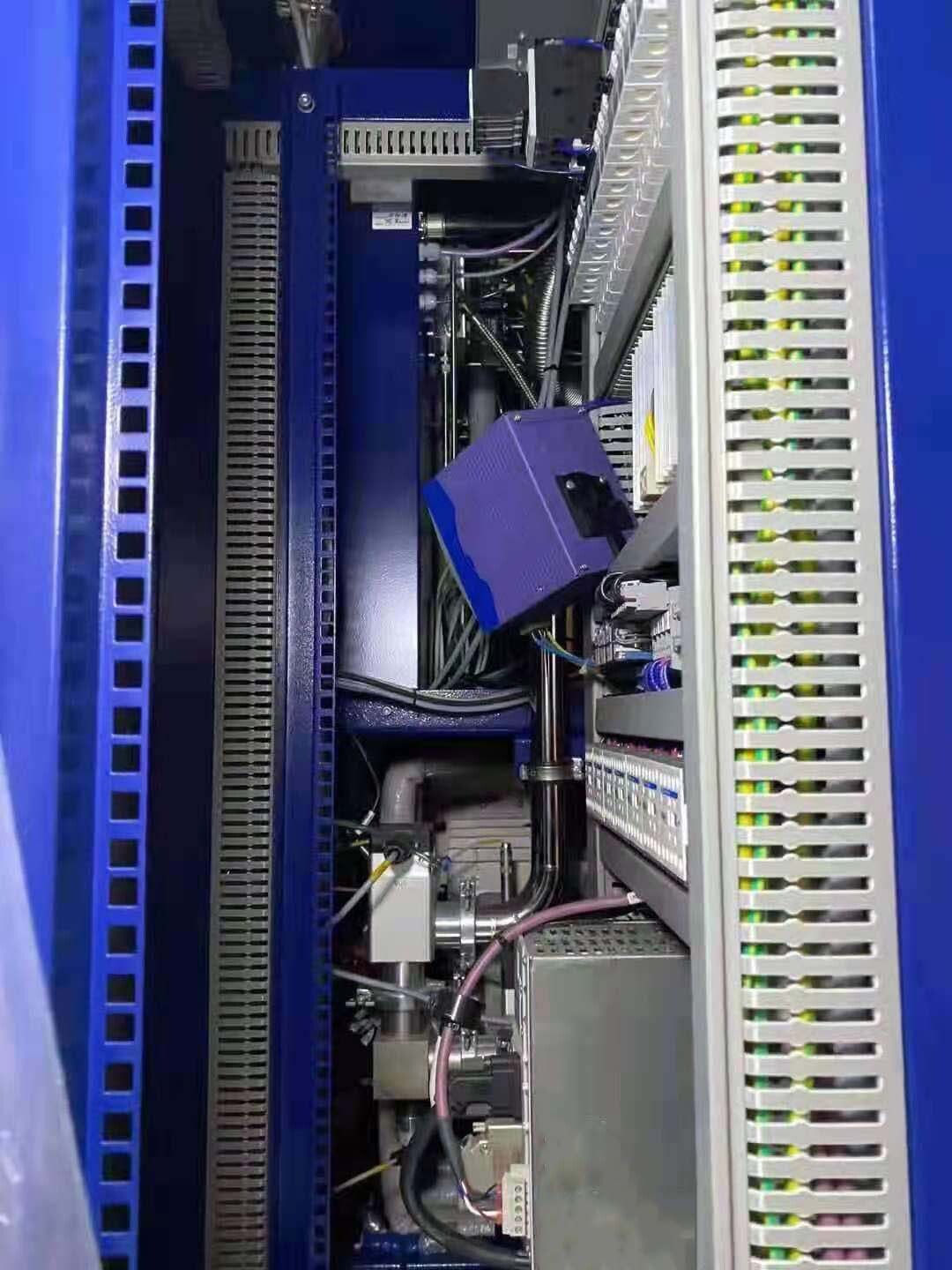

MOCVD System

GaN

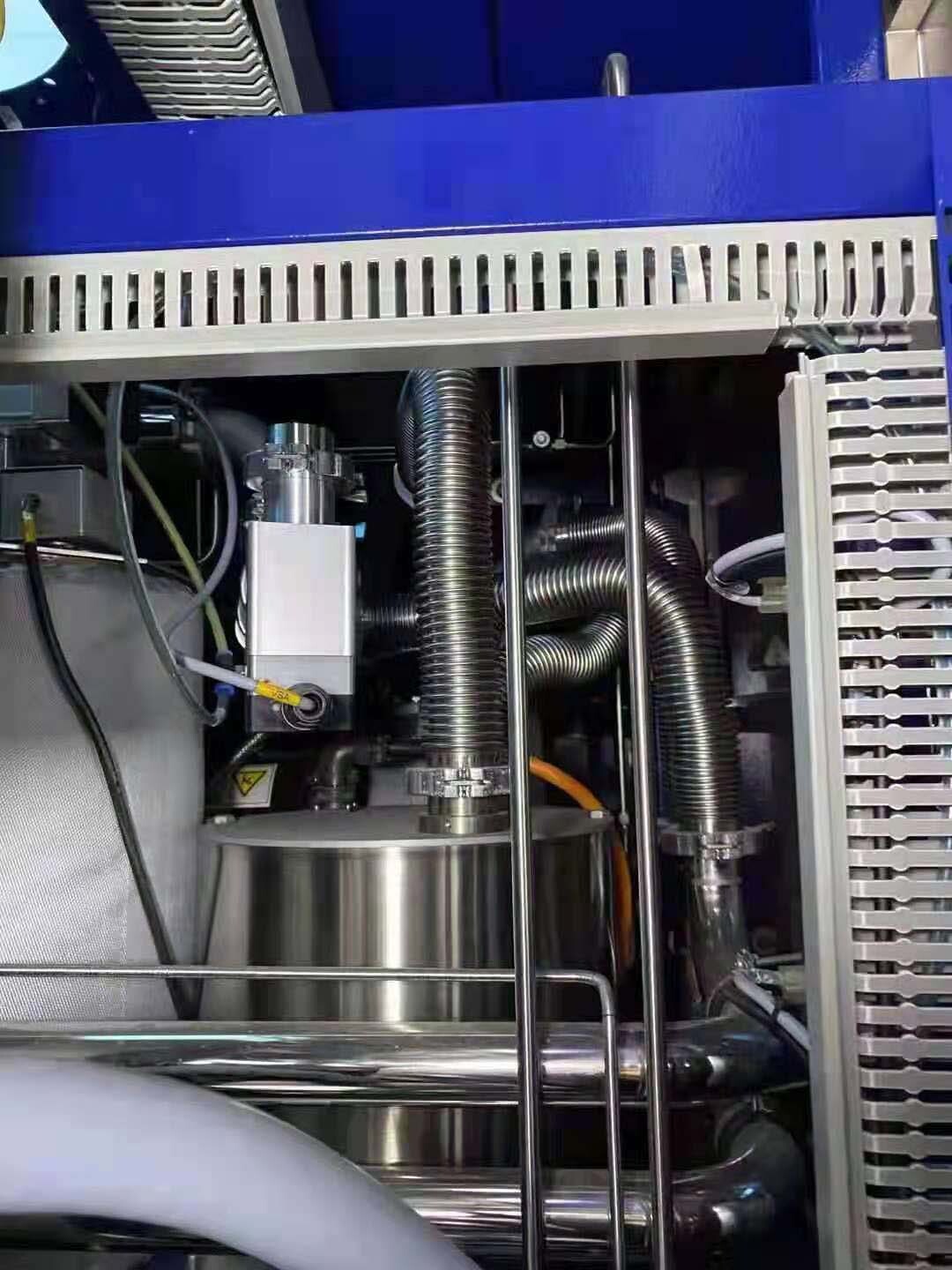

Chamber

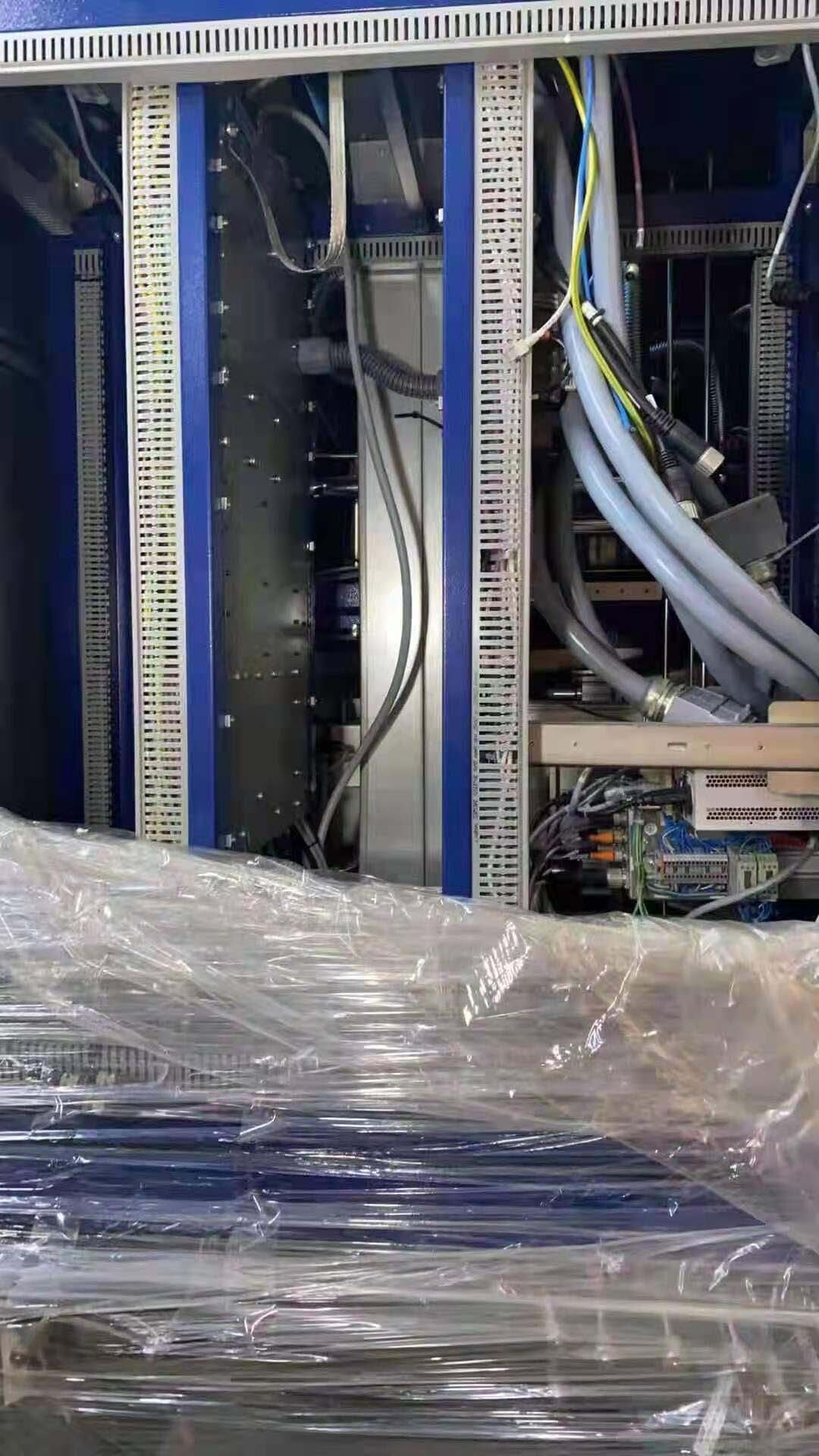

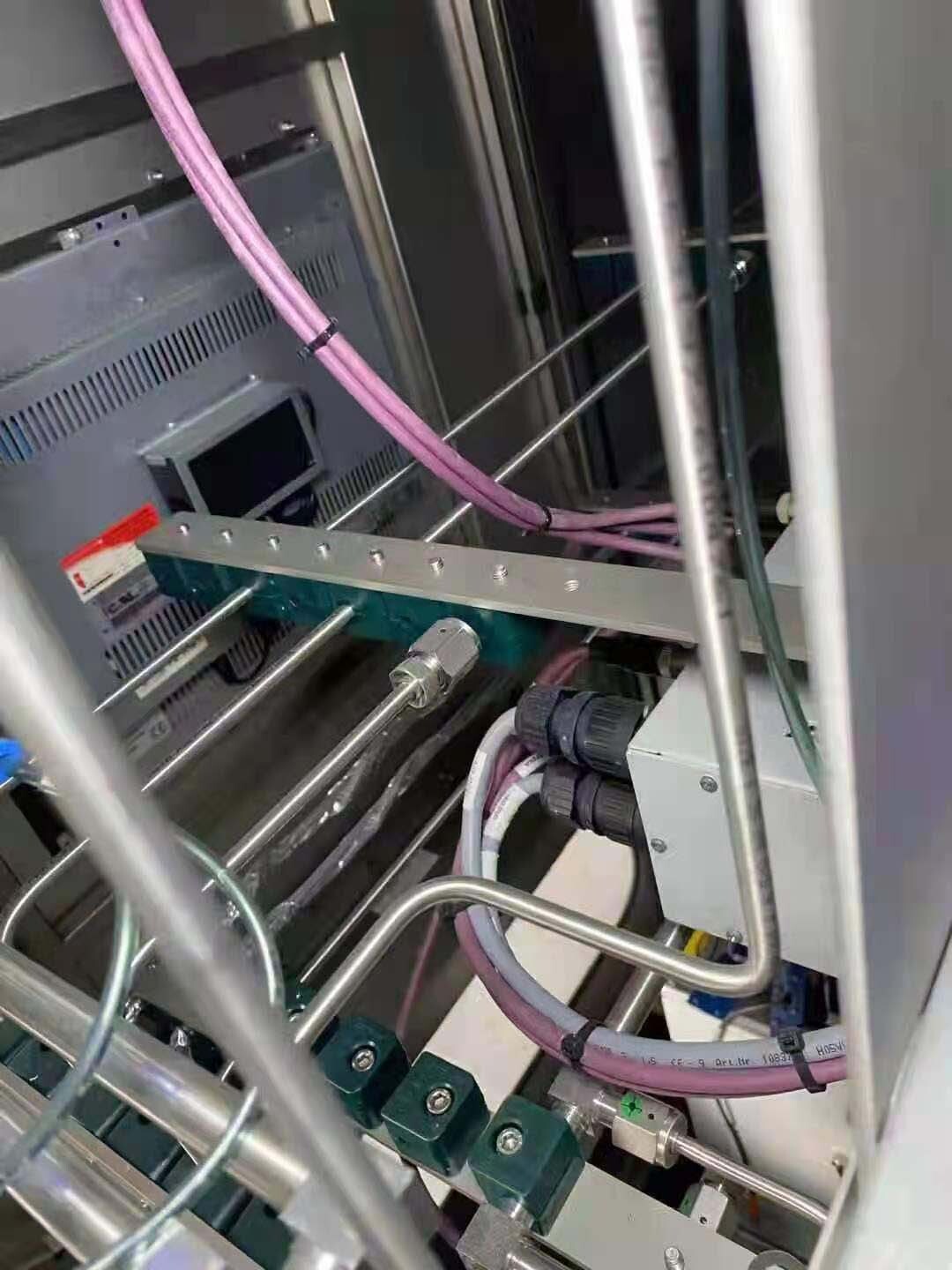

Main pump: EBARA ESA70W-D

Scroll pump

AFFINITY Chiller

RF Generator size: 1210 mm x 1200 mm x 2100 mm (L x W x H)

MO Source: TMGa-1, TMAI-1, Cp2Mg-1, Cp2Mg-2, TMIn-1, TMIn-2, TMIn-3 (7)

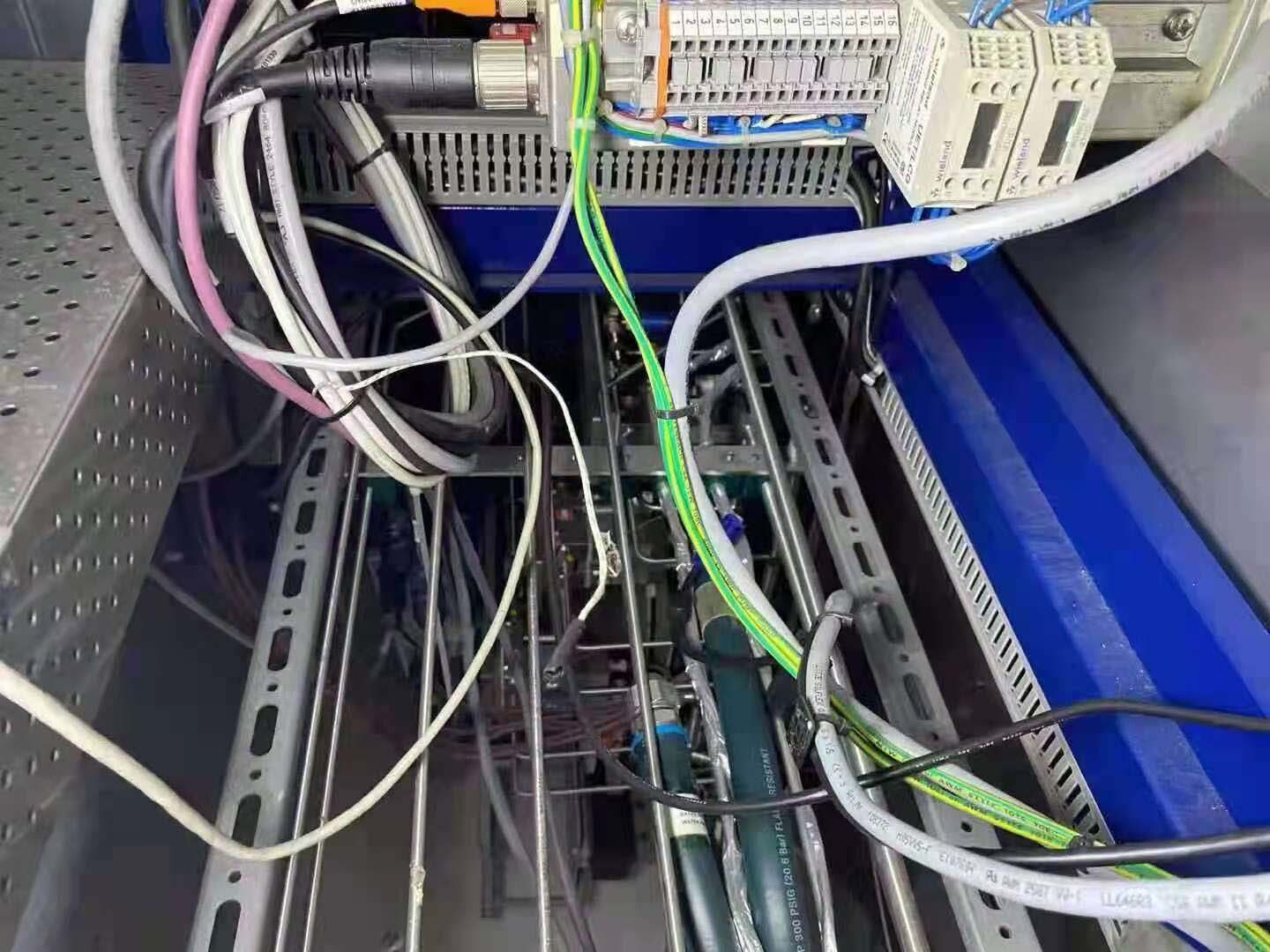

MFC Type: BRONKHORST EL-Flow

Temperature monitor: EPI Twin TT

Hydride lines: NH3-1 / NH3-2 / SiH4

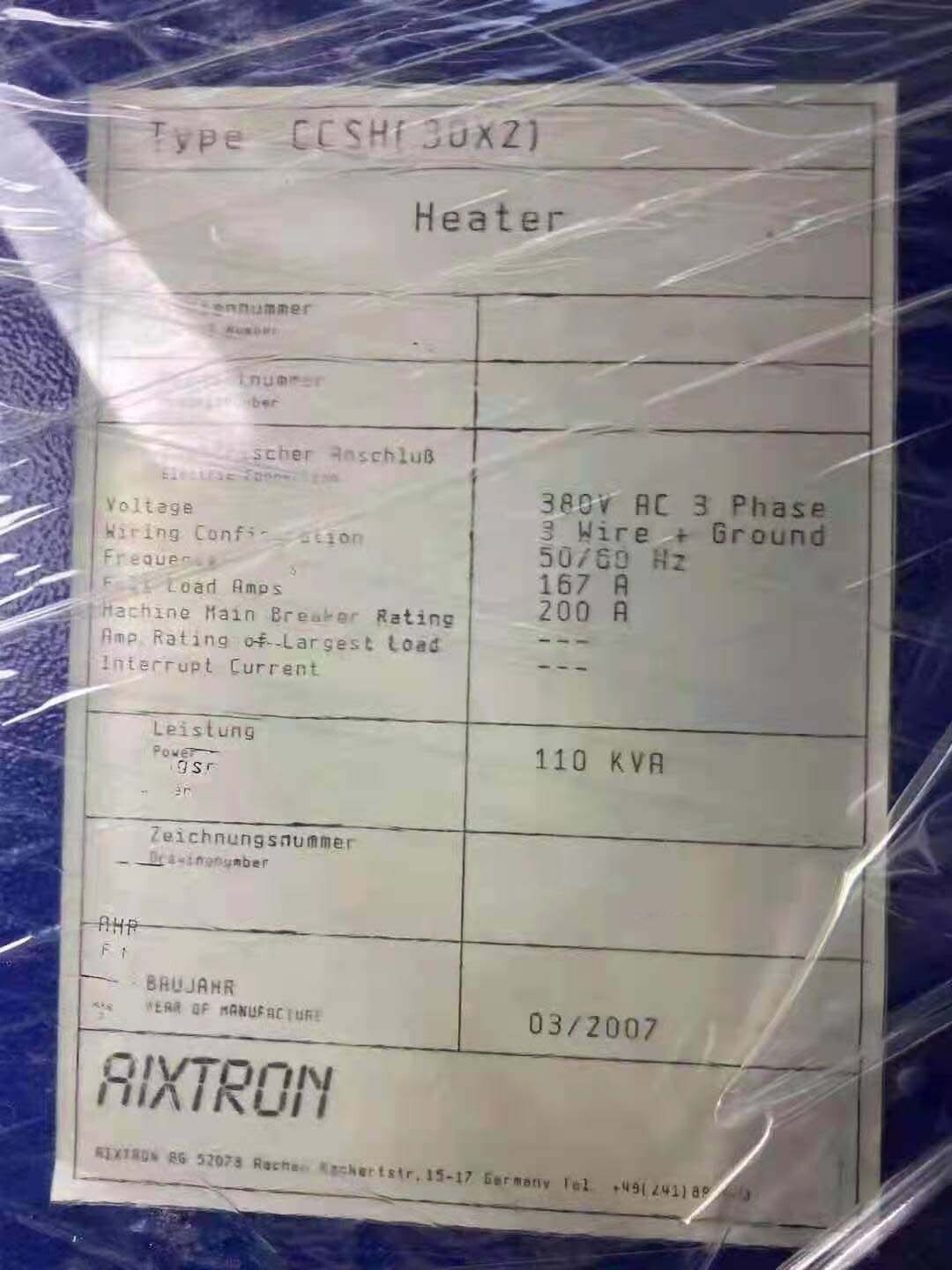

Heater voltage: AC 400V, 3-Phase

Wiring: 4-Wires and ground

Power supply: AC 208/120V, 3-Phase

2008 vintage.

AIXTRON Crius 31x2 is a commercial-scale metal-organic chemical vapor deposition (MOCVD) reactor. It is one of the leading vertical 2-inch reactors in the world and is capable of producing single-wafer 200mm wafers. The reactor is manufactured by AIXTRON, a global leader in advanced equipment for the semiconductor and electronics industries. The Crius 31x2 features a split-arc inductive coils, round ceramic crucible, fixed bipolar RF generator, and load-lock wafer handling system. The induction technology used by the Crius 31x2 offers superior uniformity for the deposition of nitrides and oxides. The round ceramic crucible also offers enhanced thermal uniformity for uniform deposition of thin films on both mono- and multi-layer wafers. The Crius 31x2 is also equipped with a temperature control system and computer control. This feature allows for precise temperature control, which ensures optimum uniformity and deposition result. The pressure control feature of this reactor also allows for increased yield and reduced waste. Additionally, the reactor has a high degree of automation, which helps in simplifying the operation process and enabling faster, more precise wafer fabrication. The Crius 31x2 is made out of high-grade stainless steel, making it highly resistant to corrosion and other types of environmental hazards. In addition, the reactor features excellent thermal insulation, which allows for minimal energy consumption and increased efficiency. The Crius 31x2 is also fitted with cutting-edge safety features, ensuring that the reactor is safe for operation managing personnel as well as the environment around it. It features electro-treated protective doors to prevent any equipment damage and guarantees the safety of the personnel. In addition, the Crius 31x2 is designed to provide a wide range of applications with longer process runs. It works best with the introduction of high deposition rates for thicker materials, enabling more efficient manufacturing processes. Furthermore, the reactor is equipped with great tool inspectability, resulting in fewer downtimes and a reduced amount of time to diagnose and solve technical problems. Overall, AIXTRON Crius 31x2 is an advanced metal-organic chemical vapor deposition reactor that offers a variety of advantages for the manufacturing of thin and thick films on single and multi-layer wafers. Its advanced technology, superior uniformity, advanced safety features, and automation simplify the manufacturing process and increase productivity and yields.

There are no reviews yet