Used AMAT / APPLIED MATERIALS 1600 #9156161 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9156161

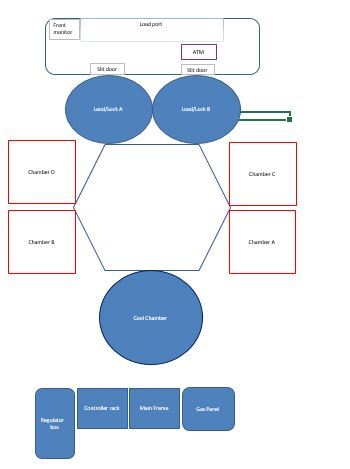

PECVD Chamber

Front

Front Monitor: Ok

Back Monitor: Ok

Load port: Sensors, Cass plate

Signal tower: R,Y,G,W

Robot: ATM robot & Vacuum chuck

Slit door: Open

Laminar flow: Load port laminar flow

Wafer transfer module

Robot: No

Baratron gauge: No

Buffer door lift : Ok

Buffer Isolation valve: Ok

Buffer throttle valve: Ok

Cool chamber: Ok

Process module

CH# A RF Match: HMN302D

CH# B RF Match: Ok

CH# C RF Match: Ok

CH# D RF Match: No

CH# A Gate valve: No

CH# B Gate valve : AV-4.0-MOD

CH# C Gate valve: Ok

CH# D Gate valve: Ok

CH# A Throttle valve: 153F-4-100-2

CH# B Throttle valve: No

CH# C Throttle valve: Ok

CH# D Throttle valve: Ok

CH# A Heater lift: No

CH# B Heater lift: No

CH# C Heater lift: Ok

CH# D Heater lift: No

Controller Board: DI/O,AI/O : Ok

DC power supply: Ok

CH# A Baratron gauge: MKS

CH# B Baratron gauge :Ok

CH# C Baratron gauge : Ok

CH# D Baratron gauge : Ok

Regulator box

Span sensor: Ok

Manual v/v & Regulator: Ok

Gas panel

NF3: 2SLM

Ar: 300SCCM

NH3: 2500SCCM

N2: 5SLM

SiH4: 500SCCM

1%PH3/H2: 1SLM

H2: 3SLM

B2H6

System control rack

Interface board: DI / O, Seriplex, VME, CPU

DC power supply: Ok

Pump control module: Ok

Servo DC power supply: Ok

Main frame

Power rack

Generator

Chamber A RFPP RF20S: 2666

Chamber B RFPP RF20S: NPG2K10S005

Chamber C RFPP RF20S: No

Chamber D RFPP RF20S: No

Pump

Chamber A QMB500 + QDP80

Chamber B QMB500 + QDP80

Chamber C QMB500 + QDP80

Chamber D QMB500 + QDP80

TM pump QDP40

Load/Lock chamber QDP40

Scrubber:

Main scrubber CDO859

Back-up scrubber CDO858

Heatexchanger SPEED-7000

Missing and ETC parts :

ETC: Part step ( scaffolding ).

AMAT / APPLIED MATERIALS / AKT 1600 reactor is a large-scale chemical vapor deposition (CVD) system designed for semiconductor applications. It is a state-of-the-art industrial reactor for producing thin film materials and structures. The systems advanced deposition technology offers superior single-wafer uniformity, excellent process control, reliable operation, and low cost of ownership. The reactor is equipped with a high-power, gas-cooled electron gun connected by a thermionic gun amplifier that allows precise control over the substrate temperature, chamber pressure, gas flows, and deposition rate. An etch collar helps reduce particle contamination, while its metal drum-based design further enhances uniformity and copper-based thin films. The reactor can accommodate a variety of substrates up to 152mm in diameter, including silicon wafers, gallium arsenide, quartz, glass, and aluminum oxide. It can process a wide variety of materials, from semiconductor metals such as aluminum, copper, and nickel to dielectrics such as silicon nitride and aluminum oxide. The system is equipped with a number of advanced features, such as an automated source tuning, vacuum level control, plasma diagnostics, automated gas delivery, and test scripts to help streamline the process. The color touch screen display and intuitive graphical user interface (GUI) allow users to quickly and accurately monitor all the parameters of the run. Additionally, AKT 1600 reactor is supported by a wide range of options, including multiple load lock chambers, parallel process chambers, and an atmospheric module for pre- and post-processing of samples. Overall, AMAT AKT1600 CVD system is capable of producing high-quality, low-cost thin films with excellent uniformity. Its advanced features and easy-to-use graphical user interface make it an ideal choice for processes requiring superior deposition quality and reliability.

There are no reviews yet