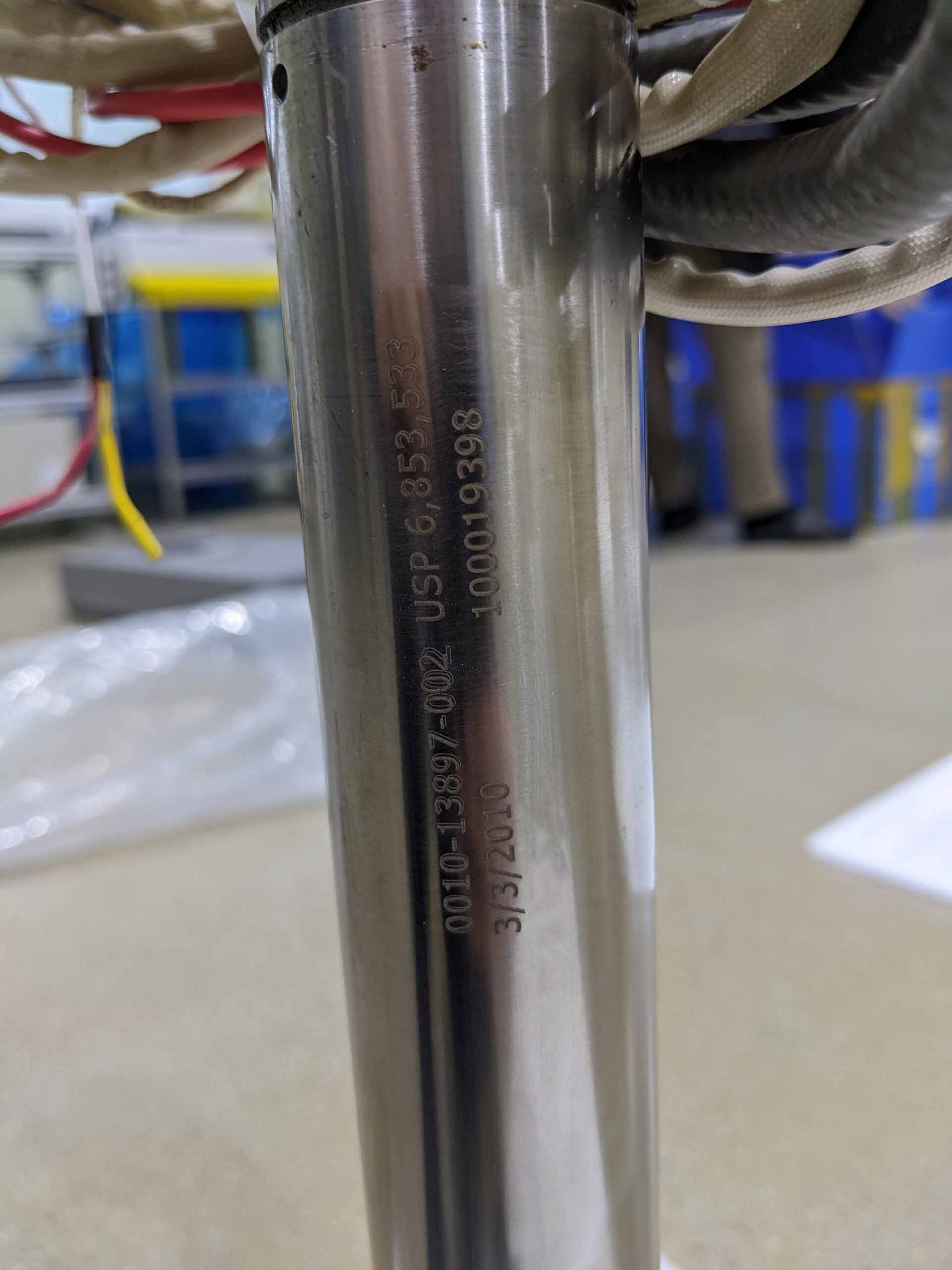

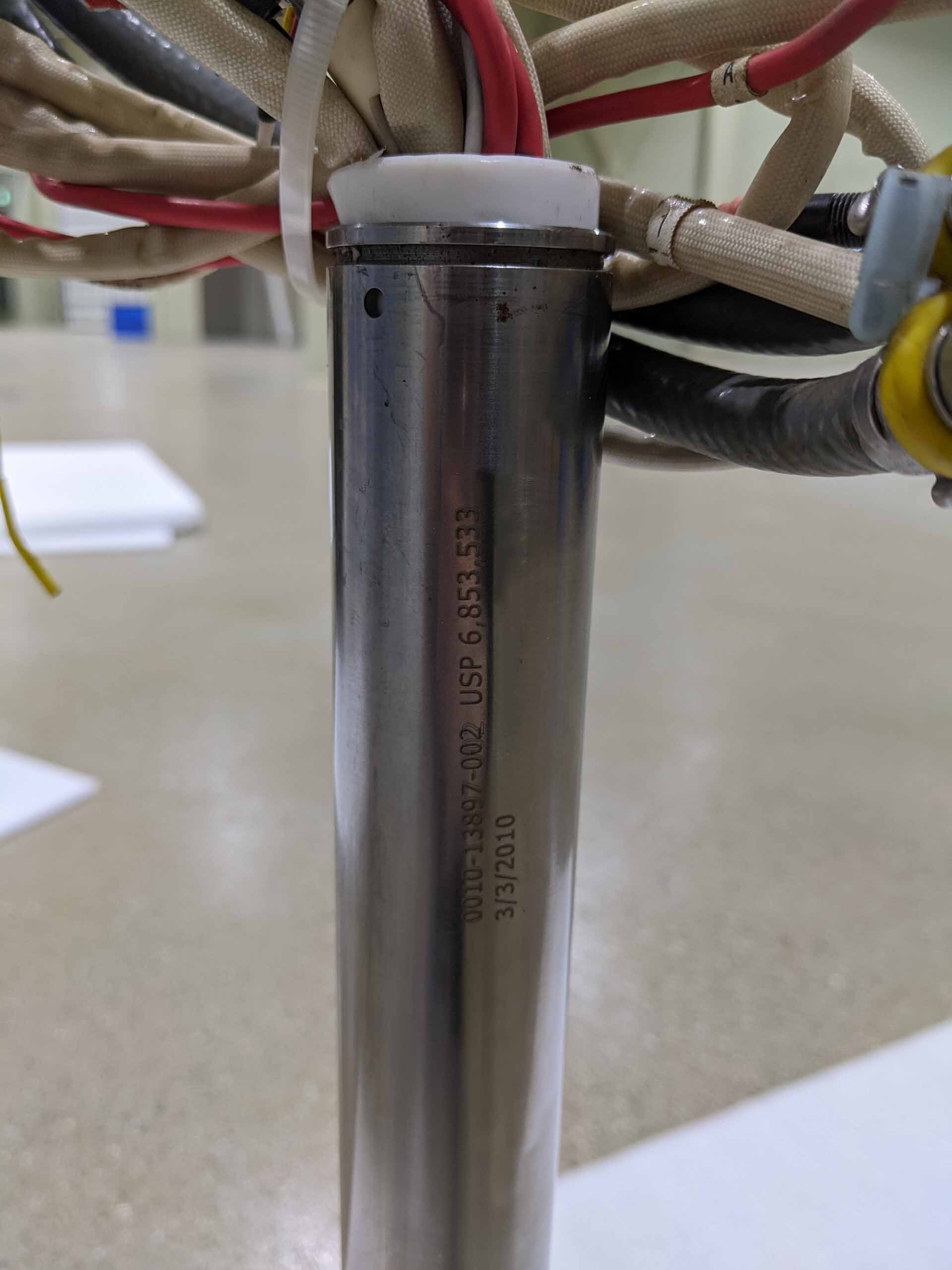

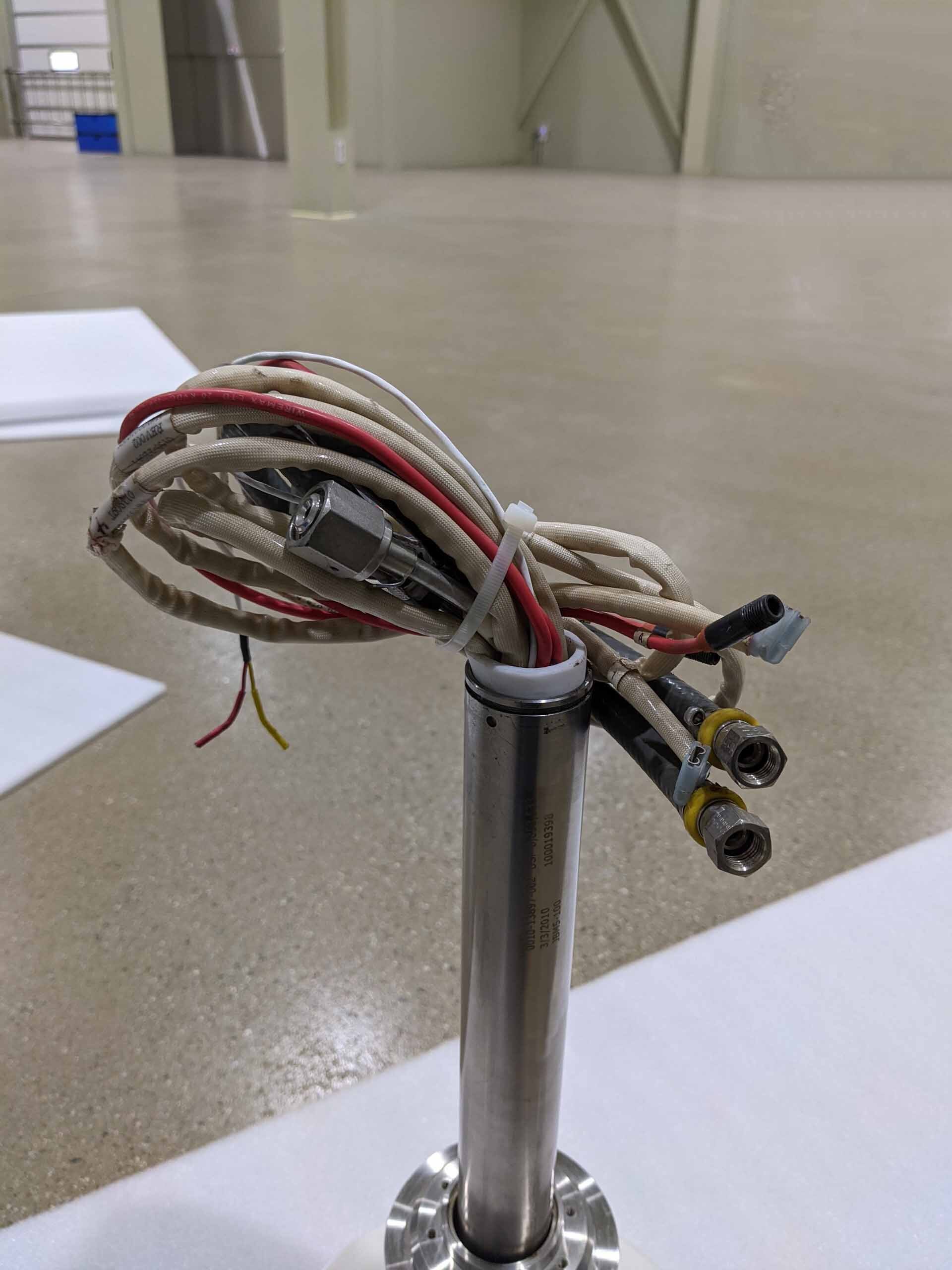

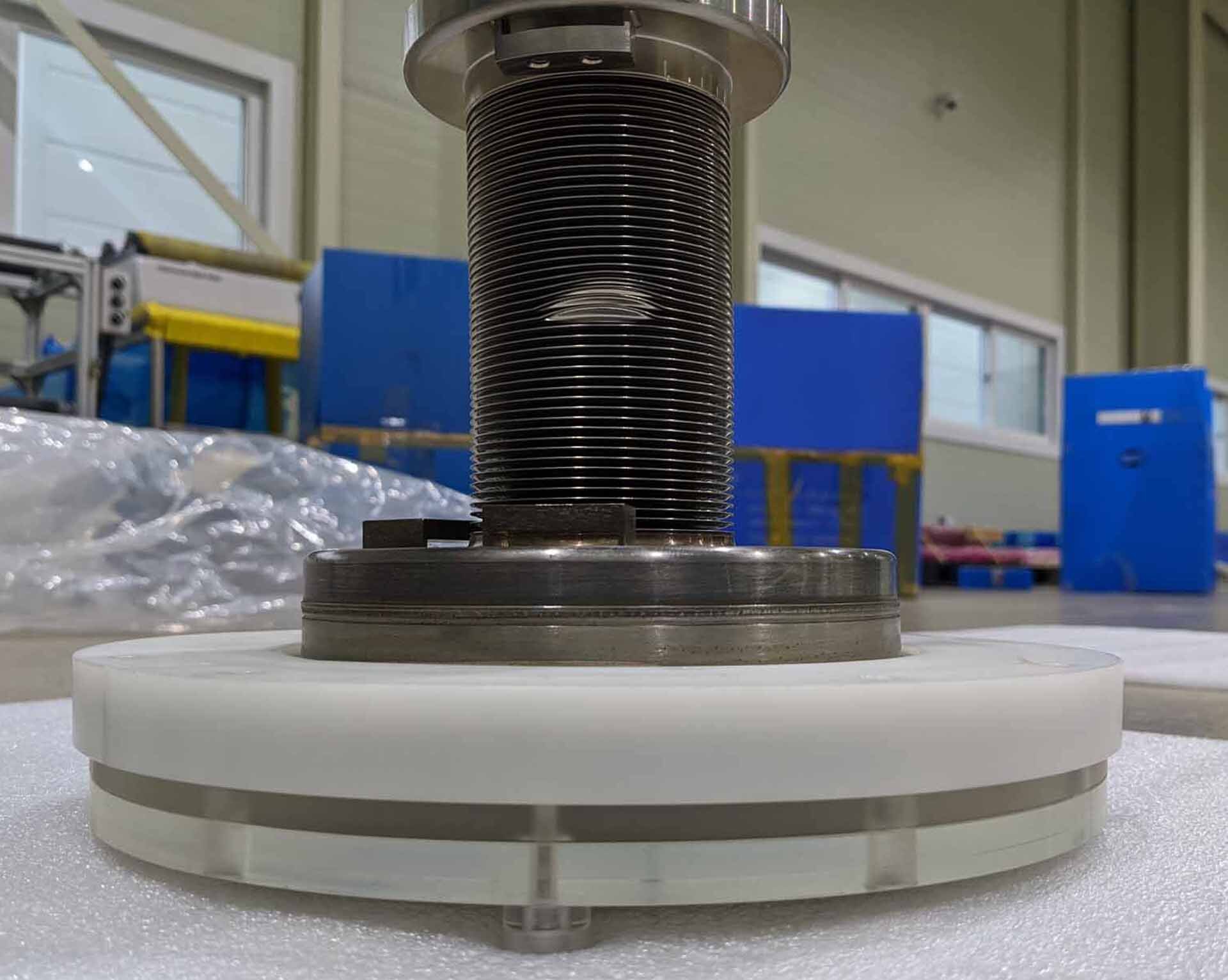

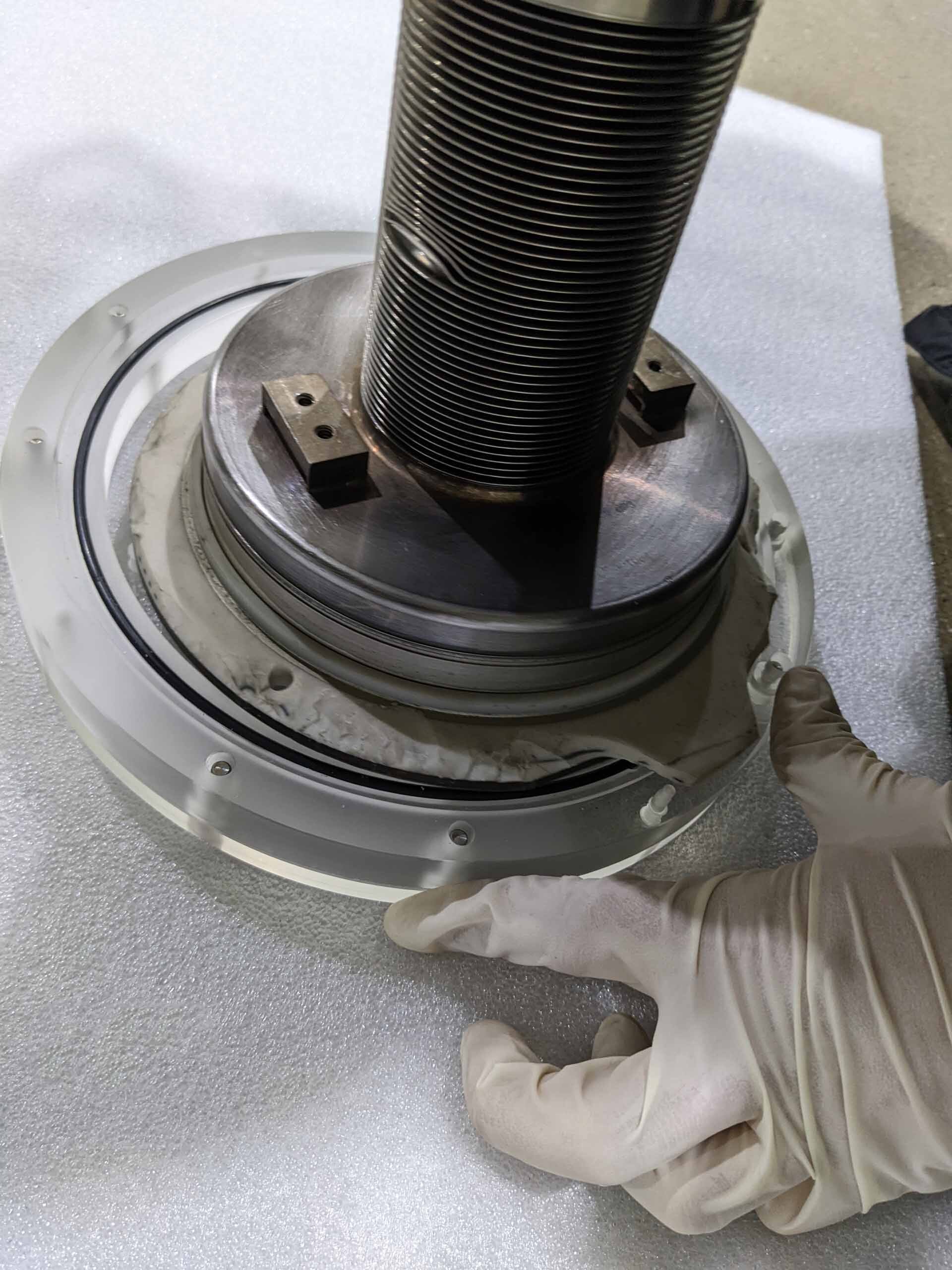

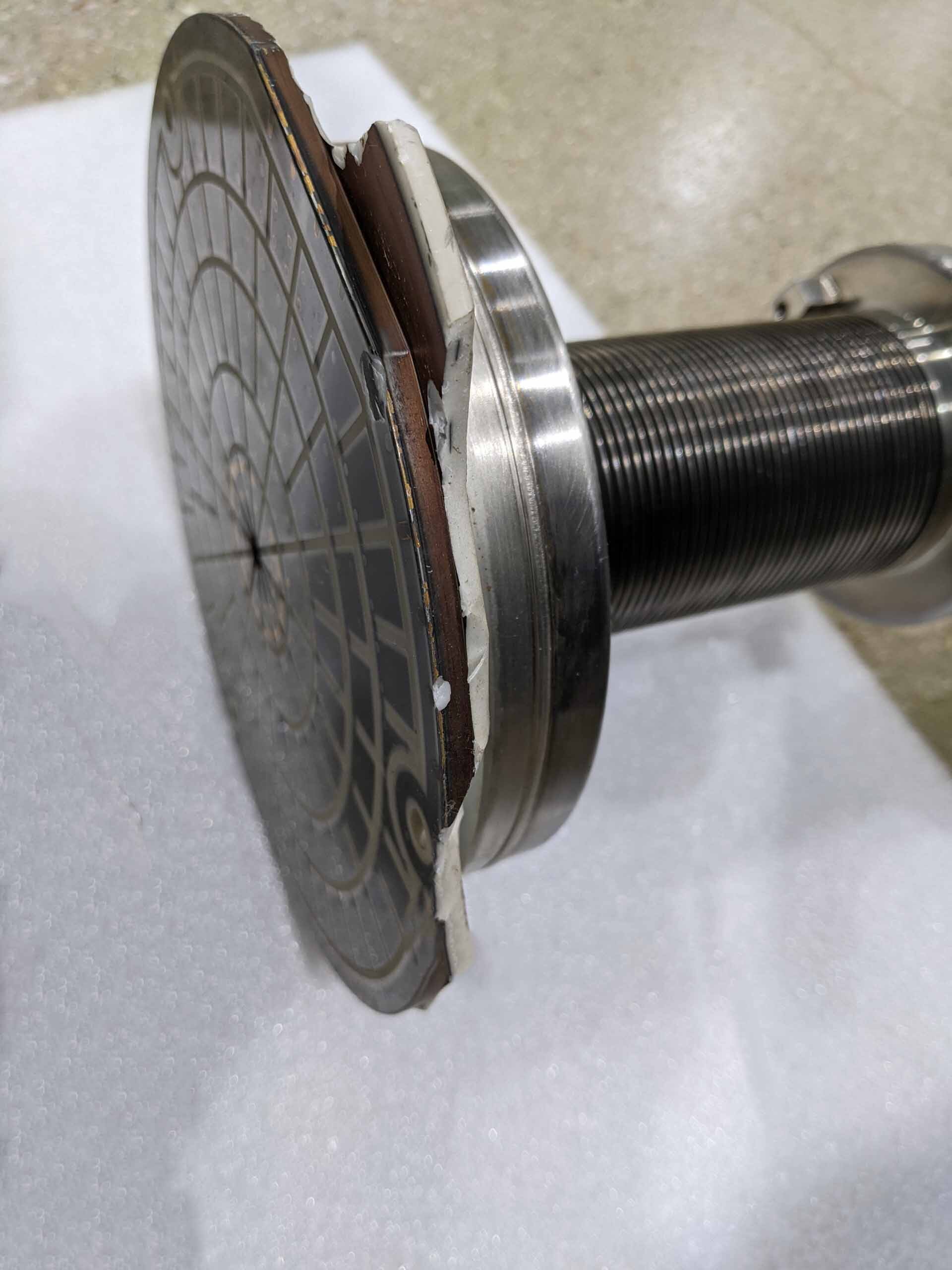

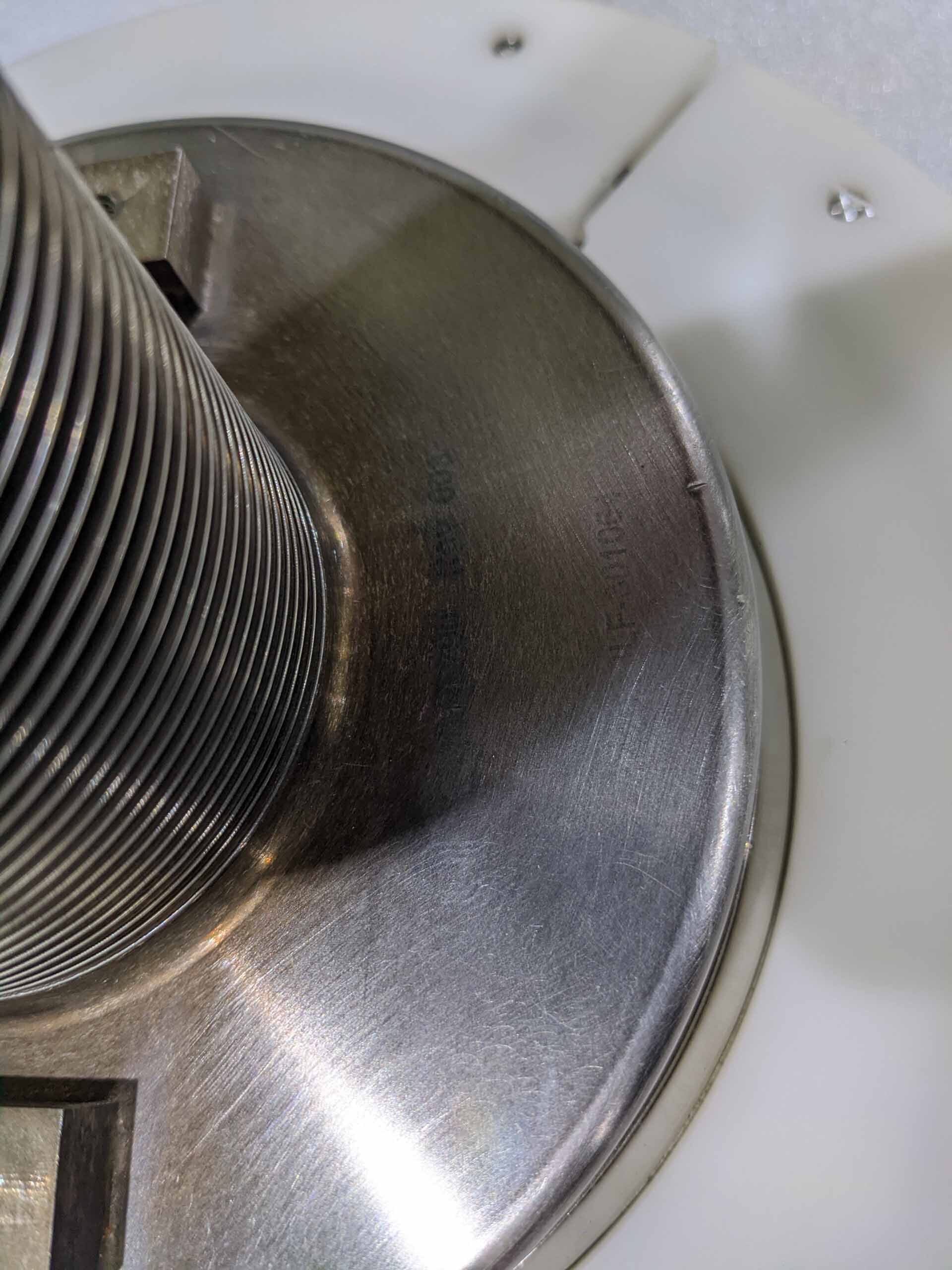

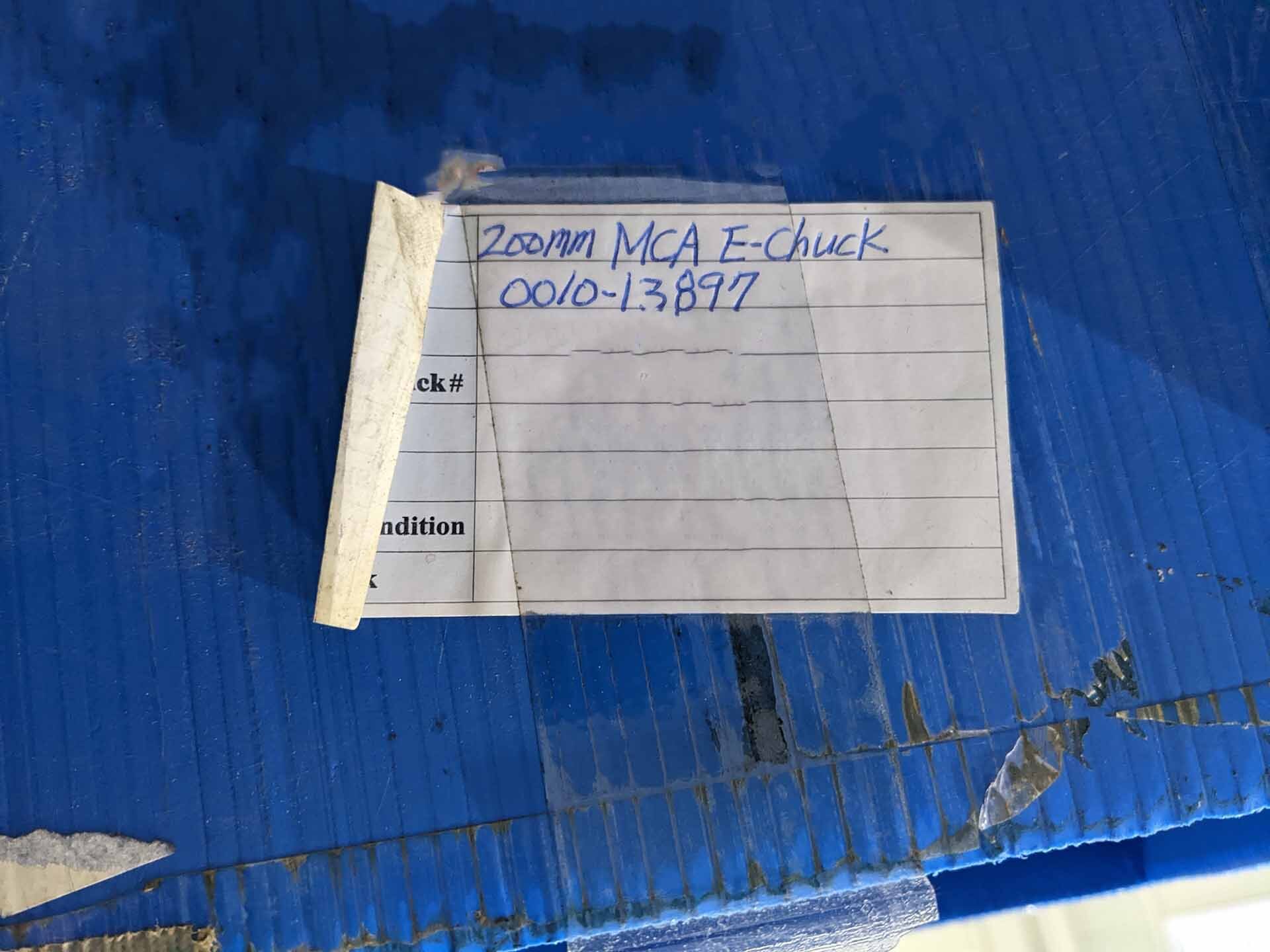

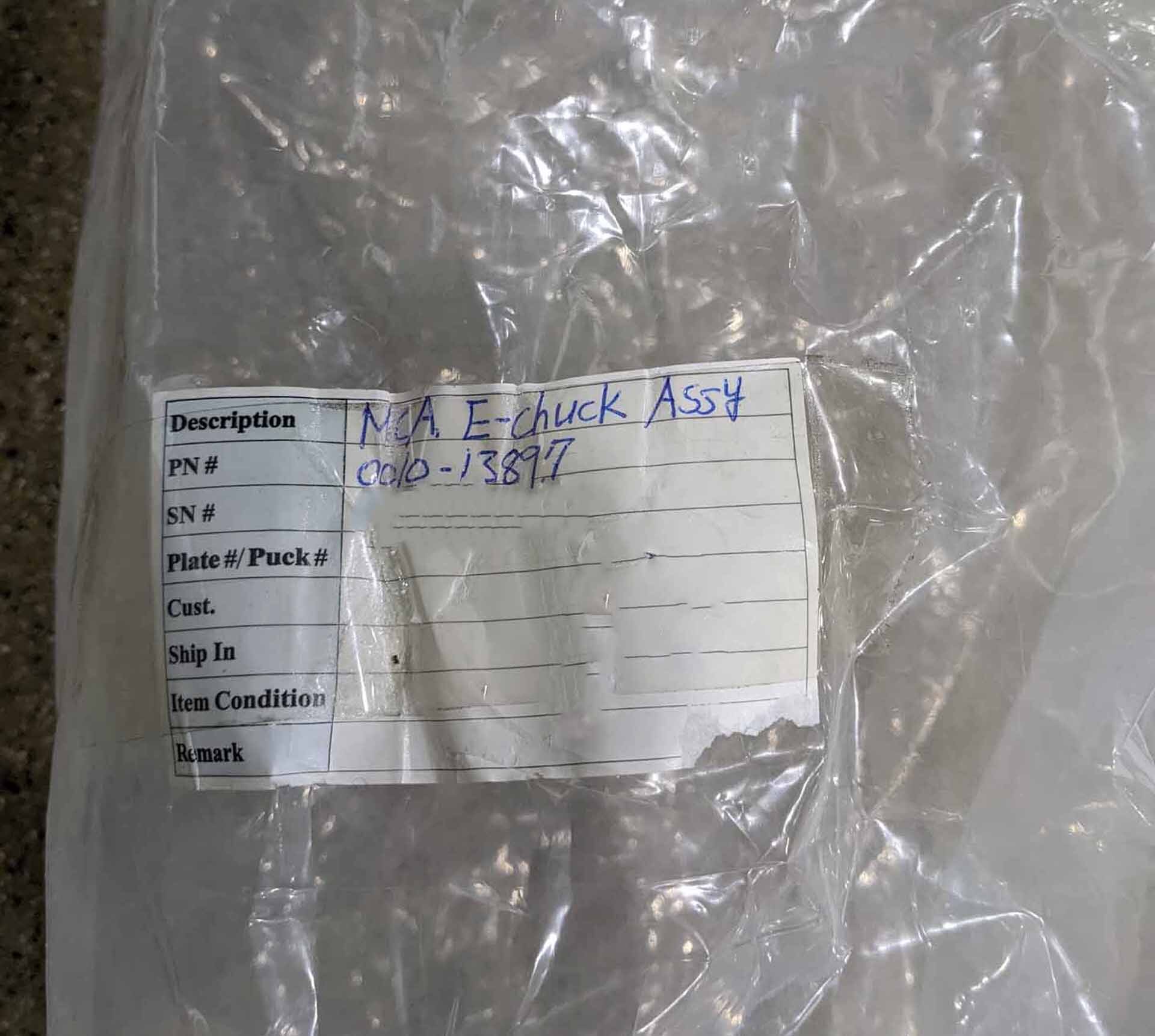

Used AMAT / APPLIED MATERIALS 0010-13879 #293640053 for sale

URL successfully copied!

Tap to zoom

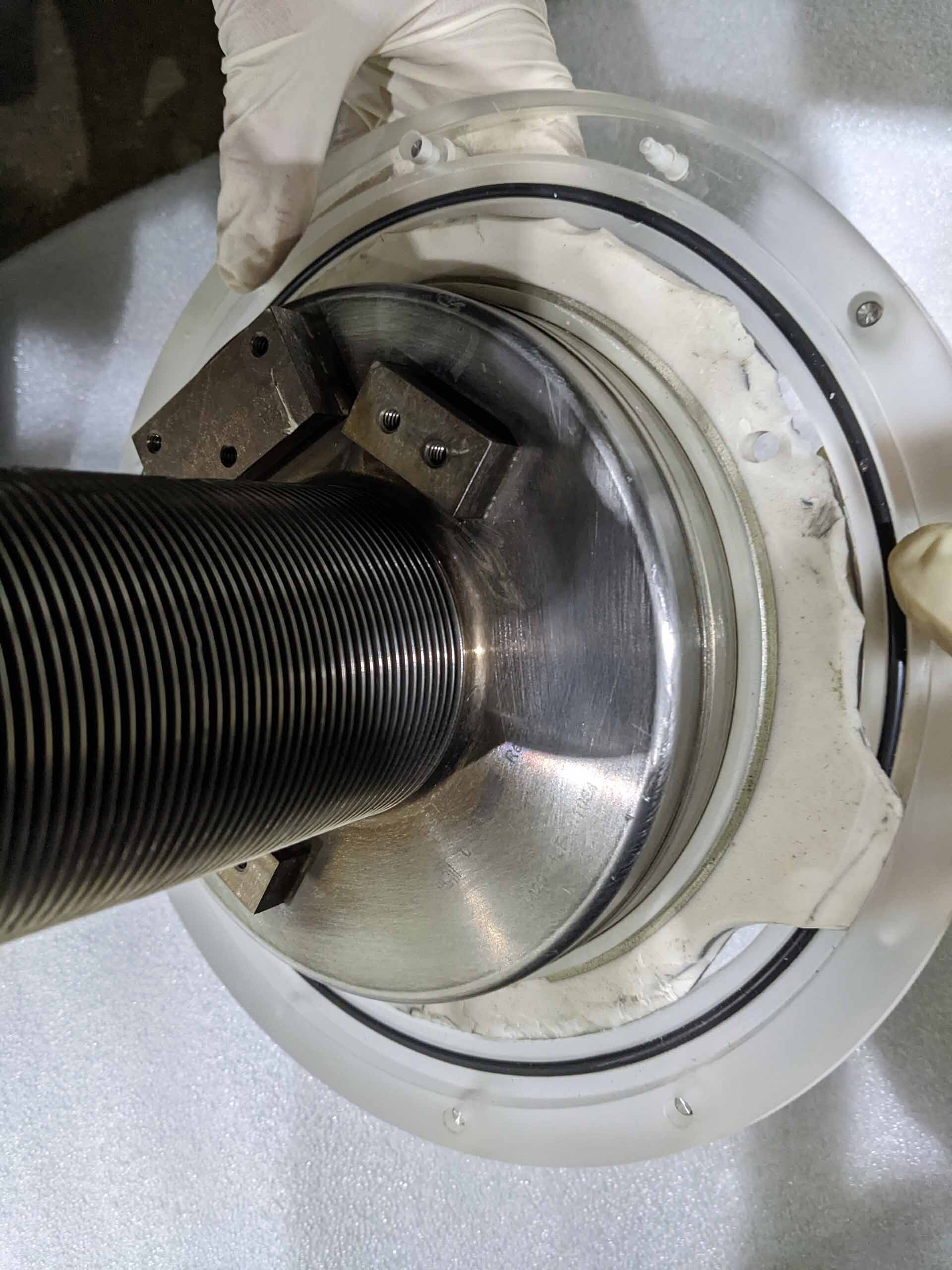

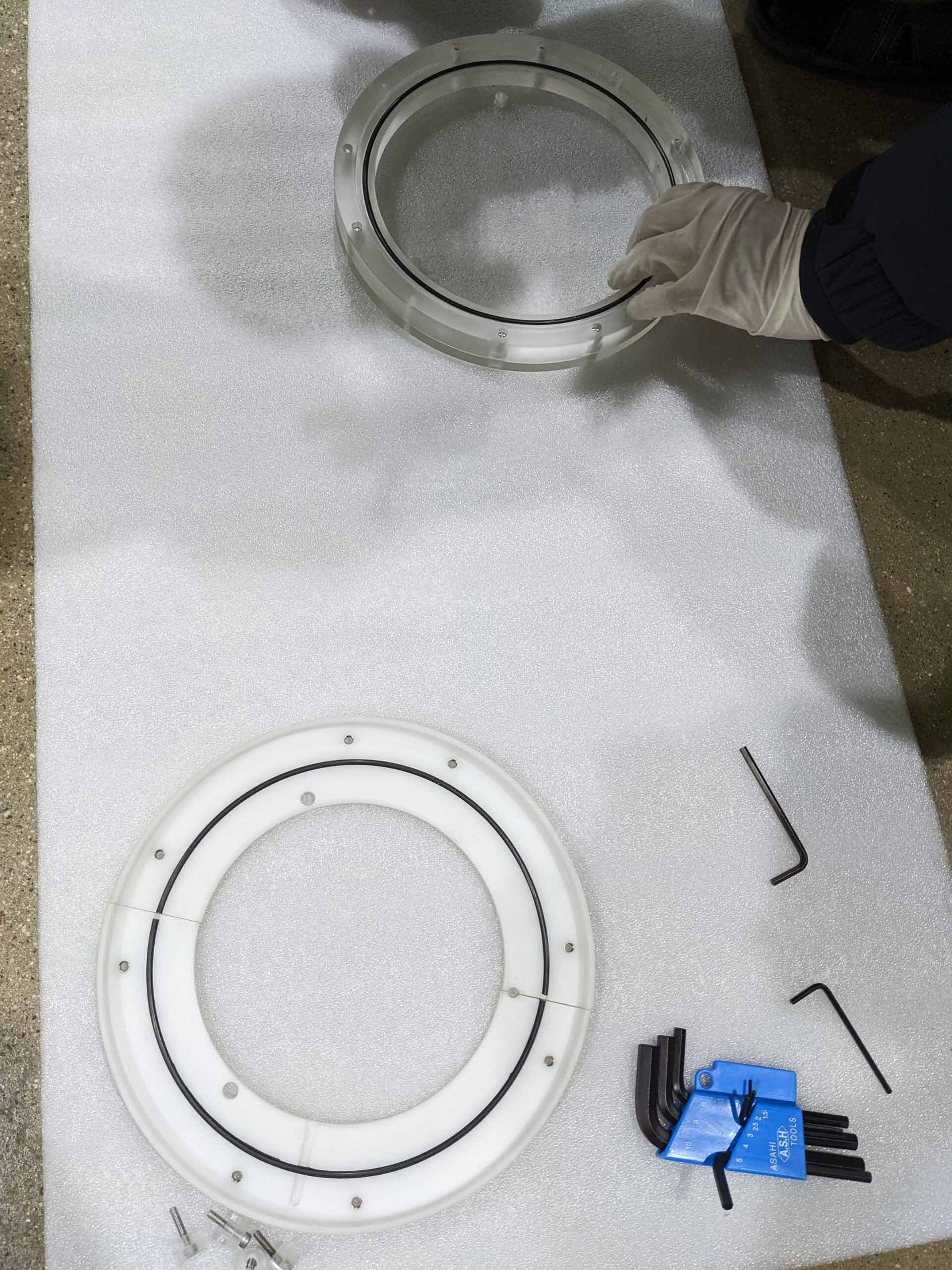

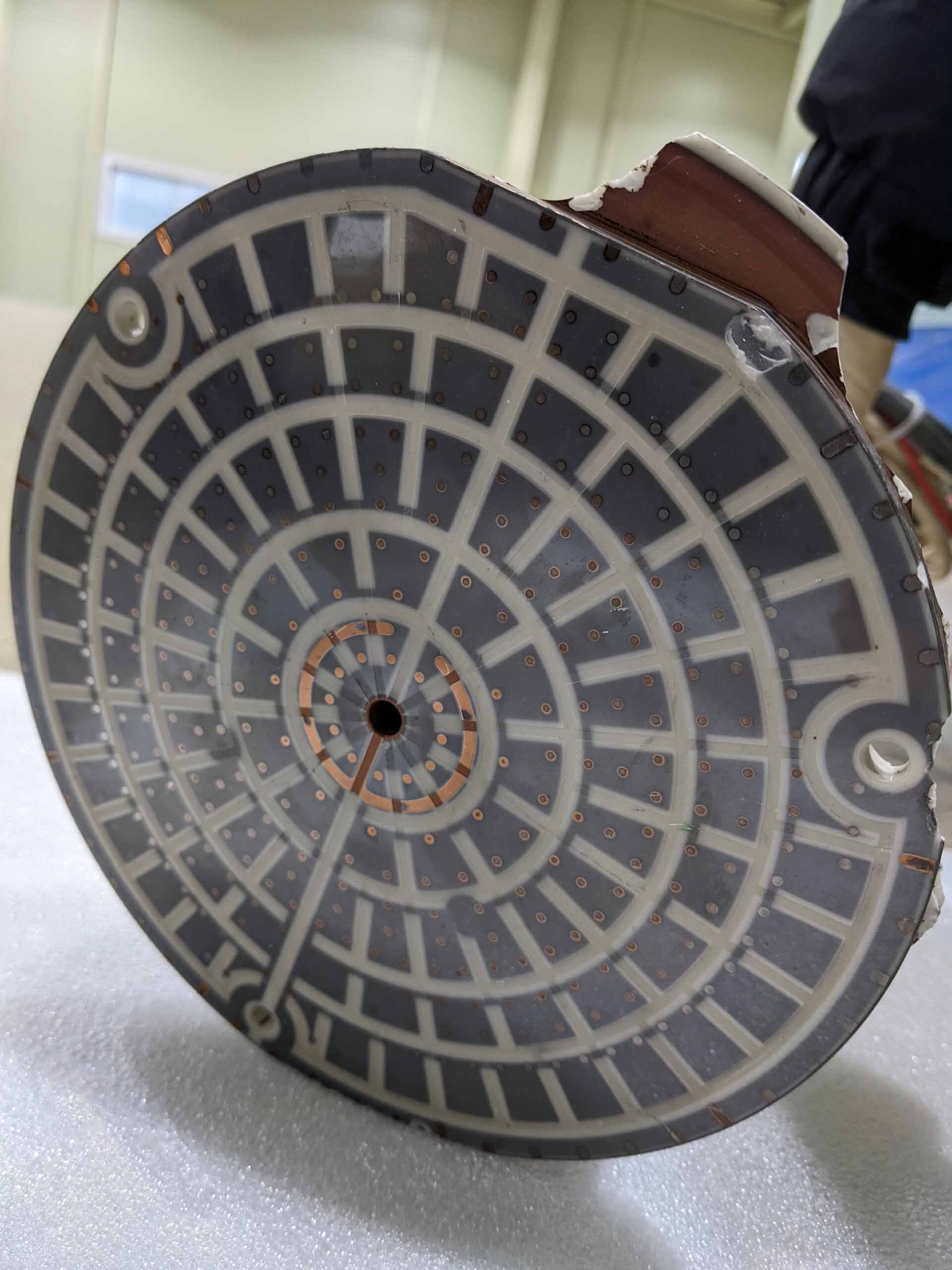

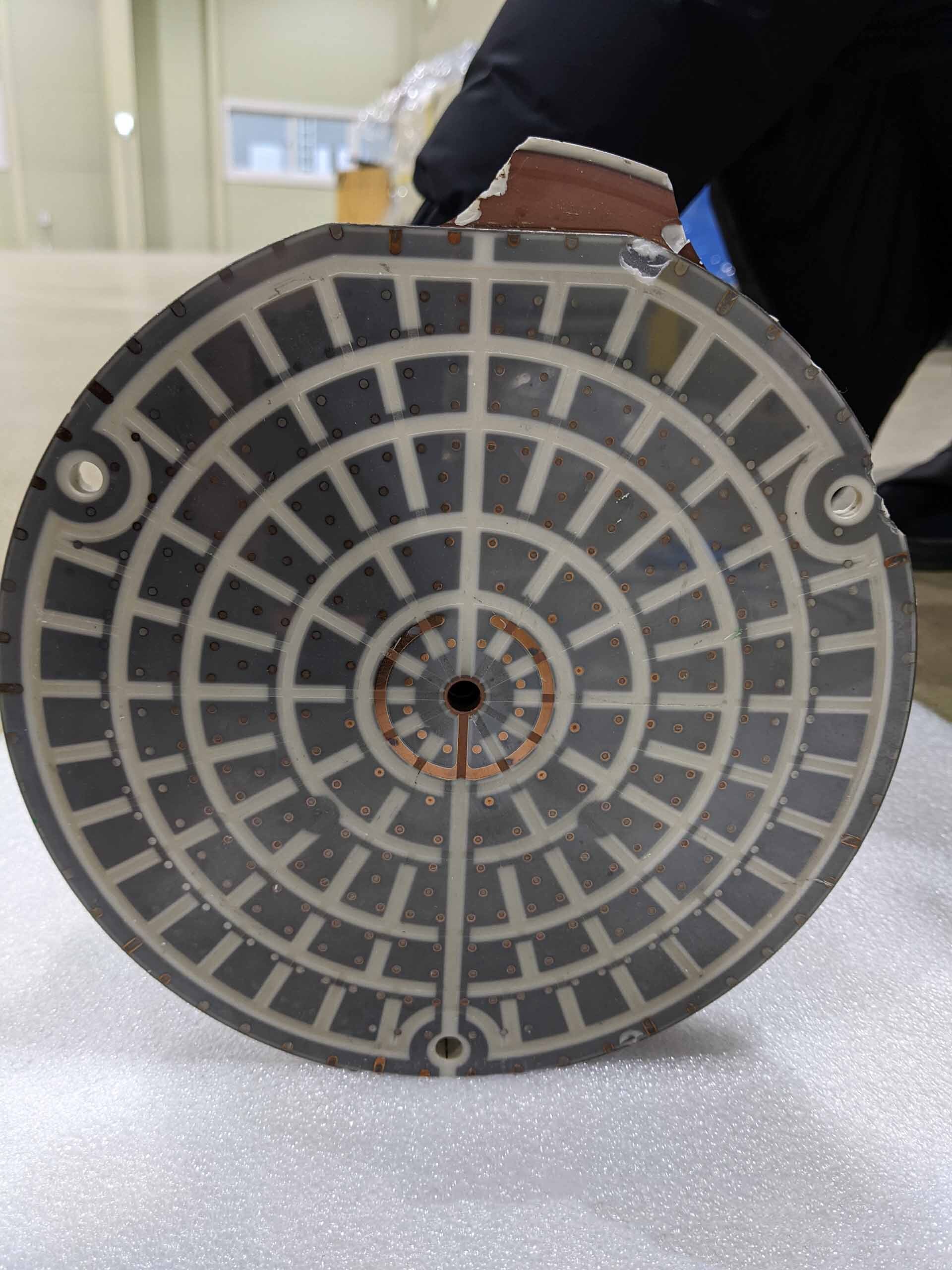

AMAT / APPLIED MATERIALS 0010-13879 is a reactor used for advanced etching and deposition processes for semiconductor manufacturing. It is a parallel plate reactor, a type of reactor frequently used in the production of memory chips and other semiconductor devices. As a parallel plate reactor, AMAT 0010-13879 uses two parallel electrodes which allow for a high degree of control over the deposition and etching processes. The two plates, spaced a certain distance apart, can be controlled separately. This type of reactor works by passing a charged particle beam between the plates, where the beam is then broken up into a plasma of ions. This allows for the deposition of materials on the upper plate, using the lower plate as the substrate, while etching the material on the lower plate. This gives the operator the ability to precisely control the shape, size and composition of the material being deposited or etched. APPLIED MATERIALS 0010-13879 is designed for use with materials that have low melting points and are easily etched, such as silicon and gallium arsenide. The electron beam of the reactor is designed to have a large energy spread, allowing for an exact etching and deposition process, as well as increased uniformity in the control of the process. In addition, the lower plate is cooled in order to reduce the damage caused by the plasma being passed between the plates. This cooling system allows for the highest efficiency operation of the parallel plate reactor, enabling the operator to utilize high power levels without fear of overheating or overloading the system. Overall, 0010-13879 is an advanced parallel plate reactor designed for use in semiconductor production. Its precise control over the deposition and etching processes, combined with its cooling system, makes it an ideal choice for the creation of memory chips and other advanced semiconductor devices.

There are no reviews yet