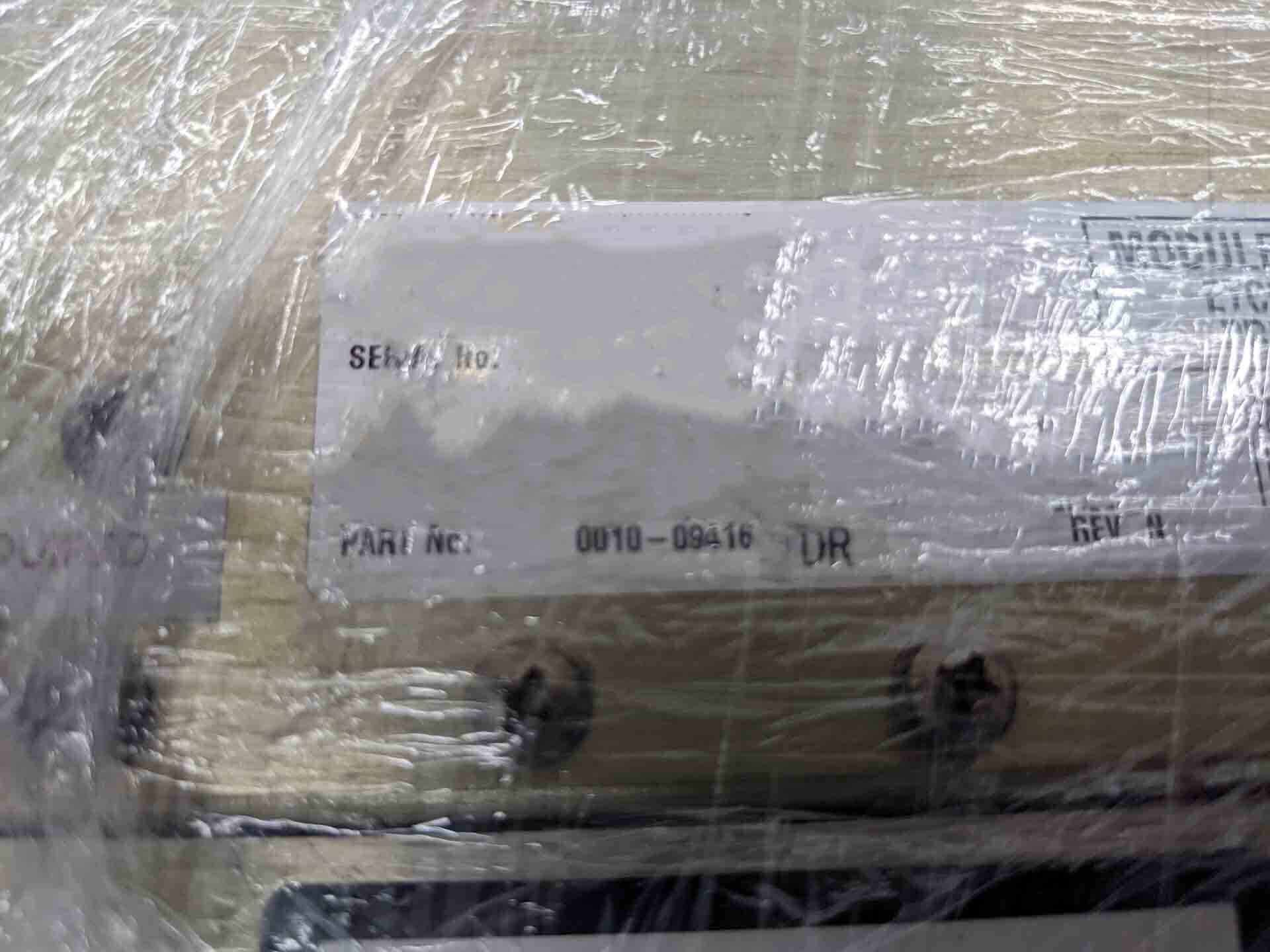

Used AMAT / APPLIED MATERIALS 0010-09416 #293602319 for sale

URL successfully copied!

Tap to zoom

AMAT / APPLIED MATERIALS 0010-09416 is a high-performance reactor used for etching and deposition processes. This reactor is designed with a pre-programmable production etch process that is both efficient and accurate. With this model, users can achieve fast and repeatable results with minimal set-up time. The reactor is made up of a stainless steel frame with quartz walls and an ionizing temperature controller. This allows for precise control over temperature and humidity, resulting in higher-quality etching and deposition results. Additional features include a variable speed magnetic monitor, an efficient cooling equipment, and an integrated gas inlet control. This control mechanism automatically adjusts for the desired etching or deposition process. AMAT 0010-09416 reactor is compatible with a wide range of materials, including silicon wafers, metals, and insulators. The use of a precise vacuum system ensures uniform etching and deposition results. This is accomplished by controlling the deposition rate and etching rate of the substrate. The unit also offers remote access via Ethernet and USB connection, allowing users to monitor, edit, and trouble-shoot the process remotely. This is an especially useful feature for users working on multiple etching and deposition systems. APPLIED MATERIALS 0010-09416 is a powerful tool for users in production facilities, as it is specifically designed for use in continuous production lines. This reactor is an ideal choice for a variety of etching and deposition processes. It can handle high production volumes while maintaining consistent, dependable results. In summary, 0010-09416 is a high-performance reactor that is well suited to a wide range of etching and deposition processes. Utilizing precise temperature control and a variable speed magnetic monitor, the machine ensures accurate and repeatable results. This reactor is a great choice for users looking for a reliable, high-performance solution for etching and deposition processes.

There are no reviews yet