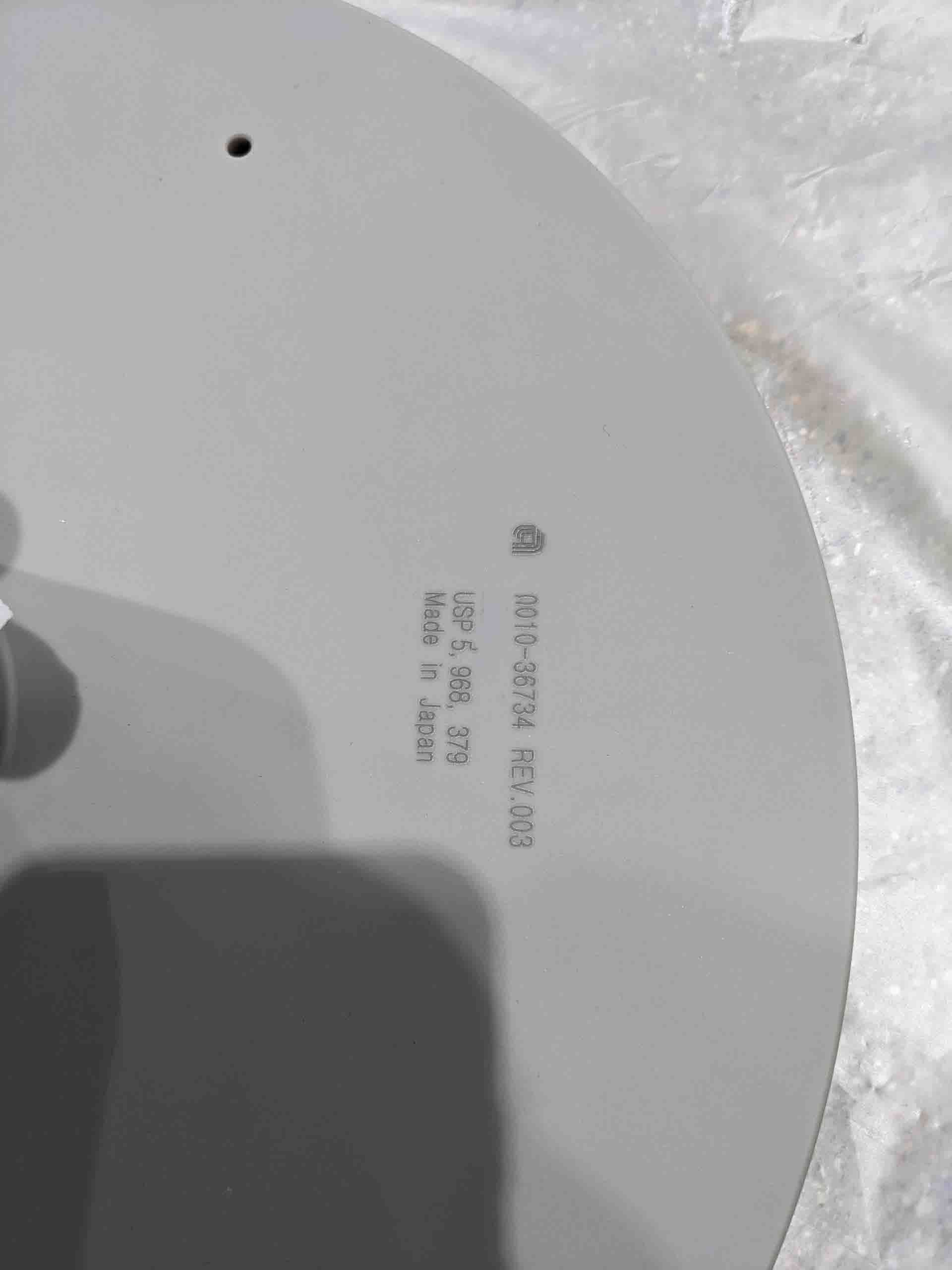

Used AMAT / APPLIED MATERIALS 0010-36734 #293640069 for sale

URL successfully copied!

Tap to zoom

AMAT / APPLIED MATERIALS 0010-36734 reactor is an upgradeable, high-throughput plasma processing equipment. This system is ideal for high-precision etching and deposition applications, including silicon etching and thin film deposition. AMAT 0010-36734 reactor combines advanced control, temperature management, and process control features. This enables rapid cycle times, optimized etch and deposition processes, and repeatable process performance in cleanroom environments. APPLIED MATERIALS 0010-36734 reactor has a process chamber with an internal volume of 27.2 liters and an external size of 827mm (32.5") wide x 1061mm (41.8") deep x 984mm (38.7) high. Included is a 3-zone isolated bi-directional pedestal capable of supporting a range of substrate sizes and shapes, including circular and rectangular substrates up to 200mm (7.9"). It has a maximum process pressure of 200 mTorr and a base pressure of 1x10-8 Torr. 0010-36734 reactor is powered by an onboard SCPI-4 process control module. This module provides extensive support for process parameters, recipe data management, and real-time pump control. There is also an external PC for additional features, including on-the-fly adjustment of process parameters, process monitoring, post-process analysis, and data logging. AMAT / APPLIED MATERIALS 0010-36734 unit is also equipped with a separate high-performance vacuum pump package. This package includes a turbo-molecular pump with a pumping speed of 40 l/s, a pair of roughing dry scroll pumps, and associated controllers. The turbo-molecular pump allows for rapid cycle times and high levels of etch and deposition control, while the scroll pumps optimize the process pressure for precision processing. In addition to the process chamber, AMAT 0010-36734 machine includes several features for optimal process control. These features include an adjustable-flow gas injection tool with two-channel gas control, a dual-zone RF generator with high-power (2.45 GHz) in-situ power measurement, and a two-zone RF generator. The gas injection asset allows for rapid and uniform gas distribution in the chamber, while the RF generators deliver accurate and repeatable plasma power to the target substrate. Finally, APPLIED MATERIALS 0010-36734 model is designed to be upgradeable with additional process modules and components. For example, an additional plasma source, chamber flush, and resistive film sensor can be added to enhance process uniformity and improve etch and deposition control. Overall, 0010-36734 reactor offers high-throughput plasma processing capabilities in repeatable and controlled conditions. With its adjustable-flow gas injection equipment, RF generators, and vacuum pump system, this unit can be used to achieve high-quality etch and deposition results. Additionally, it offers additional process modules, allowing users to customize their machine to fit their specific needs.

There are no reviews yet