Used AIXTRON Crius II #9399247 for sale

URL successfully copied!

Tap to zoom

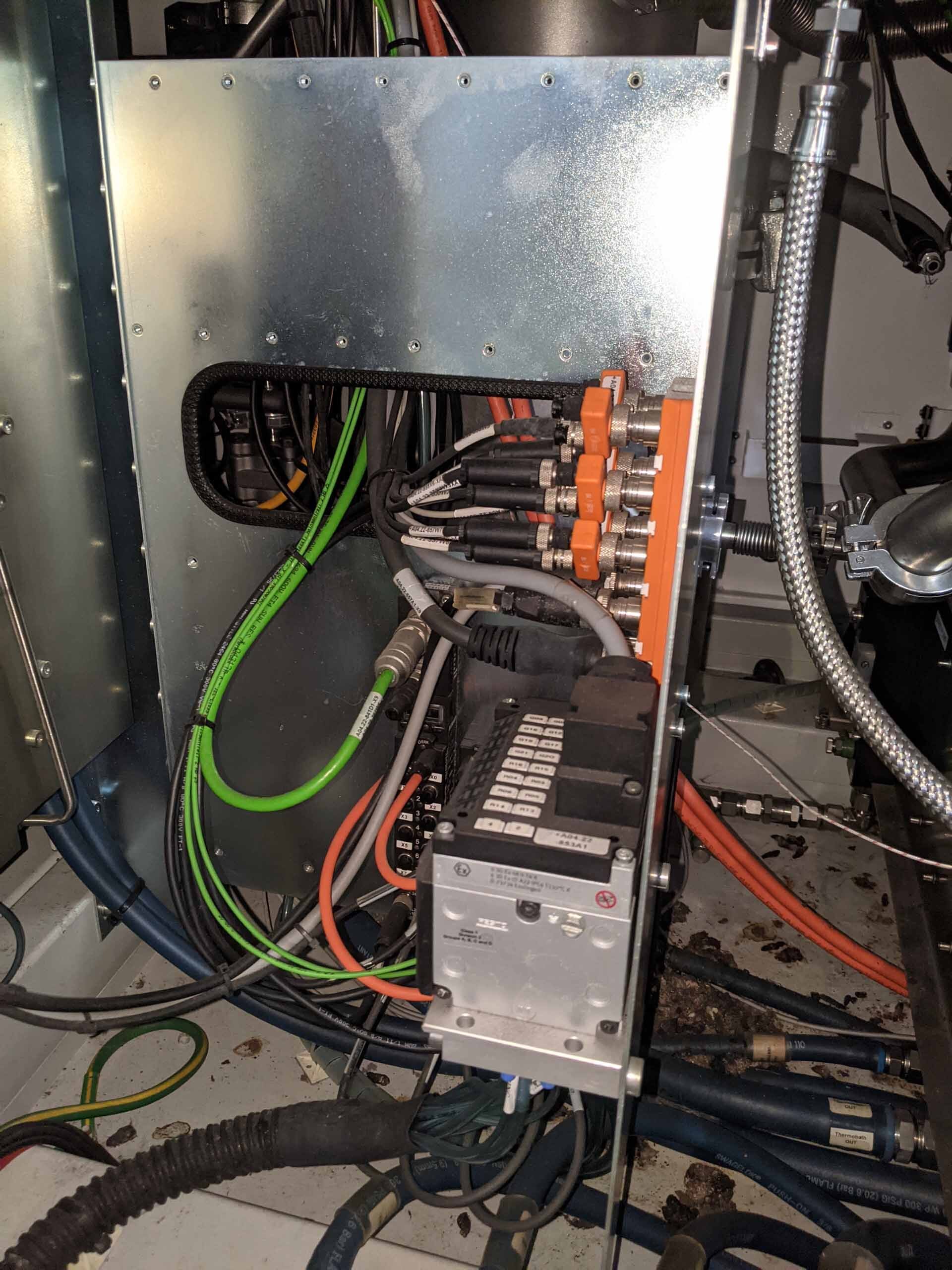

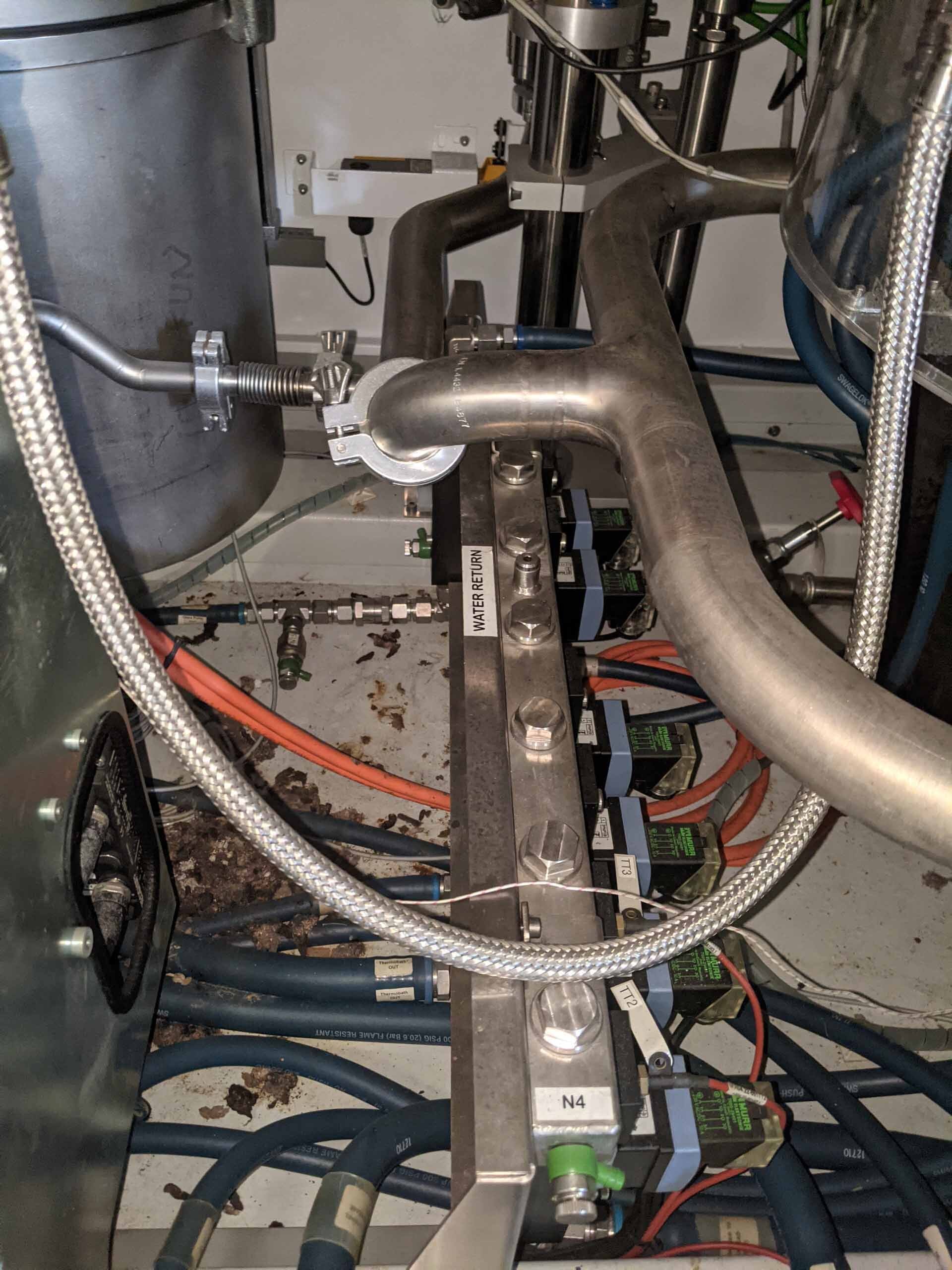

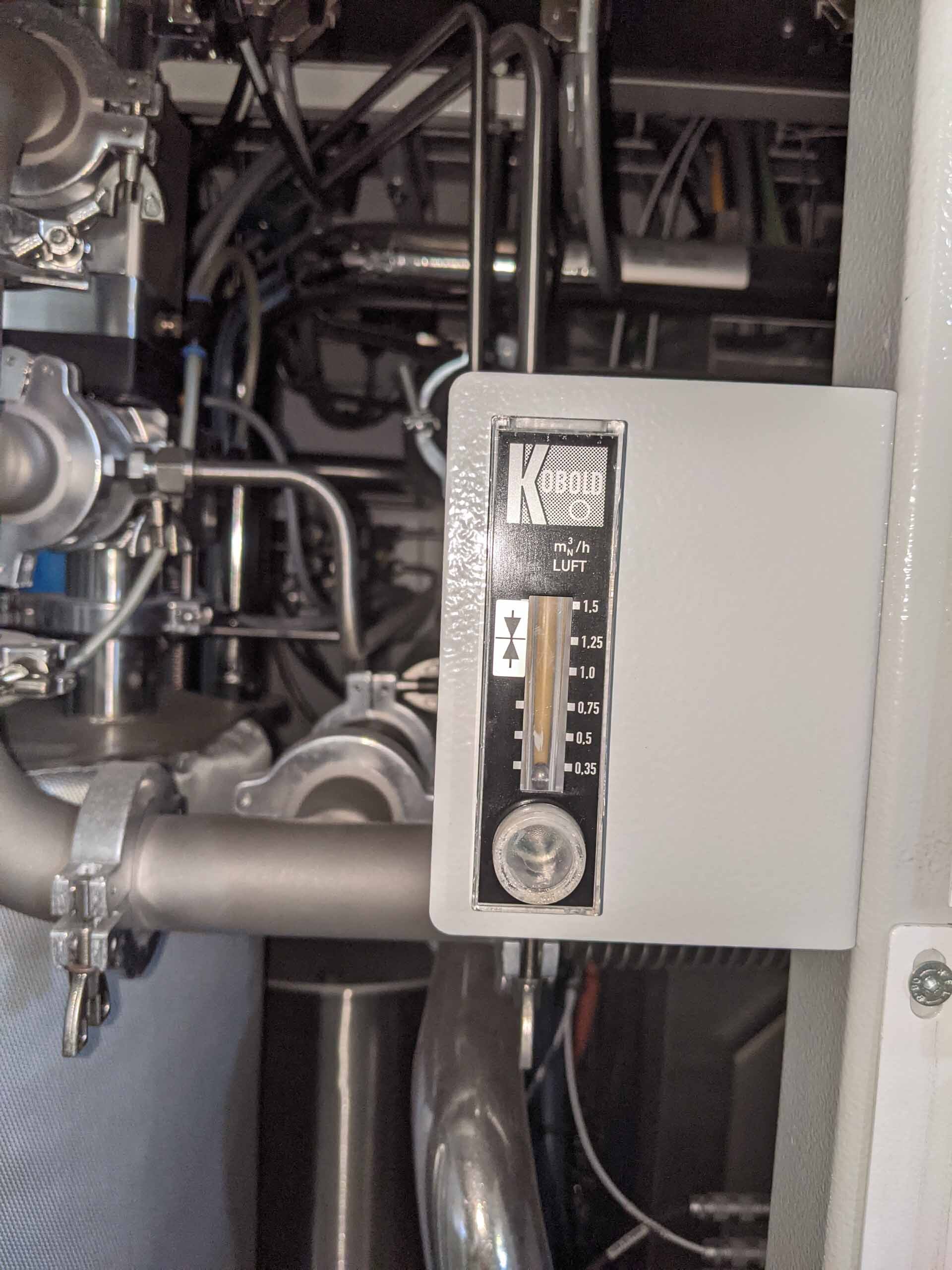

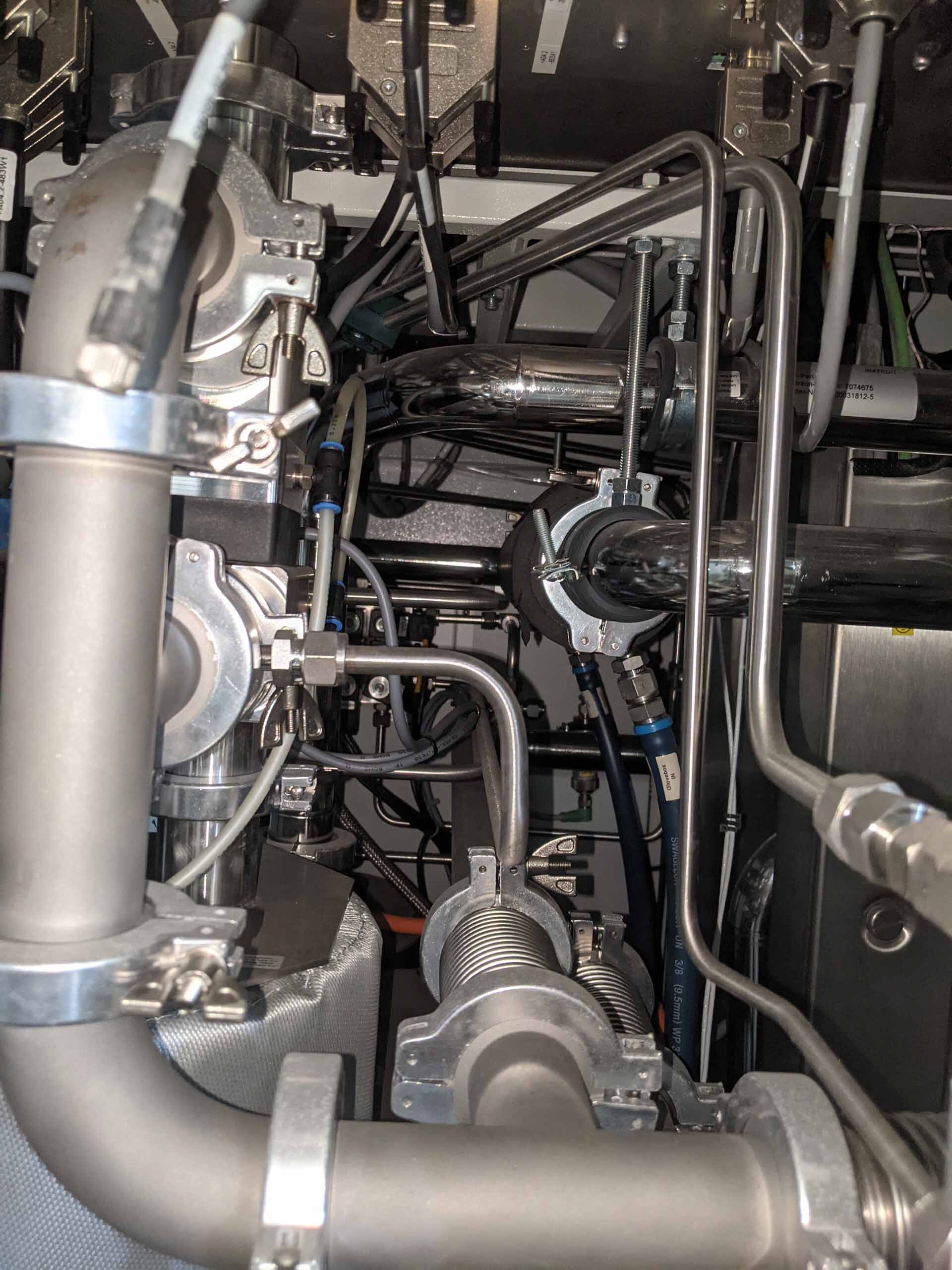

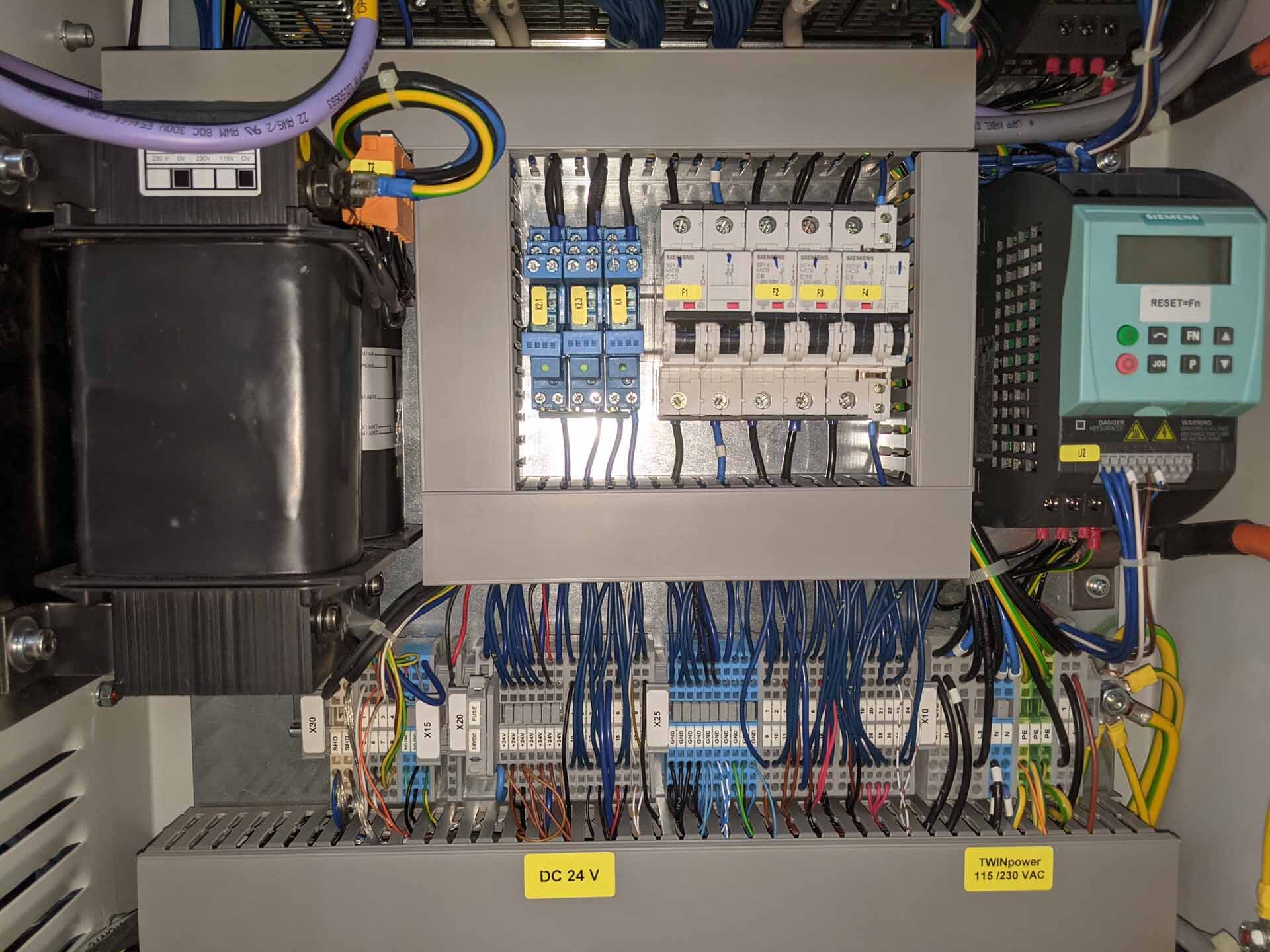

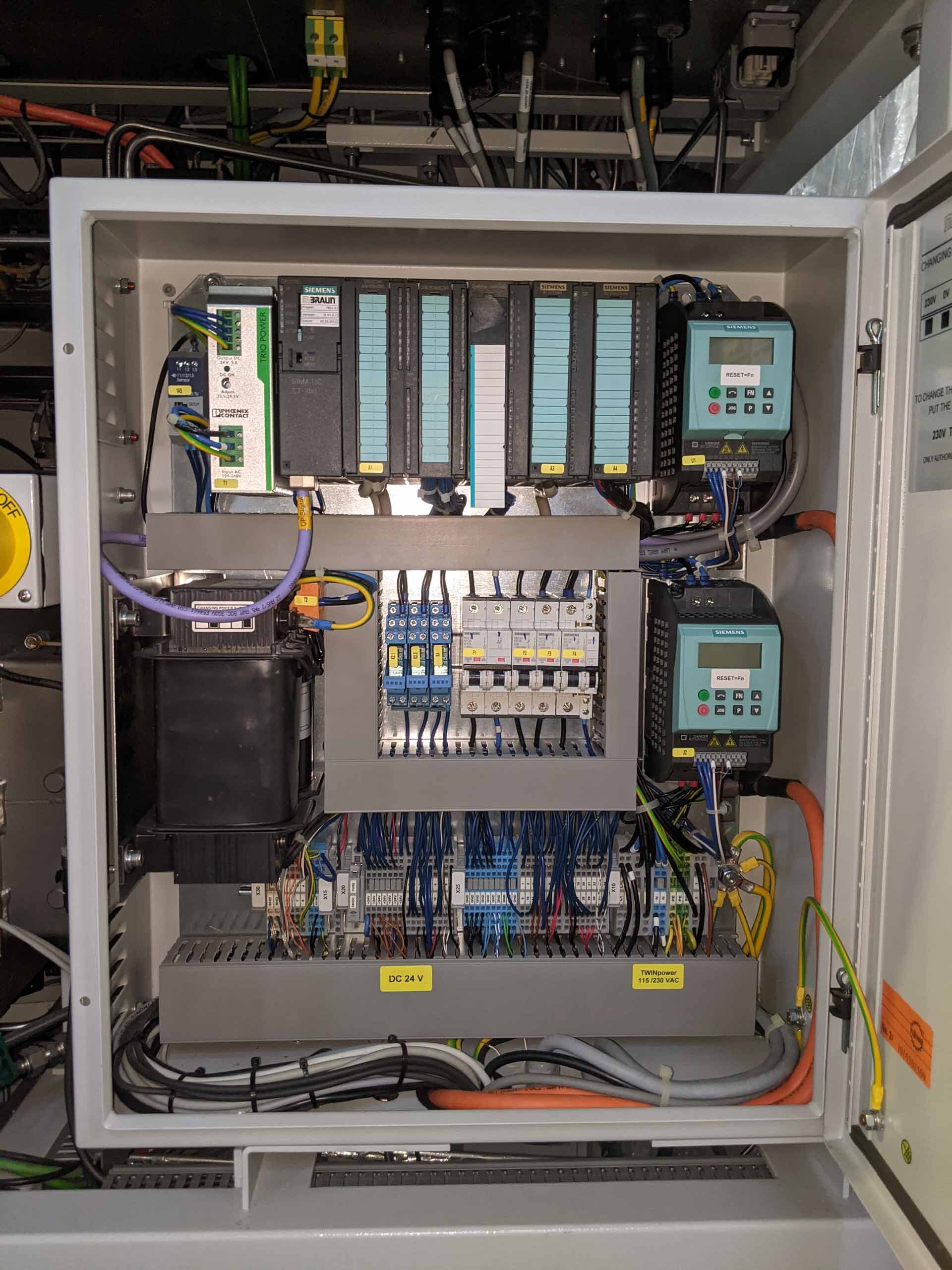

ID: 9399247

Wafer Size: 2"-6"

Vintage: 2010

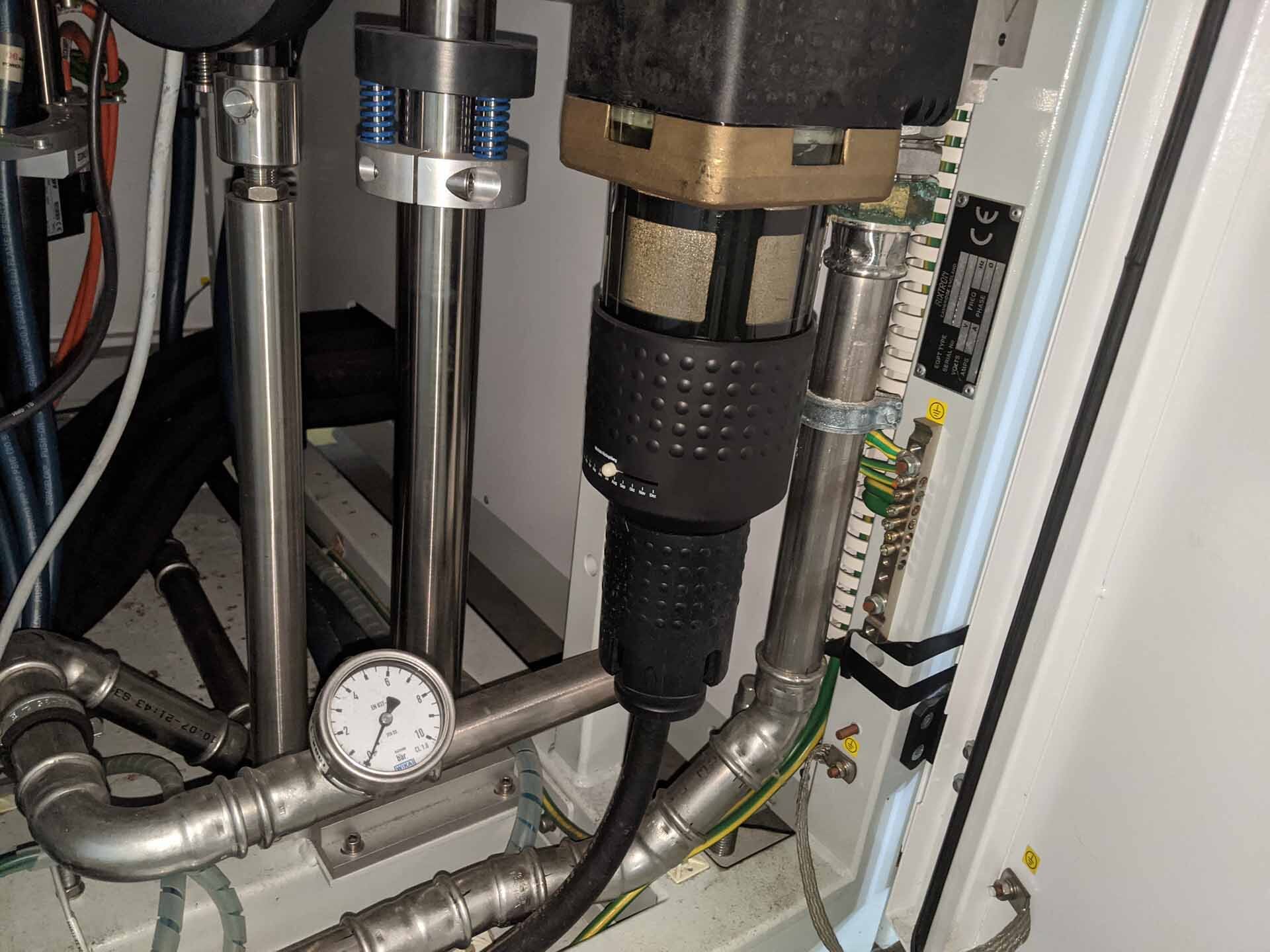

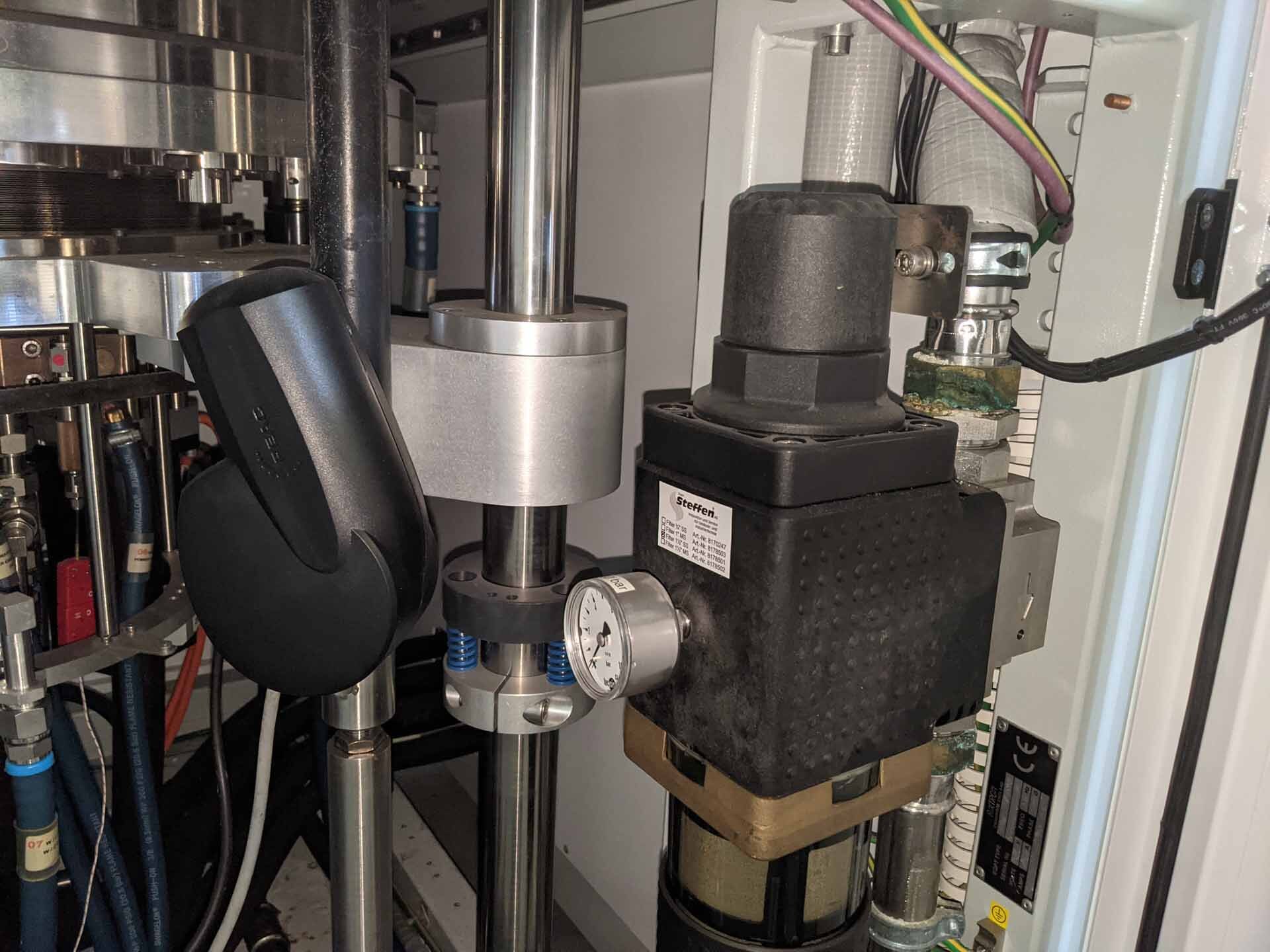

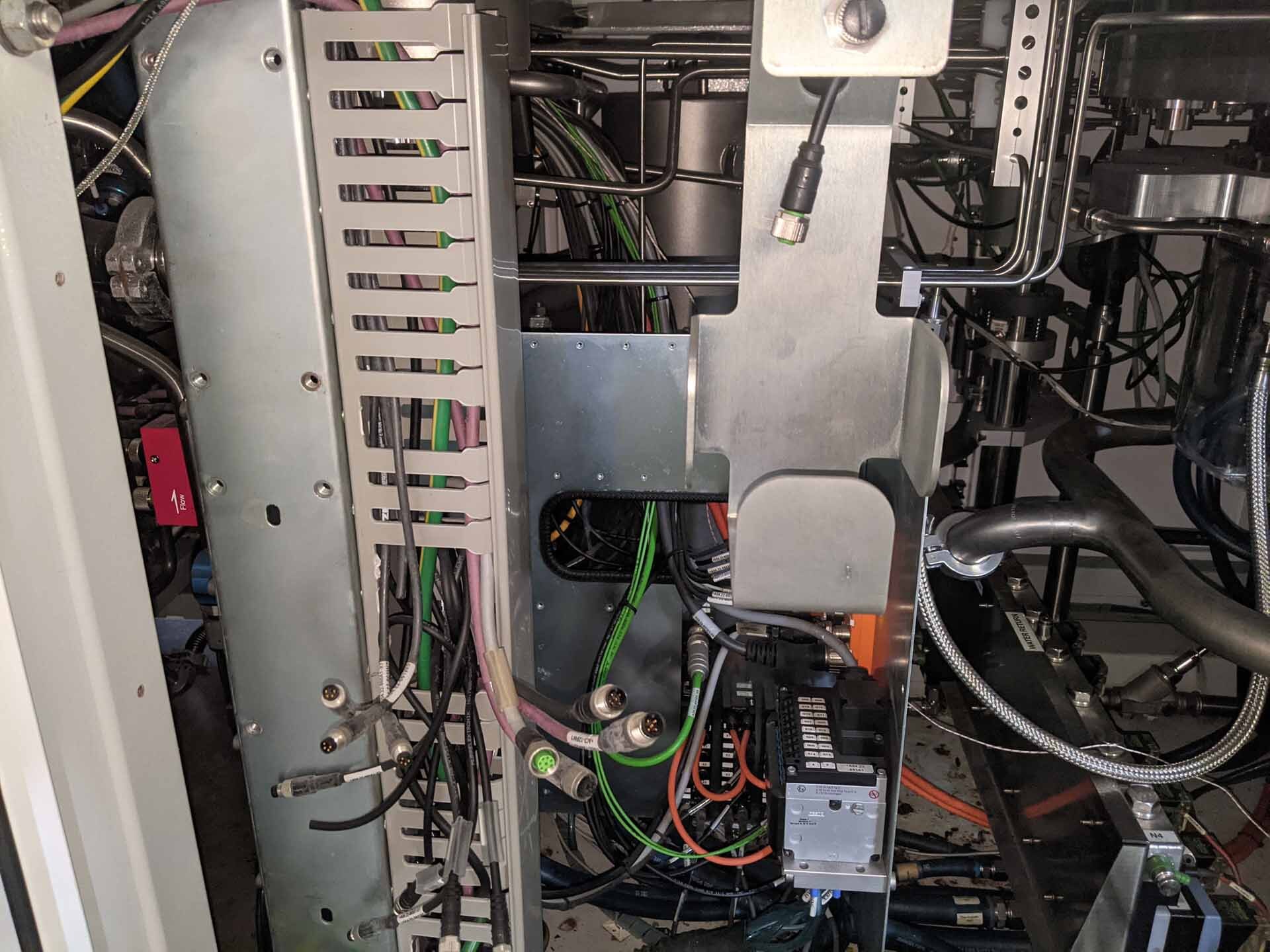

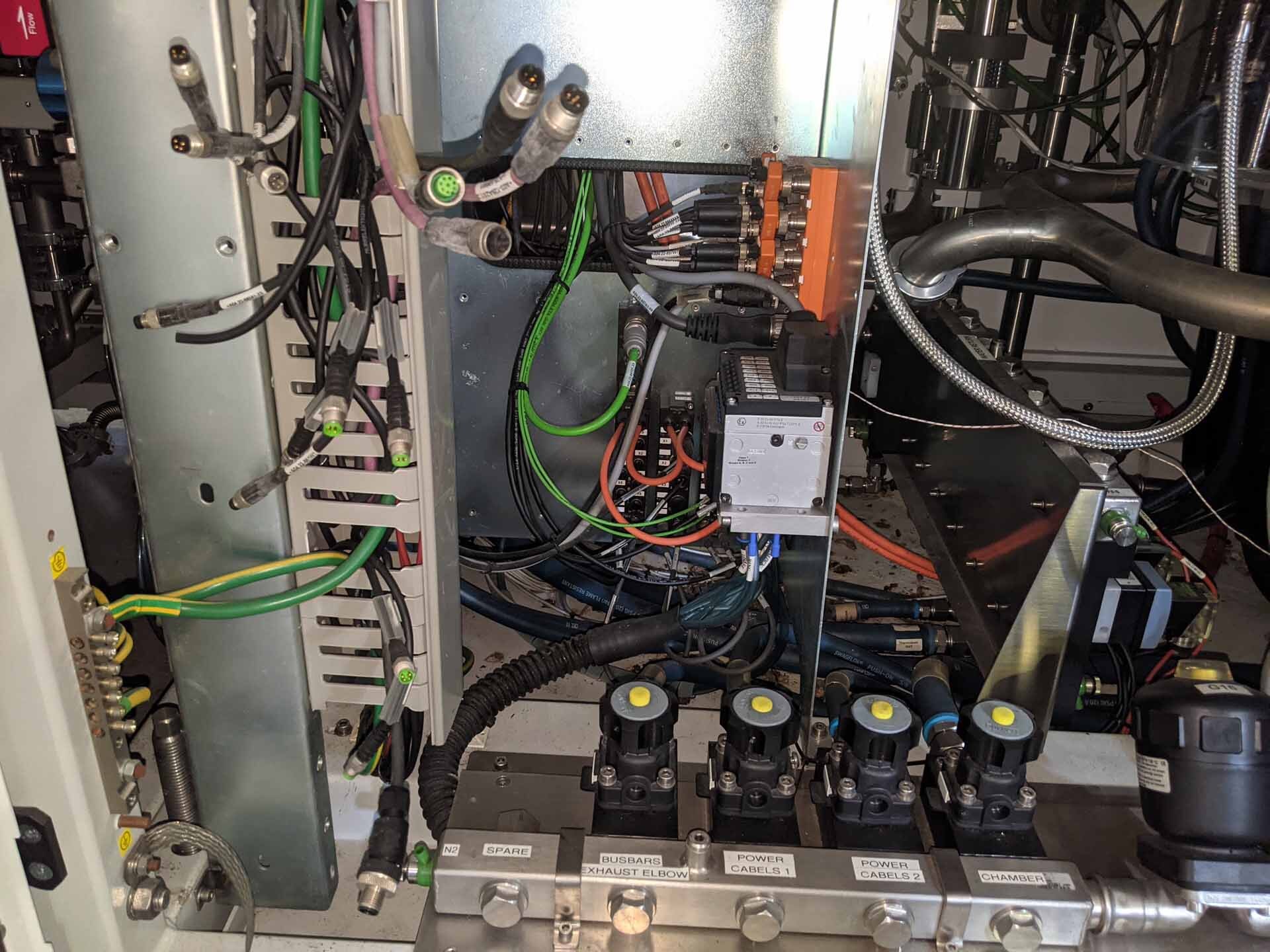

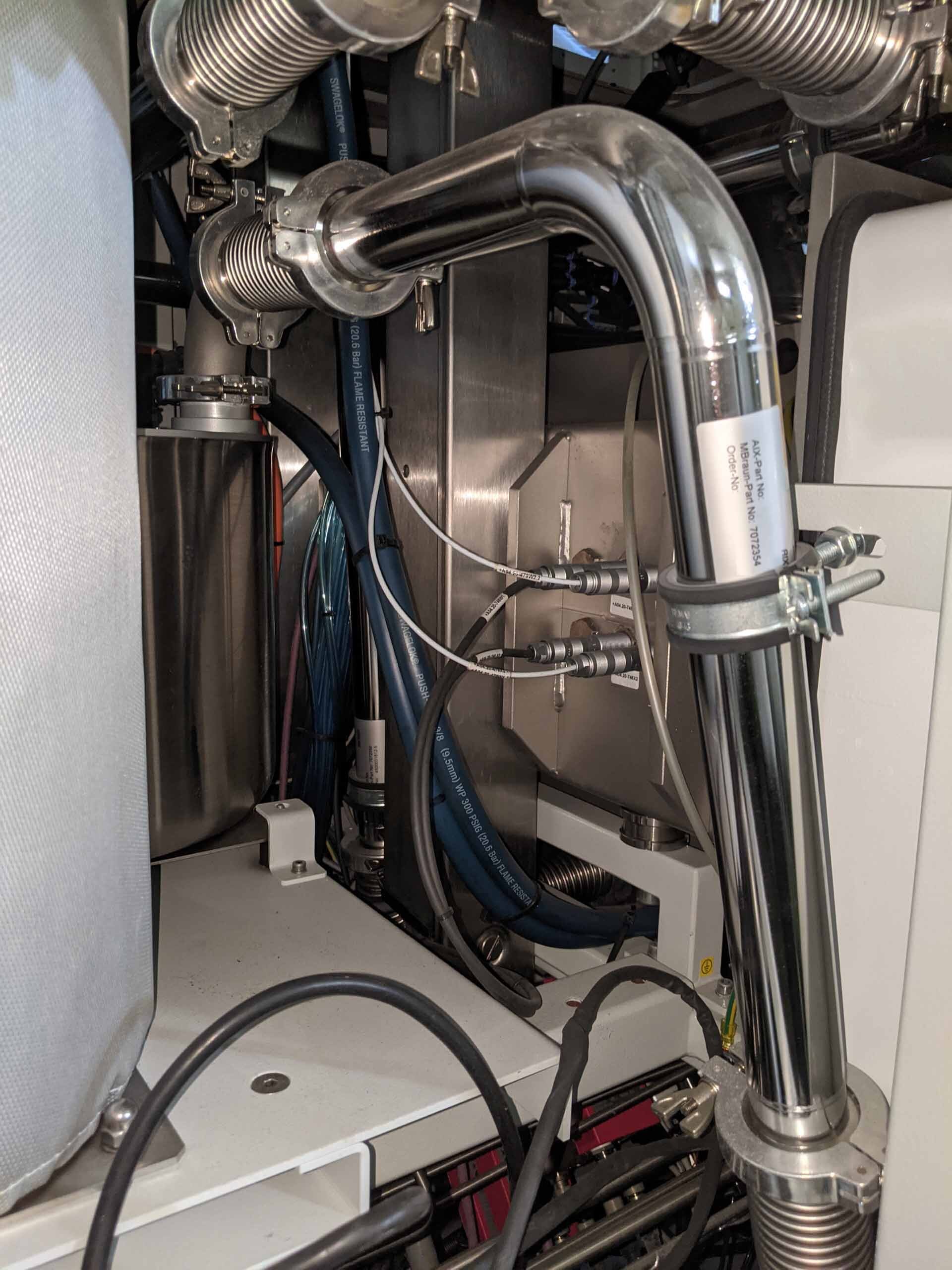

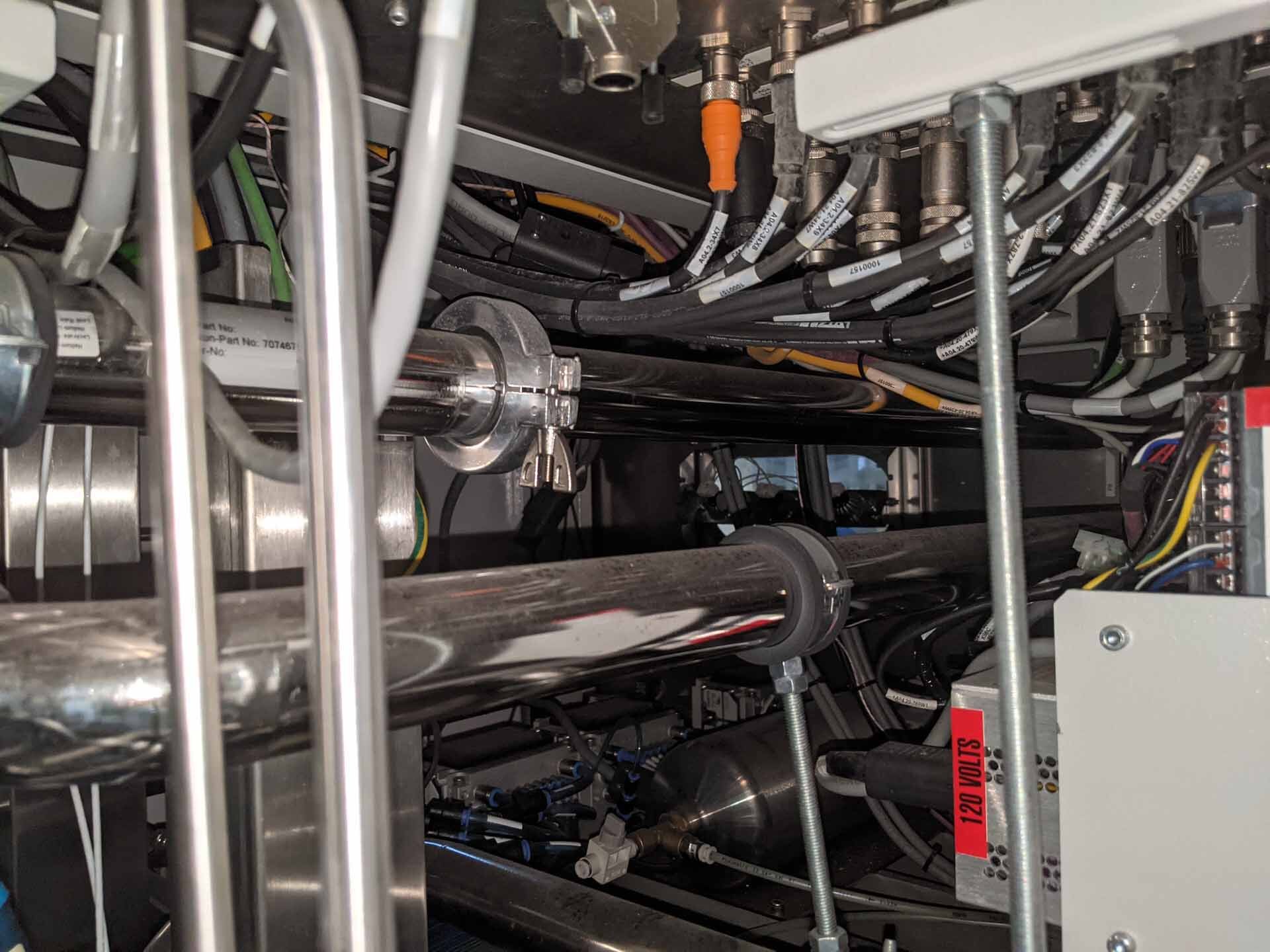

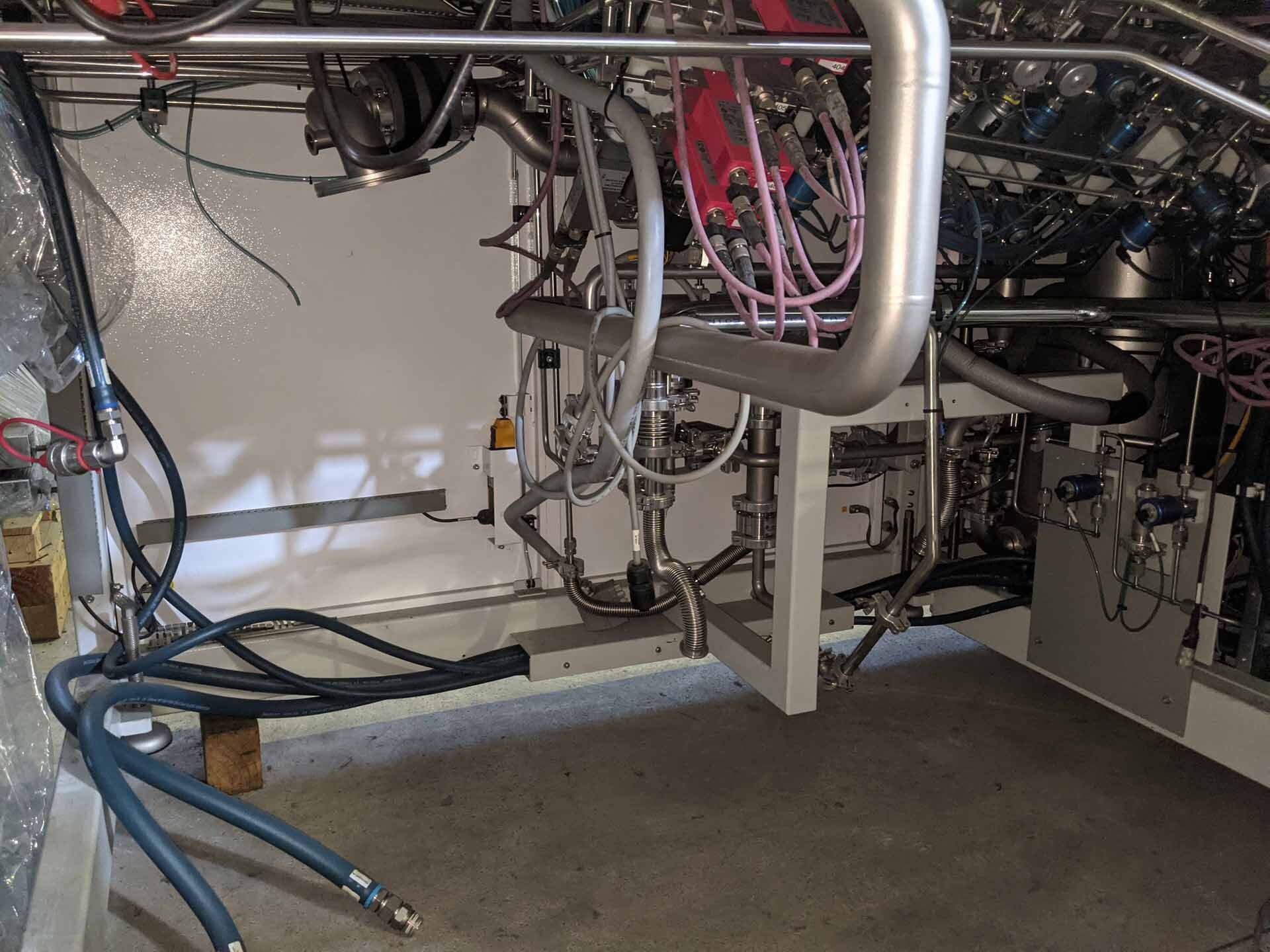

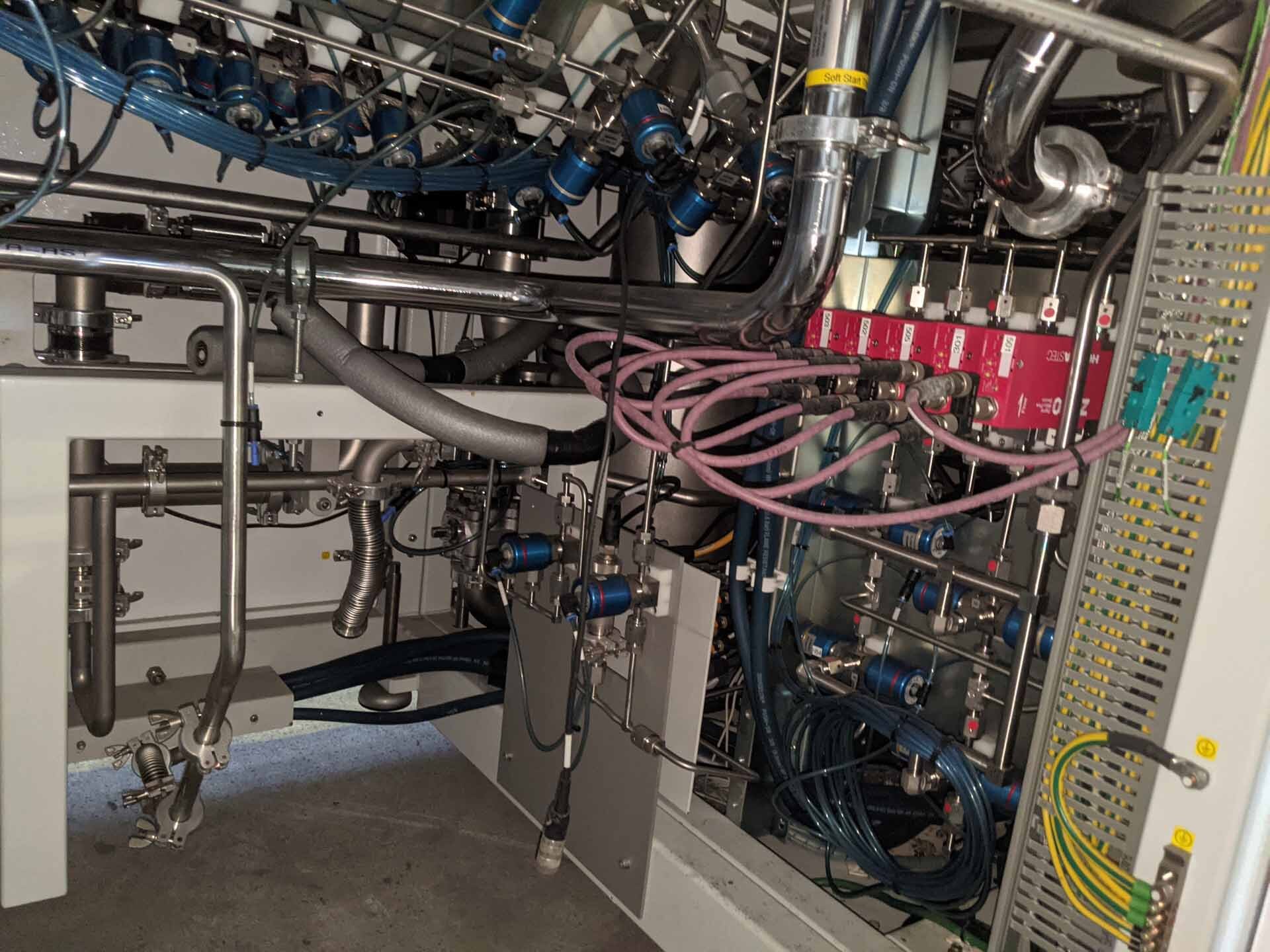

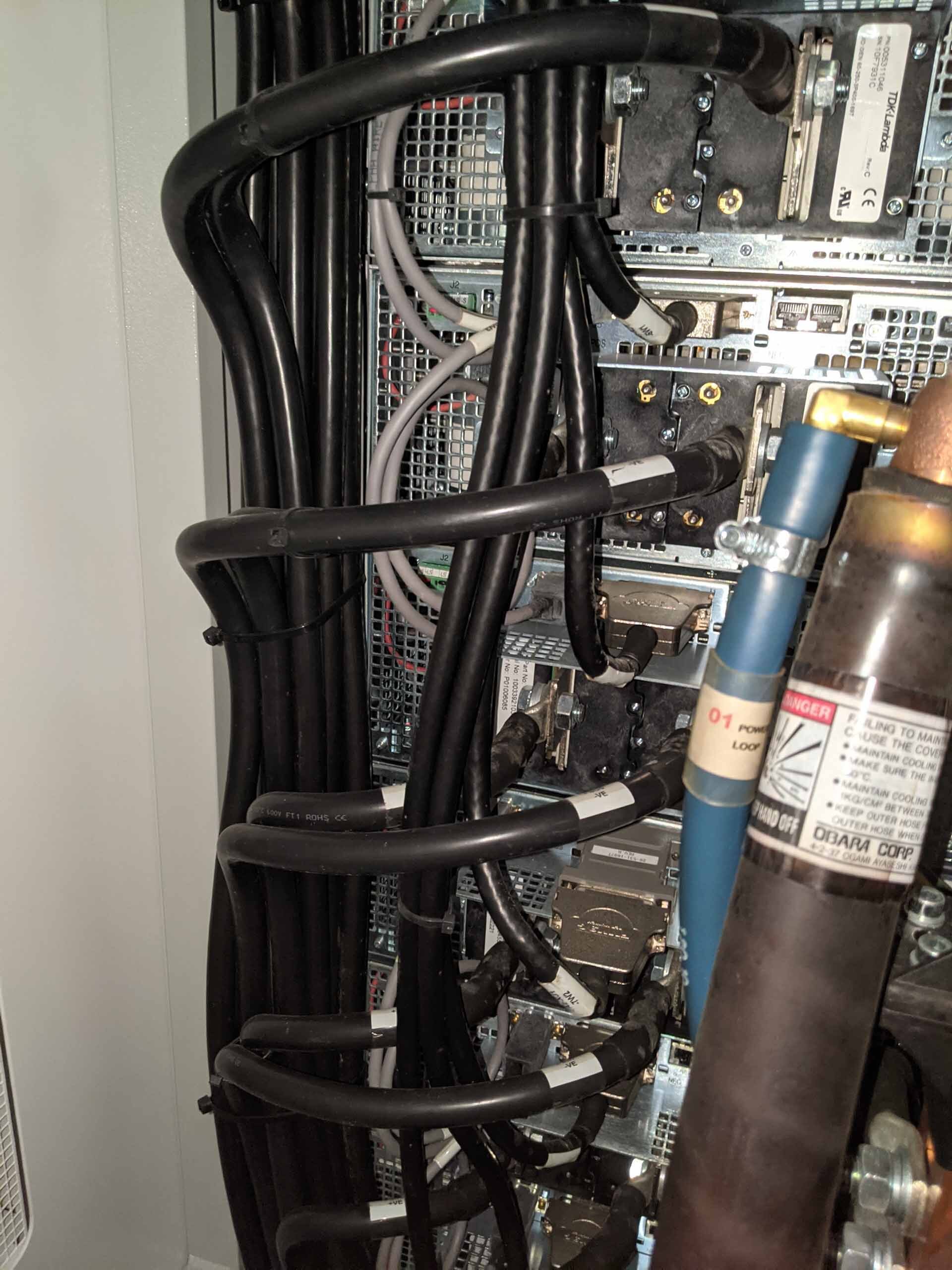

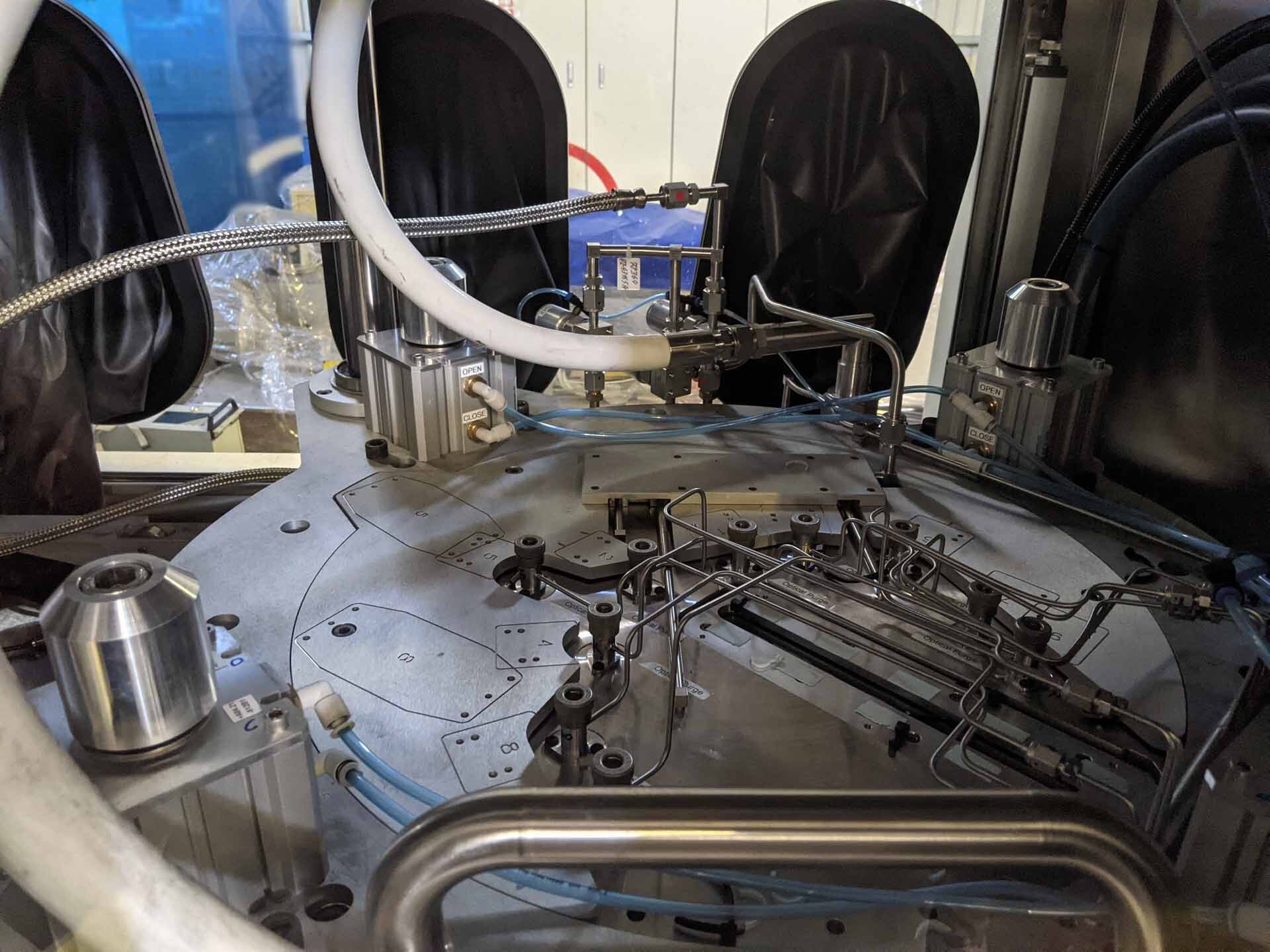

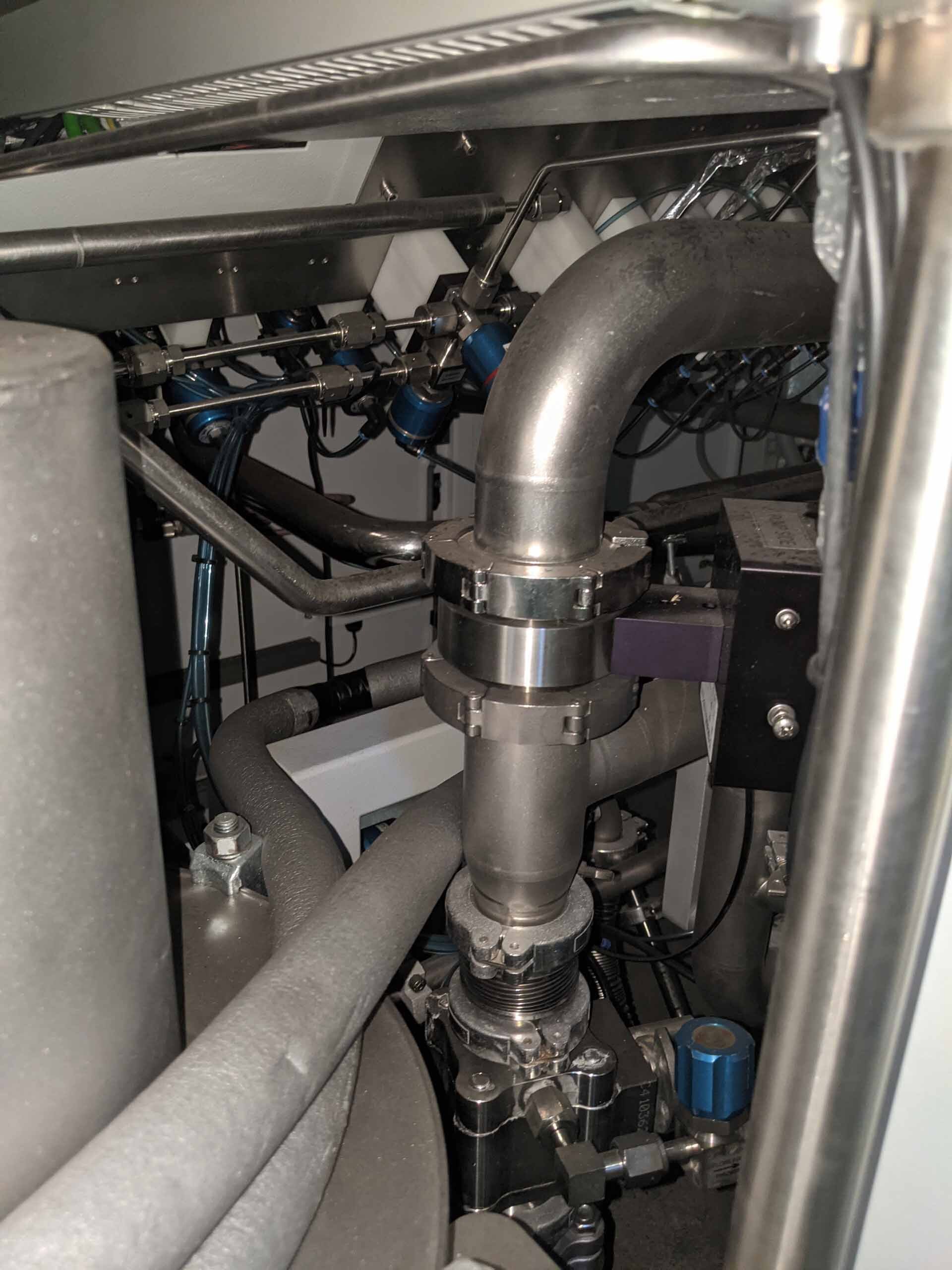

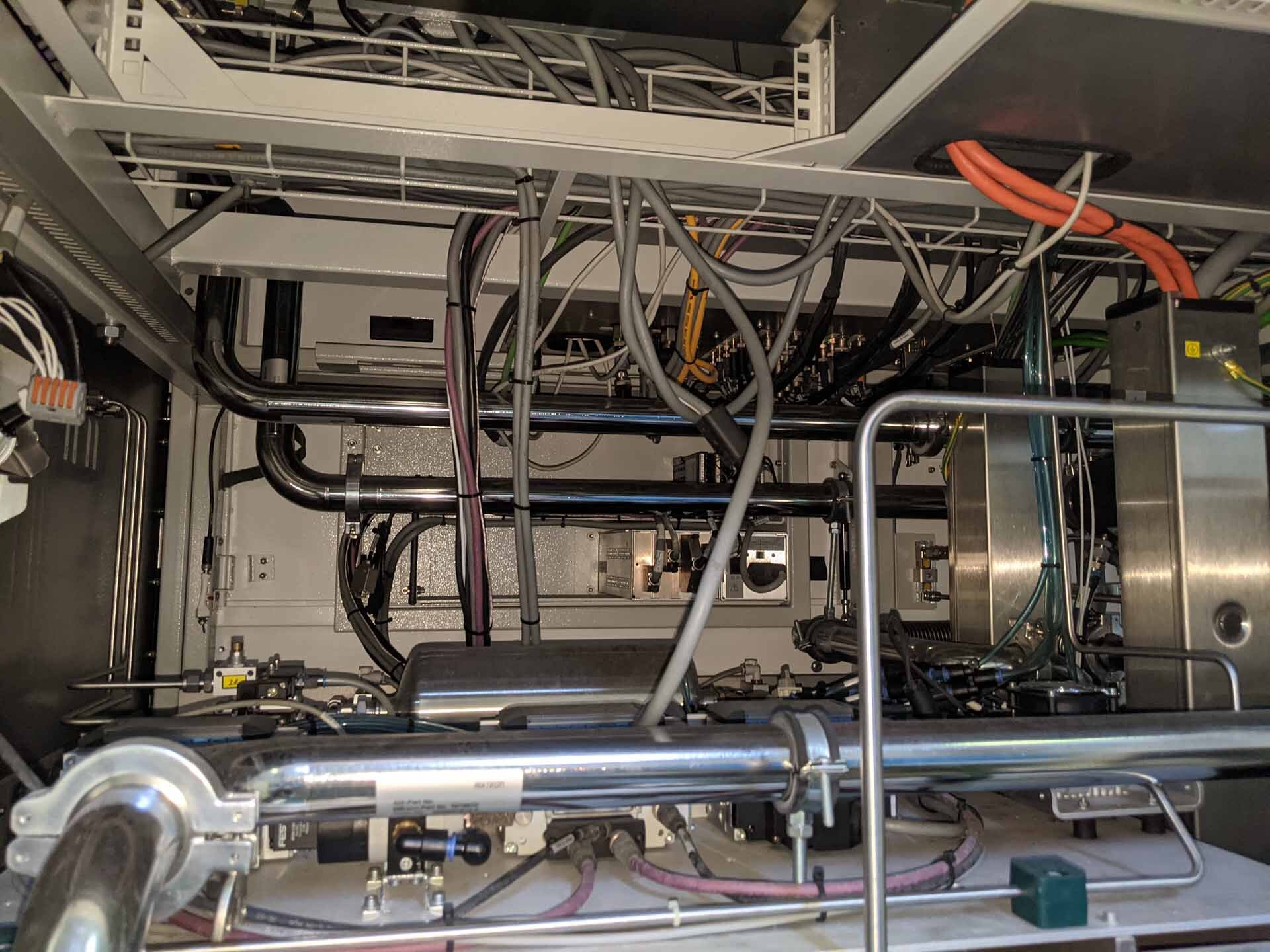

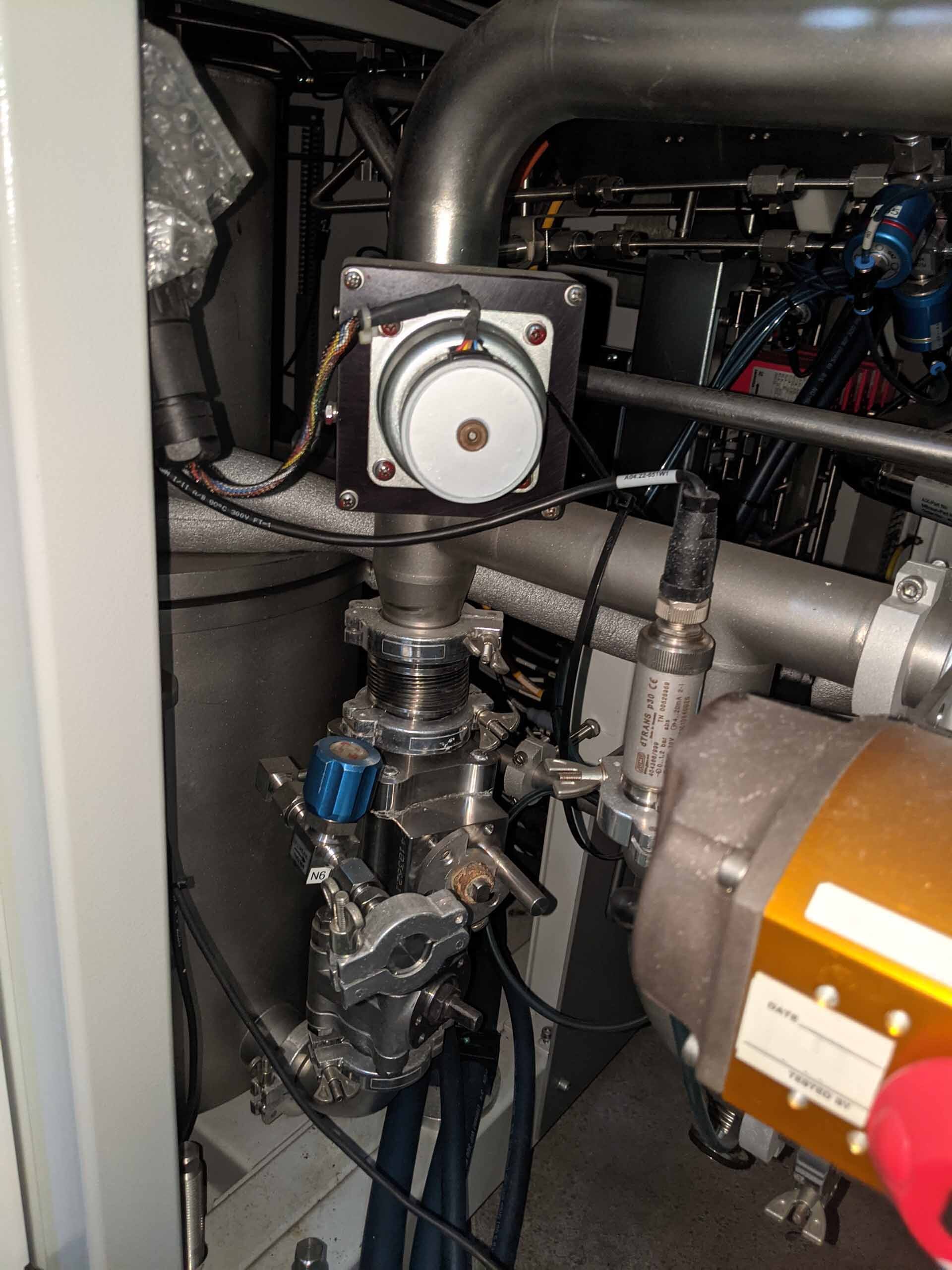

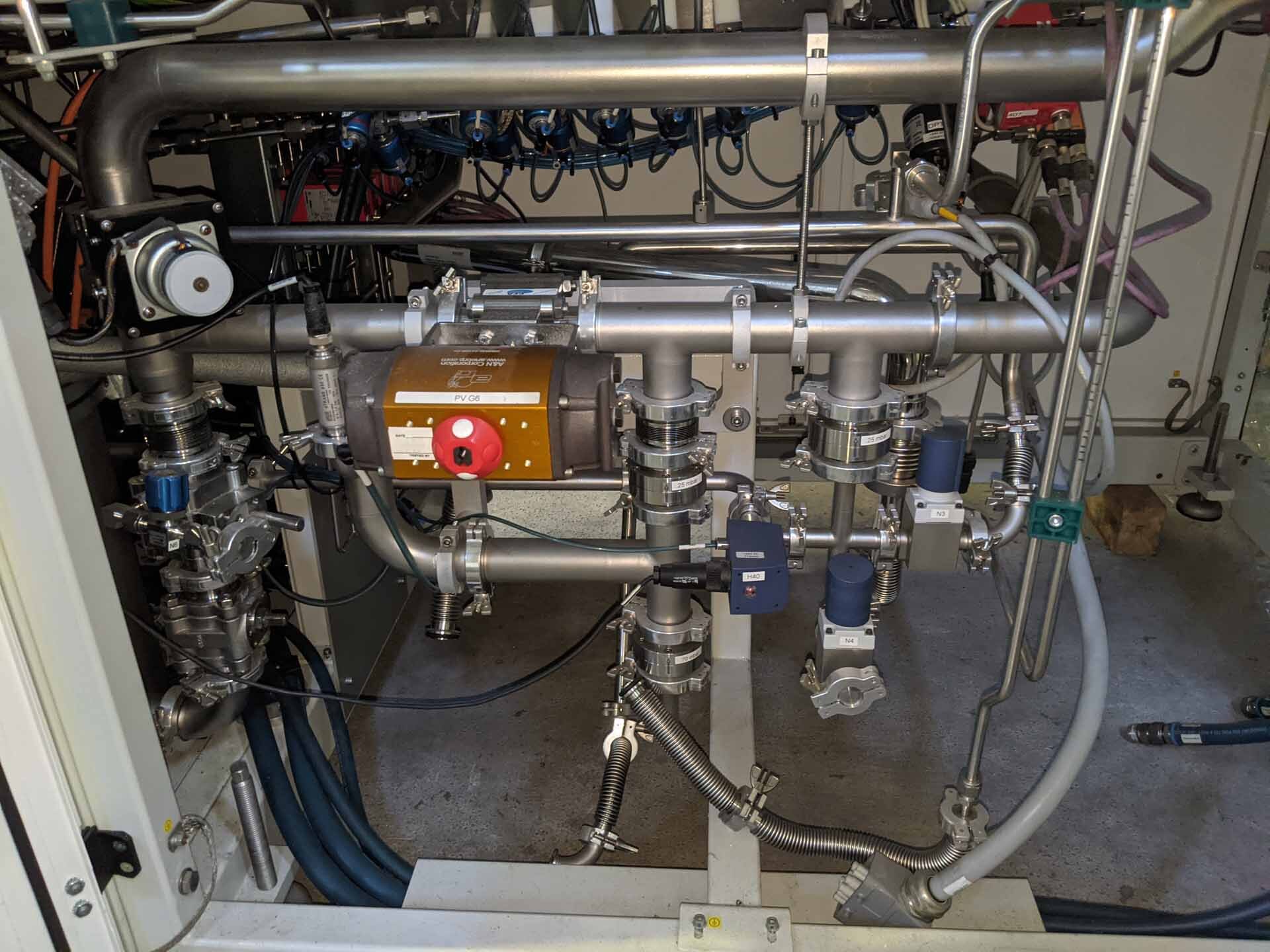

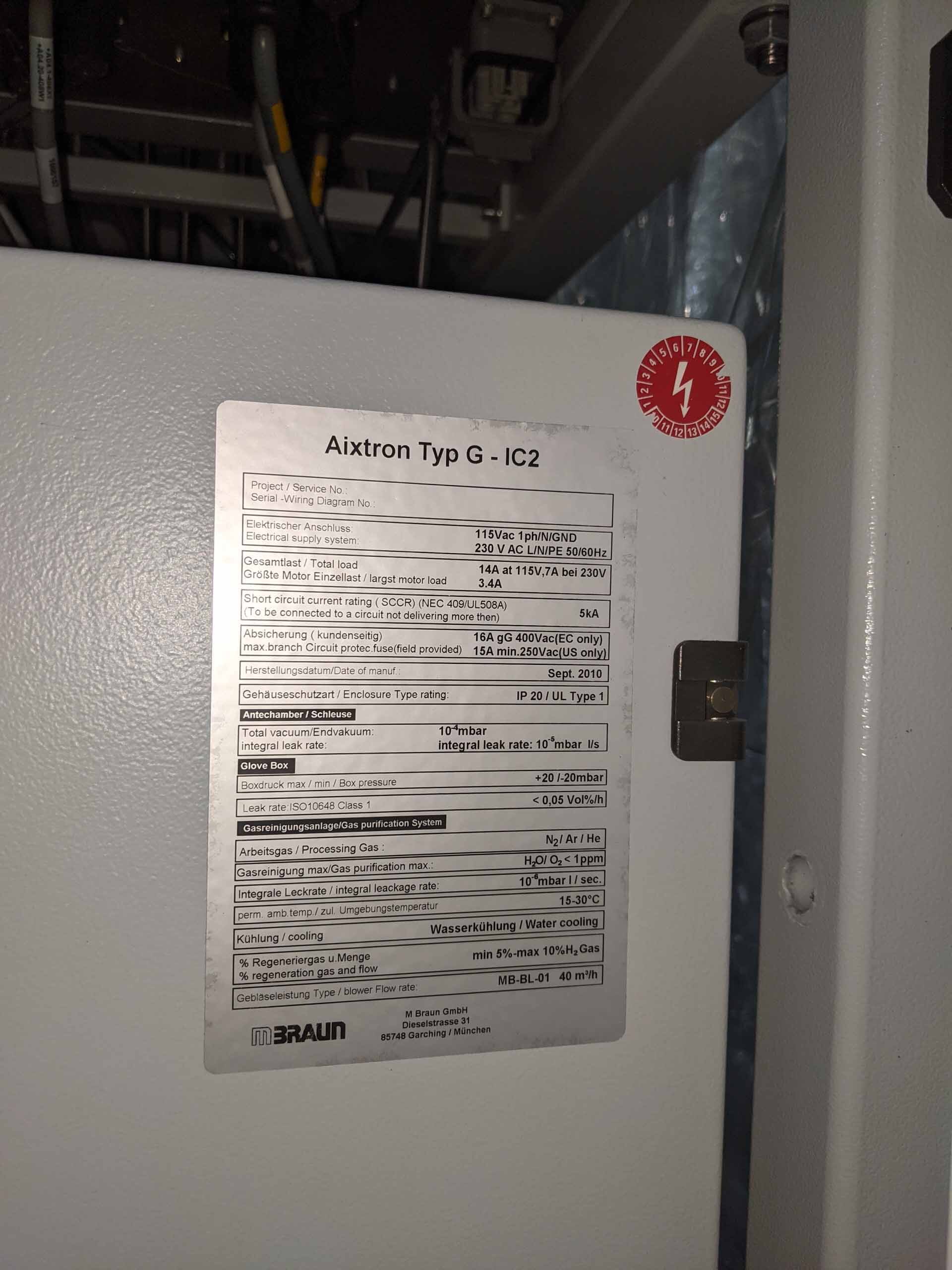

MOCVD System, 2"-6"

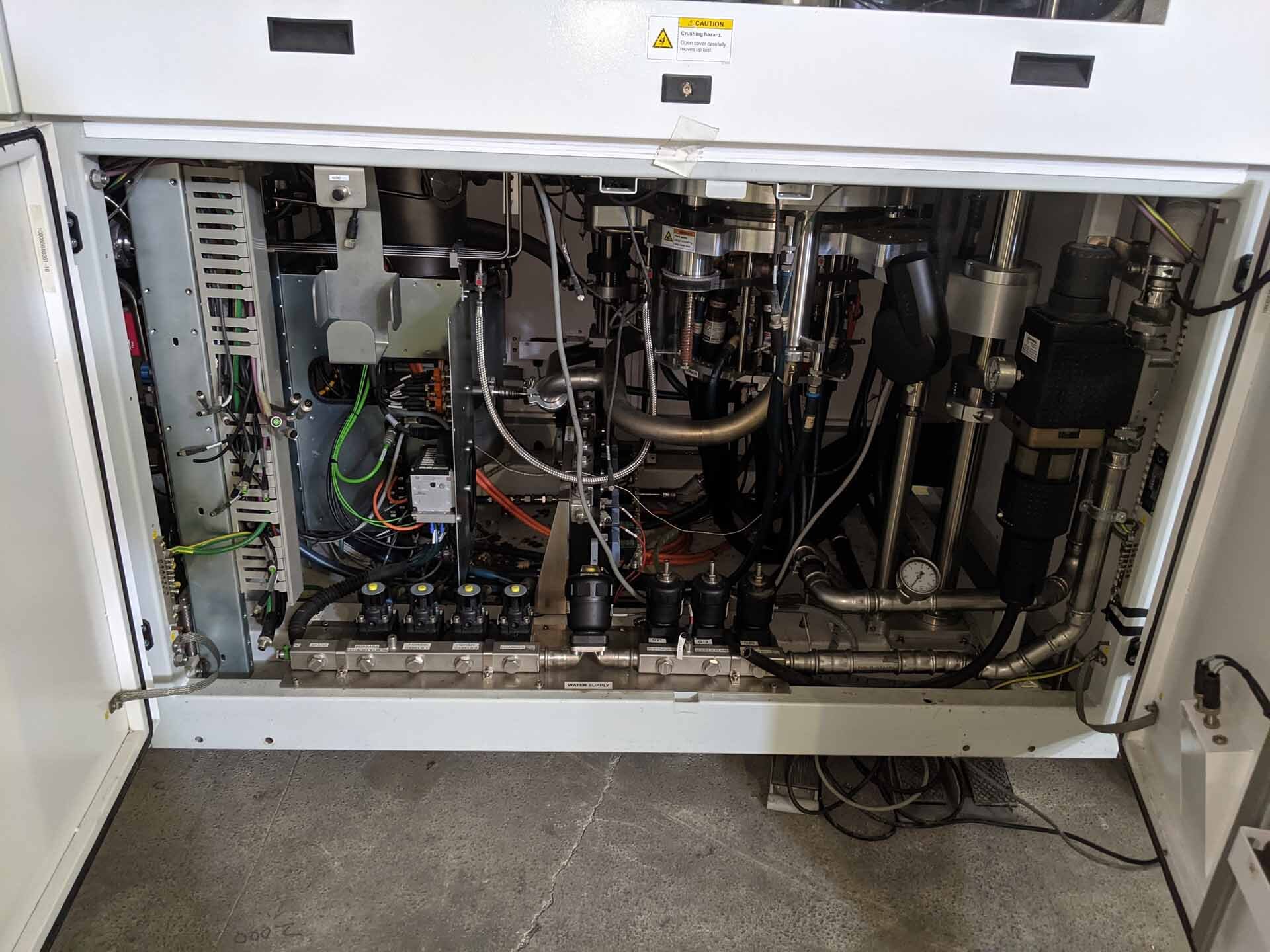

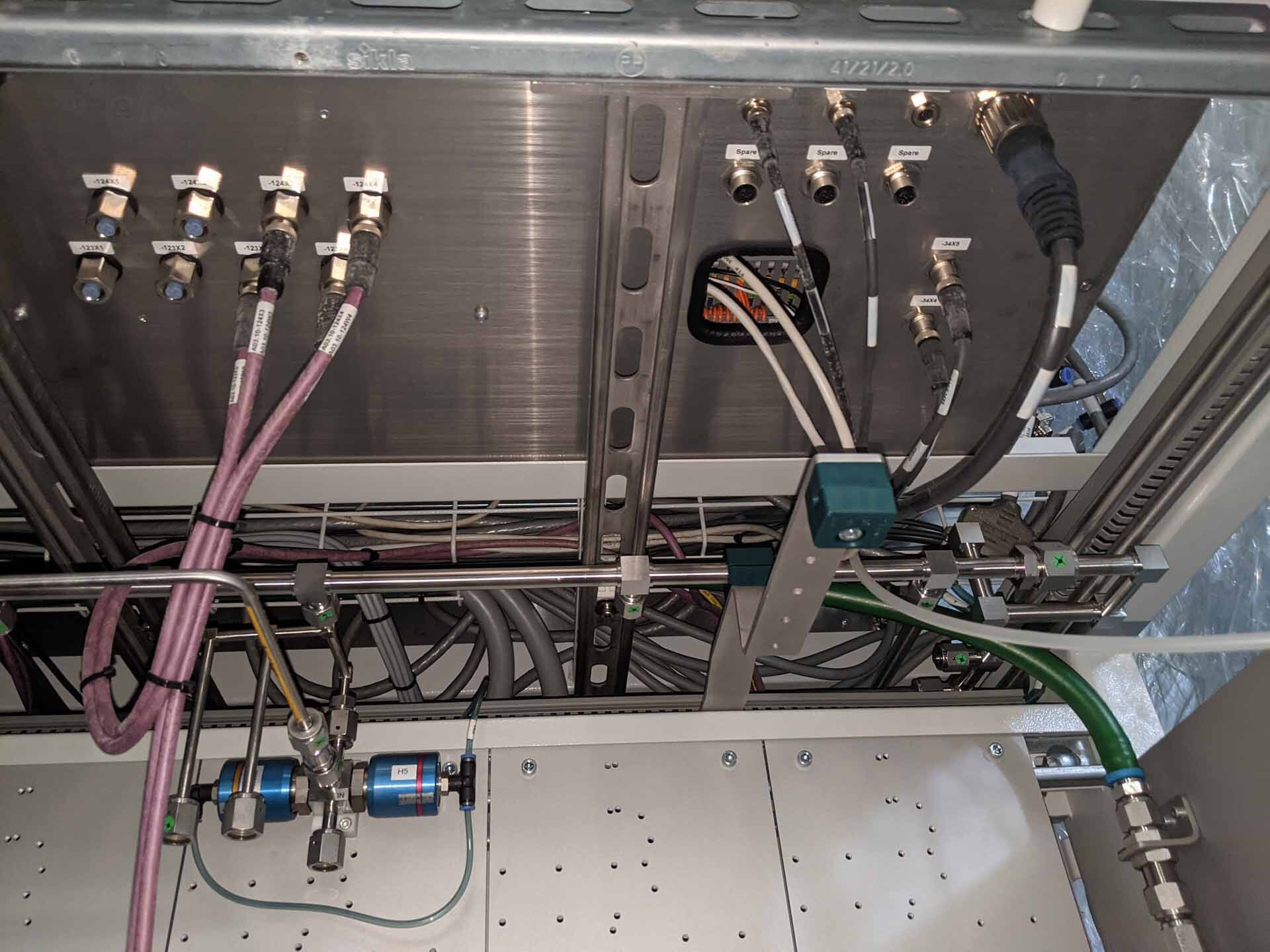

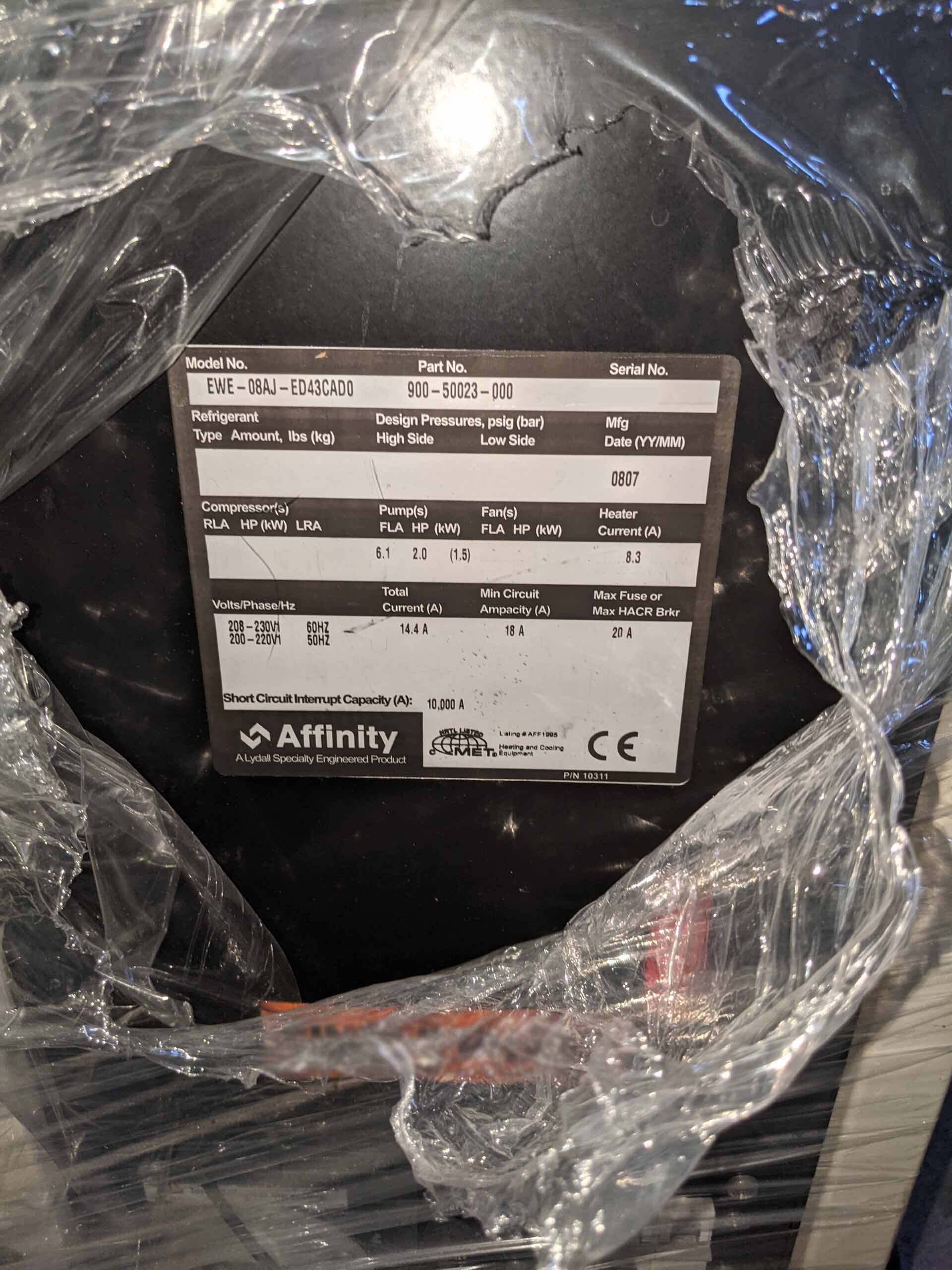

AFFINITY EWE-08AJ-ED43CAD0 Chiller

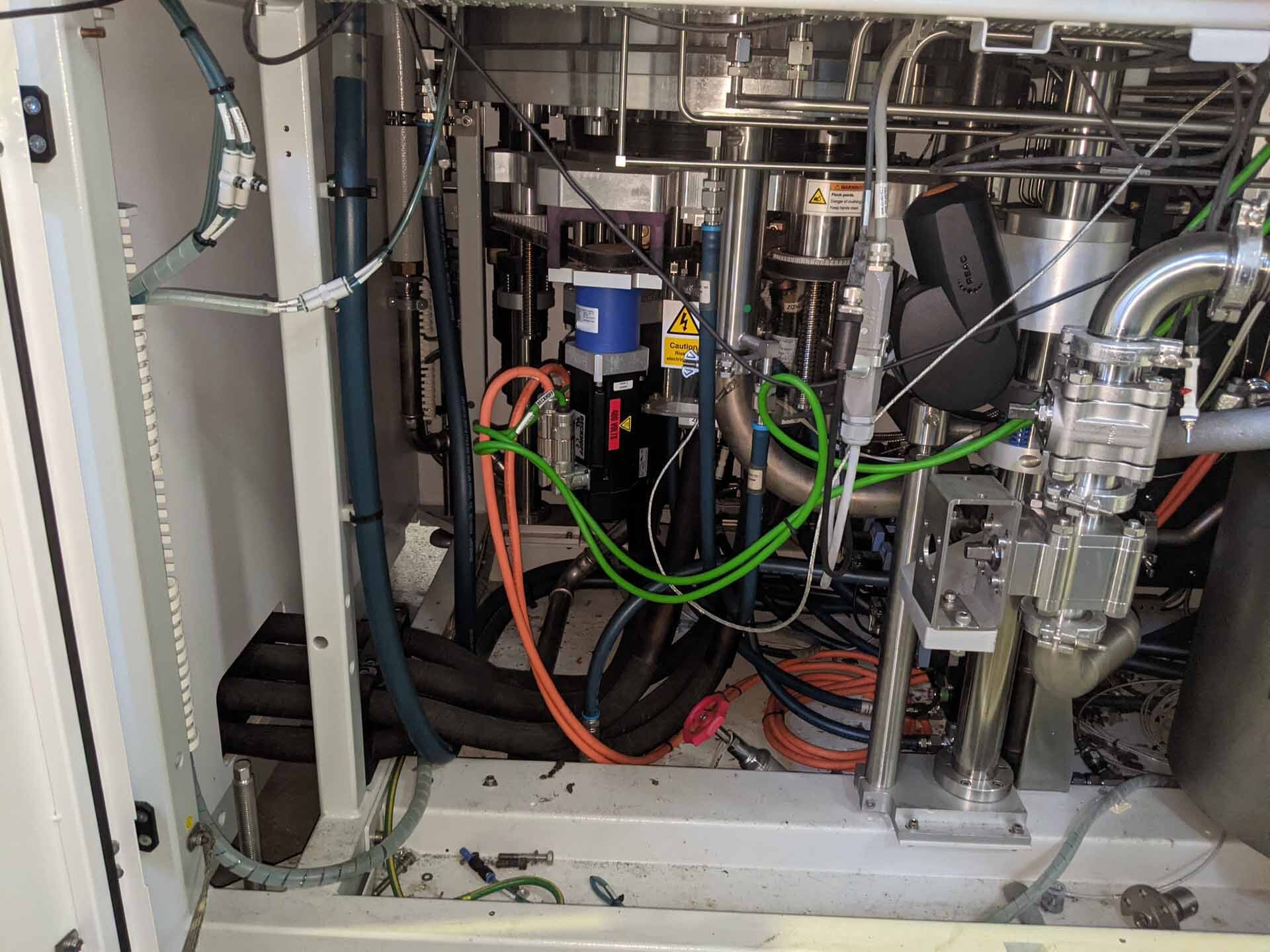

EDWARDS IXH645HLV Dry pump

ARGUS Temperature monitor

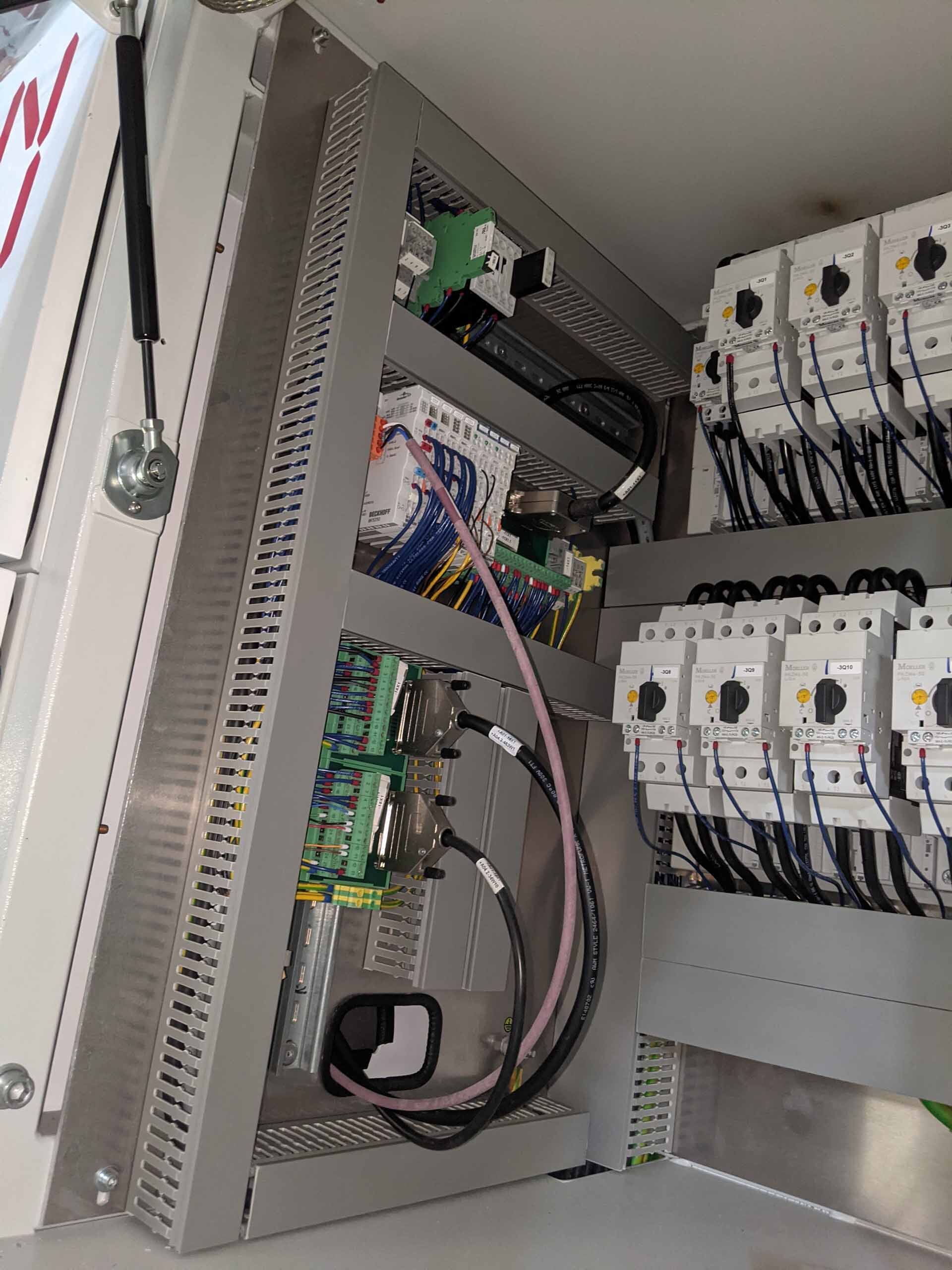

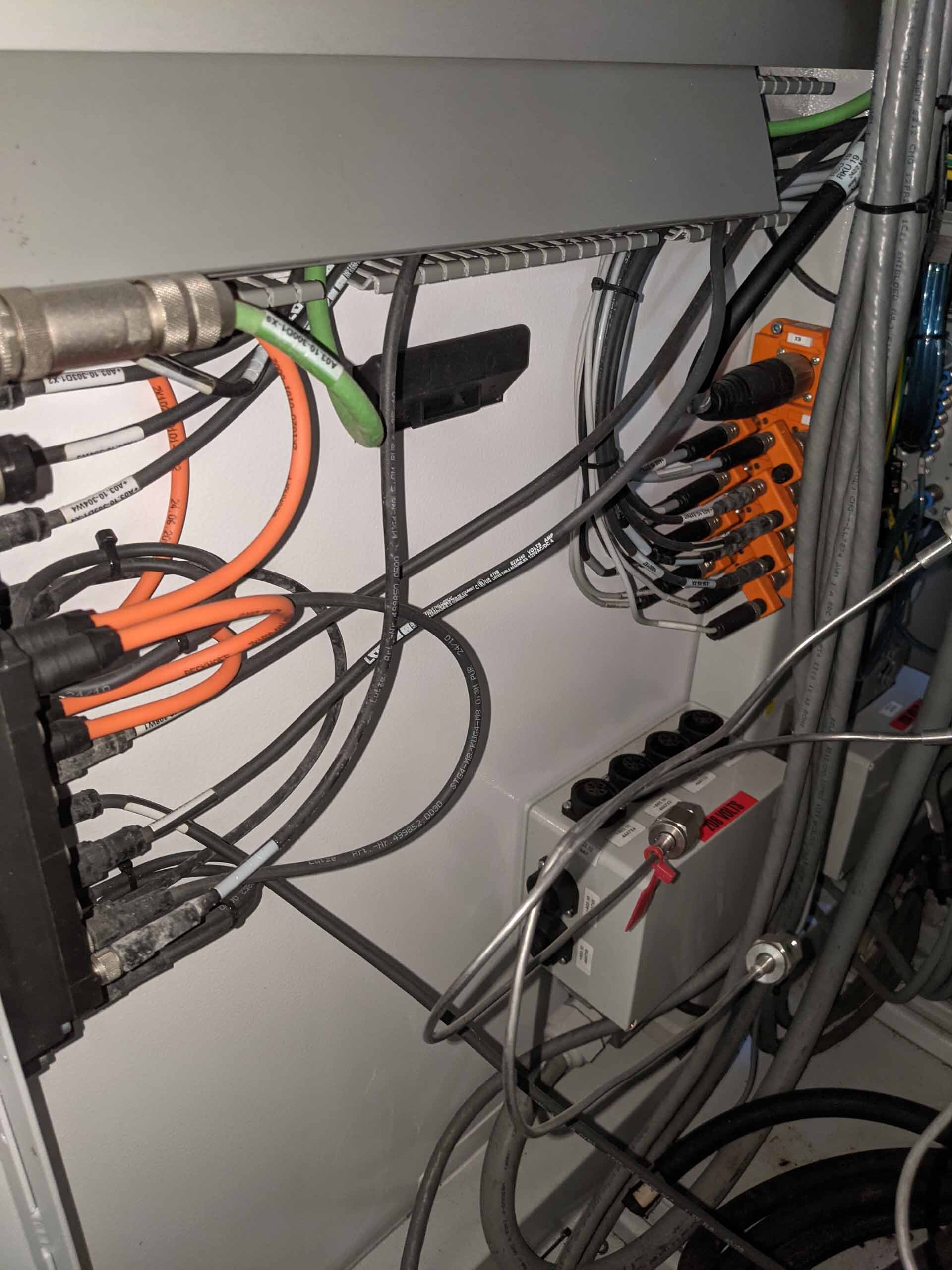

(4) Wires with ground wiring

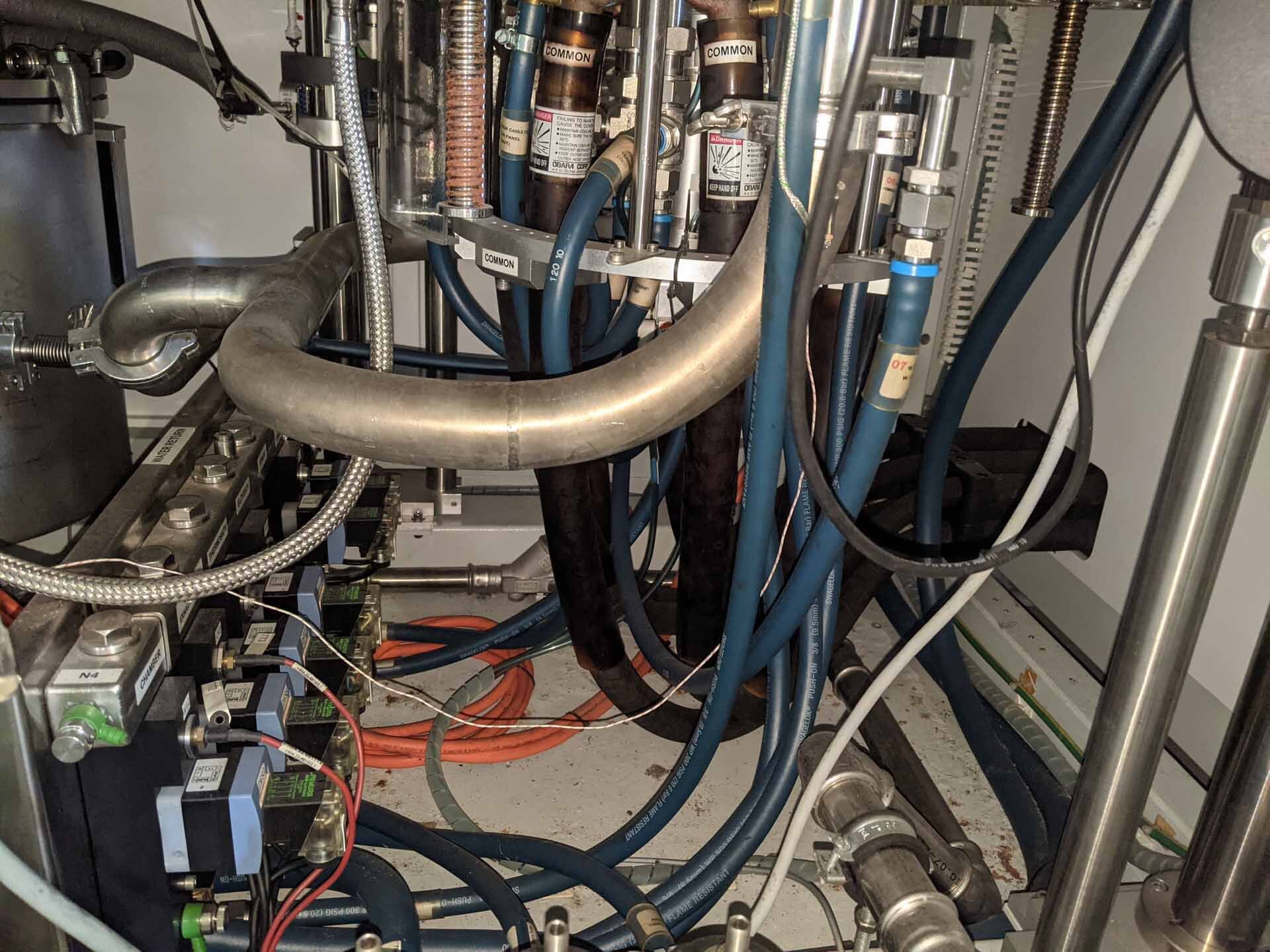

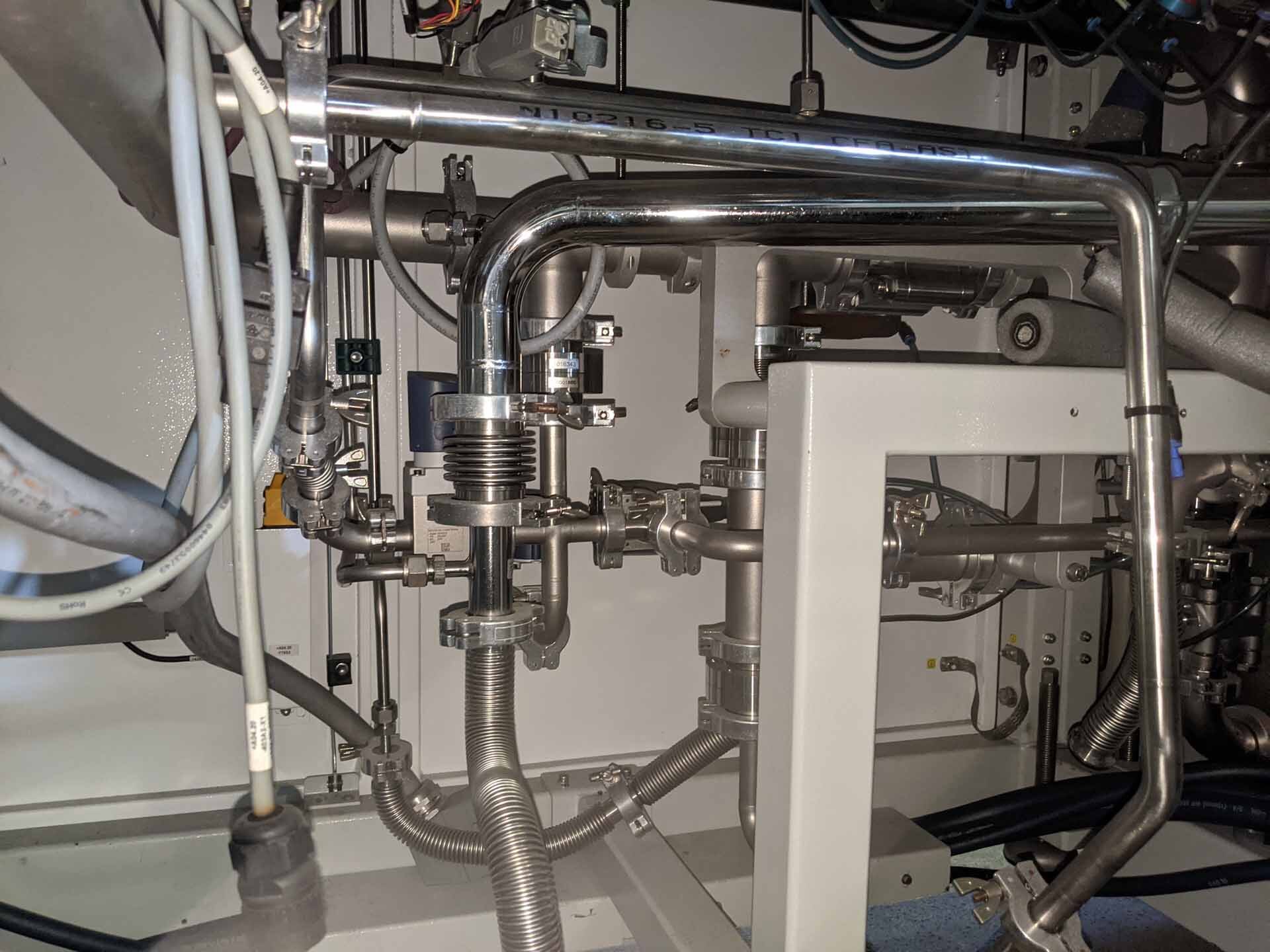

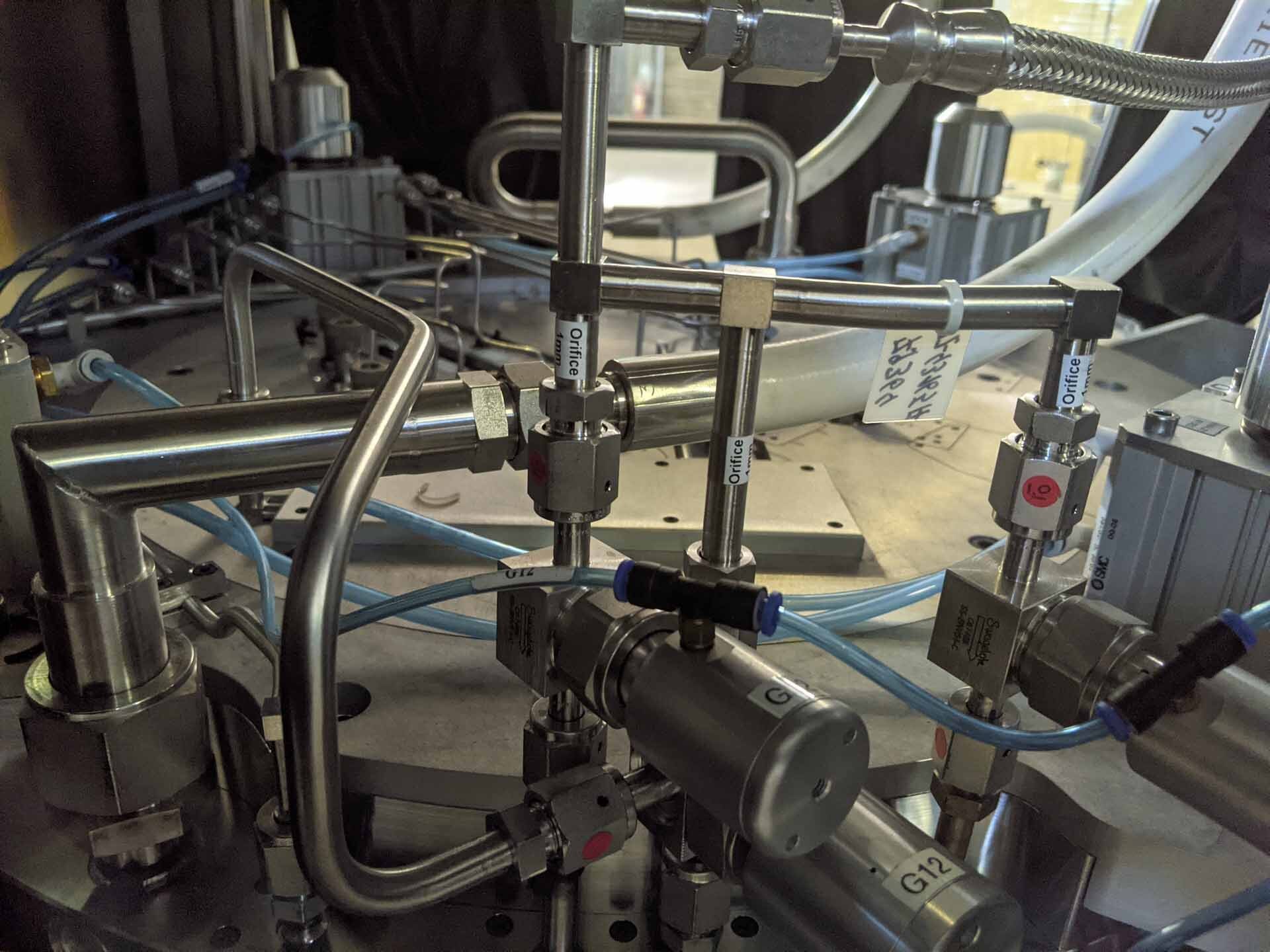

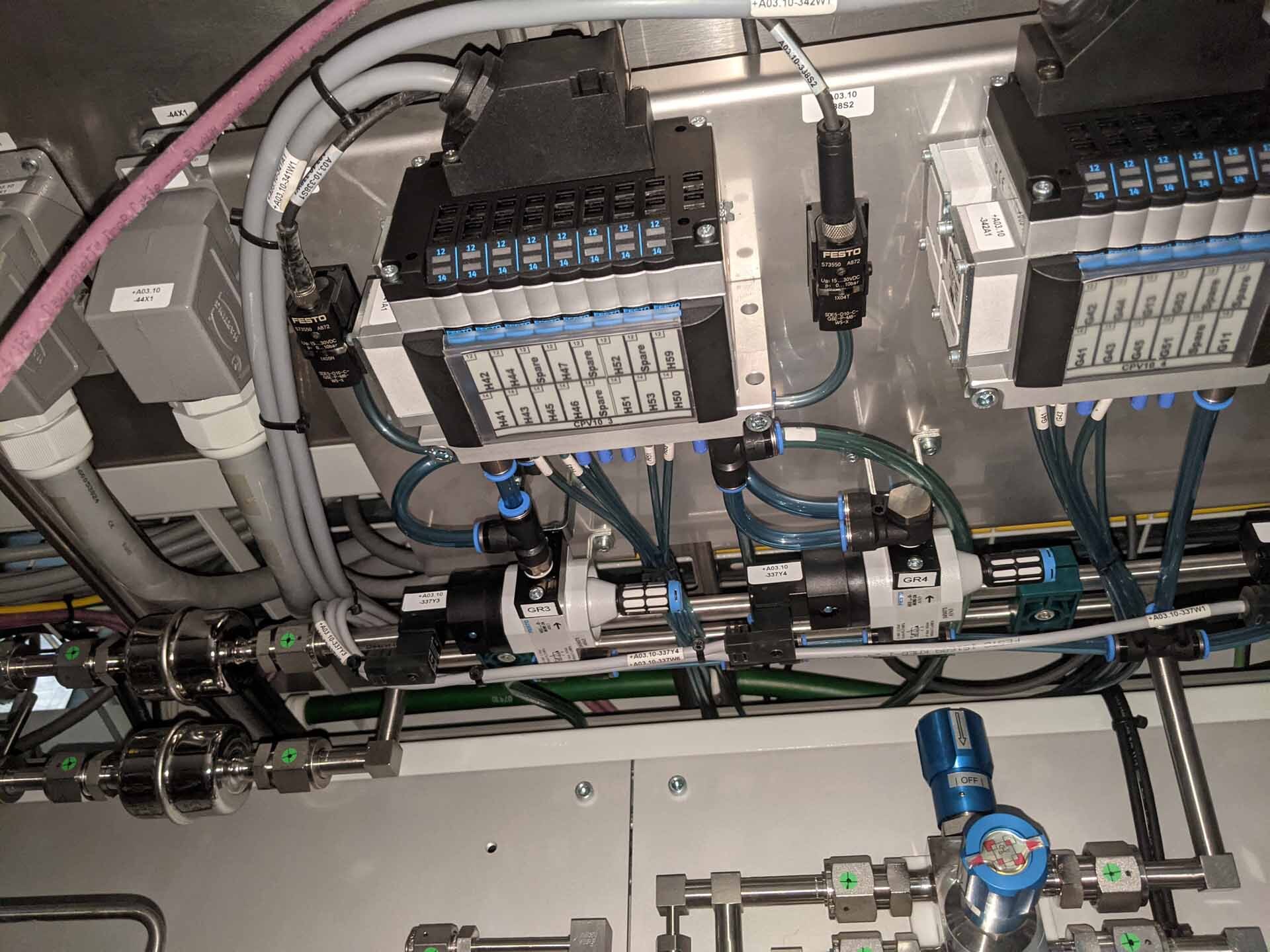

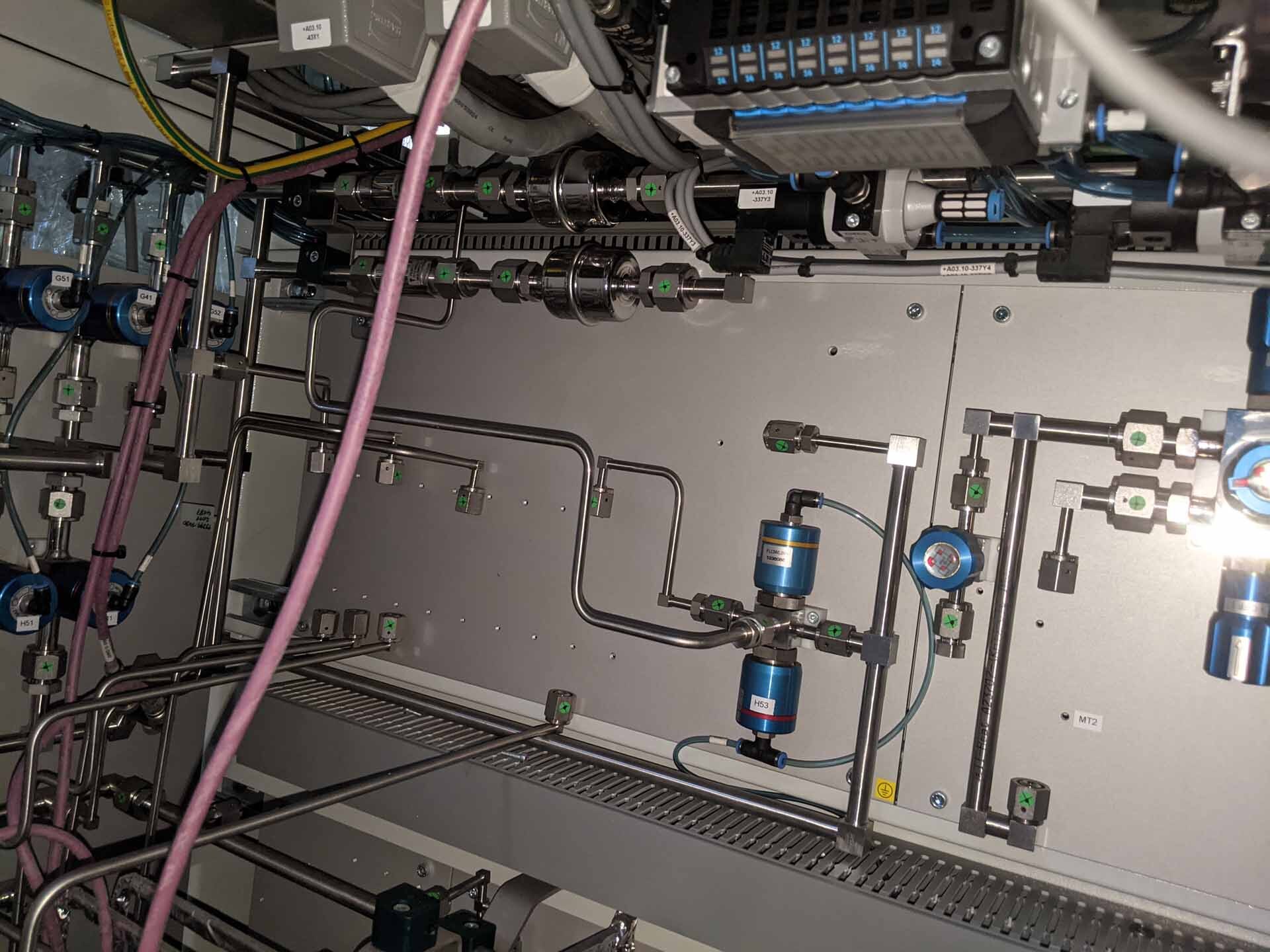

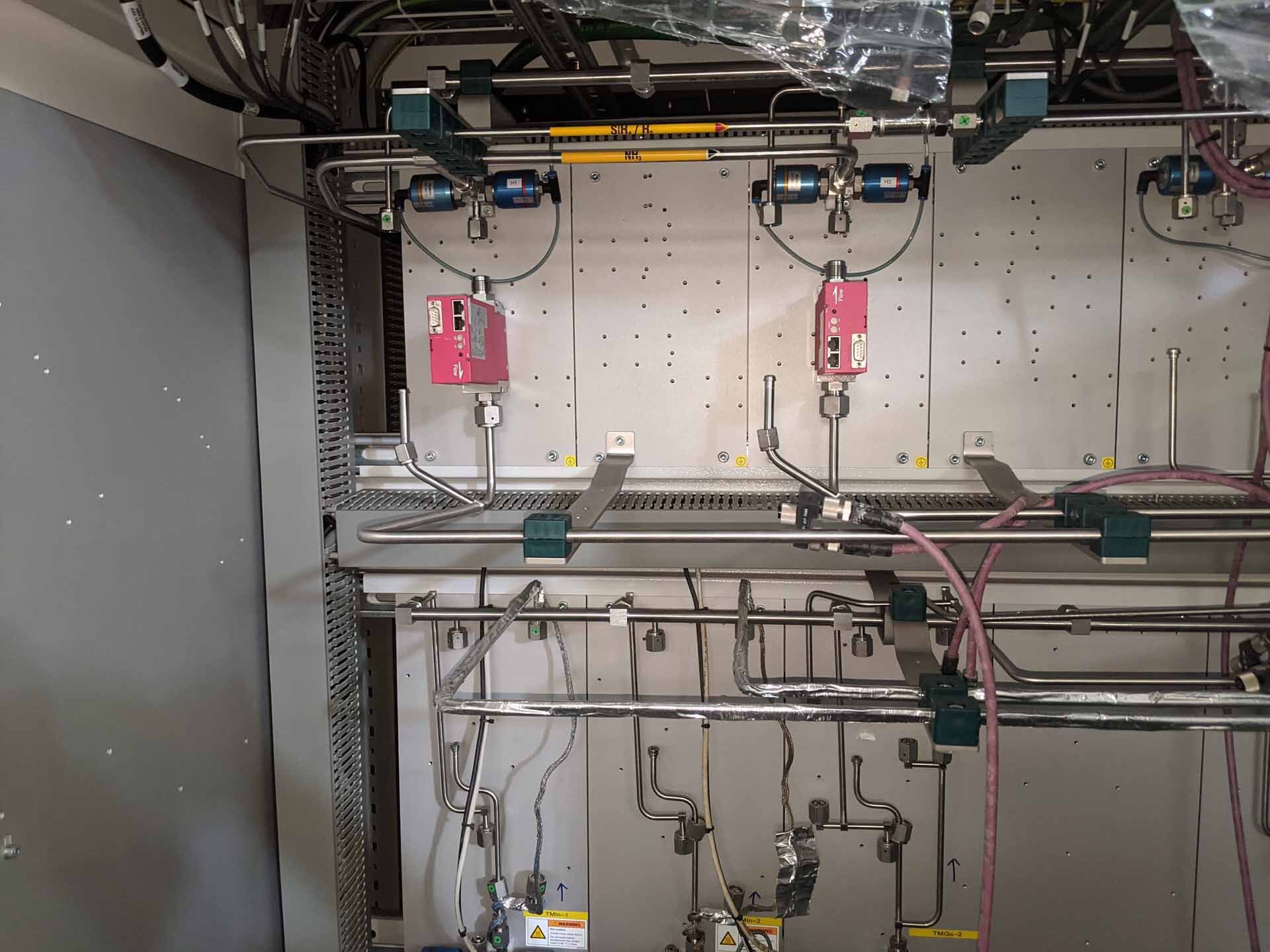

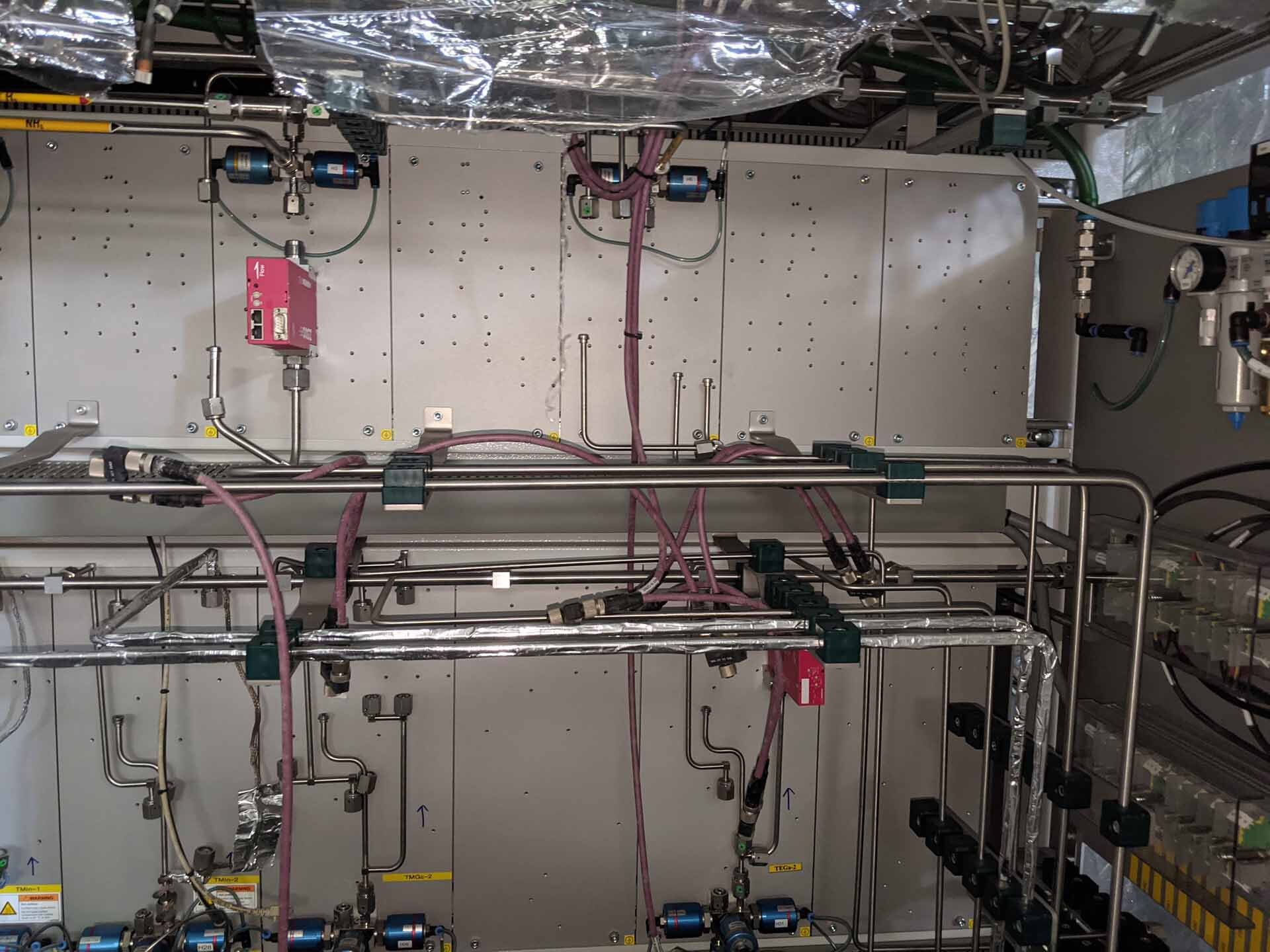

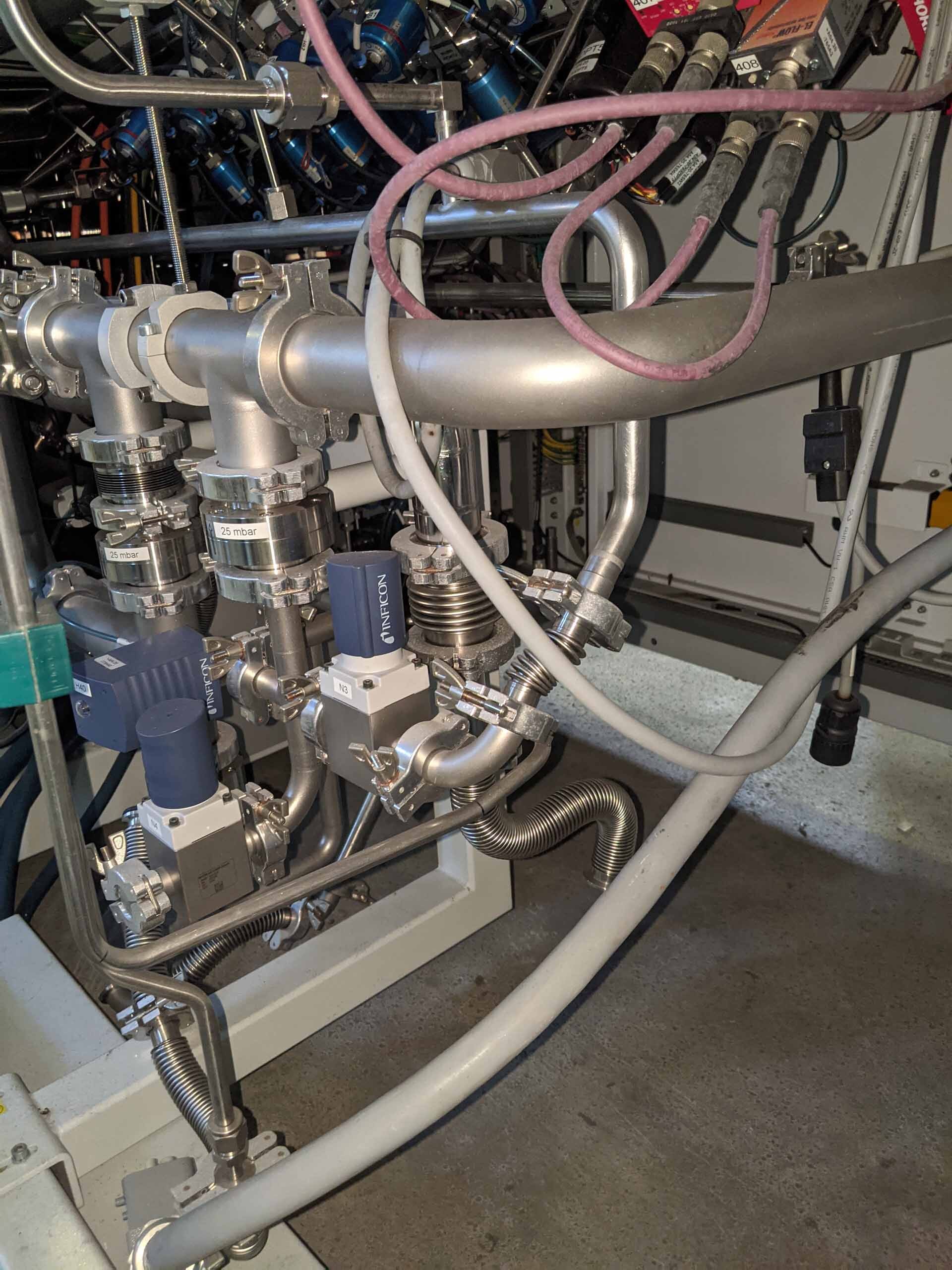

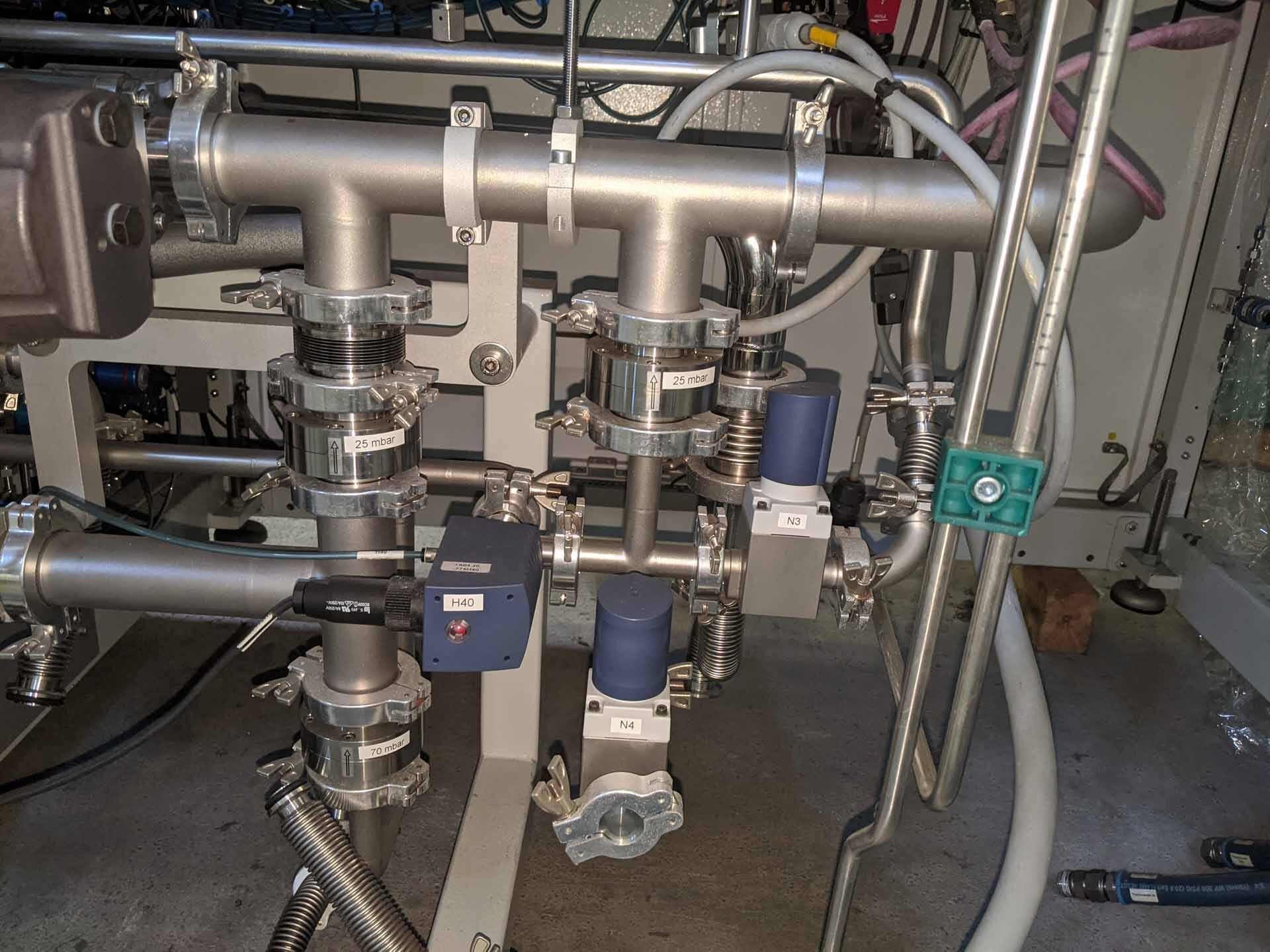

Hydride lines: NH3-1/NH3-2/SiH4

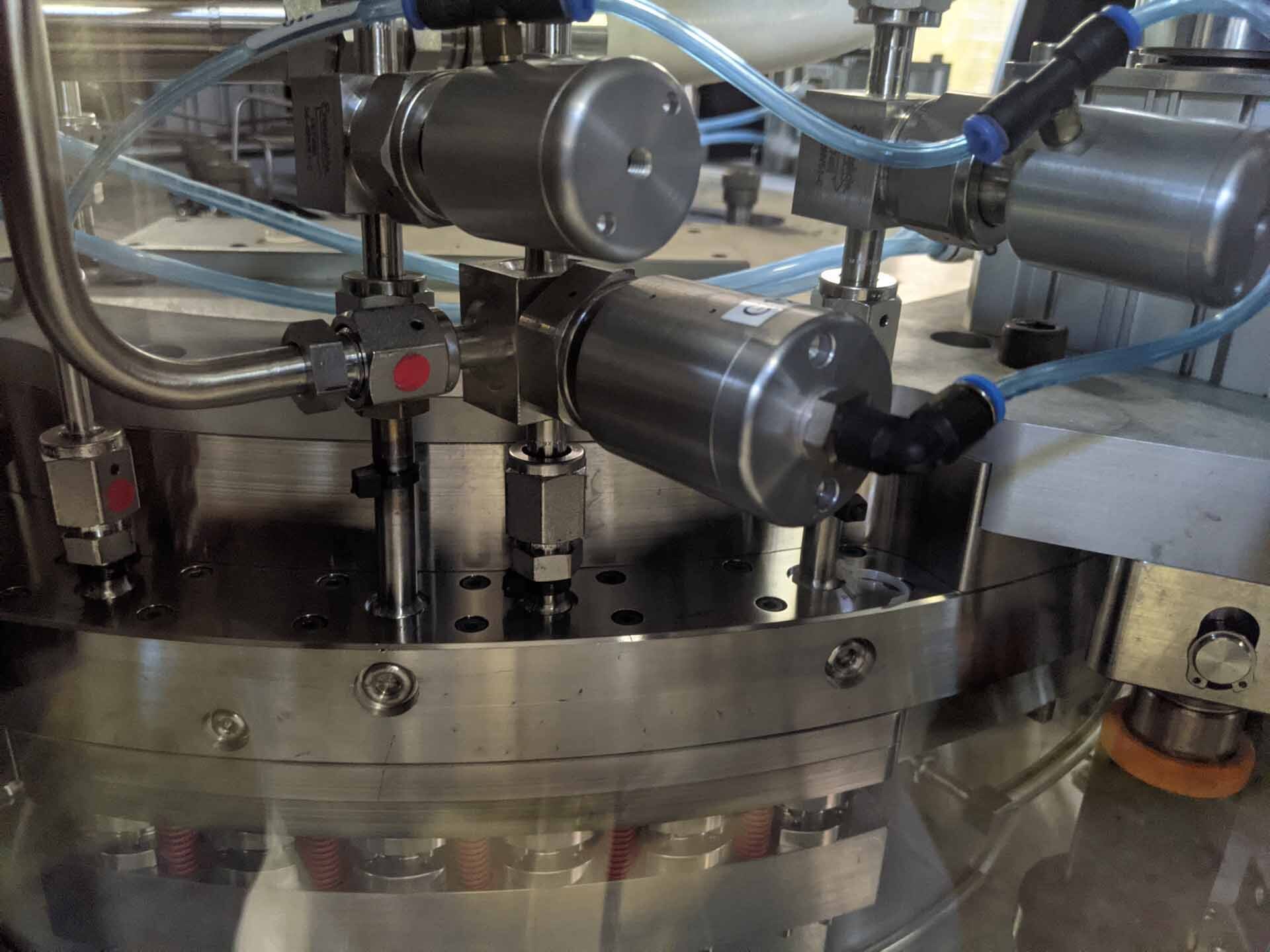

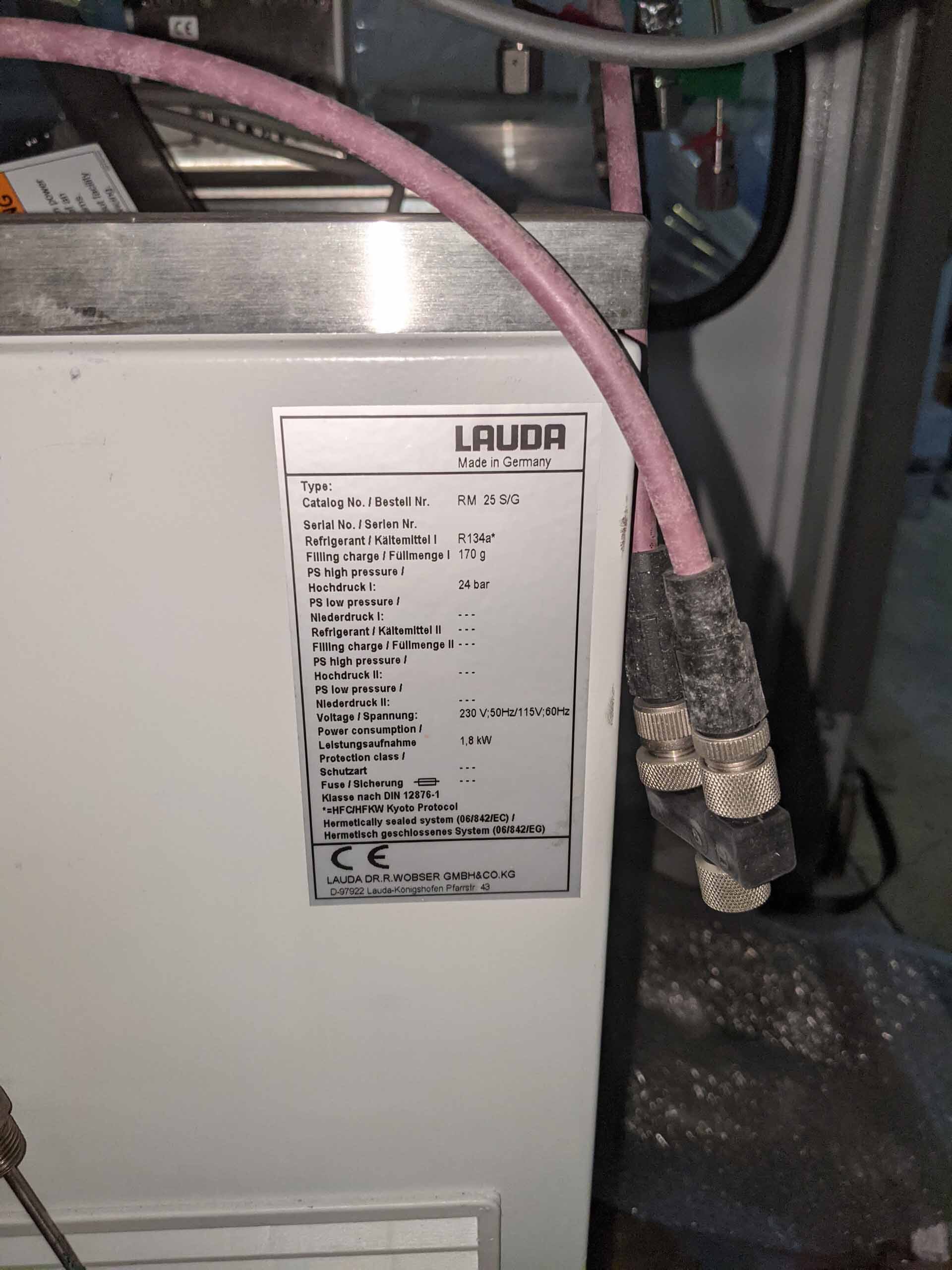

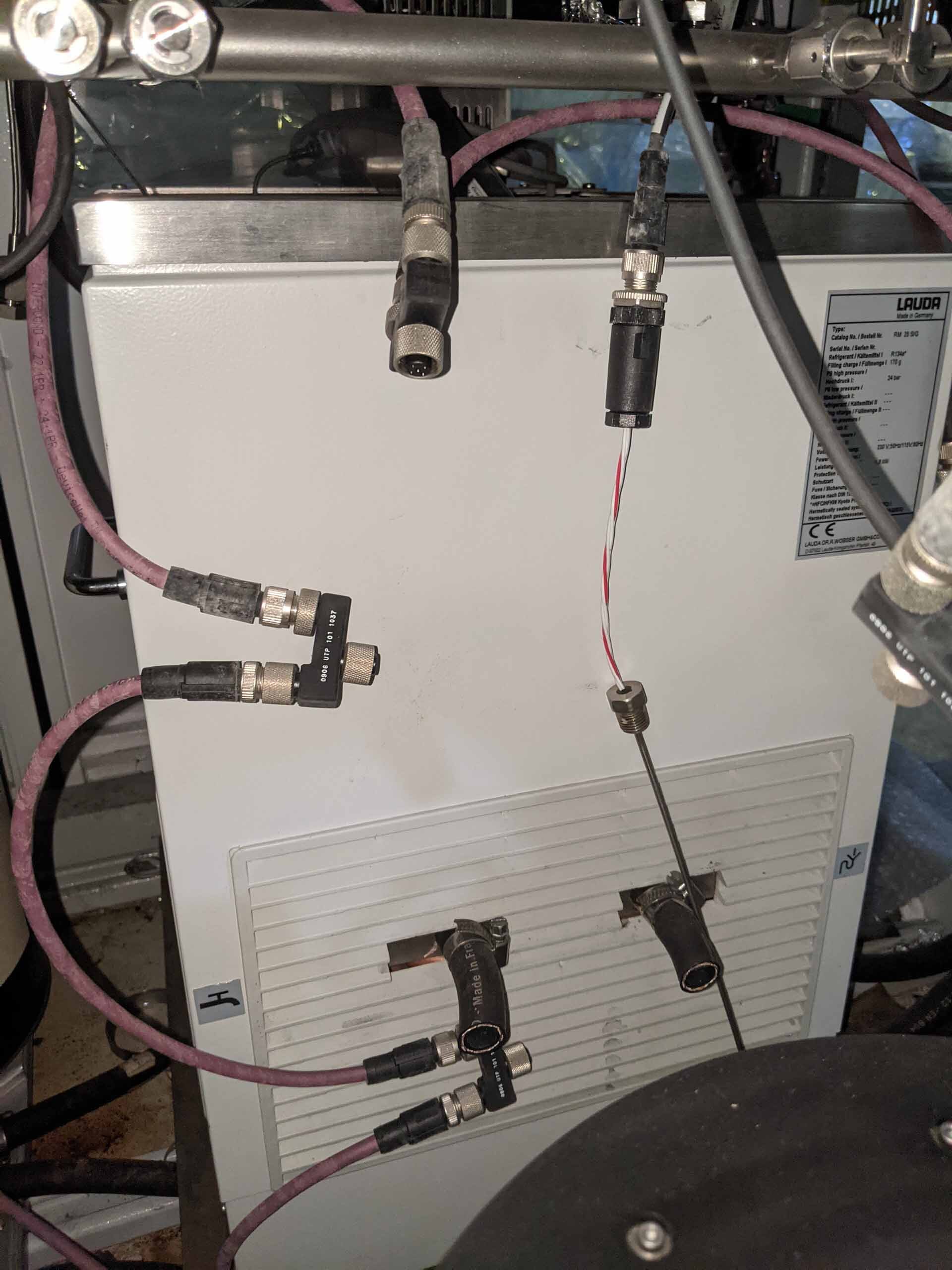

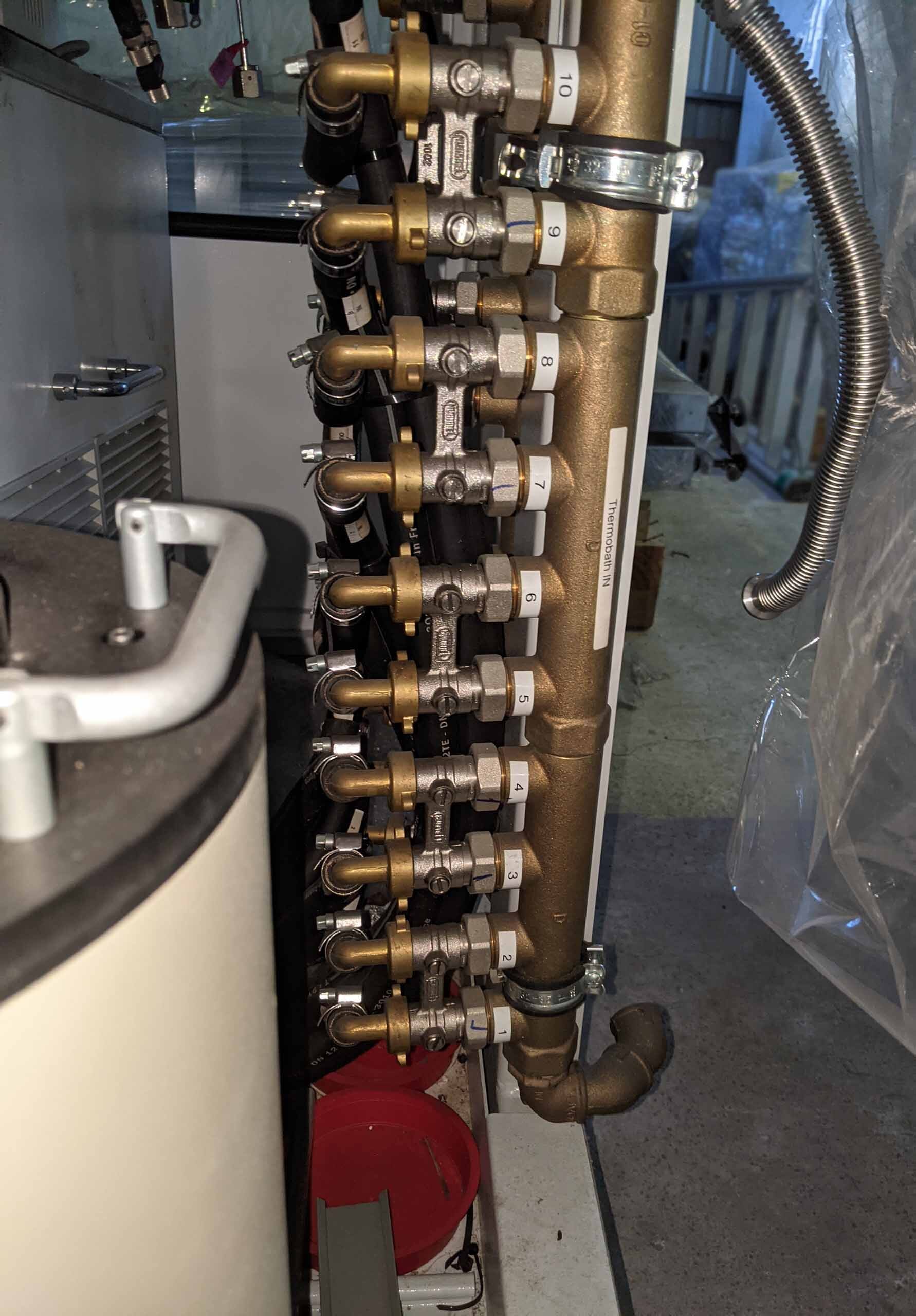

(2) RAUDA RE235 Baths

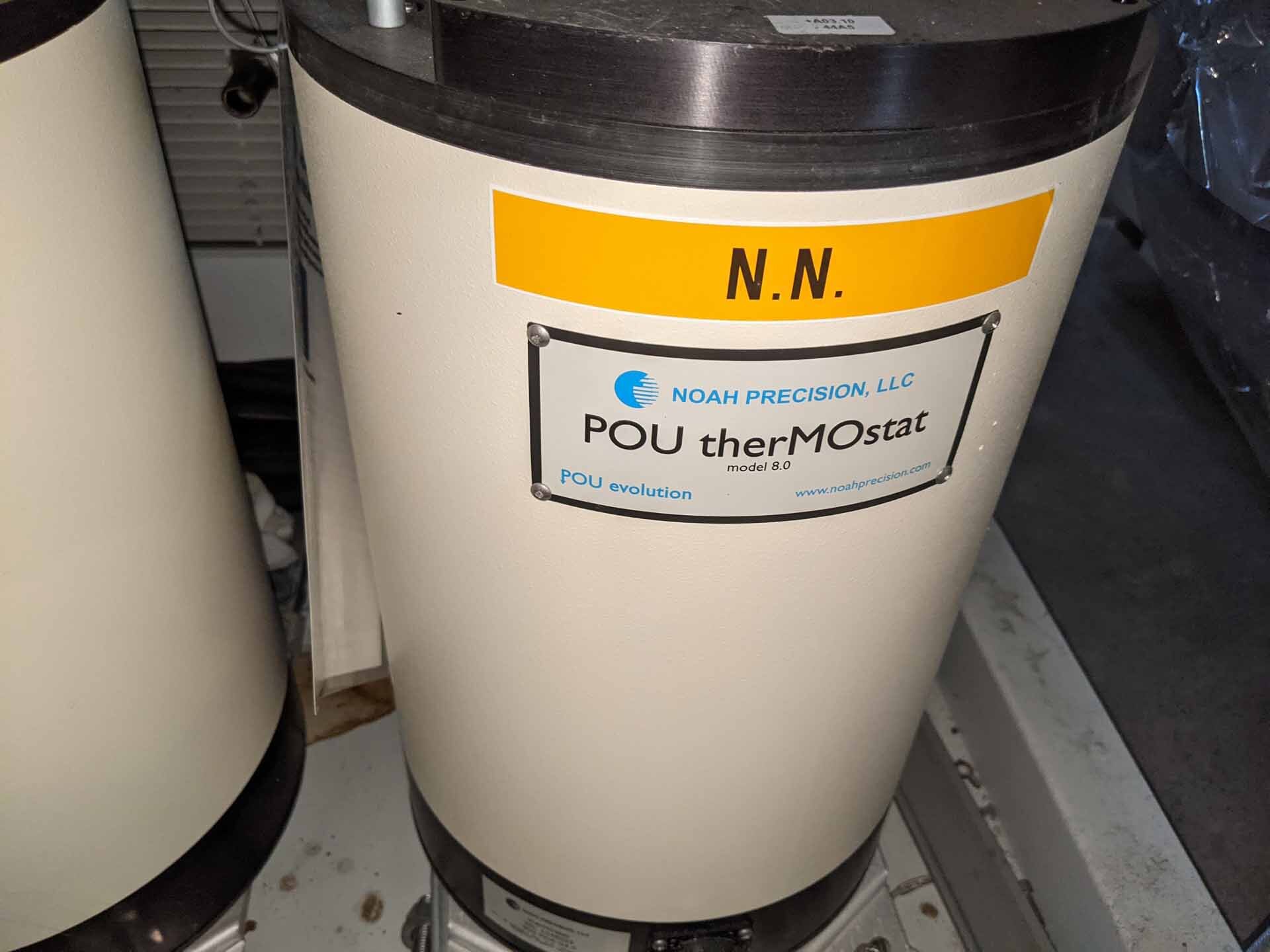

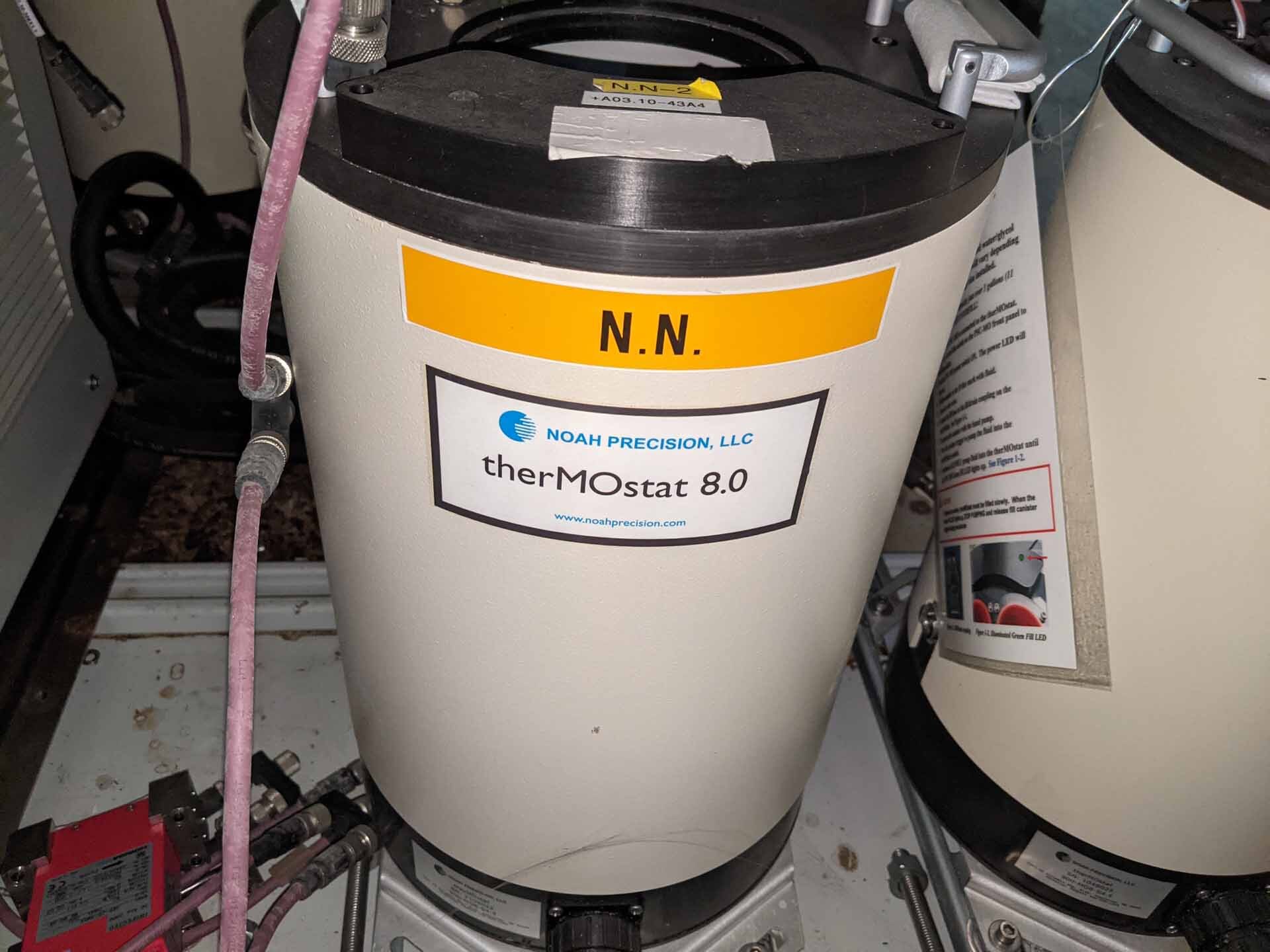

(4) NOAH Precision baths

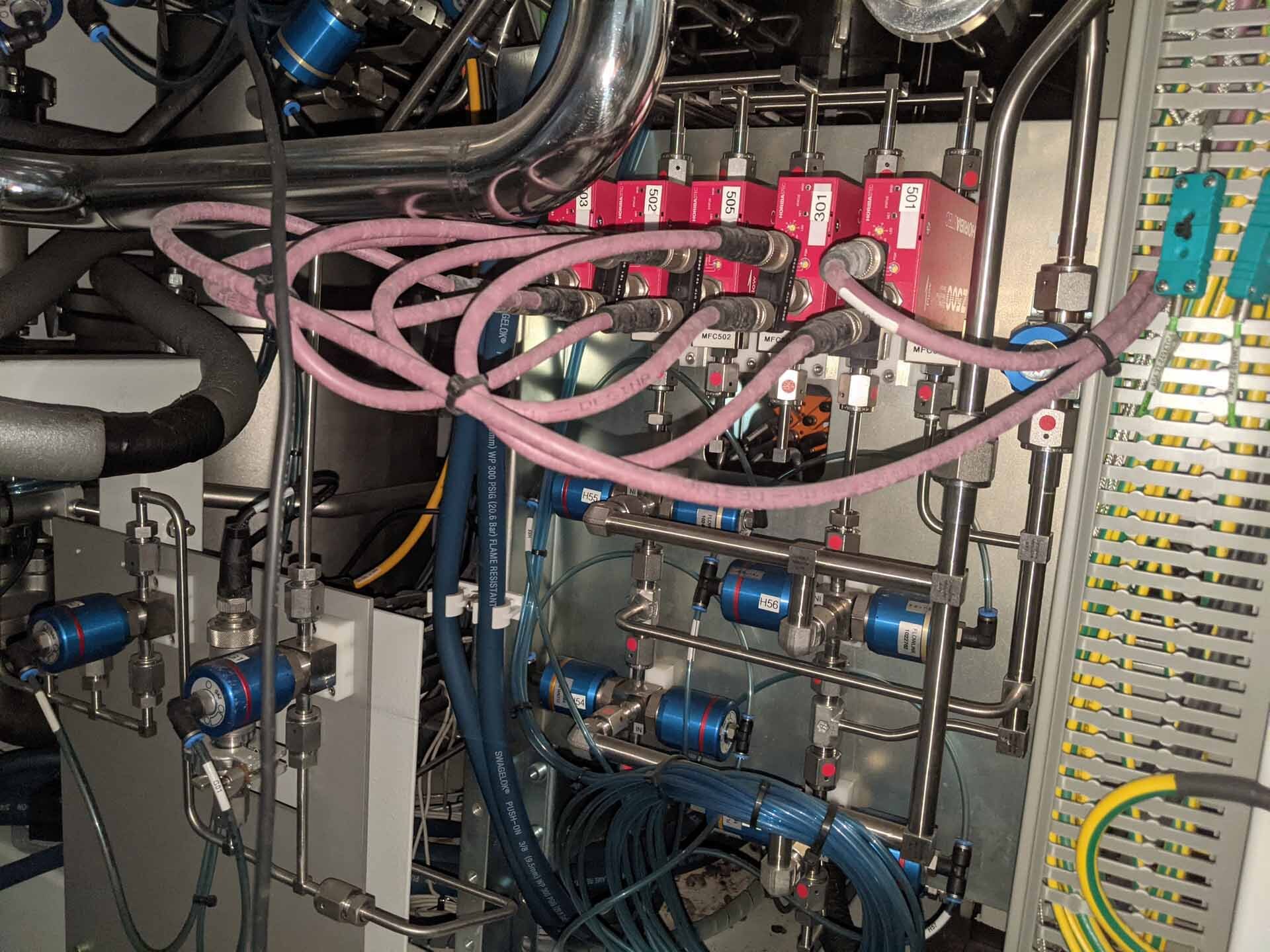

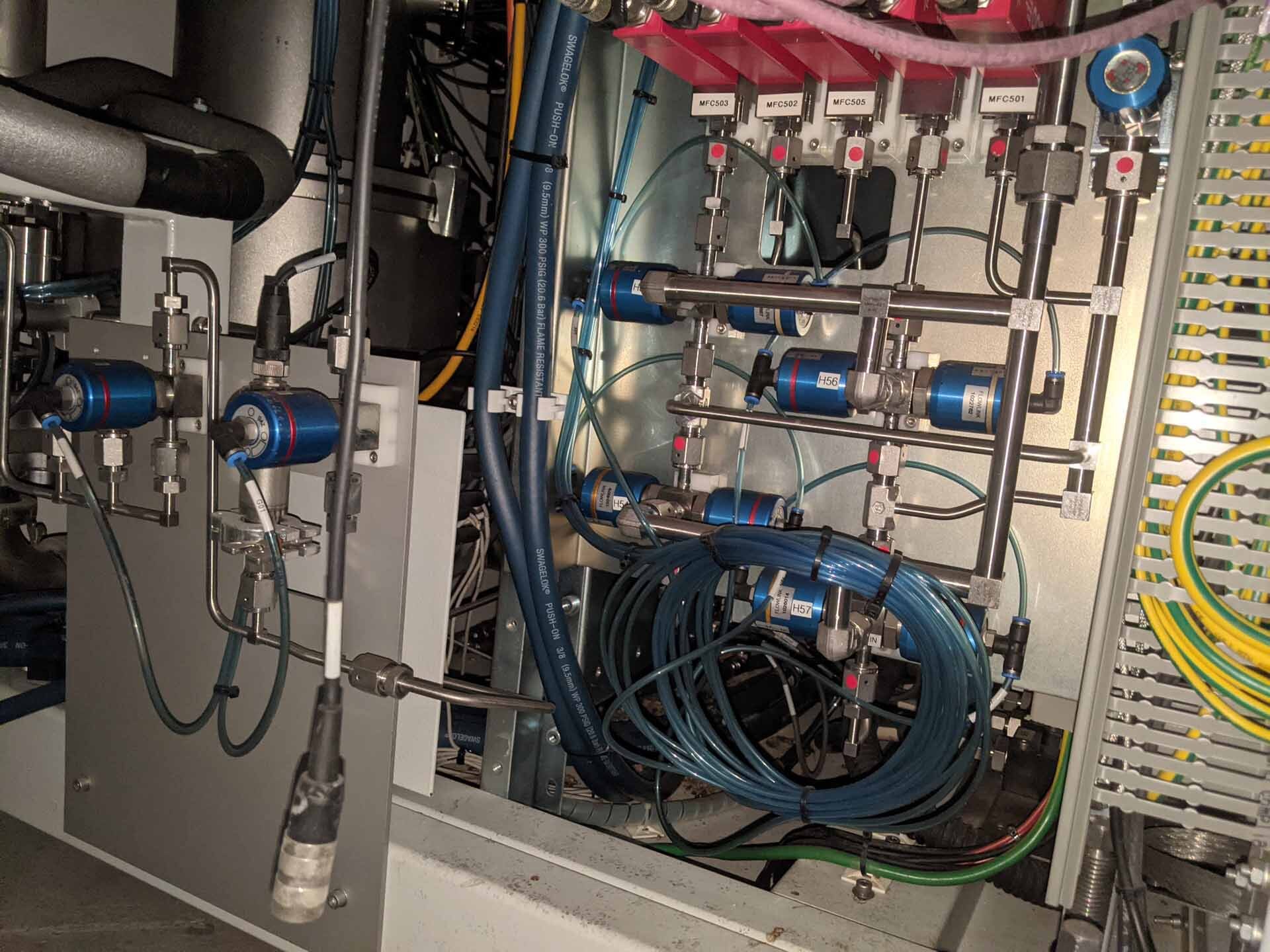

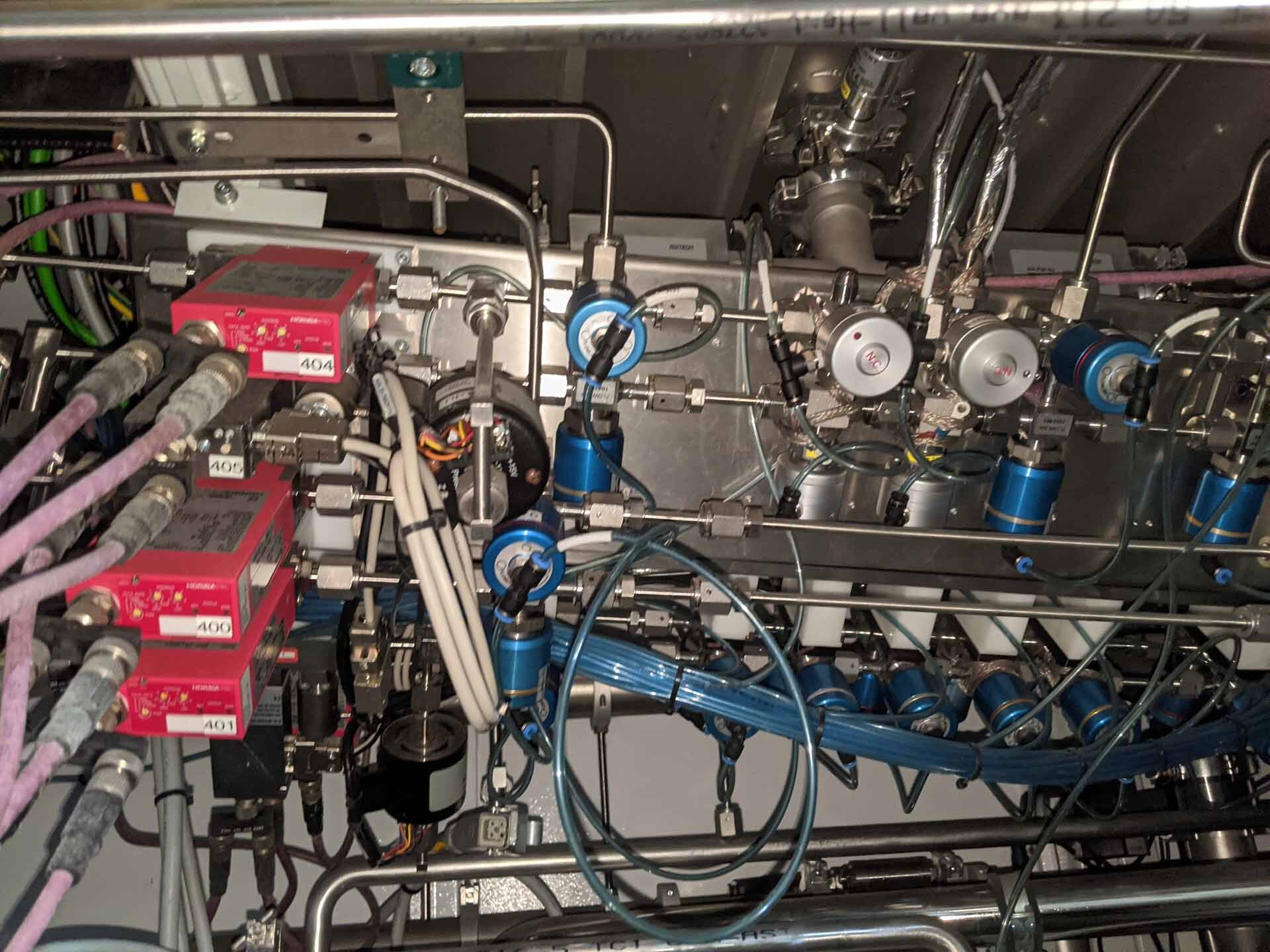

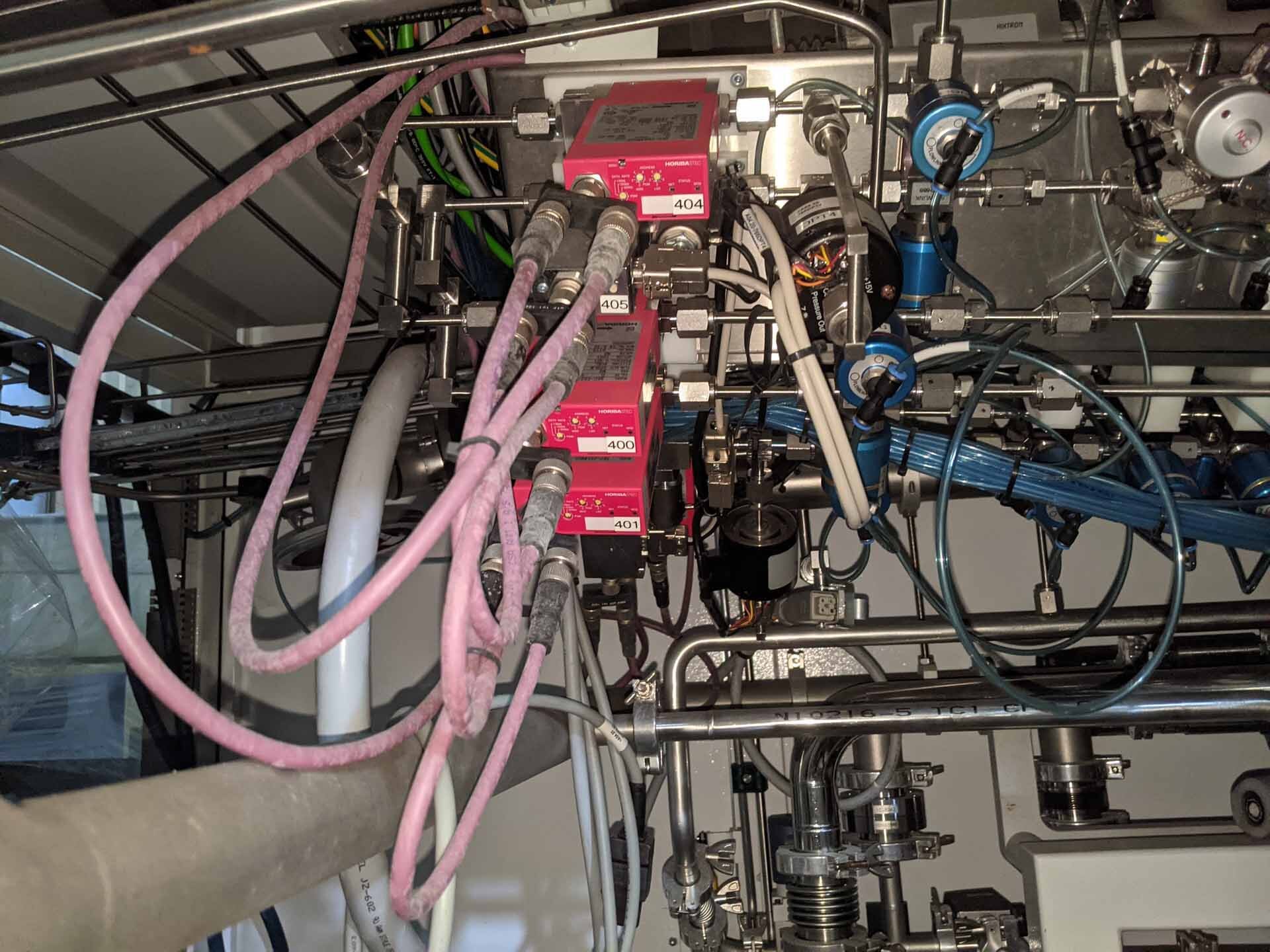

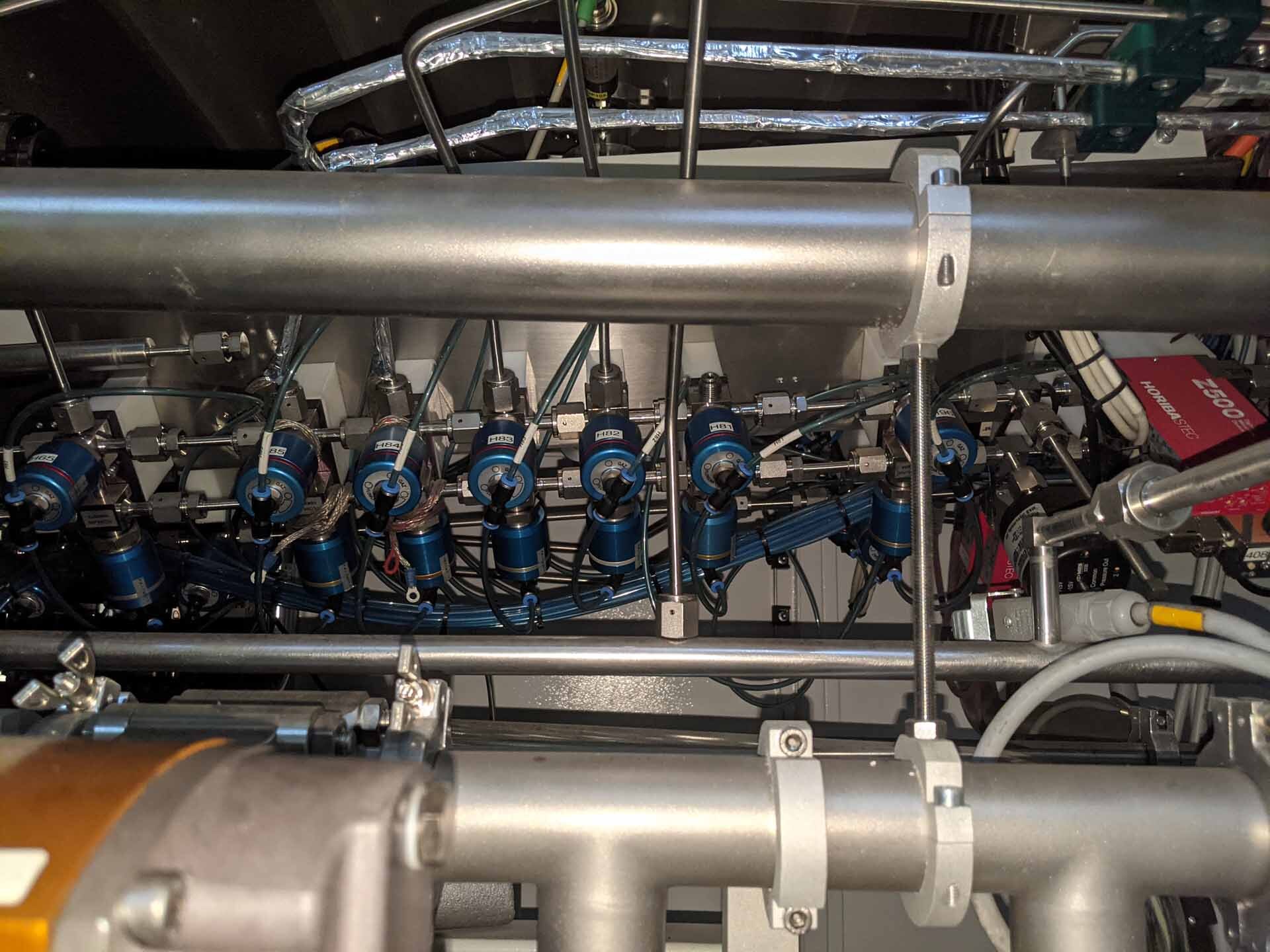

HORIBA MFC Type

GaN Gouve

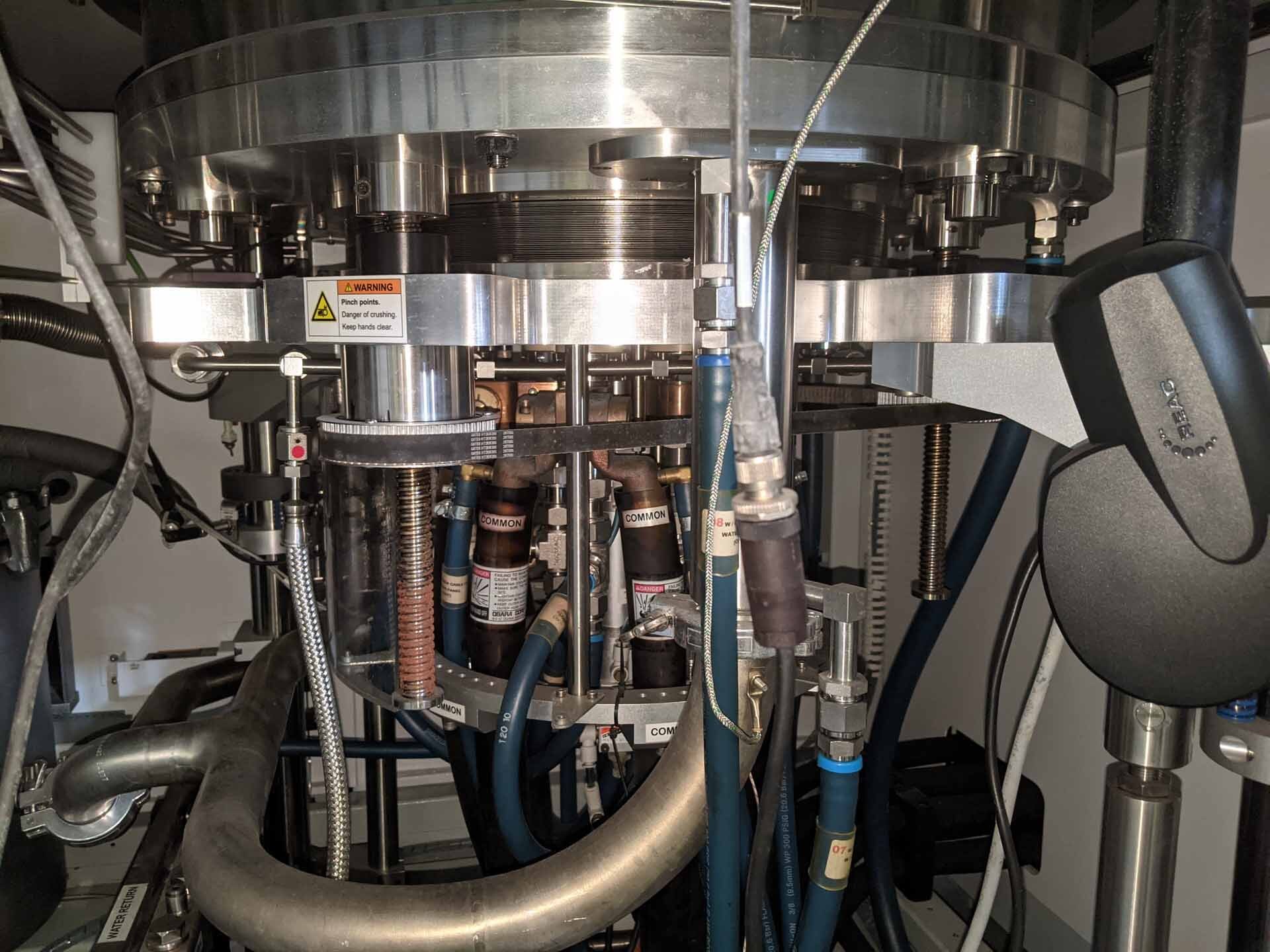

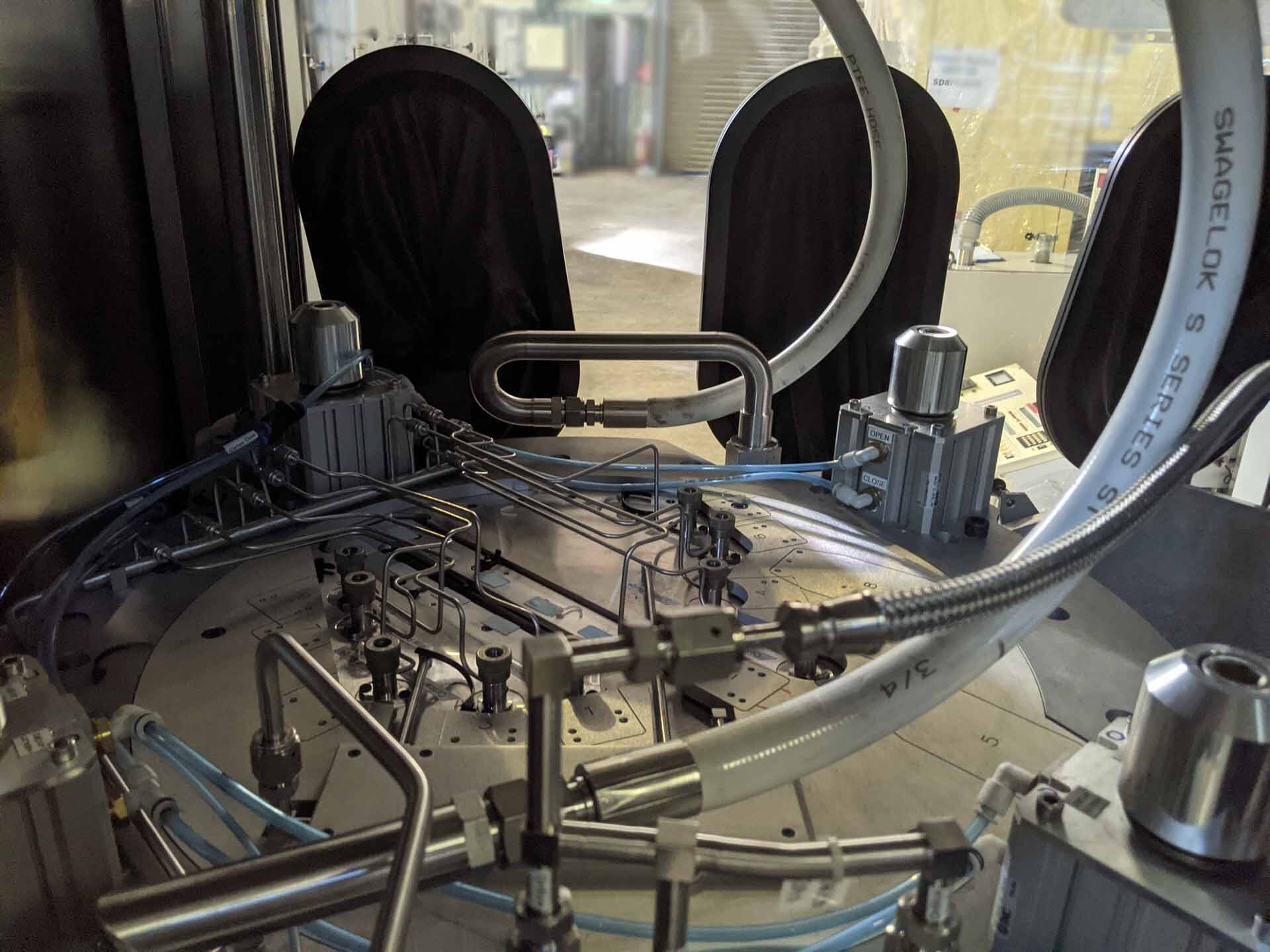

Chamber (55"x2")

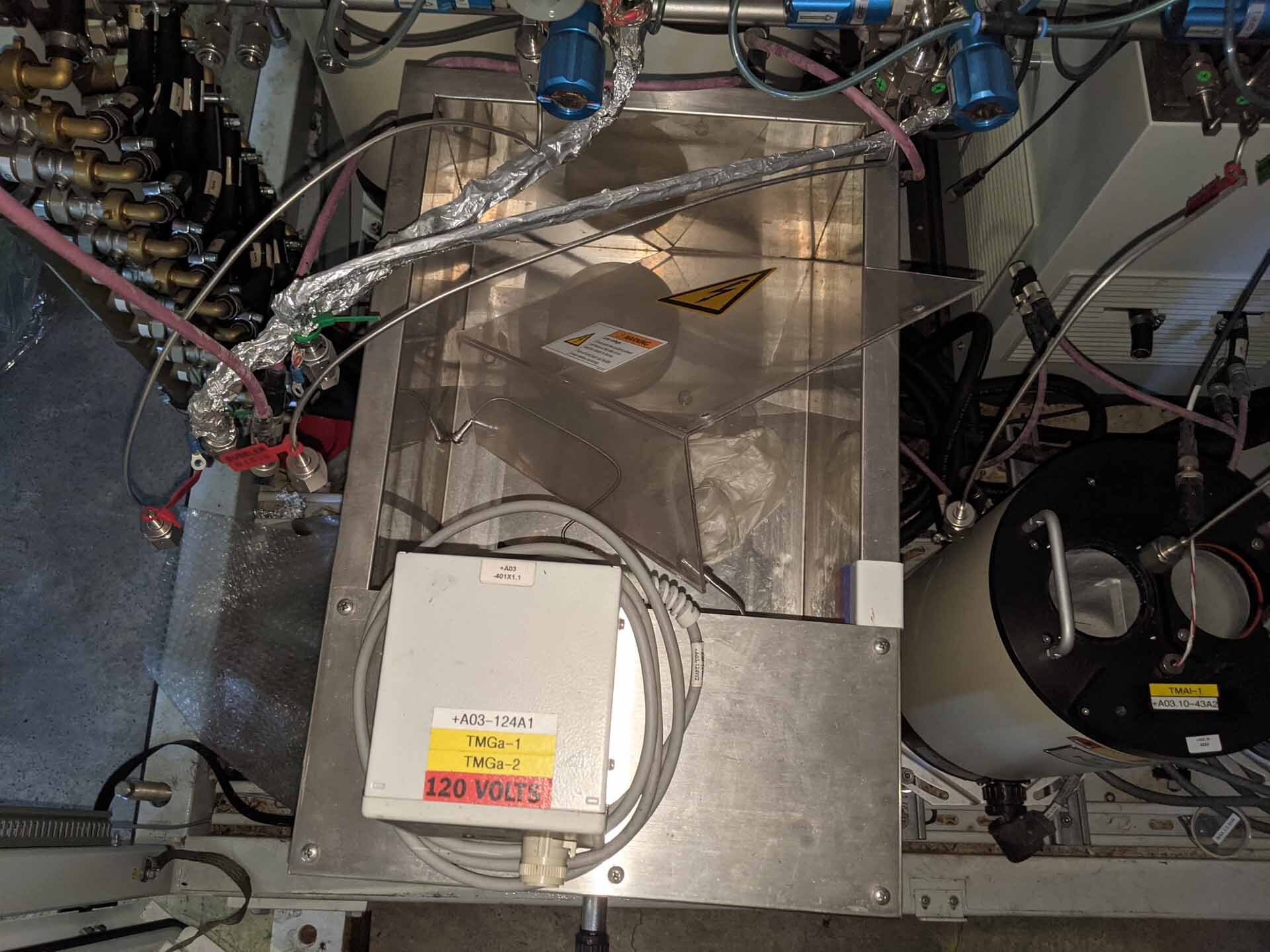

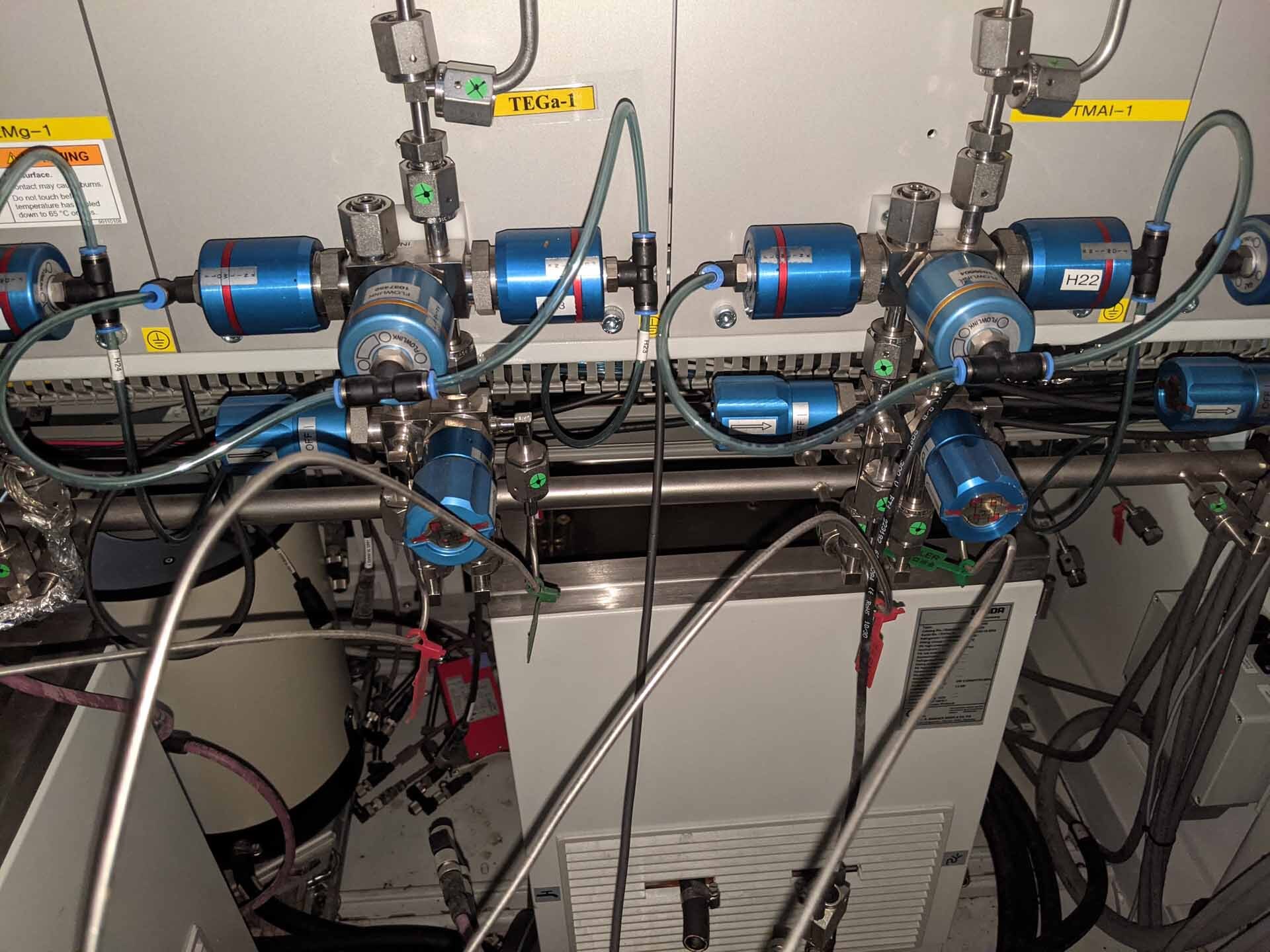

MO Source:

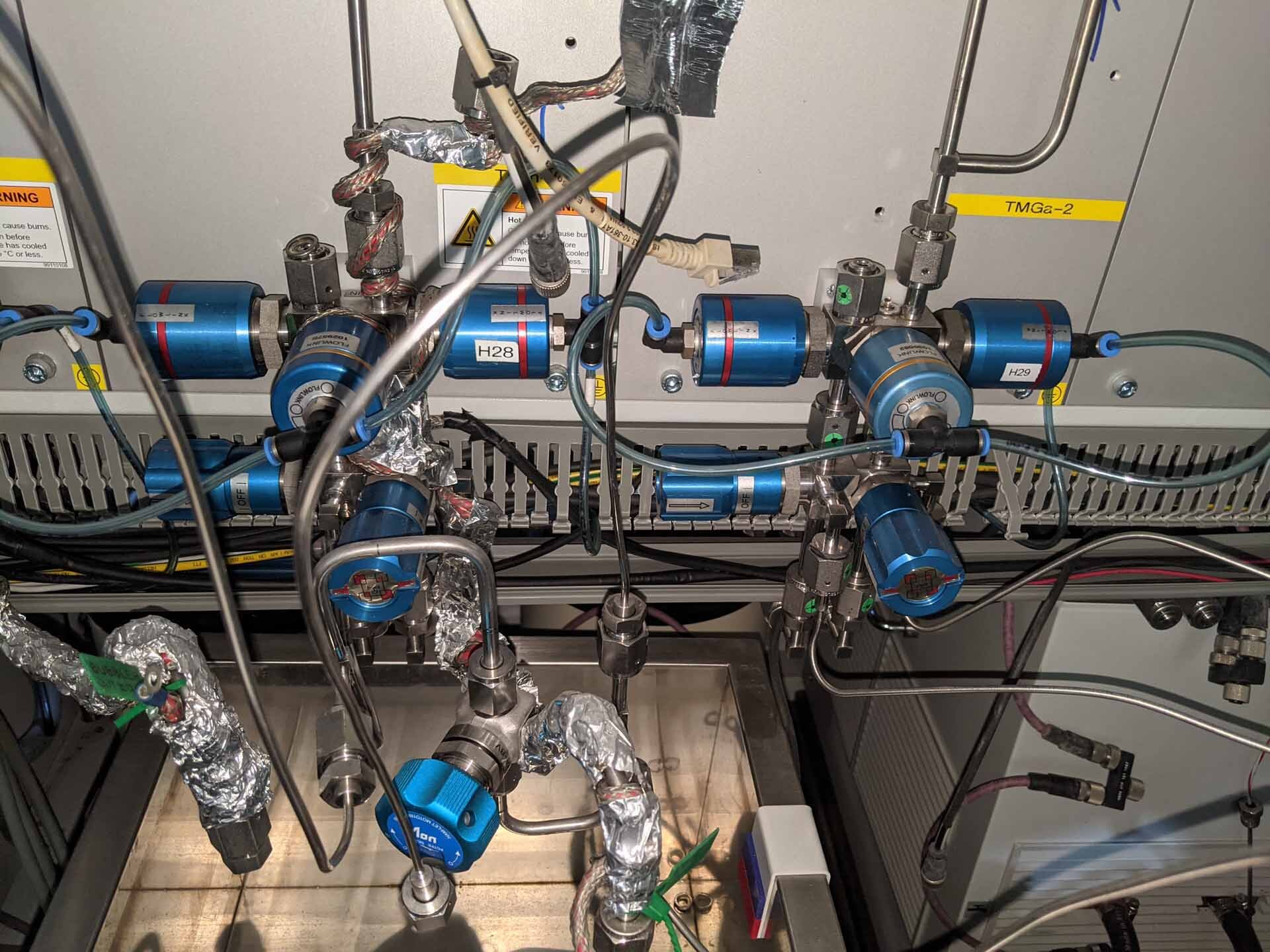

TMGa-1

TMGa-3

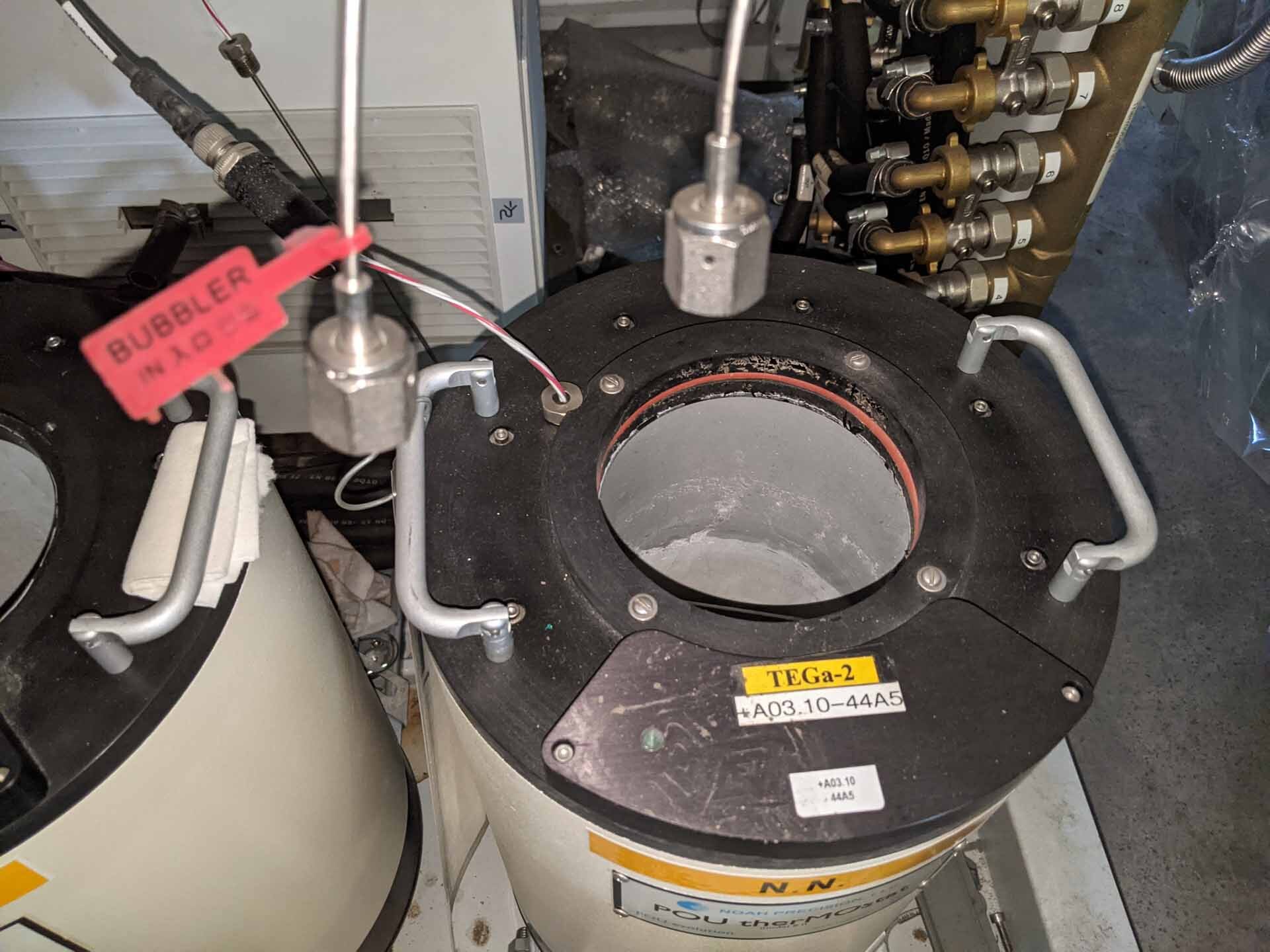

TEGa2

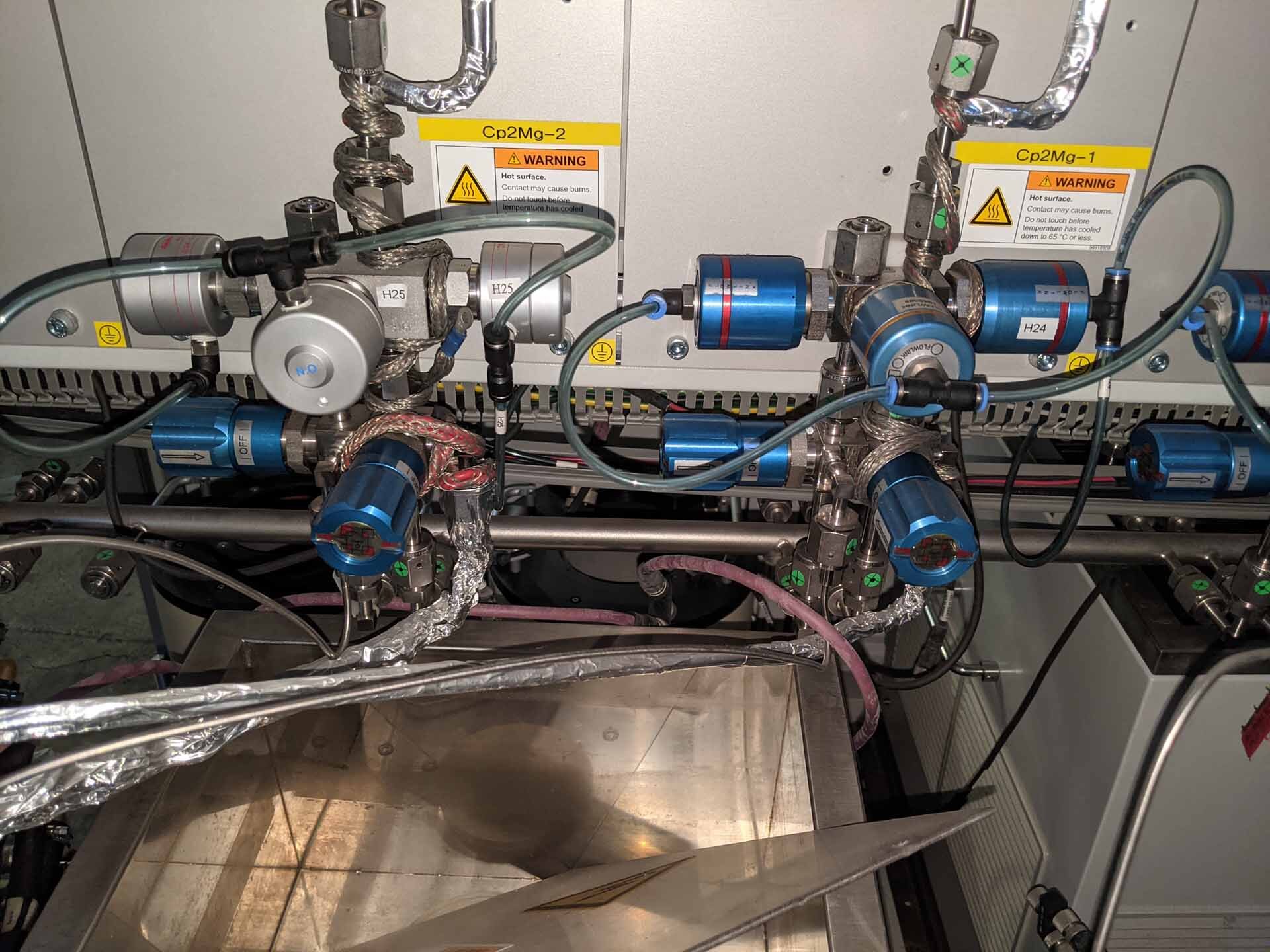

Cp2Mg-1

Cp2Mg-1

TMln-1

(7) TMAI-1

Missing parts:

ALCATEL / ADIXEN A100H/P Pump

ALCATEL / ADIXEN ACP 15 Pump

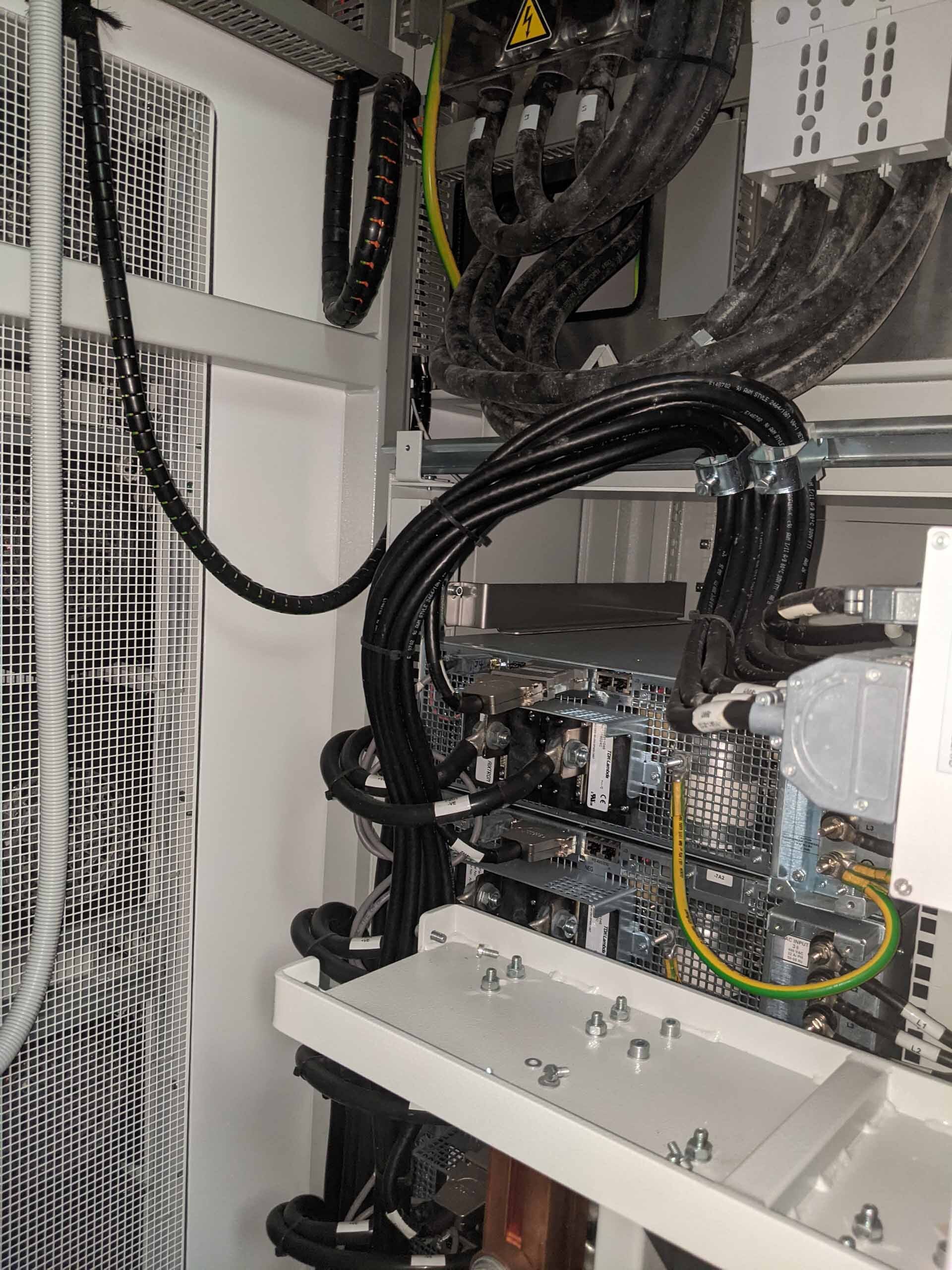

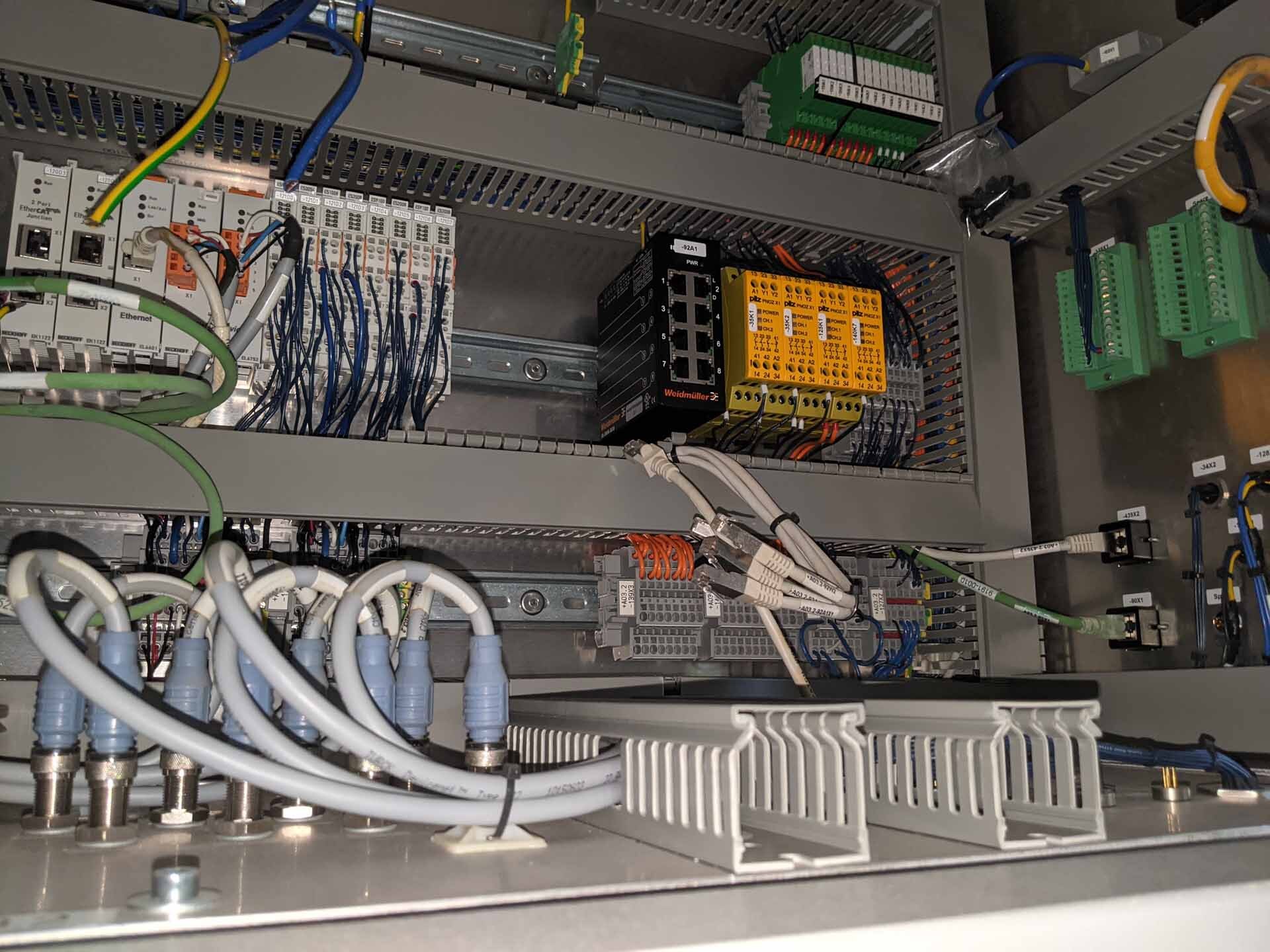

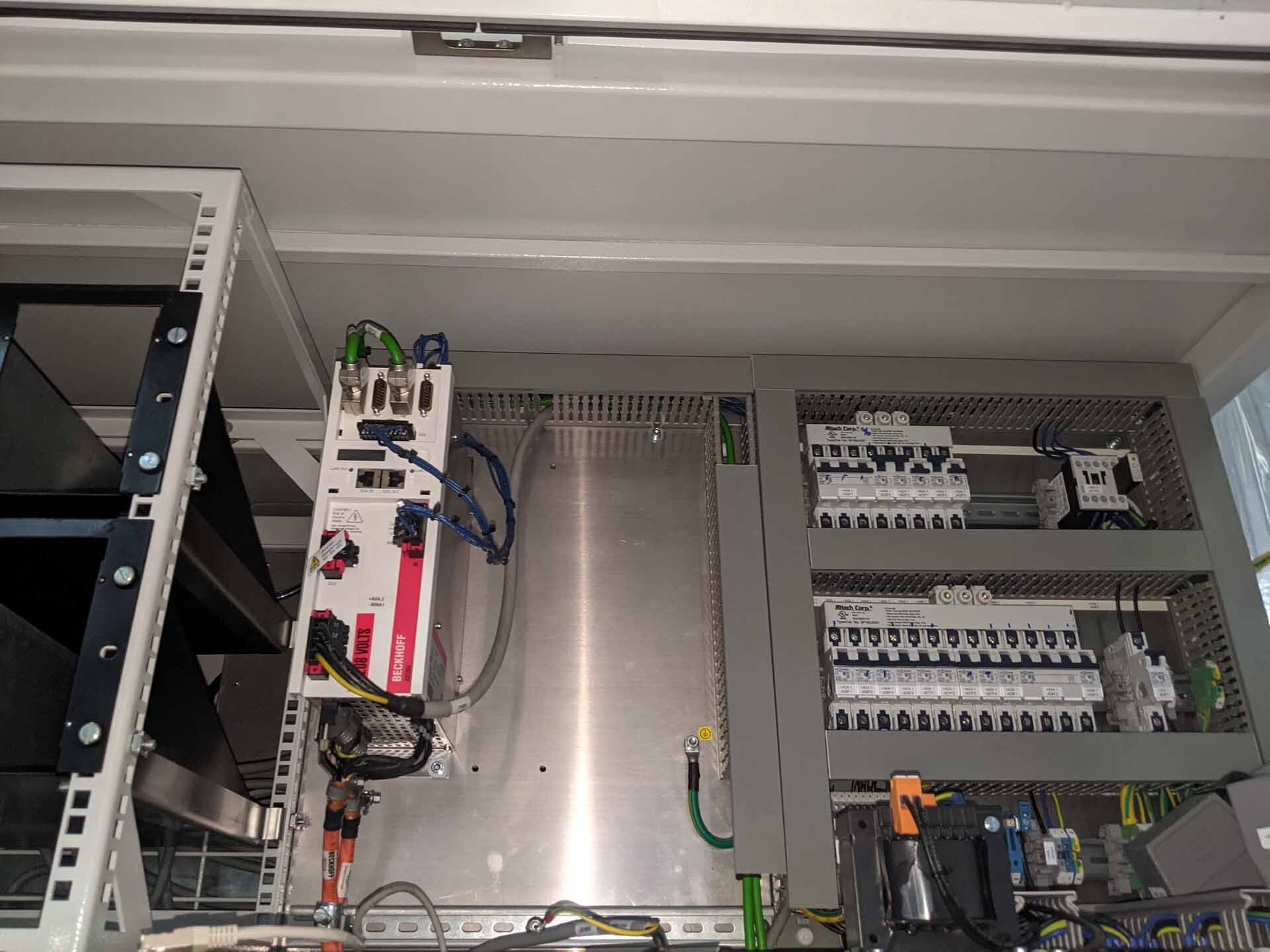

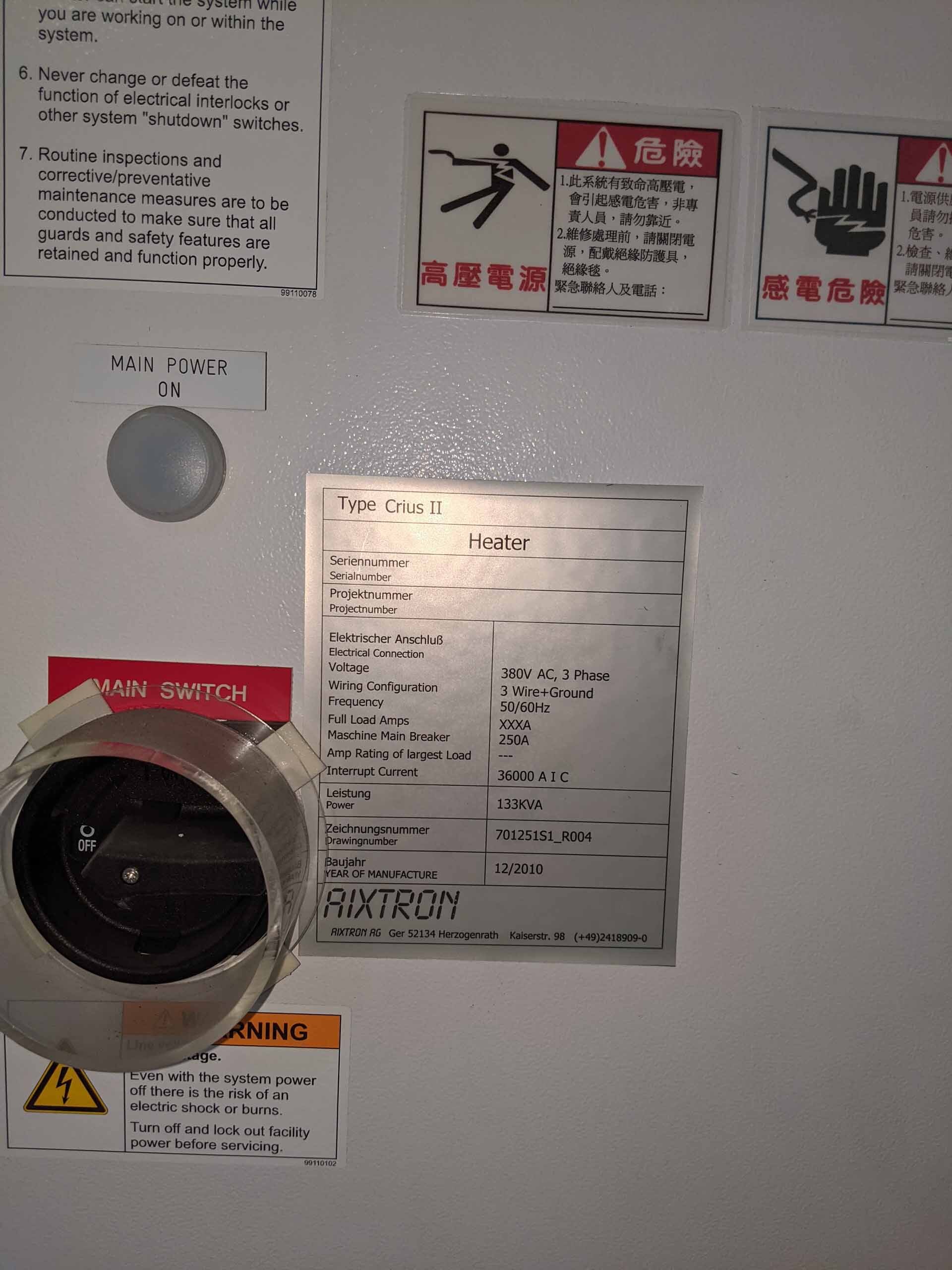

Heat voltage: 380 VAC, 3-Phase

Power supply: 208/120 VAC, 3-Phase

2010 vintage.

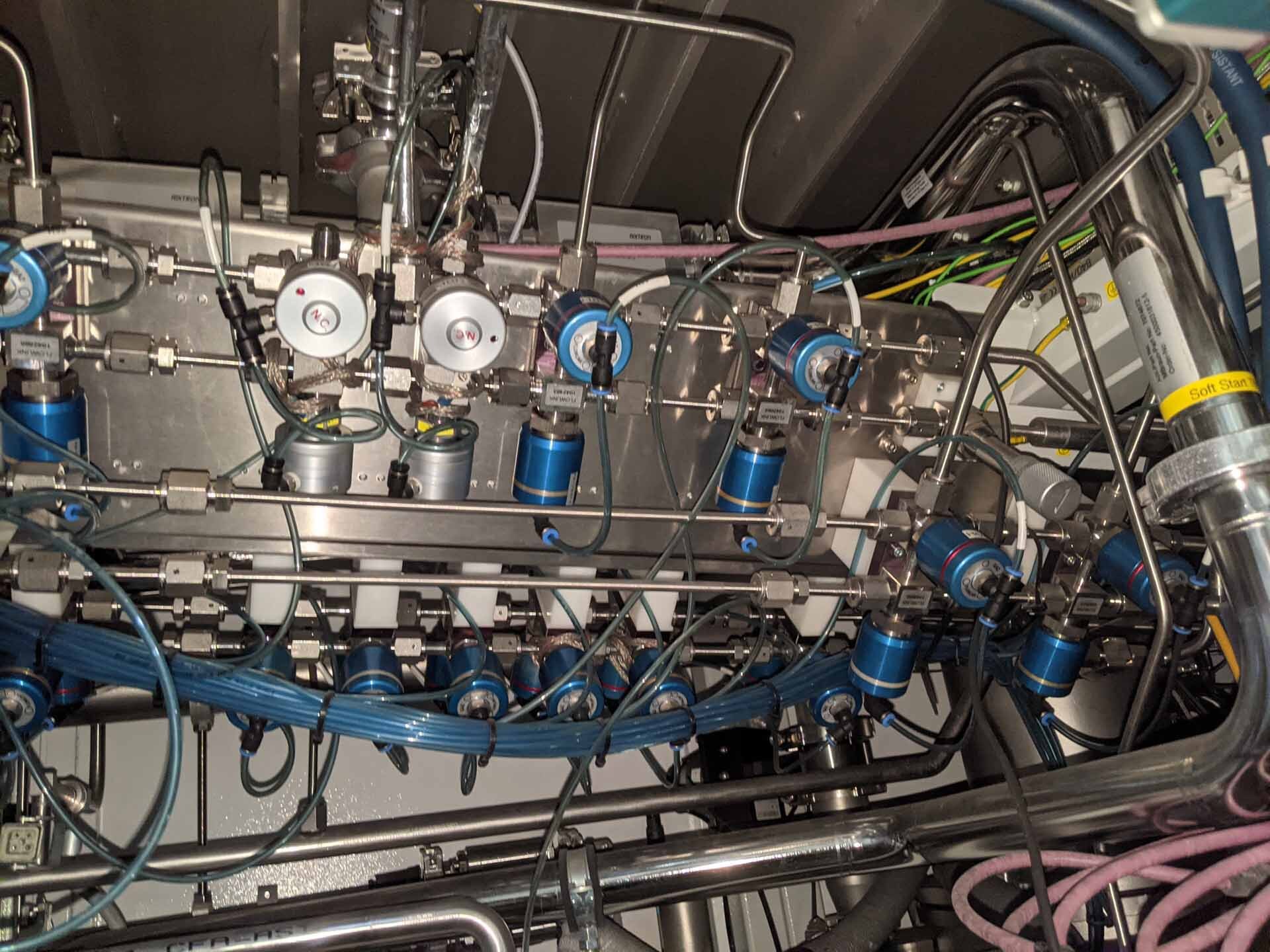

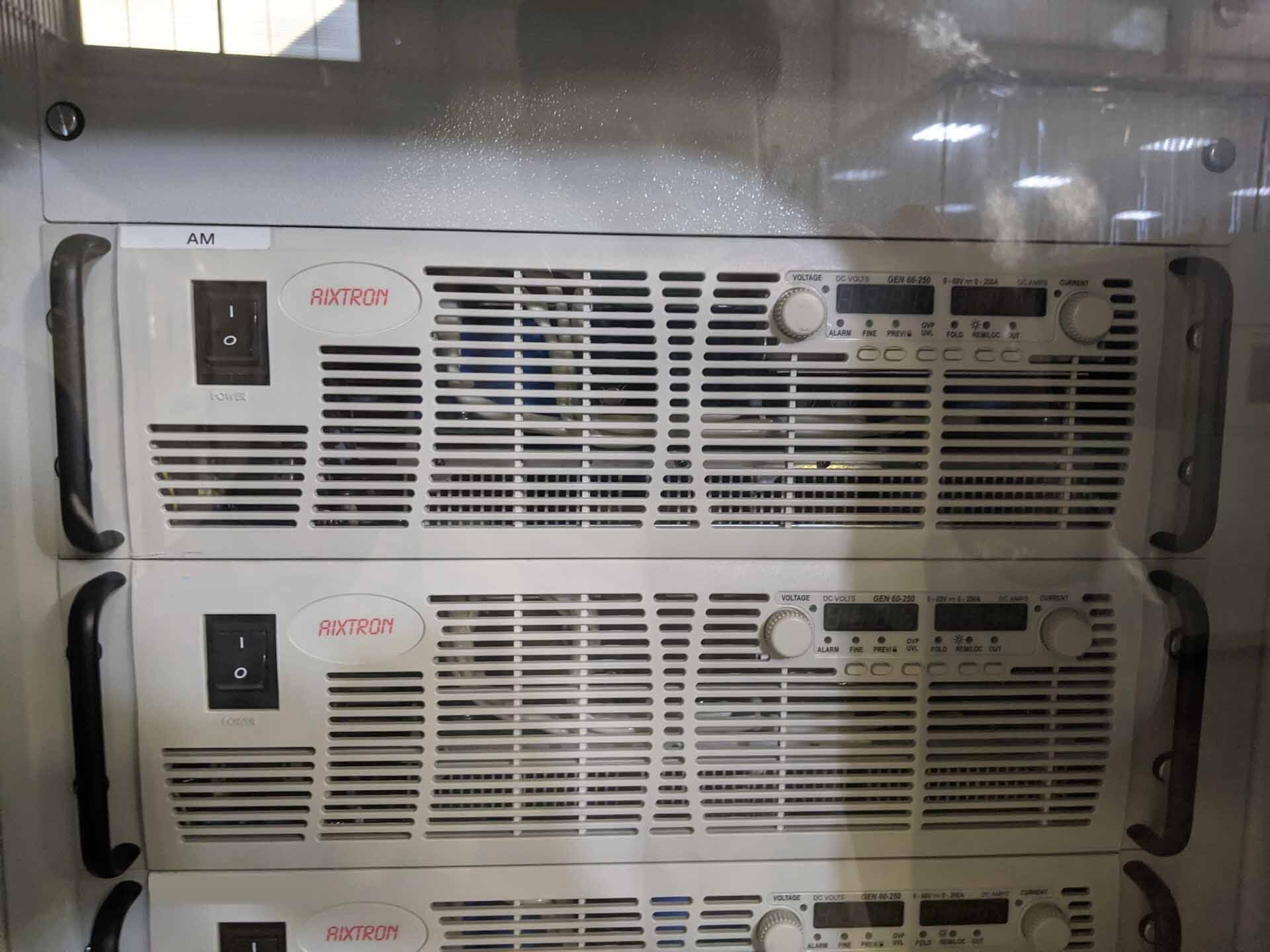

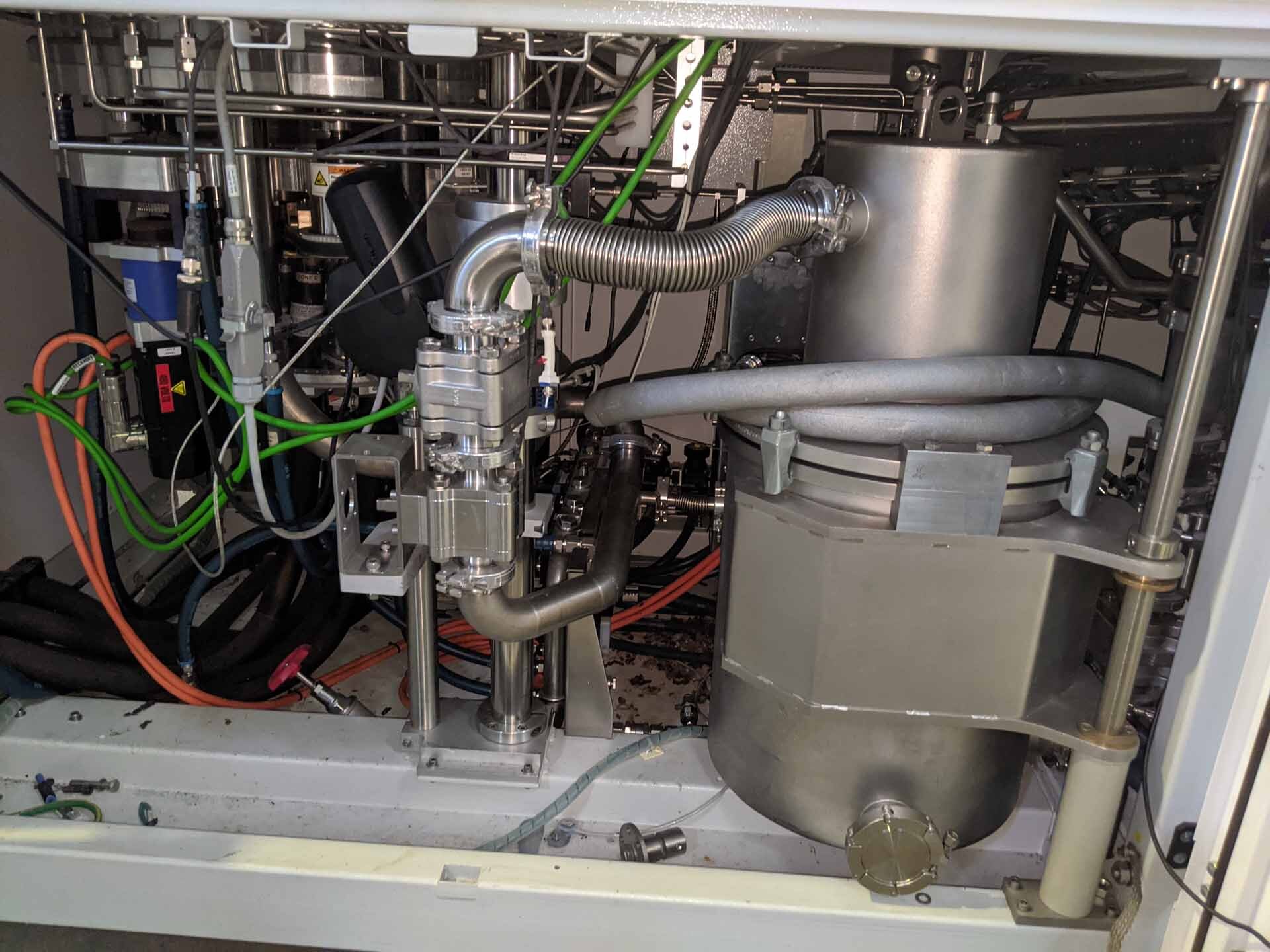

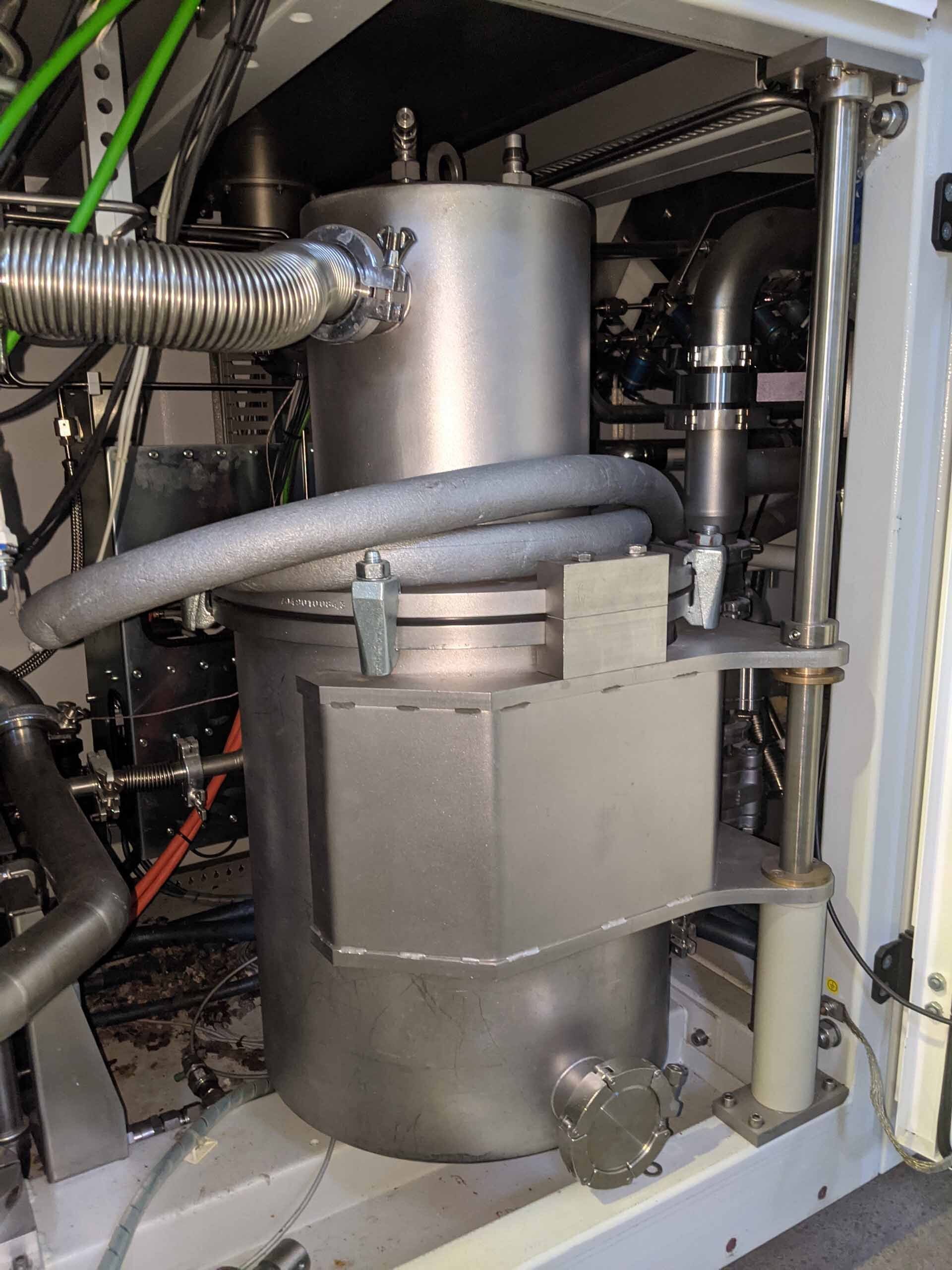

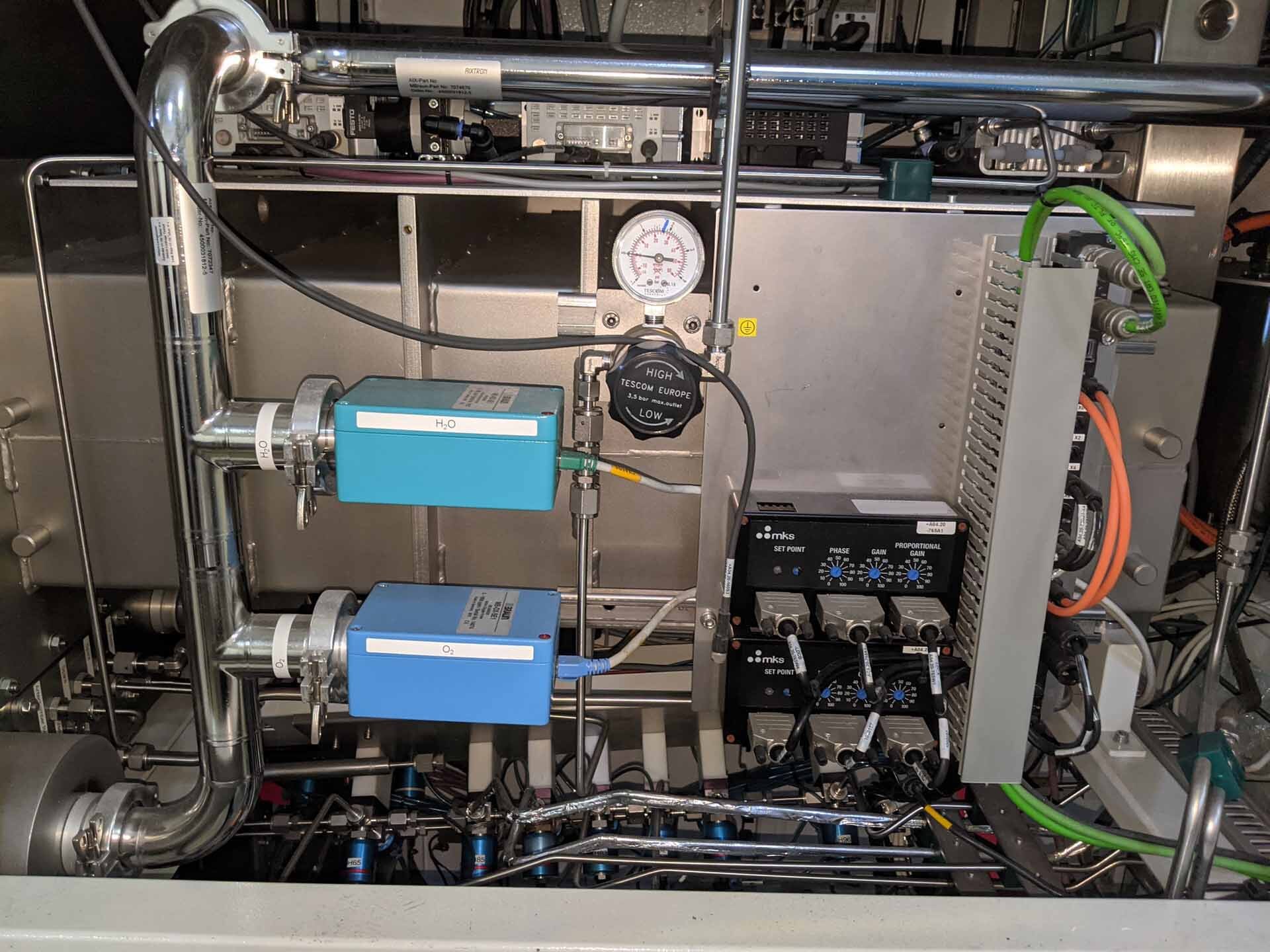

AIXTRON Crius II is an advanced chemical vapor deposition (CVD) reactor that is capable of depositing a wide variety of materials, such as metals, semiconductors, oxides and nitrides. It has been designed for production as well as for research purposes. Crius II features a robust, modular design and can be configured to accommodate a wide range of processes and substrate sizes. The main parts of AIXTRON Crius II reactor include the microprocessor-controlled gas mixing and delivery system, the ultra-high-vacuum (UHV) chamber, the heated substrate holder, and the two magnetrons that produce the plasma. The gas delivery system is used to mix and deliver gases to the chamber, while the UHV chamber is designed to maintain a low and stable pressure in order to ensure uniform growth of the materials across the entire substrate. The substrate holder can be heated up to 1,300ºC to allow for thermal doping and substrate heating for growth of high-temperature dielectrics. Crius II can accommodate substrates up to 4-inch in diameter and is compatible with various source materials such as metal-organic precursors and gaseous organometallic compounds. The two magnetrons use direct current (DC) power to generate a high density plasma, which helps to improve the reaction rate and uniformity of material growth. The magnetrons are also used to monitor and control the deposition conditions such as temperature, pressure, and plasma power. AIXTRON Crius II is equipped with a powerful software program that allows for precise control of all processing parameters, including the substrate holder temperature, the magnetron power, and the gas concentrations. It can also be used to run self-optimization cycles to fine-tune the growth process. Crius II reactor is a powerful and versatile tool for the deposition of a variety of materials, from metals, semiconductors and oxides to nitrides. It features an ergonomic design that allows for reliable and consistent deposition, as well as precise control over the growth parameters for optimization of the process. It is suitable for both research and production applications.

There are no reviews yet