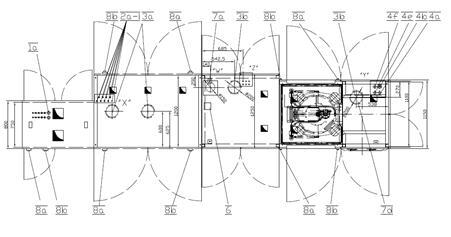

Used AIXTRON G3 #9074580 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9074580

GaN systems

Dopants: Cp2Mg, SiH4

Transfer: load lock only

Wafer loading capabilities: (24) 2” or (8) 4”

CACE software

EpiTune (in-situ monitoring)

Facility requirements:

Gas specification:

N2 – 4VCRF – 4.0 ~ 7.0 bar

H2 – 4VCRF – 4.0 ~ 7.0 bar

NH3 – 4VCRF – 3.0 ~ 3.5 bar

SiH4/H2(200ppm) – 4VCRF – 3.0 ~ 3.5 bar

HCL – 4VCRF – 3.0 ~ 3.5 bar

GN2(N2 tech) – 4VCRF – 7.0 ~ 8.5 bar

Wafer specification:

System:

Inlet – 6.5 bar (maximum) 1" Swagelok bulkhead

Minimum total flow 63 l/m

Temp - 17°C ~ 25°C stability ± 1°C

Outlet – 2.5 bar (maximum) 1” Swagelok bulkhead pump loop

Minimum differential pressure 4 bar for required flow

Inlet – 6 bar(Maximum) 3/4” Swagelok bulkhead

Minimum total flow 50 l/m

Temp - 20°C stability ± 1°C

Outlet – 2 bar (maximum) 3/4” Swagelok bulkhead reactor loop

Minimum differential pressure 4 bar for required flow

Maximum temp – 40°C

RF generator:

Inlet – 6 bar (maximum) 3/4” Swagelok bulkhead

Minimum total flow 36 l/m

Outlet – 2 bar (maximum) 3/4” Swagelok bulkhead reactor loop

Minimum differential pressure 4 bar for required flow

Electrical requirements:

Voltage: System: 208 V, RF generator: 380 V

Current: System: 80A (customer 100A), RF generator 250A (customer 315A)

Frequency: 60 Hz

Wiring requirement: System: 3/N/PE, RF generator: 3/PE

Main power location: E-rack

UPS input location: internal to E-rack, provided as spare

Exhaust specifications:

Total cabinet exhaust requirement: GMS (750m3/h) (2ea) Reactor (500m3/h) (2ea)

TGA exhaust requirement:

- Process gas exhaust connected to scrubber DN40KF flange,

50~100mm below top of glovebox open line for continuous flow

HE-leak tight ≤ 10E-9 mbar l/s

Oxygen < 1ppm

Line pressure atm > p > atm – 20mbar

- Exhaust GB pump, 3/8” Swagelok

- Exhaust Forming gas, 3/8” Swagelok.

AIXTRON G3 is an advanced metal-organic chemical vapor deposition (MOCVD) reactor used for semiconductor applications such as the production of light-emitting diode (LED) chips. AIXTRON G 3 is a robust platform with a long lifetime that is due in part to its proprietary SplitFlow design. SplitFlow is a patented, dual-flow delivery system that helps overcome limits on performance, like temperature and deposition homogeneity, while using fewer sources and allowing for lower operating costs. With SplitFlow, gases are separated and injected into multiple locations, creating a shorter flow path to the substrate and reducing chemical contact time. This can help increase process reproducibility and efficiency. G3 reactor is also capable of high chamber pressures of up to 500 millibar, enabling rapid film formation and thicker deposition without compromising uniformity. To ensure uniformity, G 3 features DualPlay, which combines gas delivery and temperature control management via two independently programmable temperature controllers and two shutters. This helps create a consistent environment throughout the reactor, which is necessary for growing crystals and thin-film layers. AIXTRON G3 features three individually-grown, ultra-stable linear motor stages for precise substrate manipulation. The stages offer low thermal drift for high positional accuracy, and a minimum pitch of 0.5 microns. AIXTRON G 3 also features the Advanced Process Control Suite, a suite of intelligent algorithms to optimize the performance of deposition recipes. G3 reactor is a reliable semiconductor reactor designed for high precision, accuracy, and repeatability. Its SplitFlow design allows for thinner films, improved level of uniformity, and higher efficiency thanks to shorter flow paths and lower operating costs. Its high chamber pressure enables thick film formation and temperature control is managed via DualPlay, ensuring uniform conditions for growing crystals and thin-film layers. The three linear stages provide high positional accuracy, and the Advanced Process Control suite helps to fine tune the entire process.

There are no reviews yet