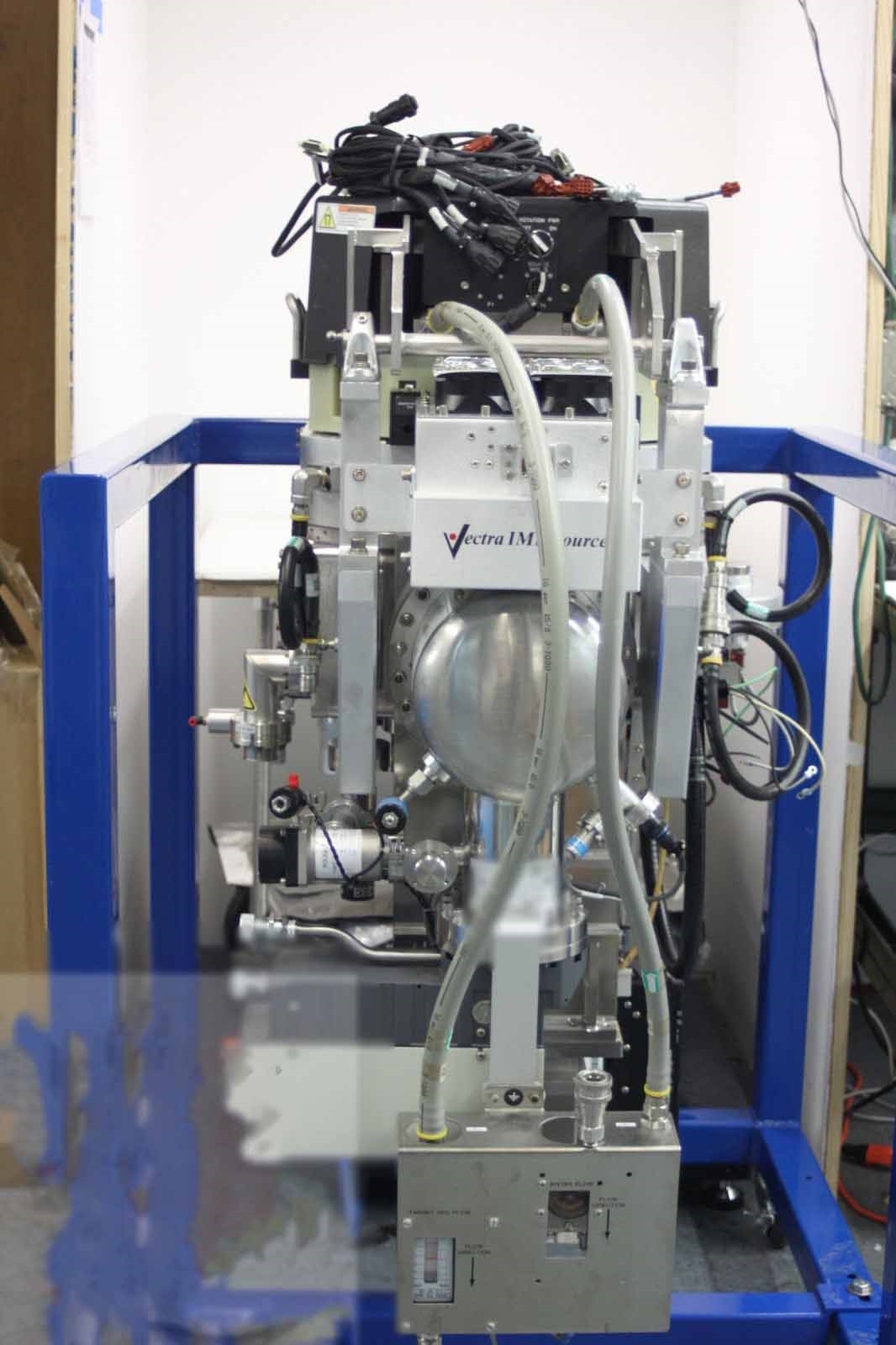

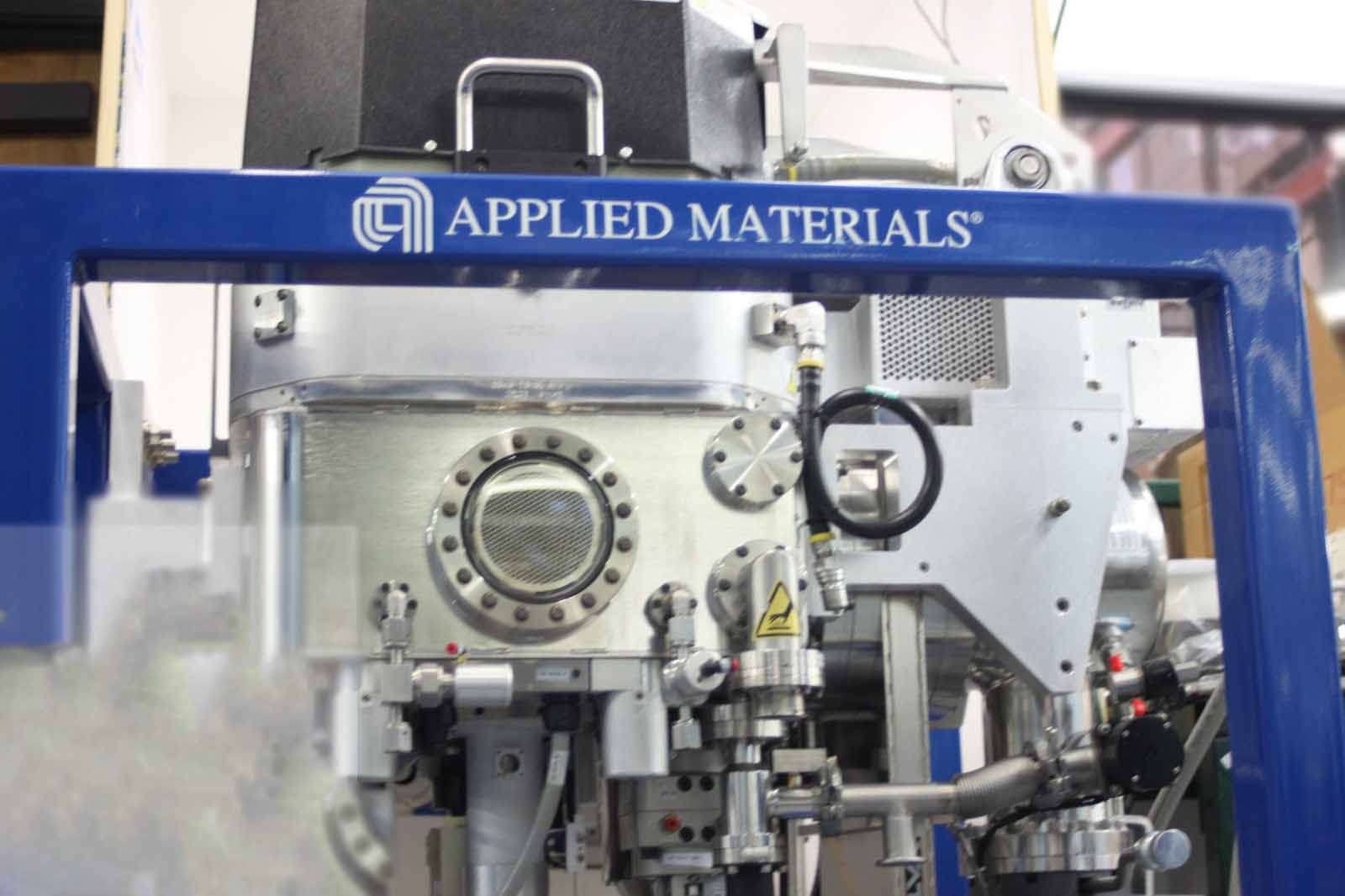

Used AMAT / APPLIED MATERIALS 0290-20094 #9203683 for sale

URL successfully copied!

Tap to zoom

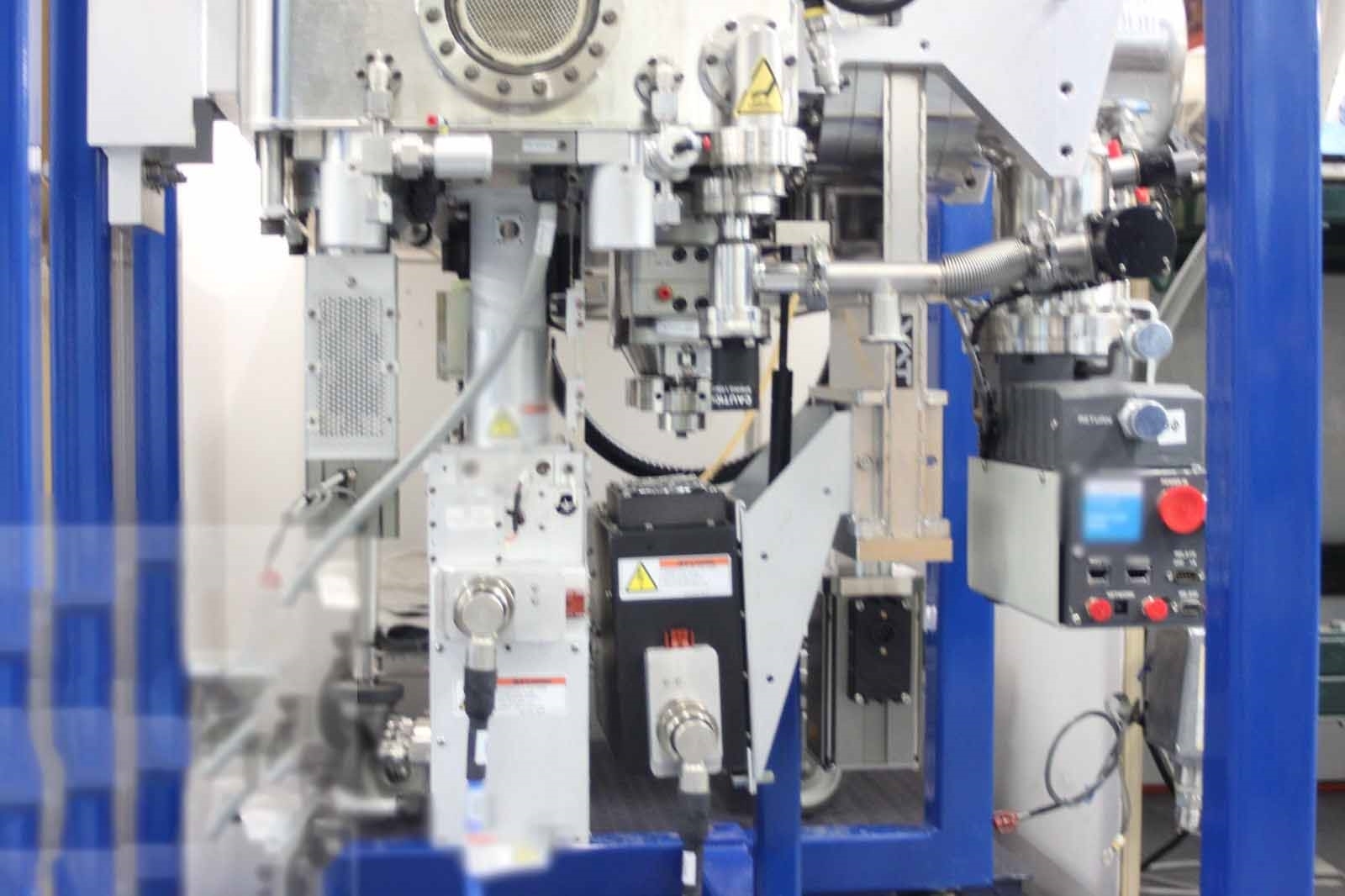

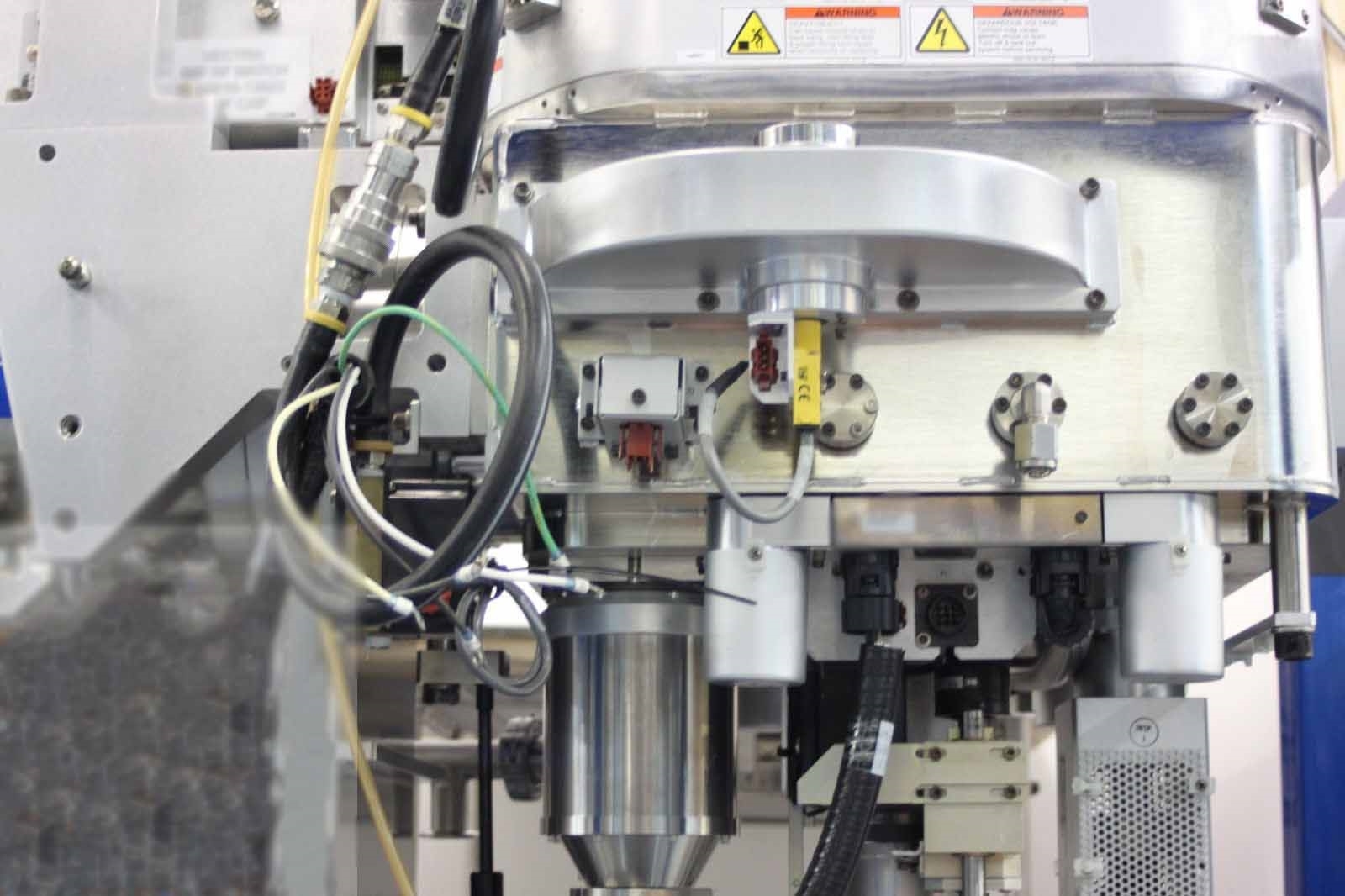

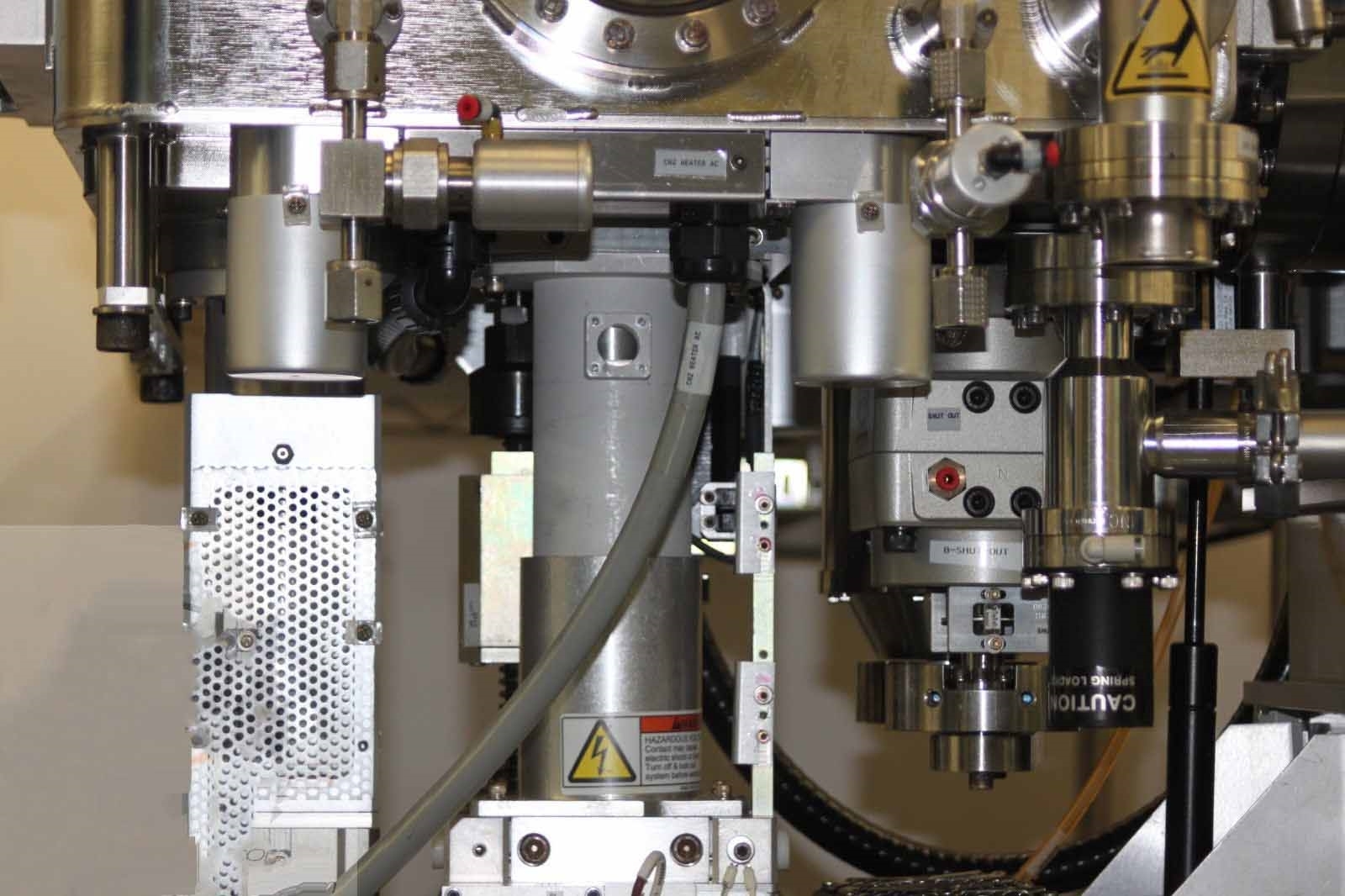

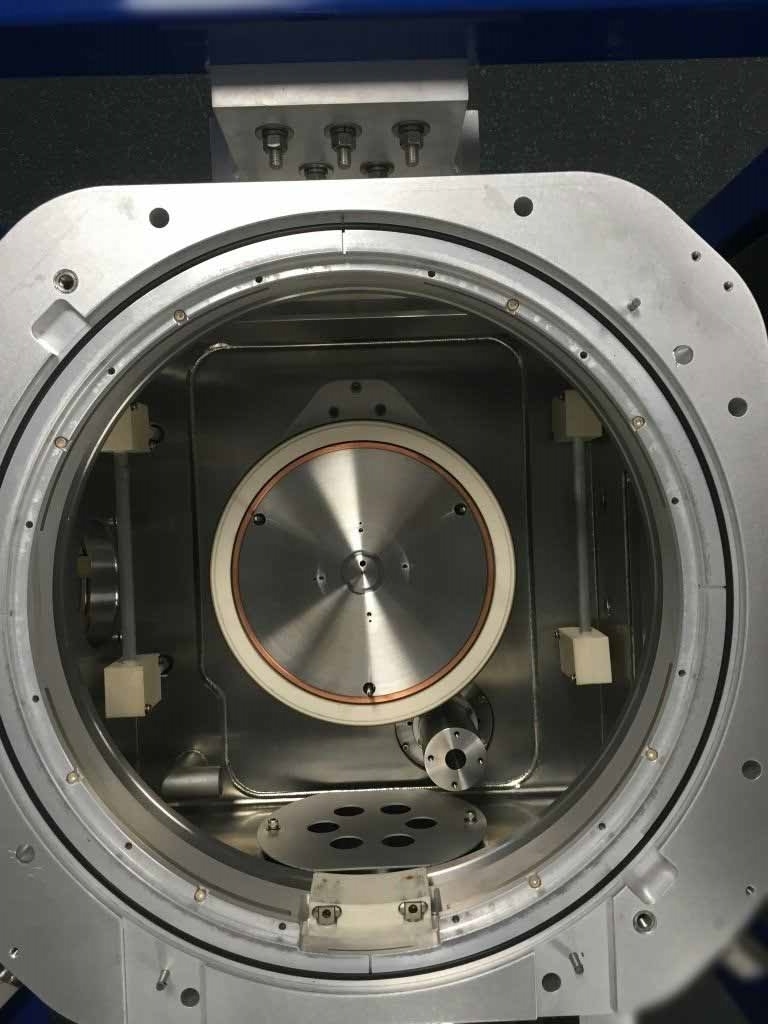

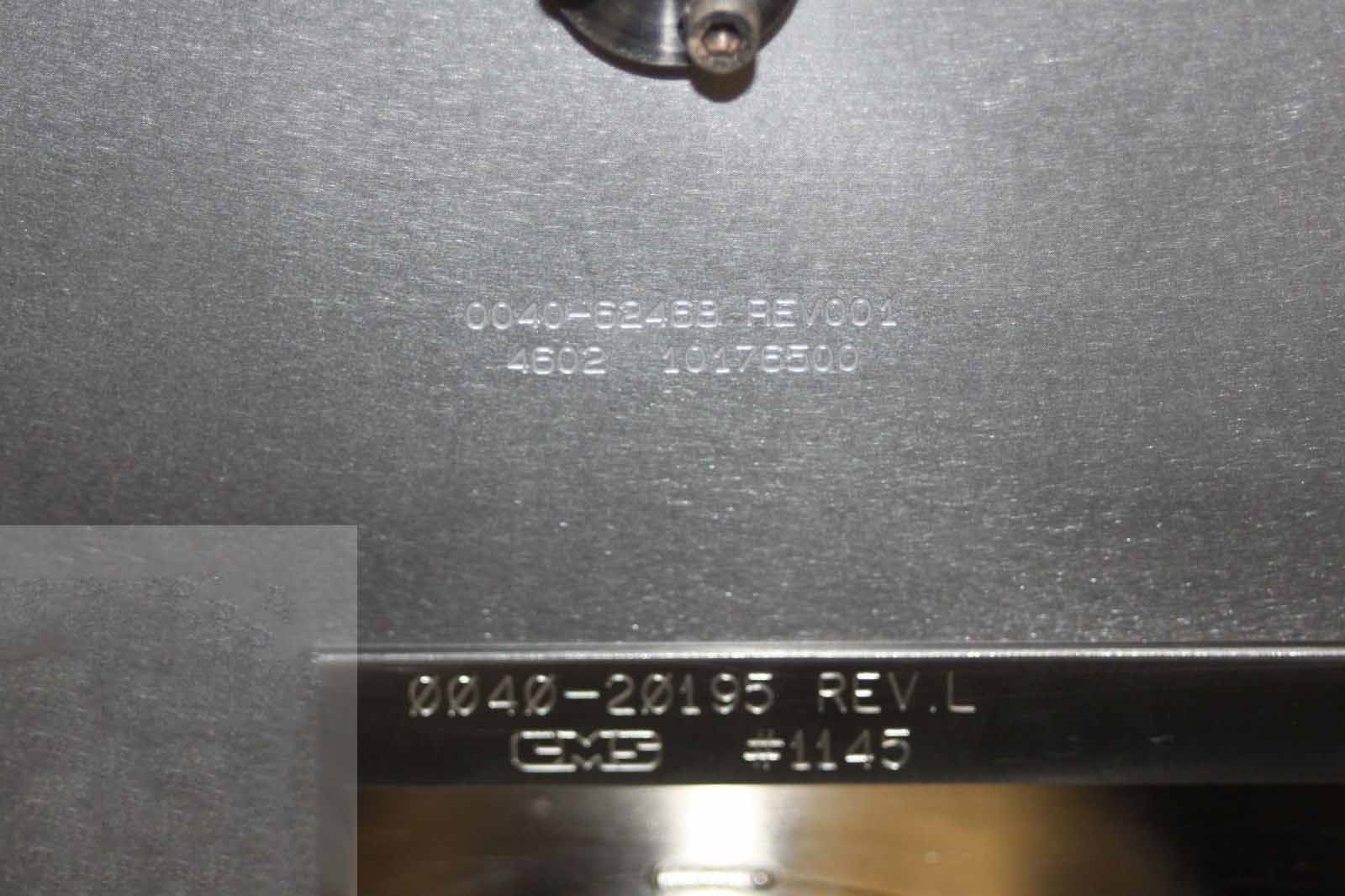

AMAT / APPLIED MATERIALS 0290-20094 is an industrial-grade chemical vapor deposition (CVD) reactor designed for the deposition of thin films using various process gases. The reactor measures 96 inches wide, 42 inches deep and 67 inches high, and is capable of producing batches up to 7 Wafers per load with 700mm diameter. It features two independent inline heaters with independent temperature control for maximum thermal uniformity, ensuring that the substrate is adequately processes with consistent uniformity. Its interior is composed of two components: the reactor vessel and the gas manifold. The reactor vessel is designed to offer an almost ideal gas-flow environment, and the interior of its cylinder is lined with Pyrolitic Graphite (PG) - a highly reflective, electrically conductive material that helps concentrate the source gases and produce uniform film formation. The gas manifold is a large chamber located at the top of the reactor, where the source gases are injected into the reactor under vacuum using an inlet plus several transfer lines. The reactor uses high-temperature furnace technology, which enables the use of more aggressive process conditions that quickly produce thick and uniform films with good morphology. The RF and DC power sources are made of high quality materials and can reach levels of power up to 2000W, providing a homogeneous lower temperature profile and uniform heating across the substrate, resulting in higher process stability and yield. In order to ensure high throughput and minimum downtime, the system includes two quartz lock chambers for wafer loading and unloading and an exhaust-management system that eliminates the volatile components from the environment. Additionally, AMAT 0290-20094 is compatible with a variety of gas-flow controllers to monitor the process. APPLIED MATERIALS 0290-20094 CVD reactor is a reliable and powerful tool for the deposition of a wide range of materials on wafers and other substrates. It provides high-quality uniform films and boasts a modular design, allowing for a customizable process and excellent scalability. As such, it has become a leading choice for high-volume, production-grade CVD deposition in the semiconductor industry.

There are no reviews yet