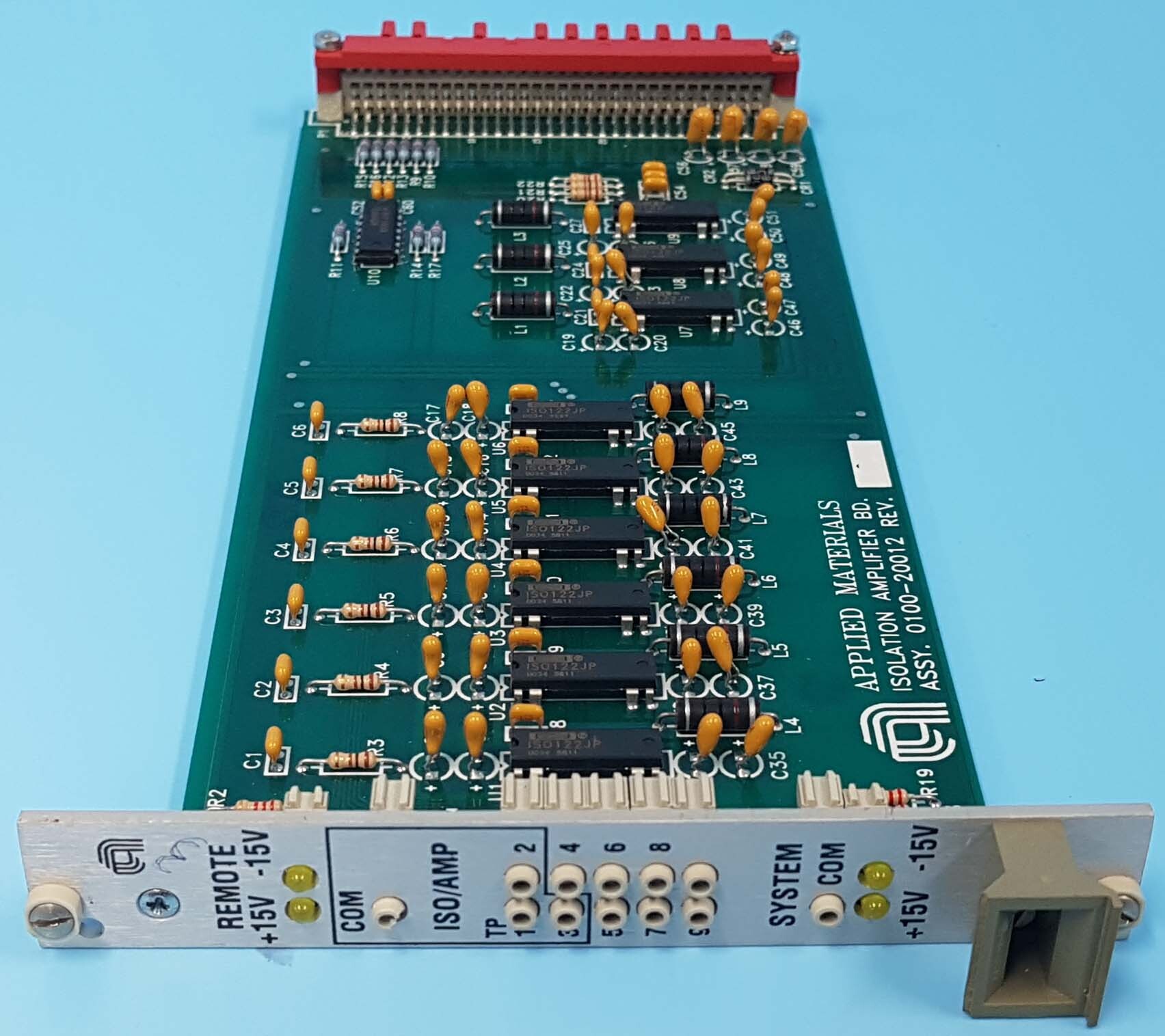

Used AMAT / APPLIED MATERIALS 0100-20012 #293666635 for sale

URL successfully copied!

Tap to zoom

AMAT / APPLIED MATERIALS 0100-20012 Reactor is a robust system developed for use in the production of semiconductor materials. This reactor is specifically designed to enable the production of high-quality, highly precise, uniform, and low-defect wafers and components that are critical in the manufacture of semiconductors for computers, consumer electronics, and other modern technologies. The reactor chamber is an ultra-high-vacuum system designed for reliable, repeatable, and safe operation. It features an advanced diffusion-pump in order to maintain a low-vacuum environment throughout the reacted substrate. This eliminates the need for additional crystallization steps involved in the manufacture of these highly complex semiconductor wafers. The reactor can withstand temperatures up to 1600° C with a low thermal coefficient of expansion. This makes the reactor well-suited for operation in a high-vacuum environment with high-temperature and high-pressure reaction processes such as for epitaxial growth, high-temperature diffusion processes, or thin-film deposition. The reactor is also capable of achieving a pressure close to atmospheric pressure with low, power-efficient operation, making it ideal for a range of film deposition, growth, and etching processes. The feedstocks used in AMAT 0100-20012 reactor can be either solid-state or gas-phase. These materials can consist of antimony, arsenic, boron, copper, gallium, chlorine, lead, and silicon. The reactor is programmed with parameter settings to ensure exacting control over temperature, pressure, and other aspects of the reaction process. It is also equipped with an advanced surface detector to ensure uniformity of the wafer. APPLIED MATERIALS 0100-20012 Reactor is an indispensable tool for semiconductor manufacturing industries. It offers an ideal combination of accuracy, precision, and repeatability,while providing a reliable, safe, and uniform operating environment for the production of quality wafers or device components. By reducing crystallization steps, reducing yields, and increasing throughput, this reactor can help to reduce manufacturing costs and time-to-market for the final product.

There are no reviews yet