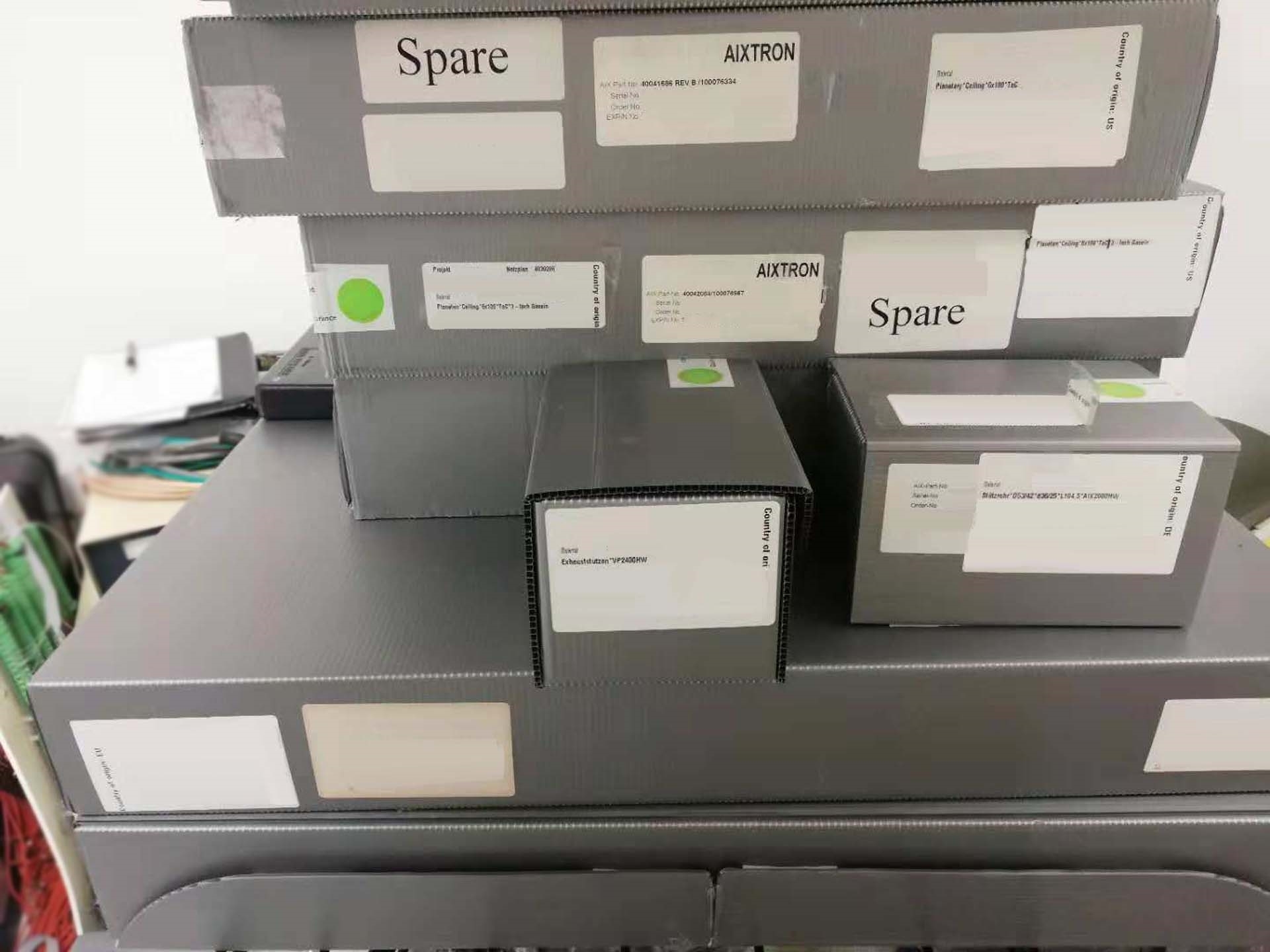

Used AIXTRON VP 2400HW #9234069 for sale

URL successfully copied!

Tap to zoom

ID: 9234069

Wafer Size: 4"

Vintage: 2012

EPI SiC Reactor, 4"

Type: Modular CVD system

Reactor: Disk-shaped horizontal laminar flow stainless steel reactor

Vacuum system: EBARA ESA70W-D Dry process pump

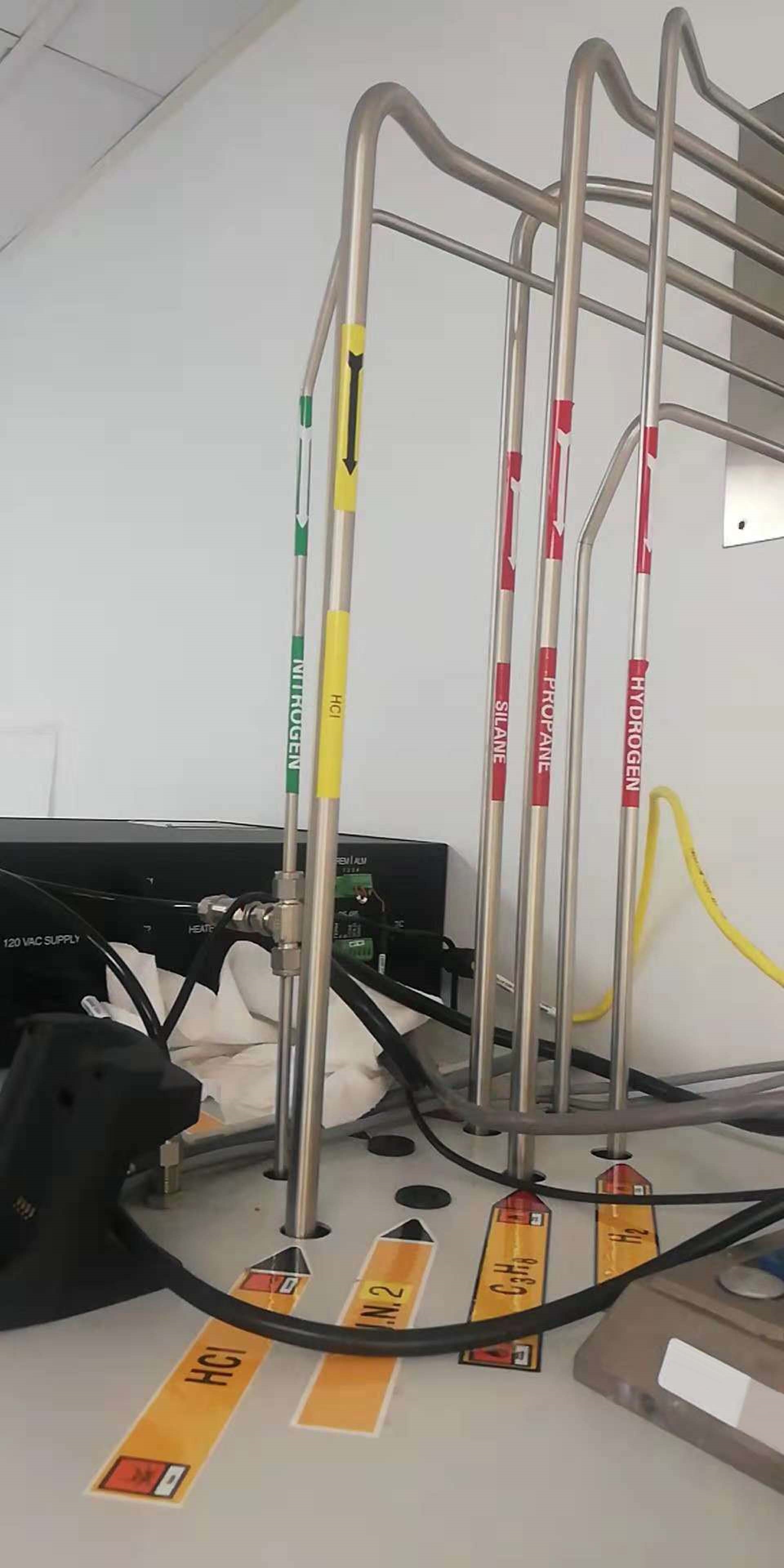

Gas handling:

(316) Stainless steel tubings

VCR Connectors

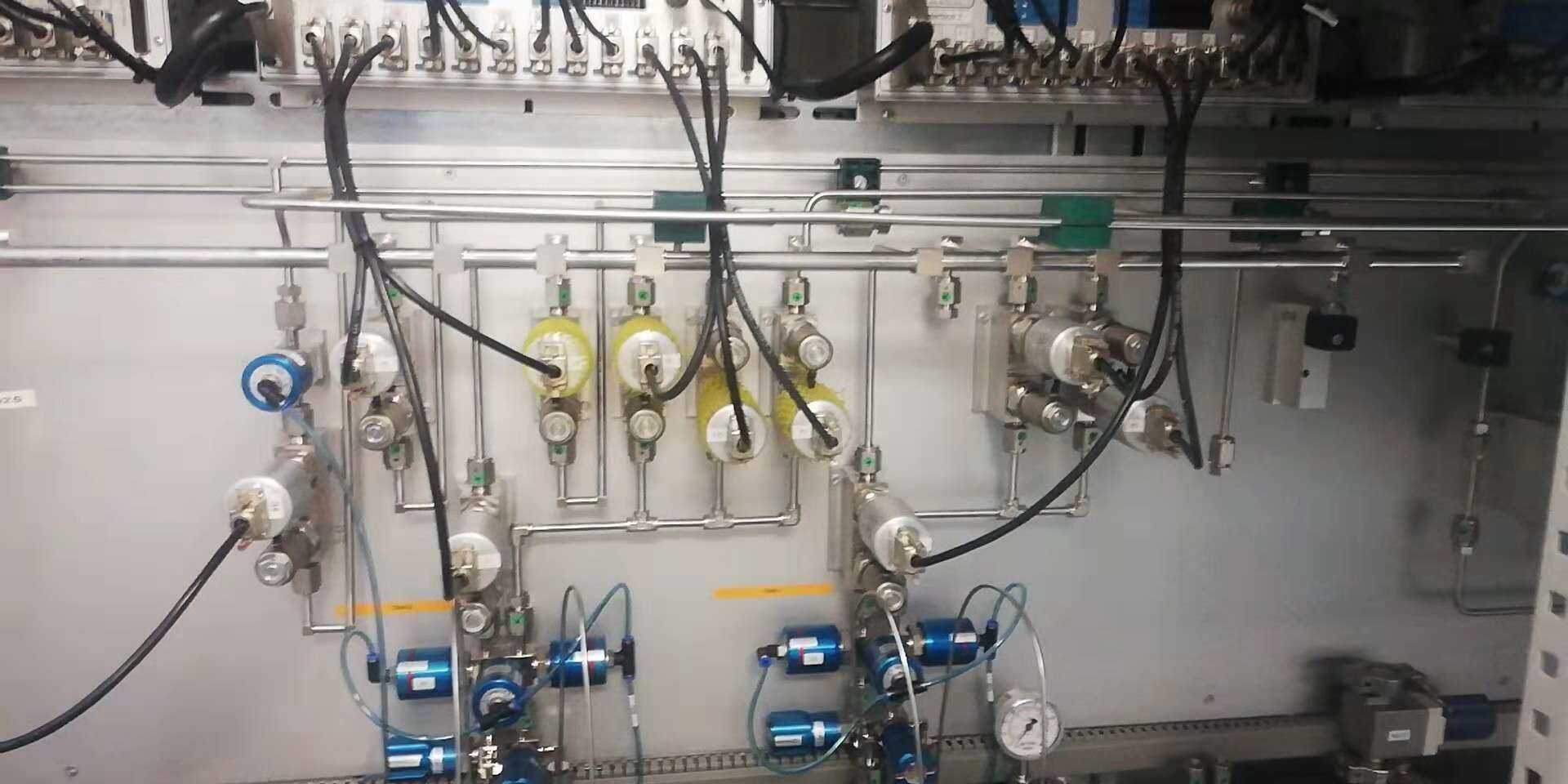

Electronic mass flow and pressure controllers

Susceptor / Ceiling:

High purity graphite with special coating

Rotating substrate holder (Gas foil rotation)

Heater: RF Induction heater 2 x 80 kW, 20-50 kHz

Maximum reactor temperature: 1600°C

Pressure range for process: 100-1000 mbar for overall flows < 100 slm

MO Temperature control:

Recirculating controlled temperature baths

Accuracy: 0.05°C

Range: -10°C to +60°C

Mass flow control: Electronic mass flow controllers (HiTec)

Pressure control: MKS Baratrons and valves

Back pressure controllers: HiTec pressure controllers

Conditions (Typical):

Total carrier gas flow at process 80 slm and process gases

Auxiliary lines: 15 slm

Power supply:

Electronic: 22 kVA (Maximum)

Heater: 88 kVA (Maximum)

2012 vintage.

AIXTRON VP 2400HW is a high-with vacuum vapor deposition (PVD) reactor for semiconductor research and development and production. It is equipped with a unique hexagonal chamber design that maximizes usable total capacity and allows rapid exchange of substrates and wafers without additional load/unload steps. The all-tungsten heating shield protects the chamber walls and ensures that they are evenly heated for uniform film deposition. AIXTRON VP 2400 HW is designed to follow industry leading best practices to ensure a stable and reliable vacuum environment. Its temperature-control equipment is integrated into a single-chamber system that allows for uniform deposition across many wafers, as well as optimized deposition uniformity across individual wafers. VP 2400HW features a patented rotating heater block and multiple process chambers, including a main process chamber, a main upstream chamber, and a main downstream chamber. The main process chamber features a central tungsten tube heater, an annular electron cyclotron resonance (ECR) RF source for ionization of process gasses, and cathode power supplies for placement of target materials. Multiple quartz crucibles and isolated gate valves can be used to dispense source material into the process chamber. In addition, VP 2400 HW is equipped with an additional RF source that can be used for electron bombardment of samples. The entire unit is equipped with advanced process software, enabling automated control of process temperature and other parameters. AIXTRON VP 2400HW process software supports processes such as sputtering, LPCVD, MOCVD, ALD, and ECR oxidation monitoring. It provides process end-point monitoring, real-time analysis, and data logging. In addition, AIXTRON VP 2400 HW has the ability to utilize multiple substrates and materials, with a variety of wafer sizes and shapes ranging from 2 to 8 inches in diameter. VP 2400HW also has numerous features for easy operation. Comprehensive and integrated safety systems are incorporated, with automatic shutoff and emergency response alarms and controls. The reactor is designed to be maintenance-free, with easy access for repair and maintenance. The machine is also designed for low power usage and fast operations for efficient use of resources and time. Overall, VP 2400 HW is a high-with vacuum vapor deposition reactor designed for superior performance in advanced semiconductor research and development and production. It is equipped with the latest technologies to ensure accurate and efficient processes and operations. It is fully compliant with safety and environmental regulations, and has a low power usage. As such, AIXTRON VP 2400HW is an excellent choice for those seeking a high-quality and reliable PVD tool.

There are no reviews yet