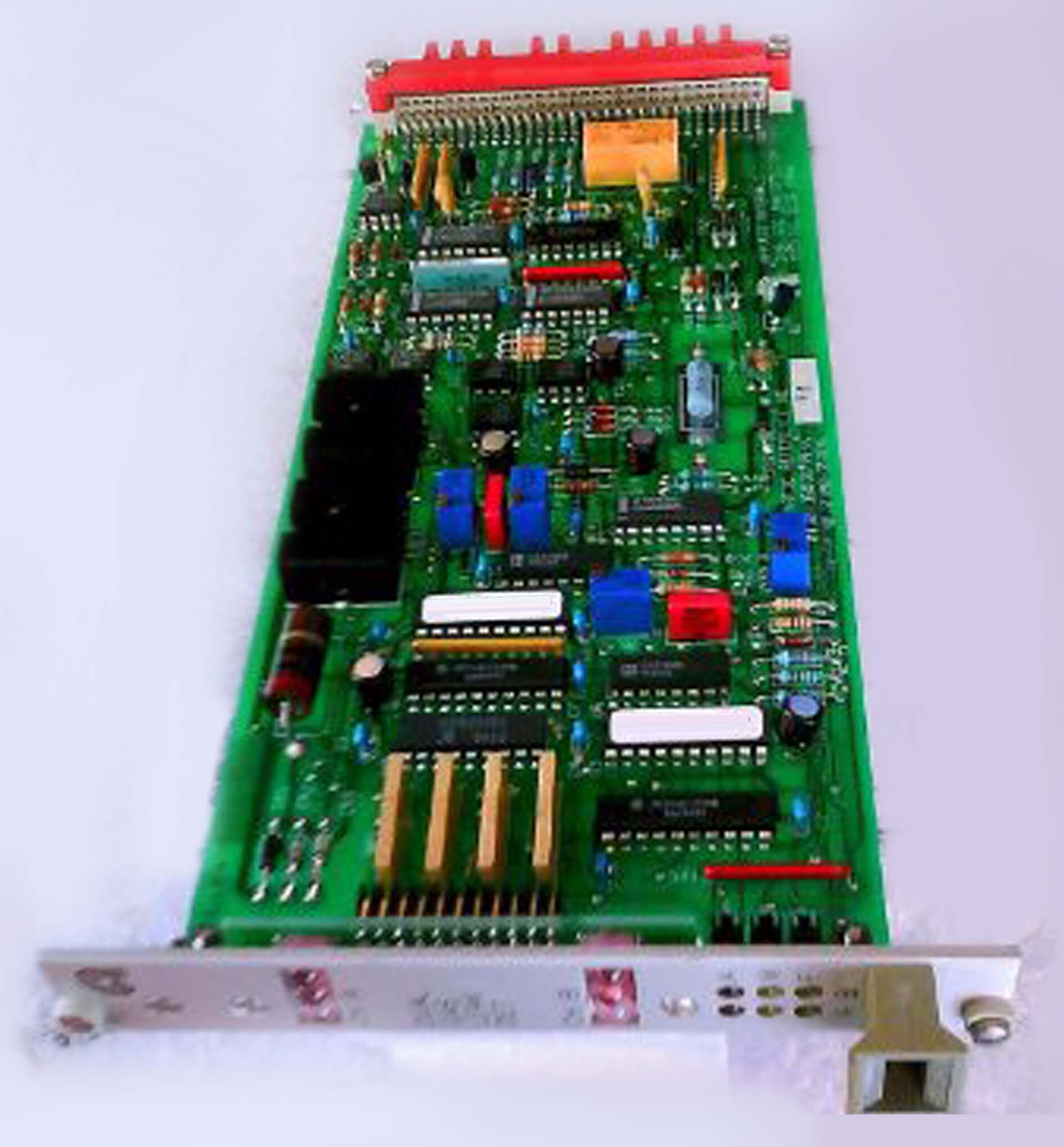

Used AMAT / APPLIED MATERIALS 0190-35066 #293659196 for sale

URL successfully copied!

Tap to zoom

AMAT / APPLIED MATERIALS 0190-35066 Reactor is an innovative and sophisticated reactor used for solid state deposition onto wafers. The reactor is designed to allow uniform deposition of material onto wafers for use in various semiconductor devices. The reactor is capable of significantly increasing the speed and efficiency of the deposition process. The reactor chamber of AMAT 0190-35066 Reactor is a vertical, metallic chamber which is heated by electric resistance. It is a cylindrical chamber made of steel alloy coated with a graphite layer which allows for superior thermal insulation. The chamber also has an adjustable bottom platen and a top gas inlet which connects to a gas distribution plate located at the bottom. The chamber also includes a quartz window which permits direct viewing of the process. APPLIED MATERIALS 0190-35066 Reactor utilizes a Univex XE miniature-scale convection furnace as its source of heat and as a controller for the process. This furnace has an adjustable temperature range ranging from room temperature to 1700°C and is highly accurate with a ±2°C temperature deviation. The chamber also features a wide variety of programmable functions to tailor the reactor to the needs of the user. In addition, 0190-35066 Reactor also features a variety of safety features to ensure user safety. The chamber doors are automatically locked when the temperature exceeds a pre-set limit and the chamber is equipped with sensors which detect any changes in the pressure and flow rate of the furnace gases. A thermal sensor is also present which shuts off the power to the chamber if the temperature exceeds a maximum limit. In addition, the chamber also features adjustable safety timers that automatically terminate the process at the end of a set period of time. Overall, AMAT / APPLIED MATERIALS 0190-35066 Reactor is an advanced and reliable reactor designed to improve the speed and accuracy of the deposition process. Its wide temperature range, adjustable platen, programmable functions, and numerous safety features make it a great choice for those looking to reliably deposit material onto wafers.

There are no reviews yet