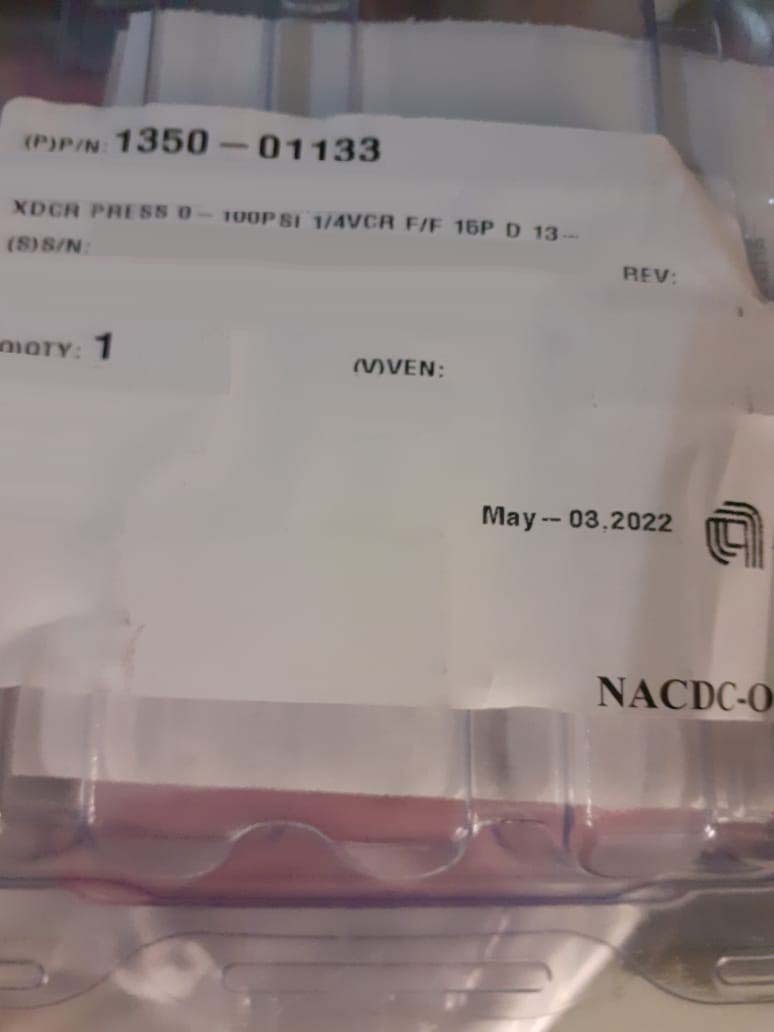

Used AMAT / APPLIED MATERIALS 1350-01133 #293668149 for sale

URL successfully copied!

Tap to zoom

AMAT / APPLIED MATERIALS 1350-01133 reactor is a unique tool for the production of semiconductor materials. It is designed for deposition, oxidation, annealing, etching, and other processes necessary to create advanced circuit structures on semiconductor wafers. The equipment is capable of operating at temperatures of up to 1400°C and pressures up to 0.2 Torr. AMAT 1350-01133 reactor is a 2-chamber cylindrical configuration that provides a number of advantages over traditional systems. It features two independent installations with separate chamber and process temperatures. The exit flange of the reaction chamber is fitted with a gas seal, preventing any reactive gases from collapsing back into the chamber and preventing gas leakage. This, along with the high-temperature quartz walls, allows for a high degree of accuracy and repeatability. The low pressure and temperature combination eliminates the possibility of non-uniformity due to the presence of gases in the chamber. APPLIED MATERIALS 1350-01133 reactor also offers low energy consumption and reduced running costs. The system can accommodate wafers up to 6-inch diameter and Teflon effusion cells up to 20mm in depth. 1350-01133 reactor can be used to produce dielectric and metal-based layers for semiconductor applications on both bulk and patterned substrates. The unit is also suitable for 2D and 3D processes. It features an advanced motion control machine, with multiple axes and positional accuracy of 0.001mm. The advanced motion control tool ensures a slow, steady build-up of a layer through a deposition process, providing excellent uniformity for integrated circuits. AMAT / APPLIED MATERIALS 1350-01133 reactor offers a number of safety features, such as an over-temperature and over-pressure safety valve, and a top-level control asset. This ensures the safety of the user, while also controlling the process environment and preventing any unexpected changes during operation. The model also features a programmable architecture for data logging and equipment control. Overall, AMAT 1350-01133 reactor is an advanced system for the production of semiconductor materials, featuring high levels of safety and accuracy. The high-temperature quartz walls and low-pressure environment result in uniform layers on semiconductor wafers, and the advanced motion control unit allows for a steady build-up of layers for complex structures. With its safety features and programmable architecture, APPLIED MATERIALS 1350-01133 reactor is the perfect choice for semiconductor production.

There are no reviews yet