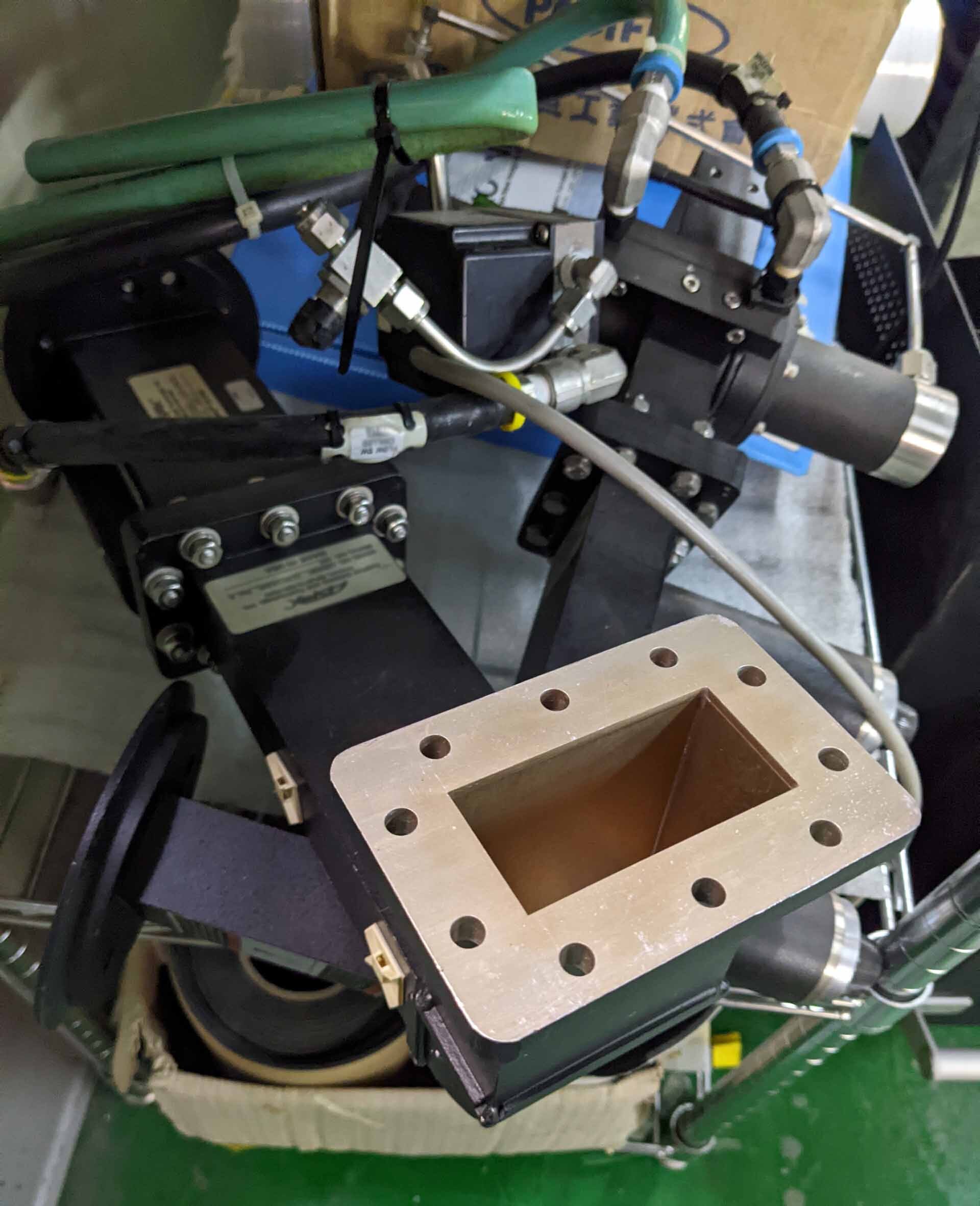

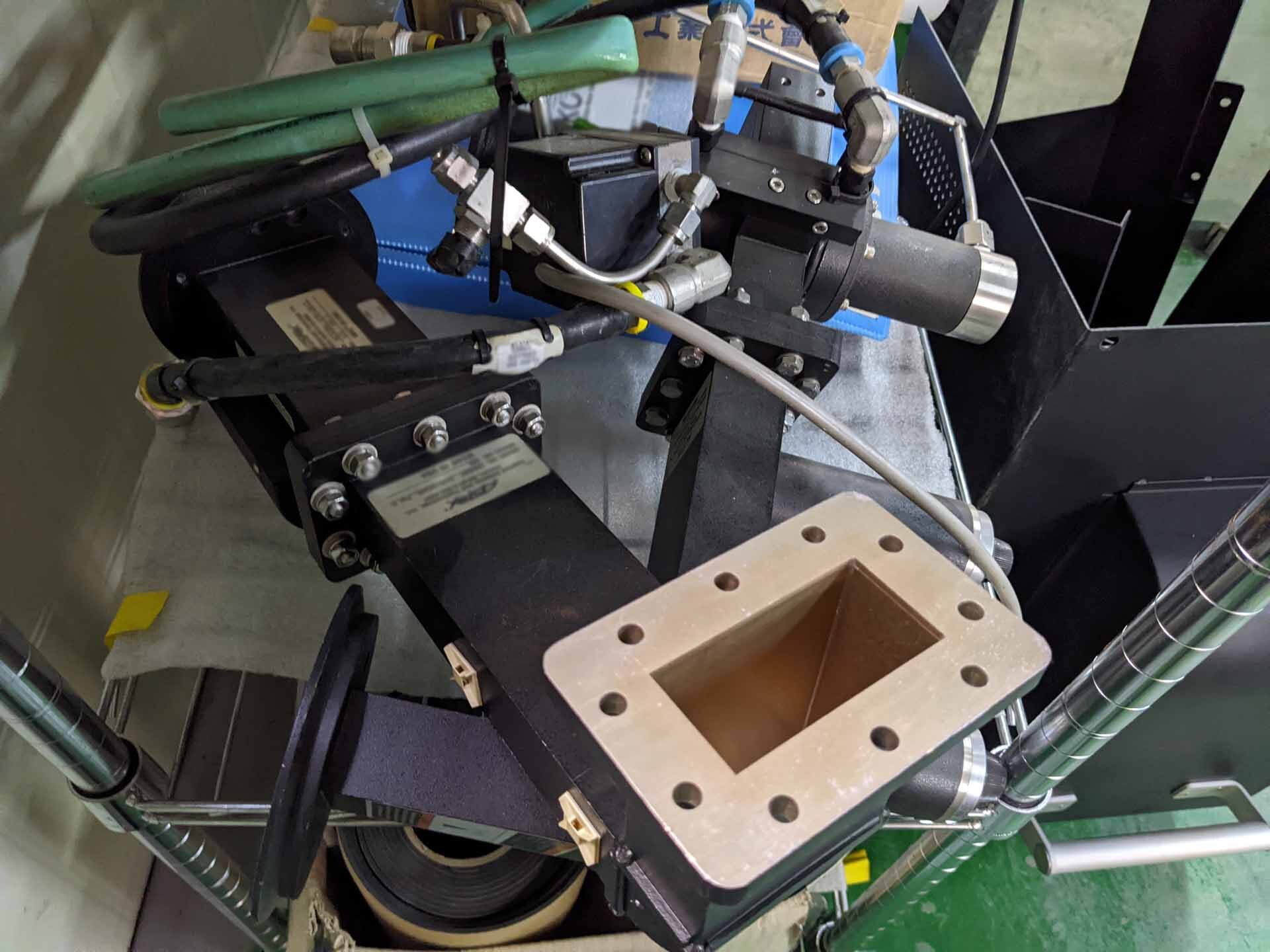

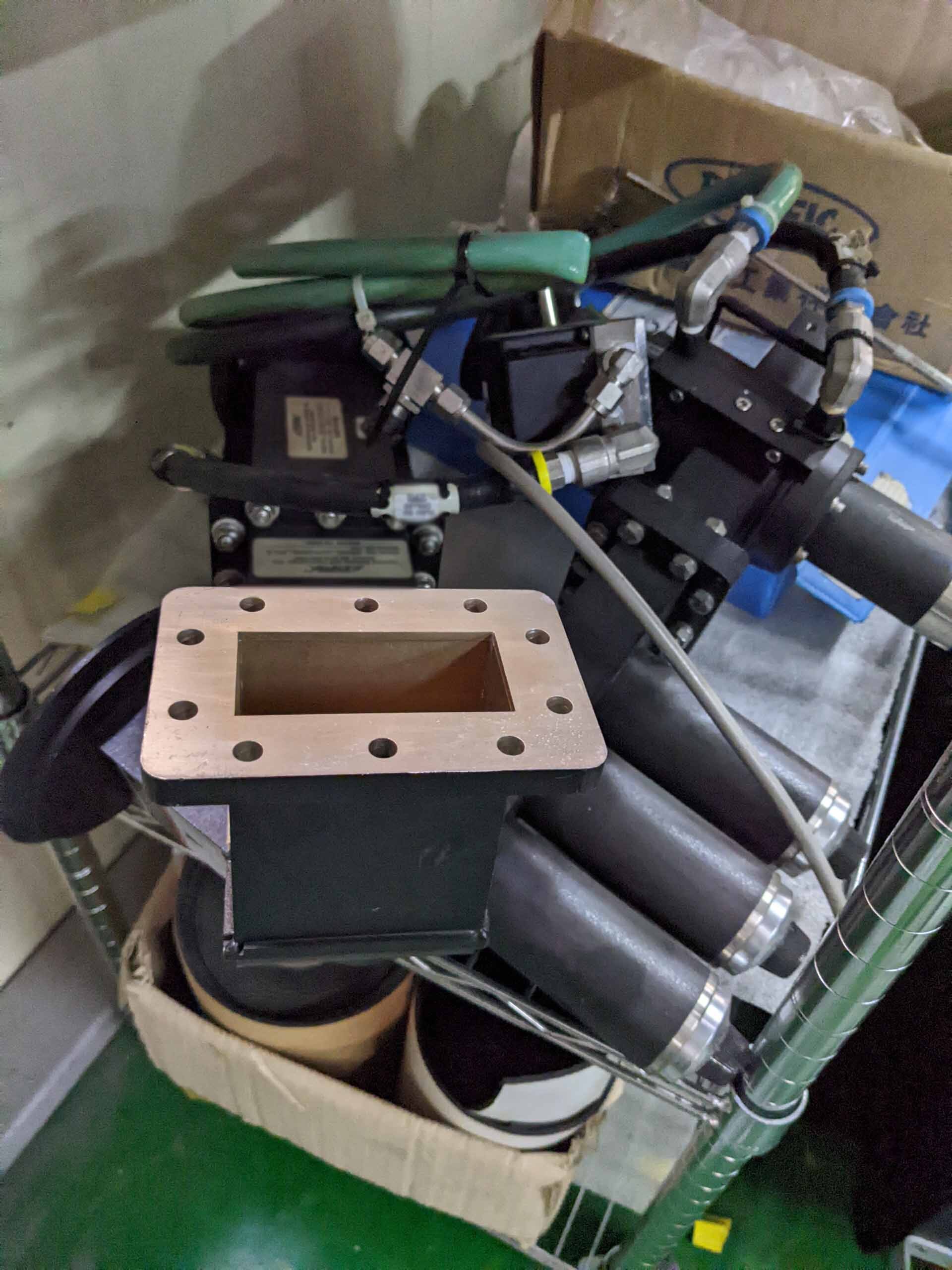

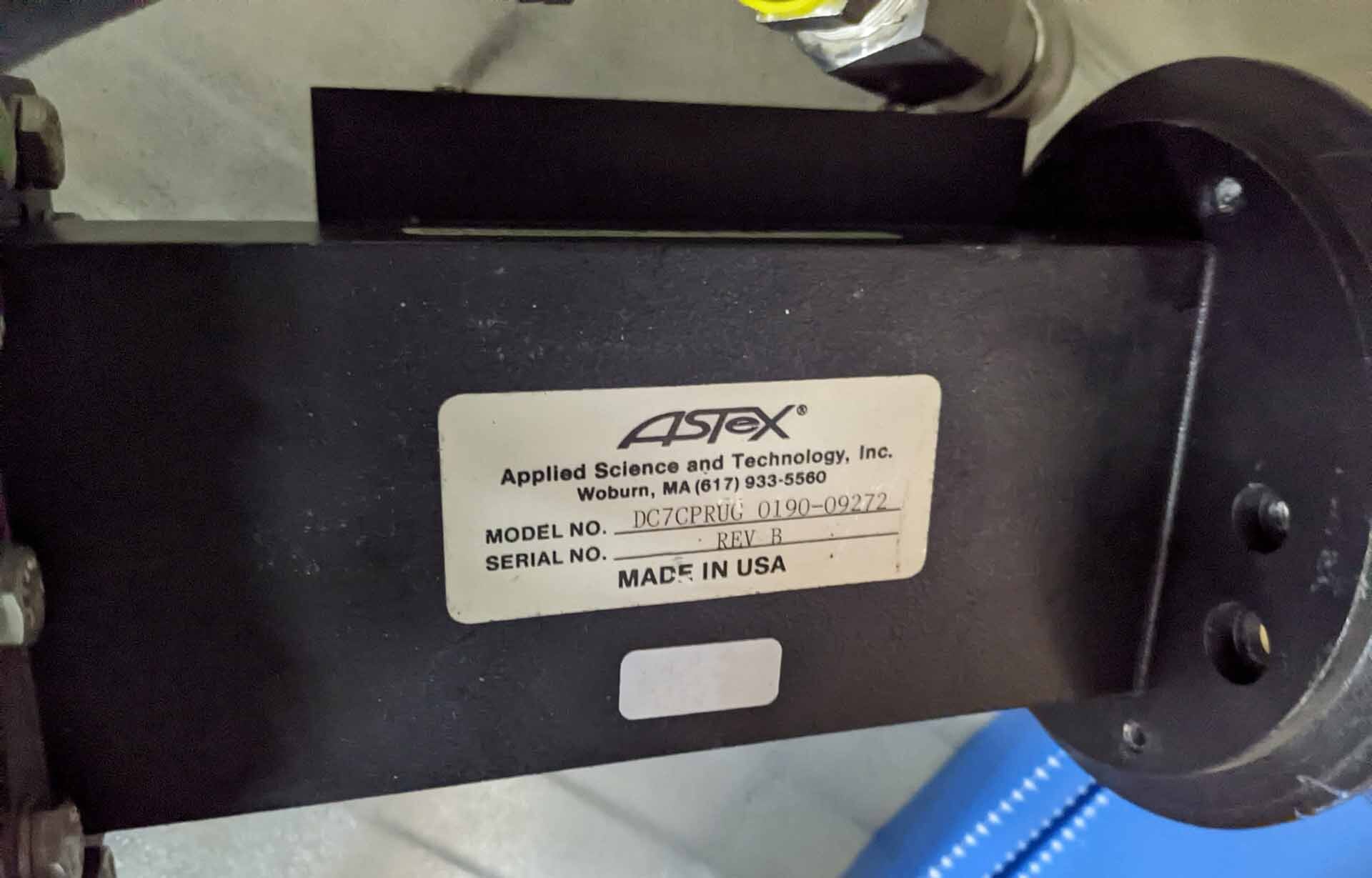

Used AMAT / APPLIED MATERIALS 019009275 / 019009272 #293658103 for sale

URL successfully copied!

Tap to zoom

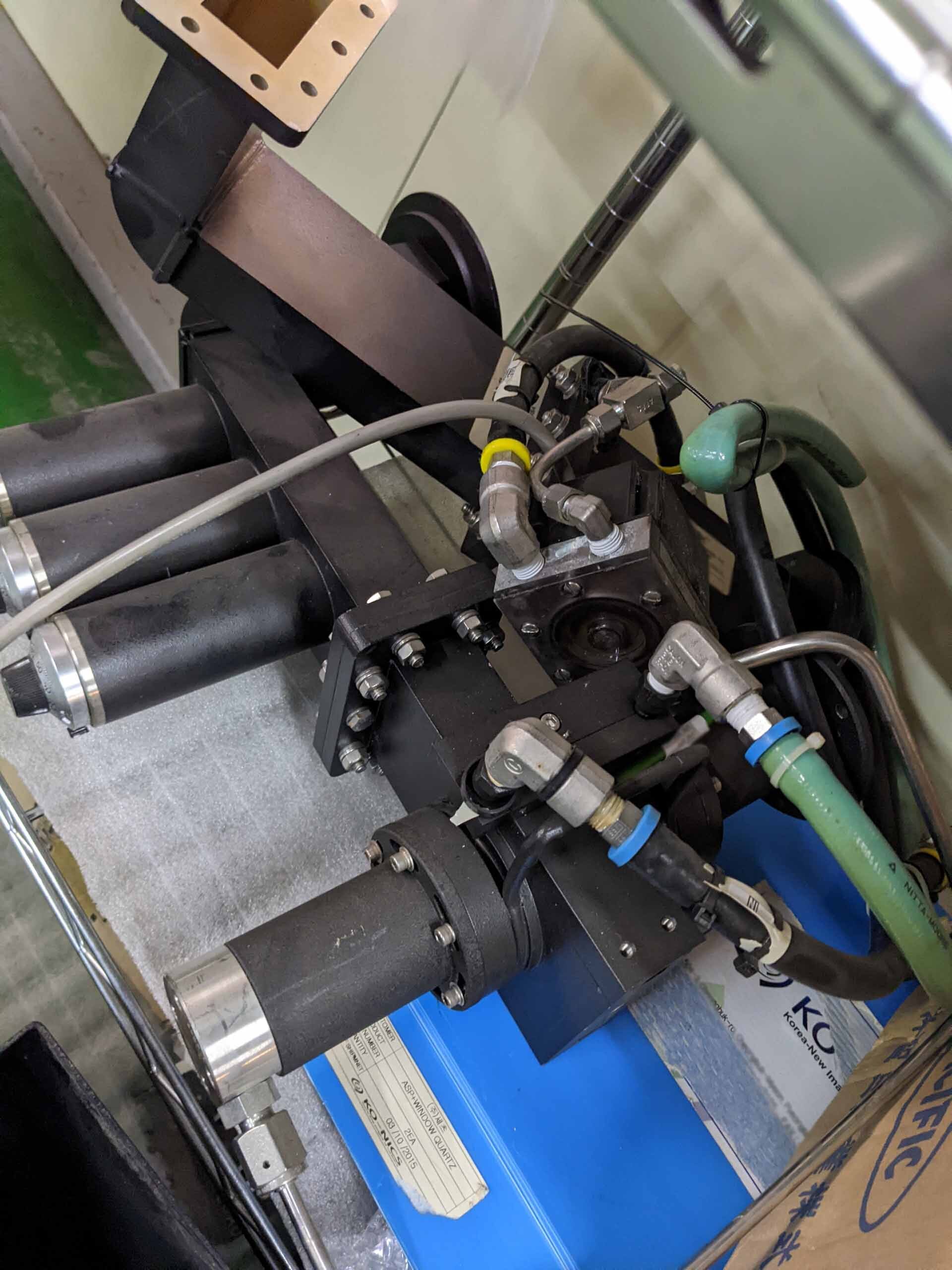

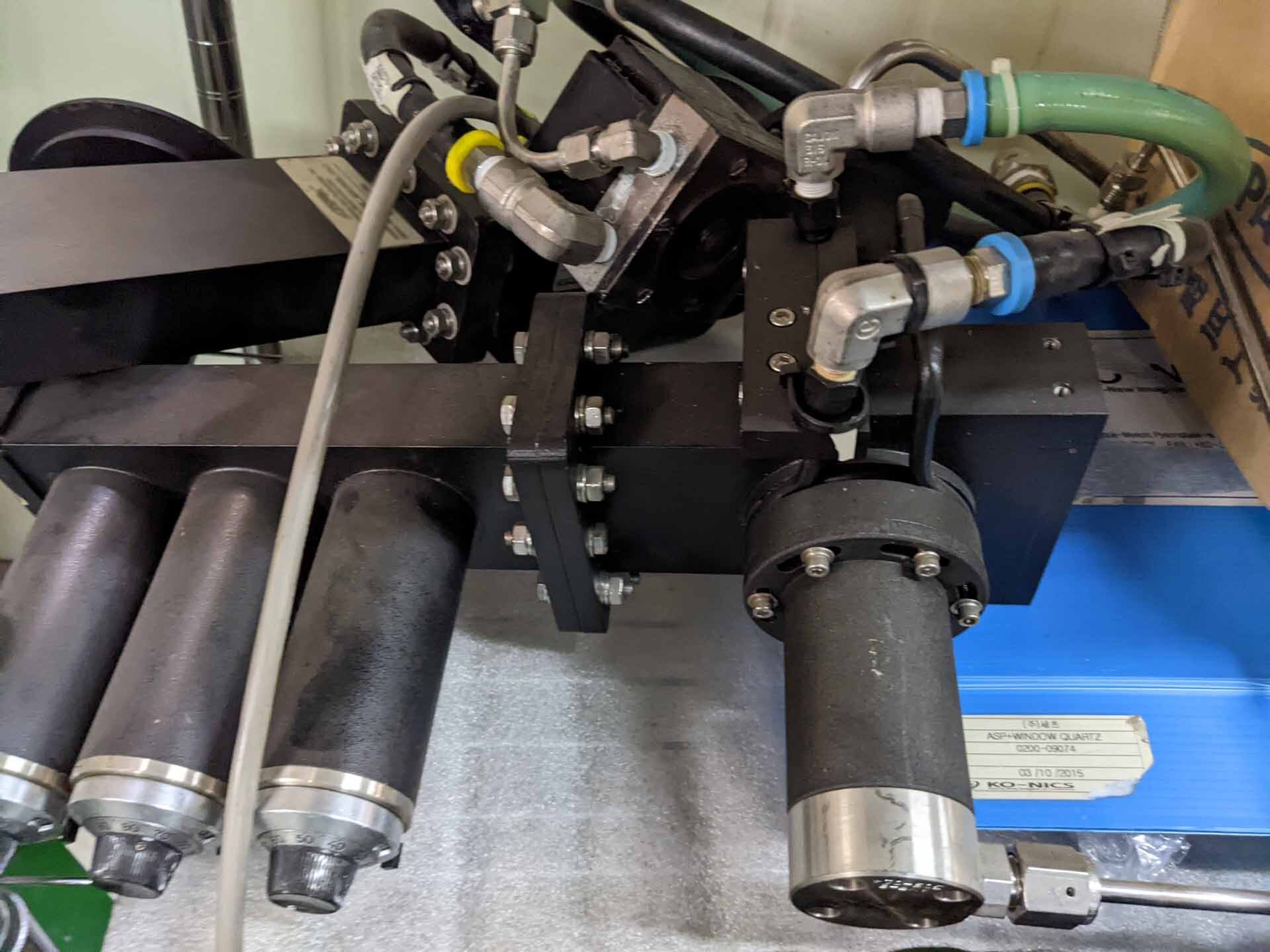

AMAT 019009275 (photoresist asher) and APPLIED MATERIALS 019009272 (photoresist etcher) are reactors used in the production of semiconductor devices on the industry-standard 300-millimeter (12-inch) wafers. These reactors use high temperatures and precise process control to clean and etch materials that are used in high-tech chip fabrication. The 019009275 photoresist asher is a single-wafer, atmospheric-pressure oxidative asher used for the removal of photoresist on semiconductor wafers. It has a highly uniform, large-capacity gas distribution equipment that ensures a homogeneous operating atmosphere throughout the chamber. The silicon chamber uses a high-temperature, direct-loading, forced-convection system that enables faster high-temperature processing. It can also automatically preheat the substrate before processing to reduce thermal stress. The 019009272 photoresist etcher is a single-wafer, electrostatic-focusing, high-vacuum etch reactor. It removes photoresist from substrate surfaces to prepare for ion implantation, as well as forming patterns for integrated circuit fabrication. It has a highly uniform gas distribution unit which ensures a homogeneous operating atmosphere, and a forced convection delivery machine to allow more efficient gas delivery. The chamber also features cooling-pin holders to help maintain wafer temperatures, and dynamic substrate bias to help control etch rate and uniformity. Both processes feature automated, real-time process monitoring to ensure process uniformity across multiple wafers, and advanced diagnostics for analysis of running processes. The process end-point detection tool also helps to reduce antireflective coating (ARC) break-down, while the post-etch cleaning asset helps reduce oxide residue on wafer surfaces. AMAT / APPLIED MATERIALS 019009275 and the 019009272 are a reliable, highly uniform, and efficient platform for the processing of semiconductor wafers. They offer reliable high-throughput manufacturing processes for chip manufacturing, making them ideal for the fabrication of high-tech chips.

There are no reviews yet