Used AMAT / APPLIED MATERIALS 0190-23942 #293662553 for sale

URL successfully copied!

Tap to zoom

ID: 293662553

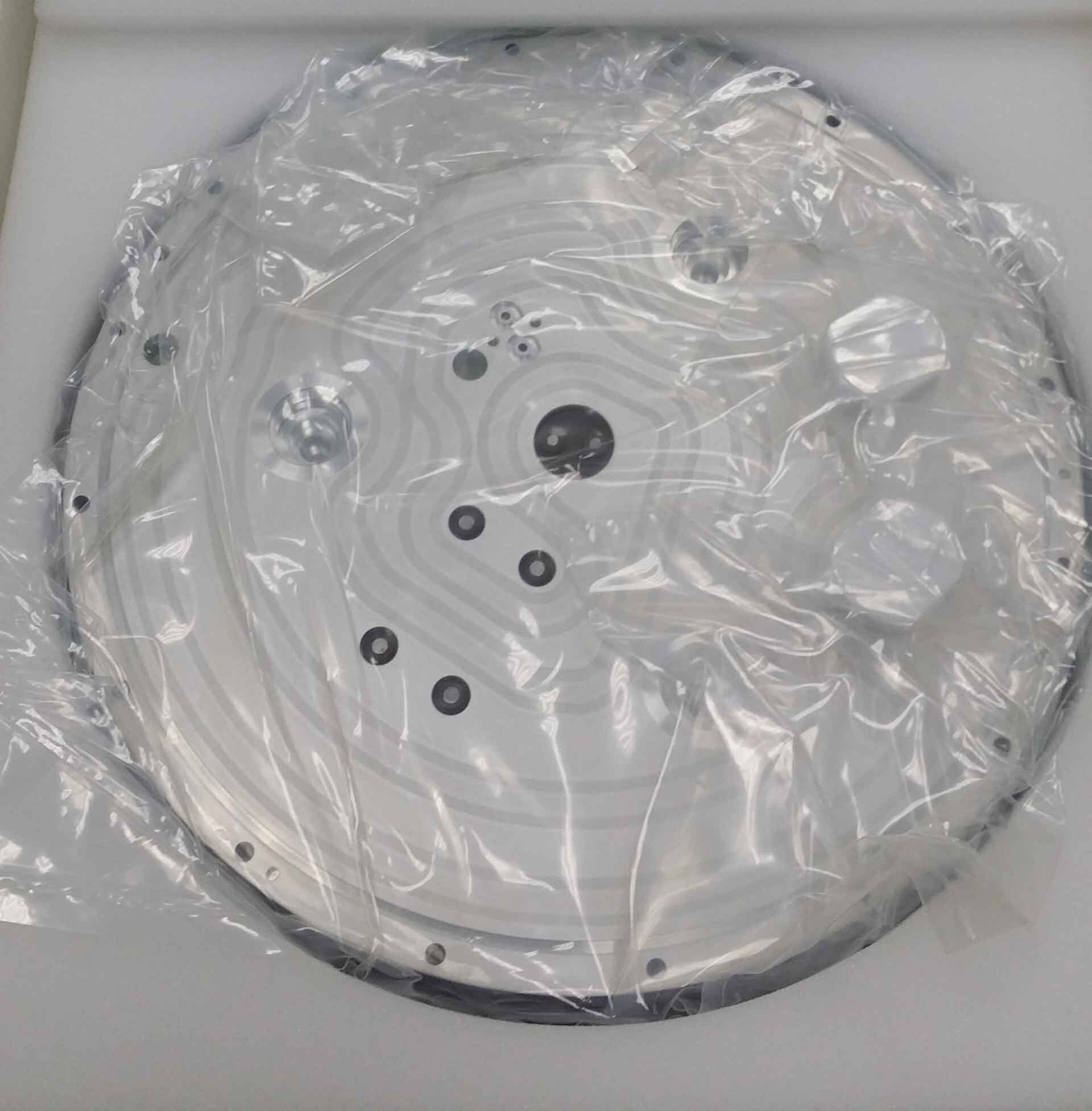

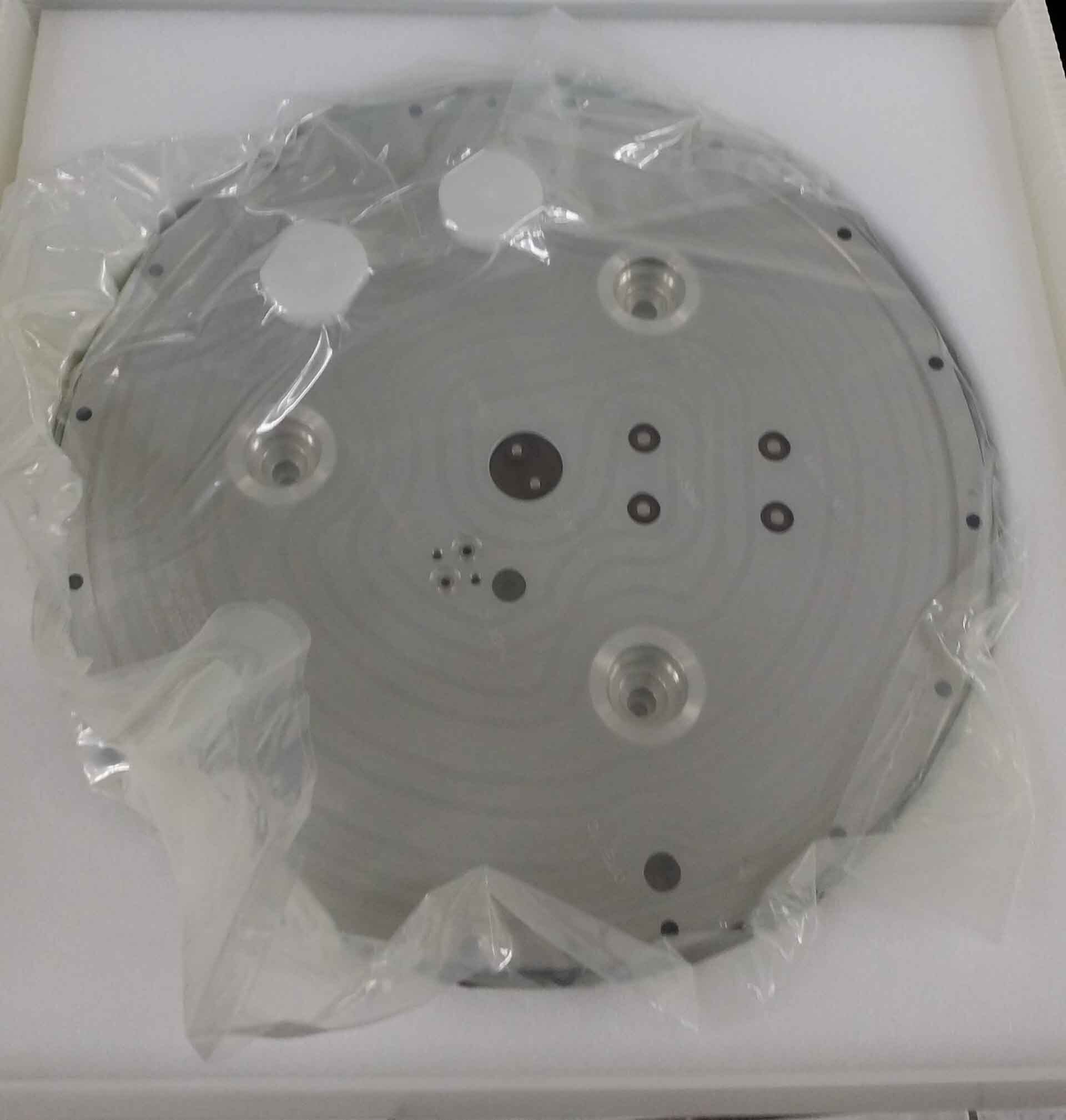

ESC Chuck

Thickness of insulating layer: 302 µm

Surface roughness: 0.5510.15 µm

Dielectric strength voltage: 2kV/60sec

Warp of the chucking surface: ≤ 30 µm

Coaxiality: ≤ 0.003"

Inner heater resistance: 15Ω ± 15%

Outer heater resistance: 16Ω ± H5%

Insulating resistance: ≥1000MQ at DC 1000V

Helium leak rate: ≤ 2.5 sccm at DC- 1800V

Dechucking time: ≤ 5 seconds

Thermal uniformity: 65 points, < 8°C by Integral wafer.

AMAT / APPLIED MATERIALS 0190-23942 is a vertical, single-wafer, atmospheric-pressure, batch, low-pressure chemical vapor deposition (LPCVD) reactor equipment. It is ideal for processing silicon, silicide, nitride, polysilicon, oxide, and other epitaxial device films. This system features fast and efficient processing, delivering high deposition rates with excellent uniformity. It is equipped with a bell-type quartz chamber that ensures superior consistency and control of the deposition gas flow. The reactor also features an enlarged, cylindrical showerhead with four-station gas delivery manifold which helps to evenly distribute the reactor gases to all areas of the wafer. AMAT 0190-23942 is equipped with four gas inputs, allowing for the simultaneous delivery of process gases, enabling fast and accurate film deposition. It is capable of depositing at temperatures ranging from 400°C to 1250°C and pressures as low as 0.5 Torr. In addition, the in-situ heater-bias unit ensures temperature accuracy and consistency of deposition by adjusting the voltage controlled heater. APPLIED MATERIALS 0190-23942 utilizes an automated loadlock unit with two independent chambers for easy transport and handling of wafers. An automated mercury cathode cold wall source supplies reactive gases for deposition. Furthermore, the machine is equipped with a mass flow controller that maintains precise gas flow rates and accurate control of the deposition process. 0190-23942 is ideal for high throughput processing with its rapid weight heating and cooling cycle time, producing LT (low temperature) crystalline material in short manufacturing runs. In addition, it is equipped with Safety and Environment Monitoring Tool that monitors air flow, oxygen levels, temperature, and pressure, helping to ensure continual safety and reliability of operations. This asset is designed to process up to 8" wafers on two levels using a single wafer approach. The model also features advanced process metrology capabilities, including non-destructive analysis where substrate integrity is maintained. Overall, AMAT / APPLIED MATERIALS 0190-23942 is a reliable and efficient LPCVD reactor equipment that is capable of producing high quality and uniform epitaxial device films. It is especially well-suited for silicon, silicide, nitride, polysilicon, oxide, and other film applications.

There are no reviews yet