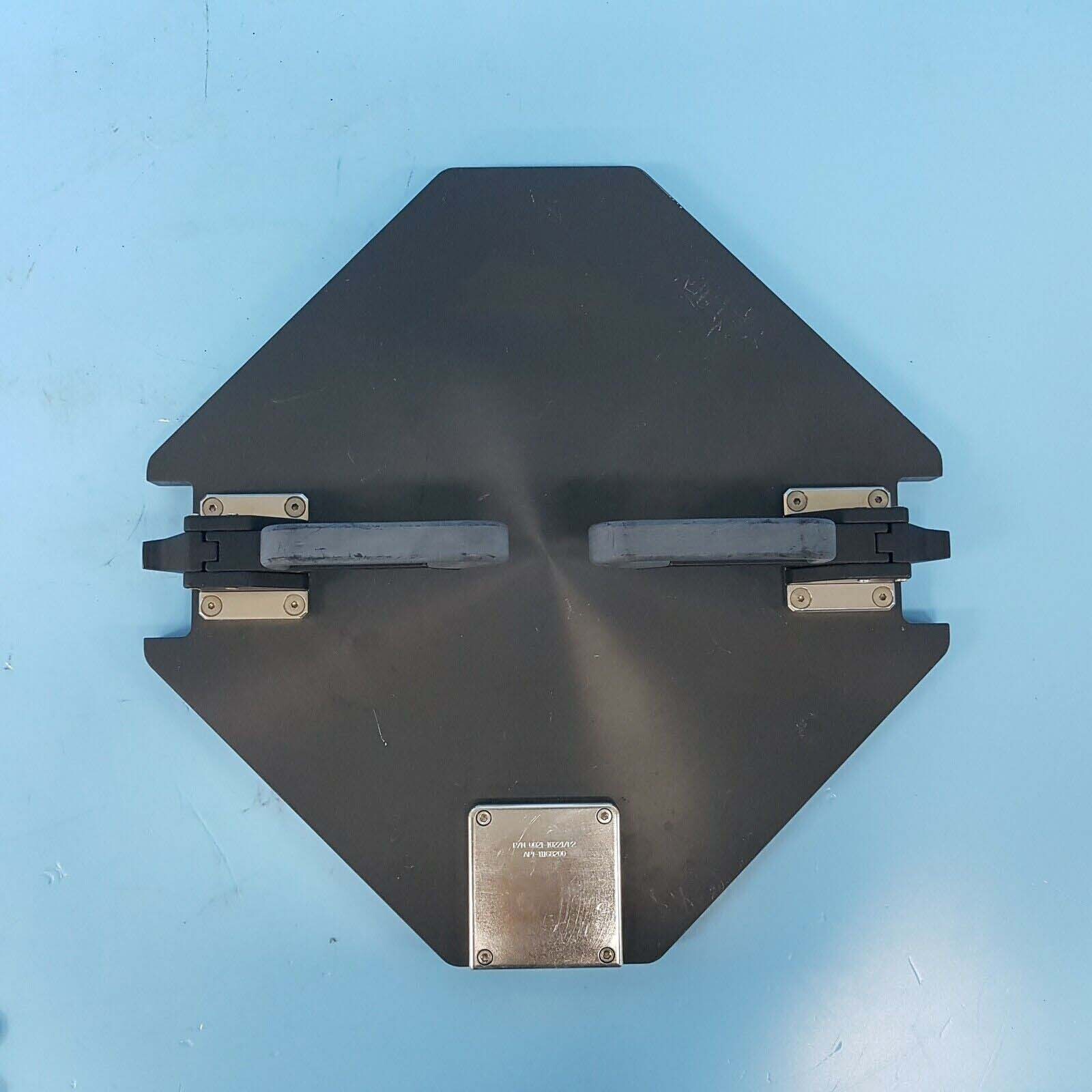

Used AMAT / APPLIED MATERIALS 0242-38209 #293661400 for sale

URL successfully copied!

Tap to zoom

AMAT / APPLIED MATERIALS 0242-38209 is a chemical vapor deposition (CVD) reactor used for the deposition of thin films on substrates. This type of reactor operates on the principle of heating volatile source gases—often organometallic or organosilicon compounds—to a high temperature where they then break down to form reactive species that then deposit on the substrate. AMAT 0242-38209 is used for both in-situ and ex-situ precursor delivery. It also is able to deliver up to three precursors simultaneously, which allows the reaction rates to be more precisely controlled. APPLIED MATERIALS 0242-38209 is a horizontal parallel plate equipment that contains two vertically-aligned, stacked quartz chambers. The top chamber contains two silicon carbide heaters and a metal mesh heating element that are used to heat the chamber and the substrate. The substrate is placed on a heated, metallic susceptor that holds the substrate at a fixed working distance from the quartz walls and helps facilitate uniform heating across the substrate. The lower chamber is separated into two sections, with each section being partitioned via a subsidiary plate. The upper section contains a flush injector that introduces the precursor gases into the lower chamber. The lower section is used to control the pump-down process, transfer the gases from the injector, and to heat the control the reaction environment. The heating system of 0242-38209 reactor is a combination of both electric and radiant heaters. The susceptor plate contains two elements that are insulated from each other and connected by an induction heating unit. This heating unit is used to deliver uniform and efficient heating across the substrate, ensuring the film deposits homogeneously. A series of adjustable nozzles are also present in the machine to control deposits on the substrate. AMAT / APPLIED MATERIALS 0242-38209 reactor also contains a series of windows in the upper quartz chamber that are used to monitor the deposition process. These windows are made from sapphire and quartz and have a layered, carbide-coated, dielectric coating that allows for optical access to the process while still providing protection from contamination. An advanced Raman spectrometer is integrated into AMAT 0242-38209 tool to accurately measure the composition of the films. Additionally, APPLIED MATERIALS 0242-38209 contains an imaging asset that can be used to assess the surface morphology and geometry of the substrate. This imaging model allows for precise control of the deposition process, which in turn leads to high-quality film deposits. Overall, 0242-38209 CVD reactor is a highly advanced thin film deposition equipment. Its combination of heating elements, specialized injectors, and windows allows for precise control over the deposition process. Its Raman spectrometer and imaging systems also enable the composition and morphology of the films to be accurately monitored. As a result, this type of reactor is often used in the production of semiconductor devices, integrated circuits, and various other products.

There are no reviews yet