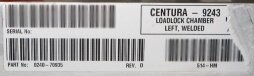

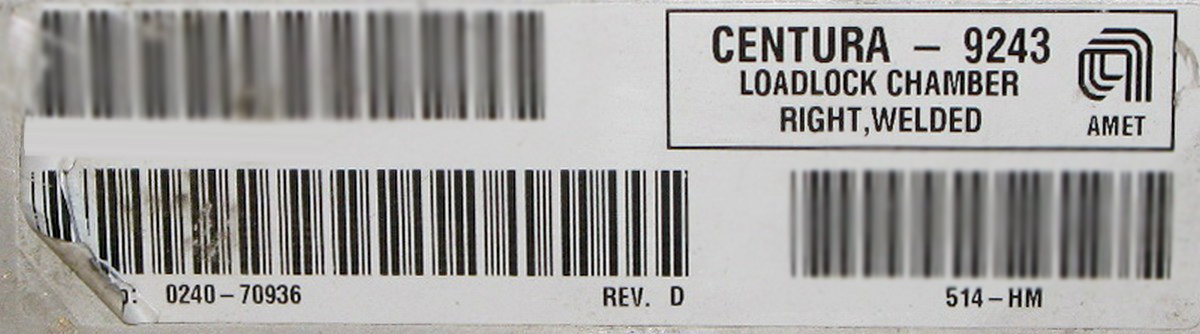

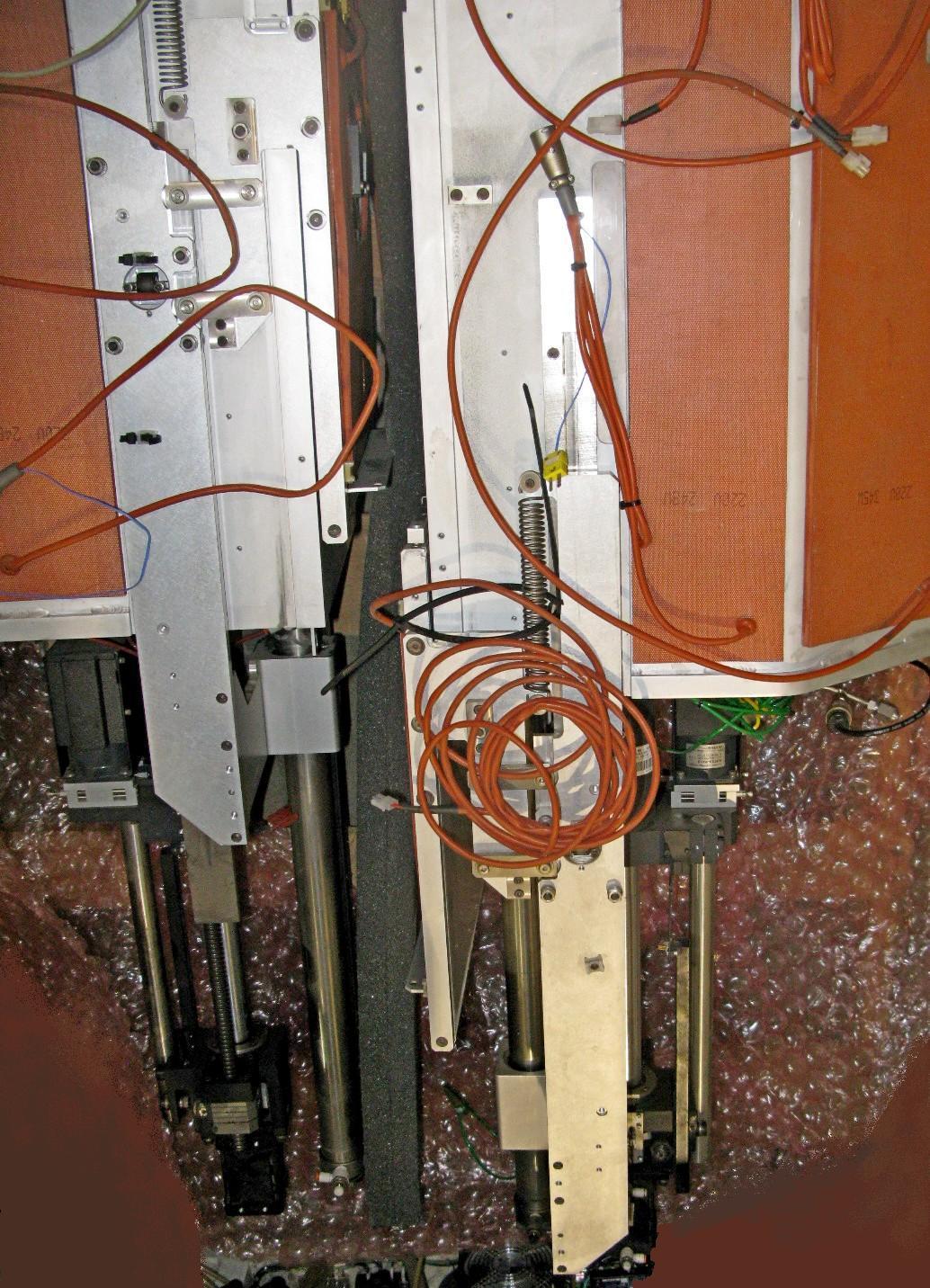

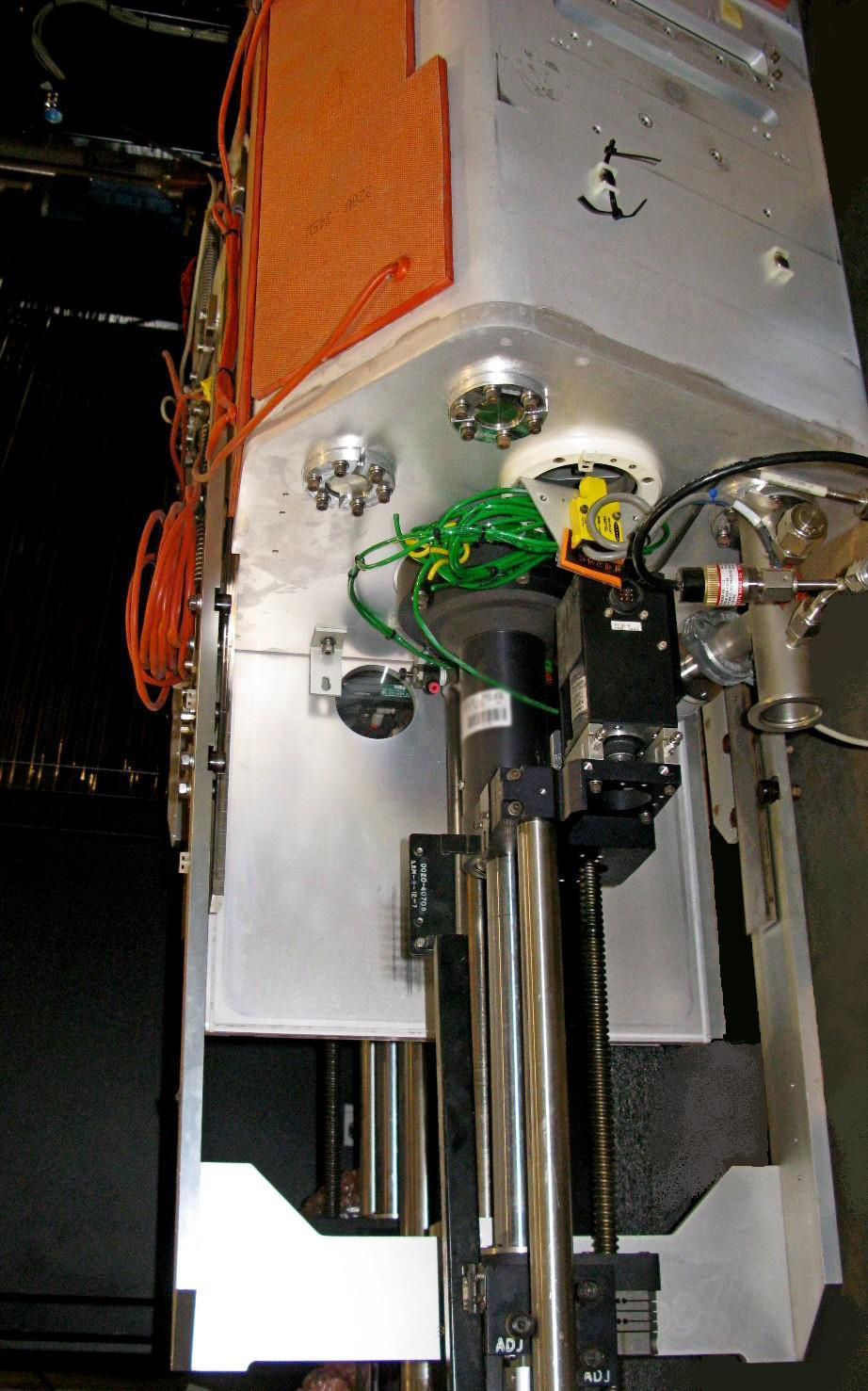

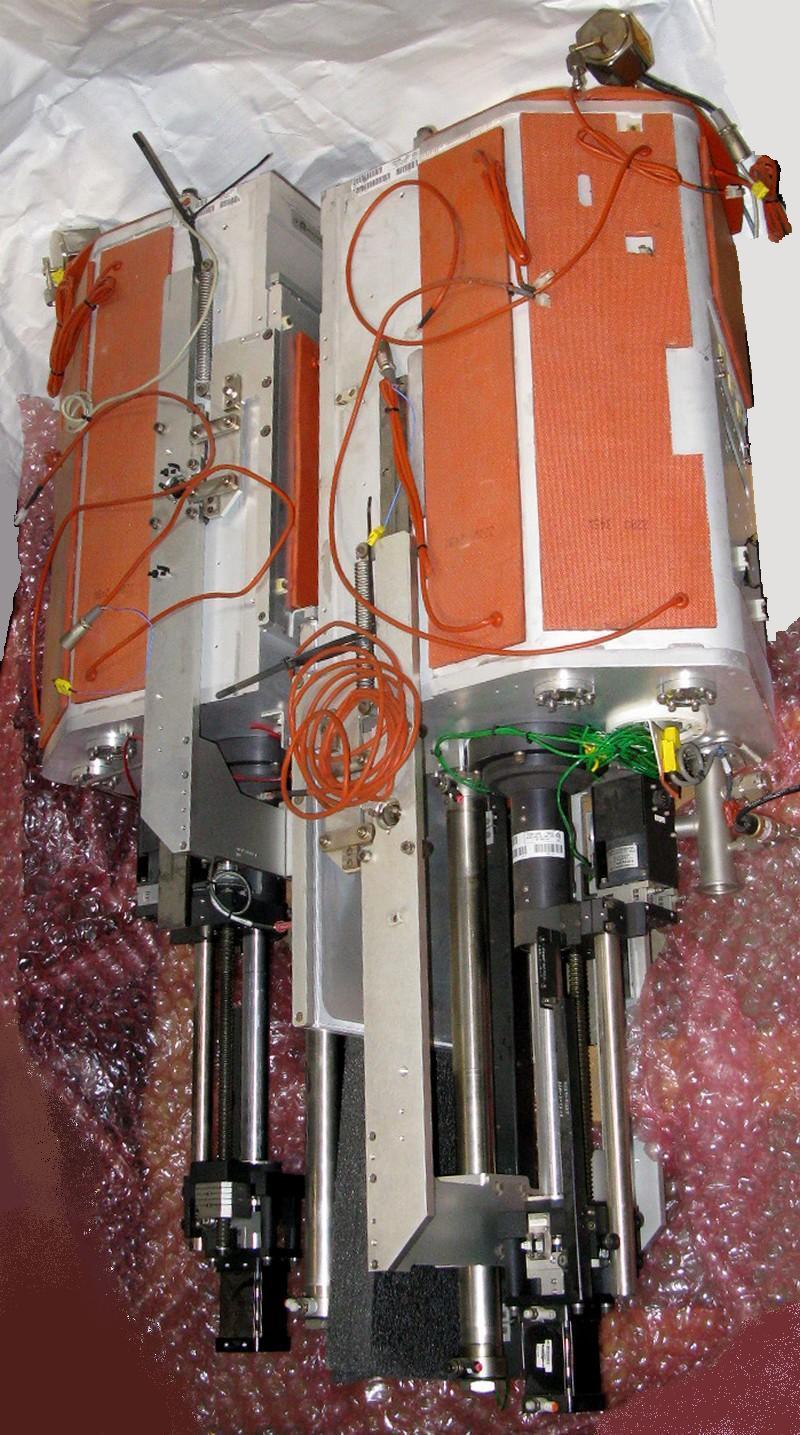

Used AMAT / APPLIED MATERIALS 0240-70935, 0240-70936 #9038984 for sale

URL successfully copied!

Tap to zoom

ID: 9038984

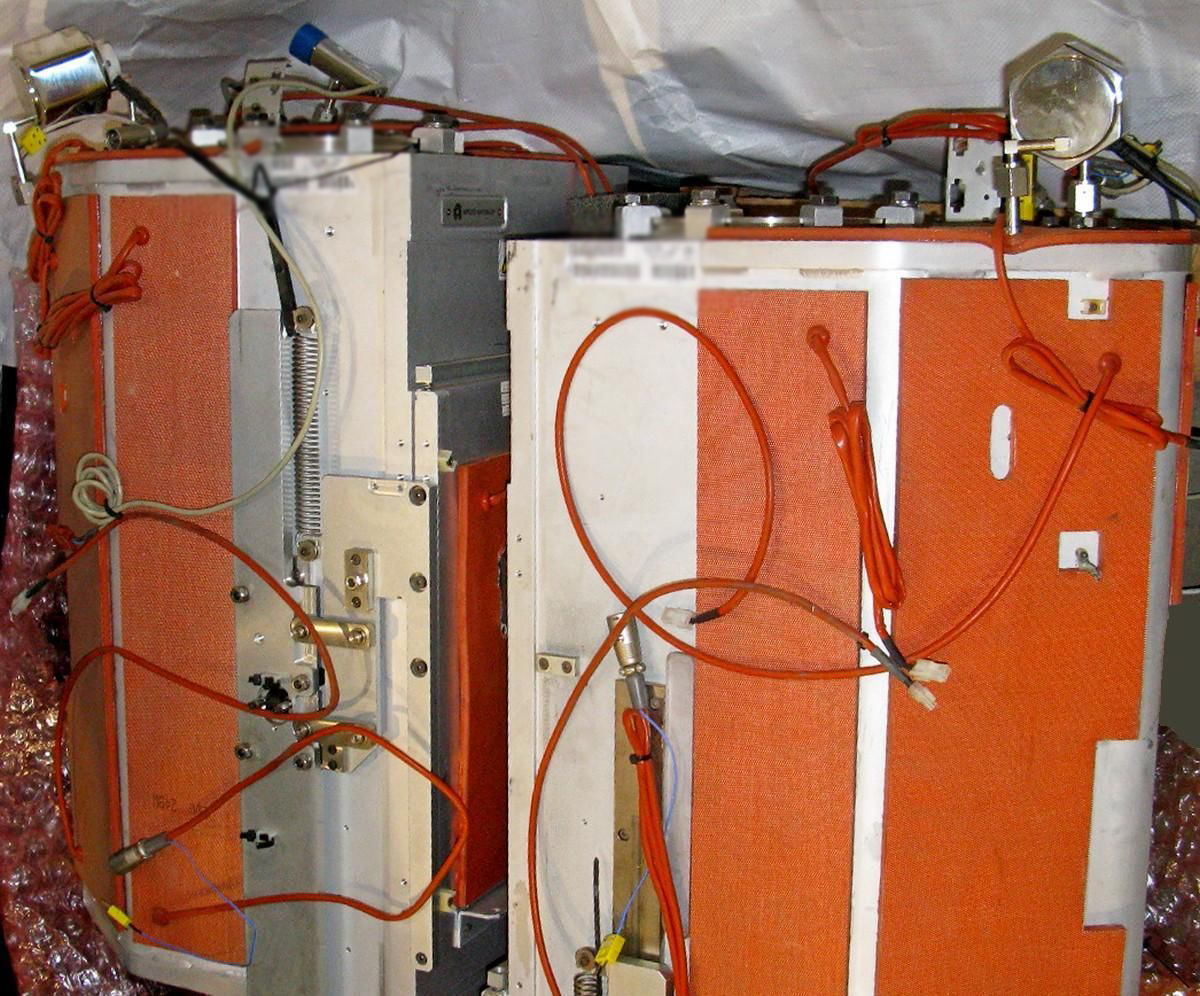

Wide body loadlocks pair for Centura

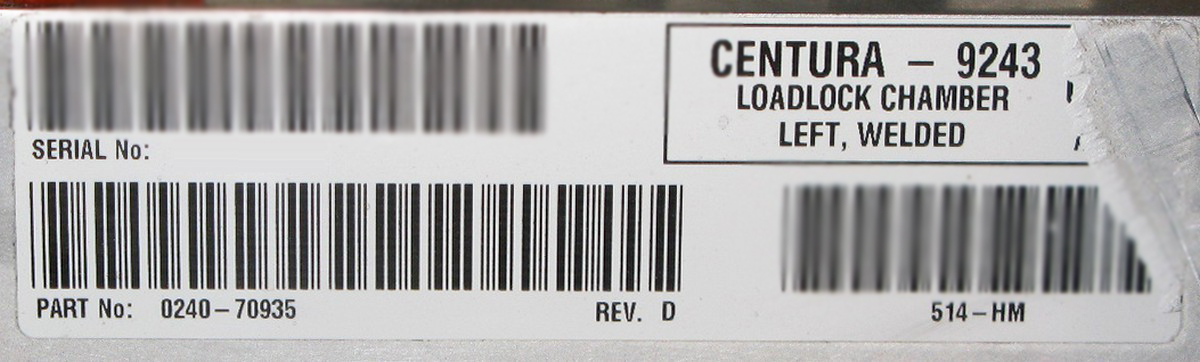

Chamber left welded: 0240-70935

Chamber right welded: 0240-70936

Basic indexers, Non-ENP right and left 0240-70903

Cassette platform, non tilt-out.

AMAT 0240-70935 and 0240-70936 massively parallel reactors are specialized tools for depositing a variety of materials onto substrates with the highest throughput speed and repeatability available. Constructed with a series of parallel flow reactors, these systems are able to quickly and effectively deposit a variety of single or multilayer thin films onto flat, as well as patterned substrates. Thanks to the low thermal mass design, these reactors can produce high-quality films with a wide range of thicknesses, sizes, and resolution. Additionally, all of these processes are carried out in a precise, low-temperature chamber environment which helps to reduce defect rates and thermal damage. This reactor also has applications for both high-volume production and research-based experimentation. APPLIED MATERIALS 0240-70935/70936 reactors are equipped with controls for accurate, repeatable production of a wide variety of films. The base elements of the system are the dual independent mass flow controllers. Theses controllers allow for precise control over the individual layers that will be deposited, the thickness of each layer, and the required temperature settings. For deposition process, the reactor utilizes an electrothermal chemical vapor deposition method (also known as "precision electrochemical vapor deposition"). This process provides greater accuracy of film properties than other methods like sputtering or physical vapor deposition. The reactor's process chamber itself is equipped with a 4-way valve, vacuum port, and gas injector for precise control of the deposition process and to ensure that only high quality, uniform deposits can be made. In order to ensure that film properties always remain consistent, the chamber pressure is also carefully regulated. Furthermore, AMAT / APPLIED MATERIALS 0240-70935/70936 has a self-contained electrostatic fan system that helps ensure reliable and repeatable flows and pressures throughout the deposition process. In order to help with accurate monitoring of the process, a real-time online thickness monitor (ROTM) has been included to allow for accurate film thickness measurements. These reactors are also customizable, with the ability to incorporate additional components for future expansions. For example, a controller can be added to regulate etching, rapid thermal annealing, and extended etching processes. With these considerations in mind, AMAT 0240-70935/70936 massively parallel reactors can operate as either single, stand-alone processes or as part of an integrated multi-module system. The unique features of these reactors make them the perfect tool for those looking to deposit a variety of single or multilayer thin films of the highest uniformity, thickness, and resolution in a precise, low-temperature environment.

There are no reviews yet