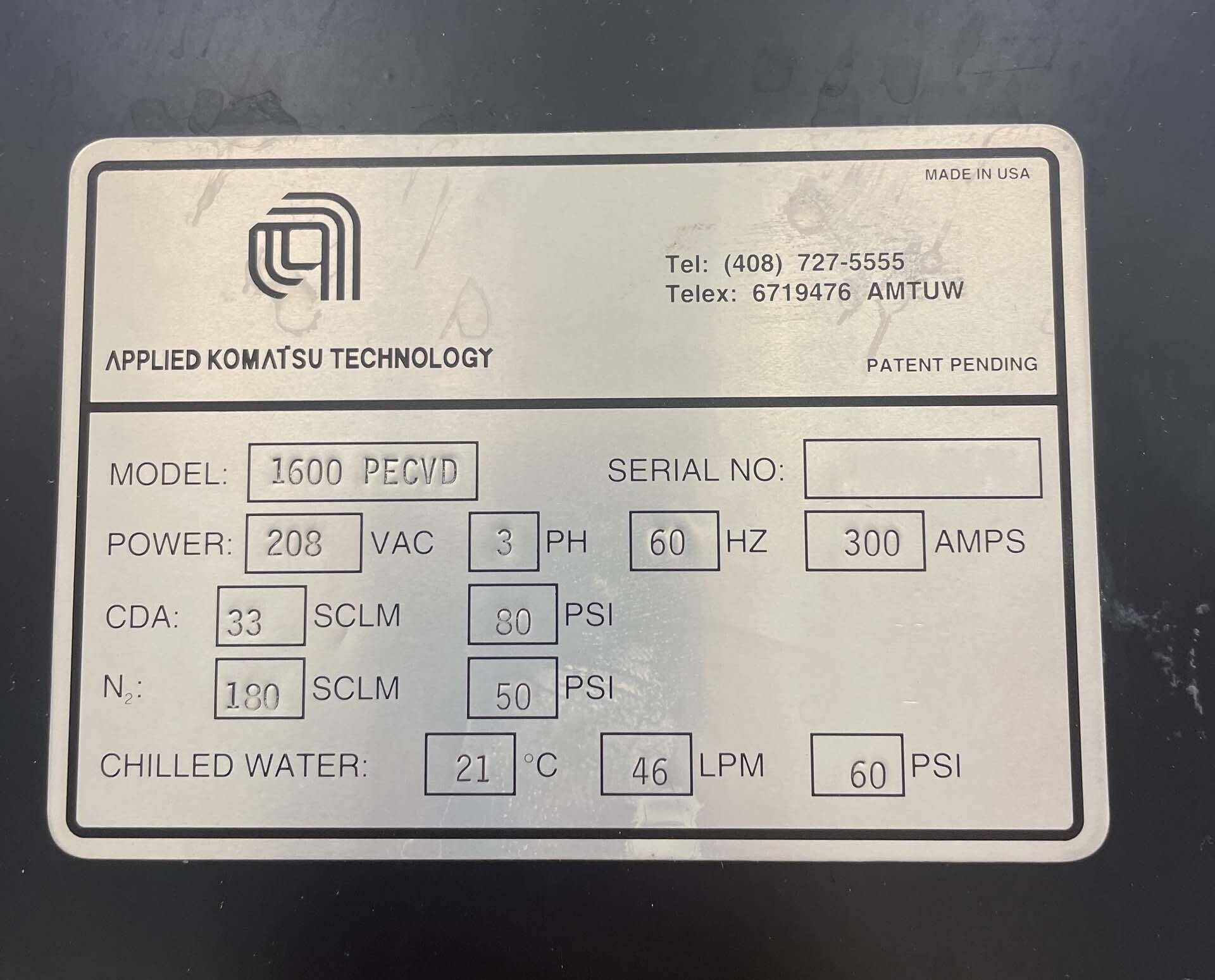

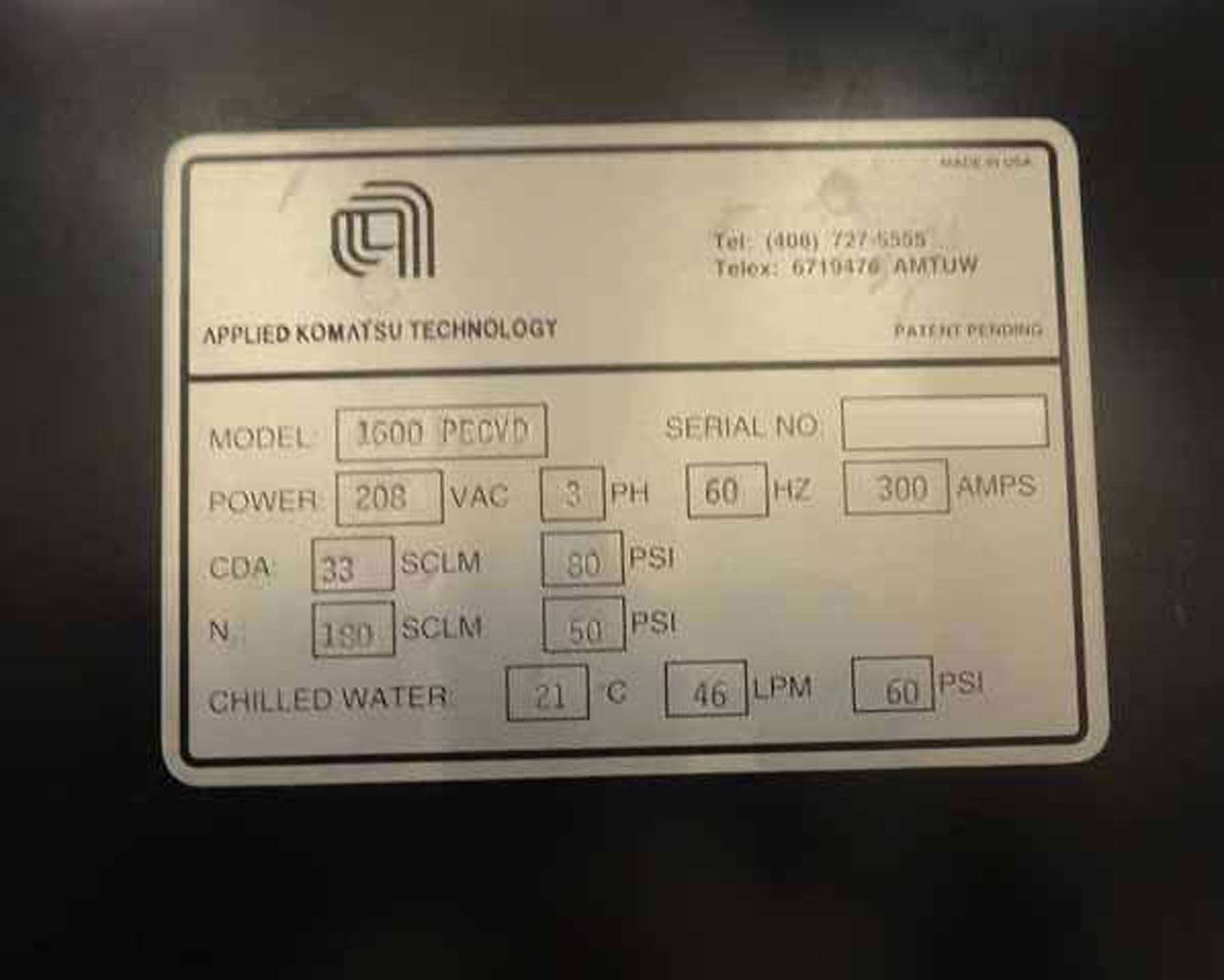

Used AMAT / APPLIED MATERIALS 1600 #9195141 for sale

URL successfully copied!

Tap to zoom

ID: 9195141

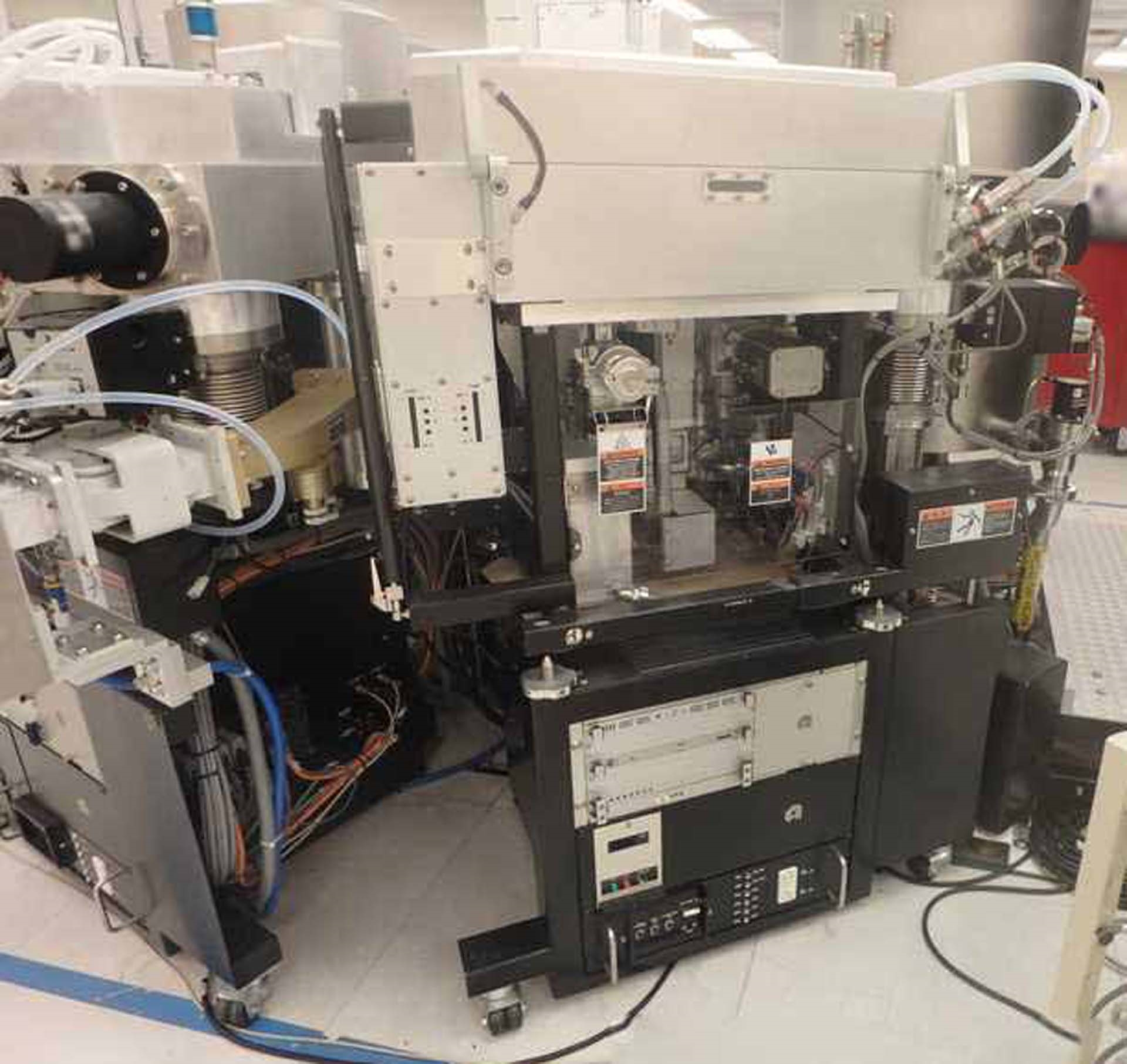

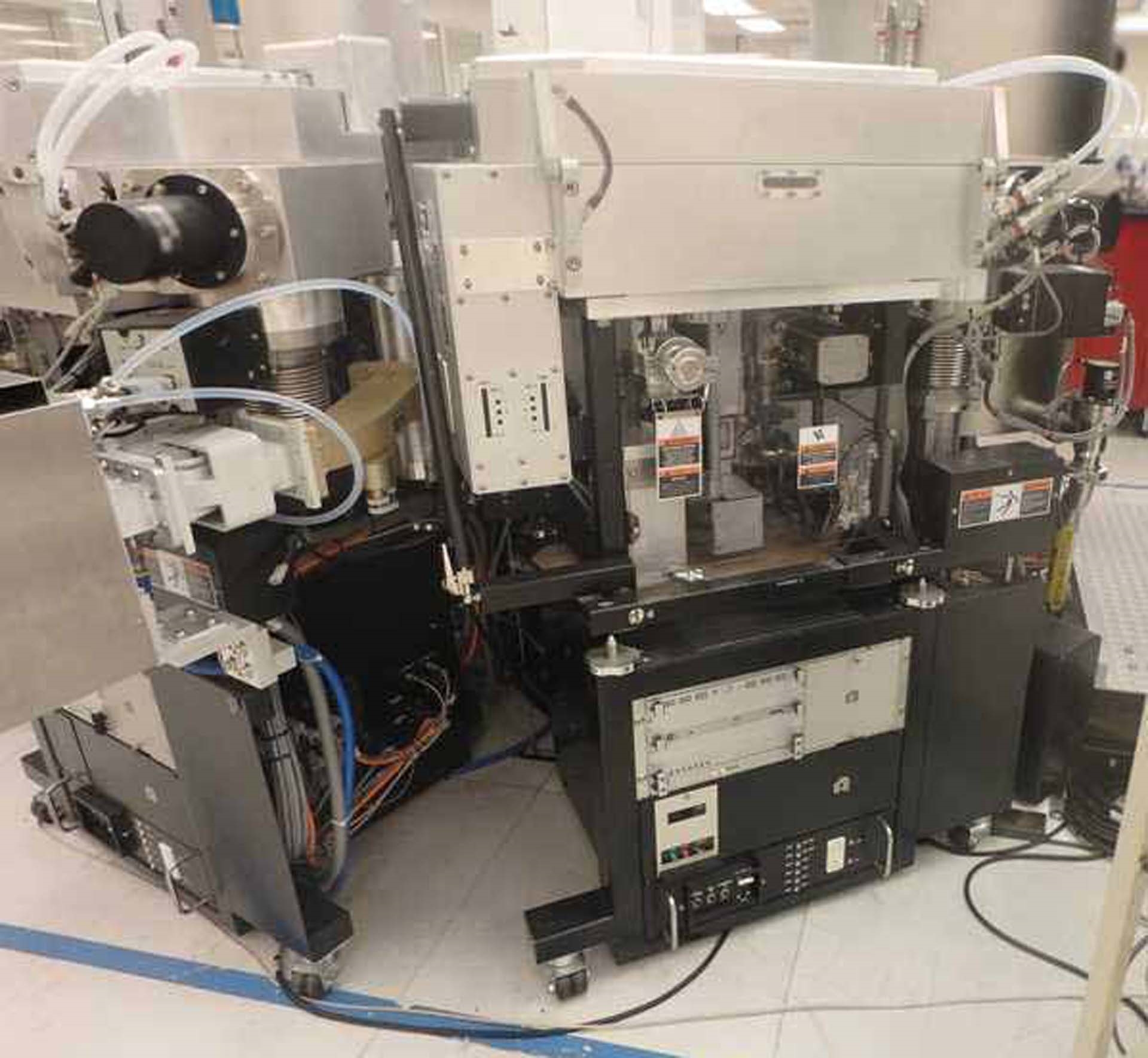

PECVD System

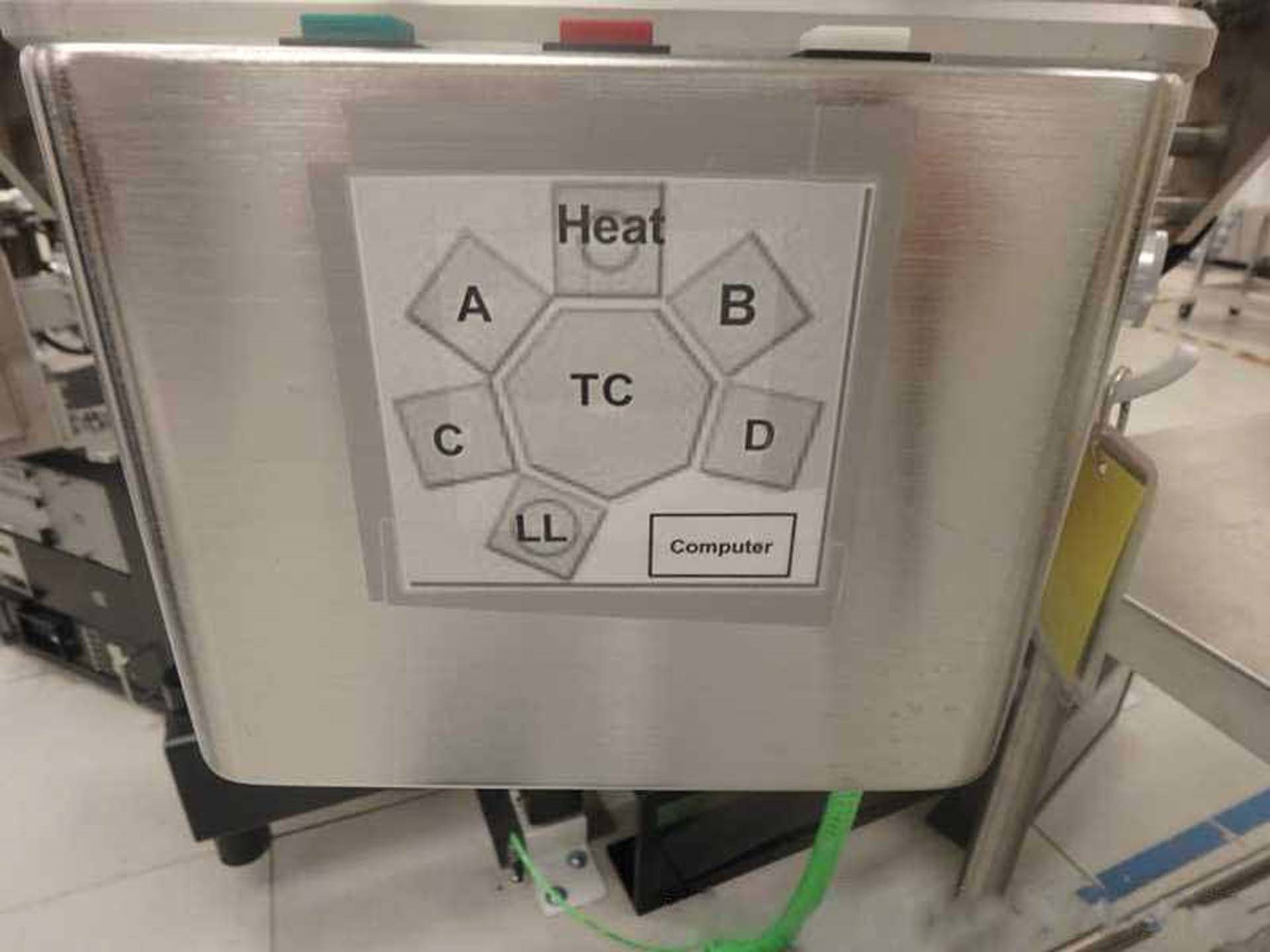

(4) Chambers

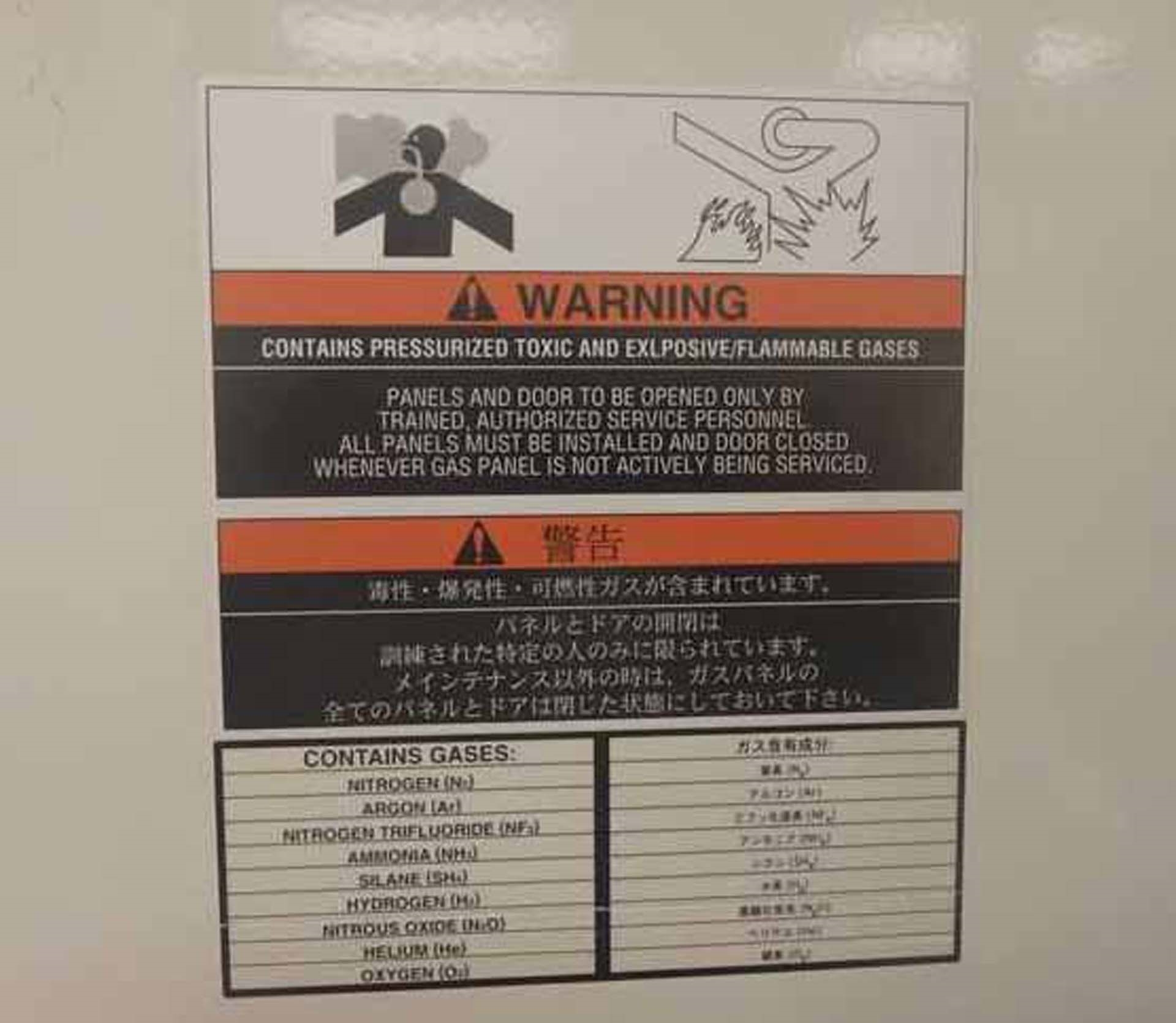

Gas box

Gas distribution cabinet

(4) Acid cabinets

Flammable cabinet

(2) Stainless steel tables

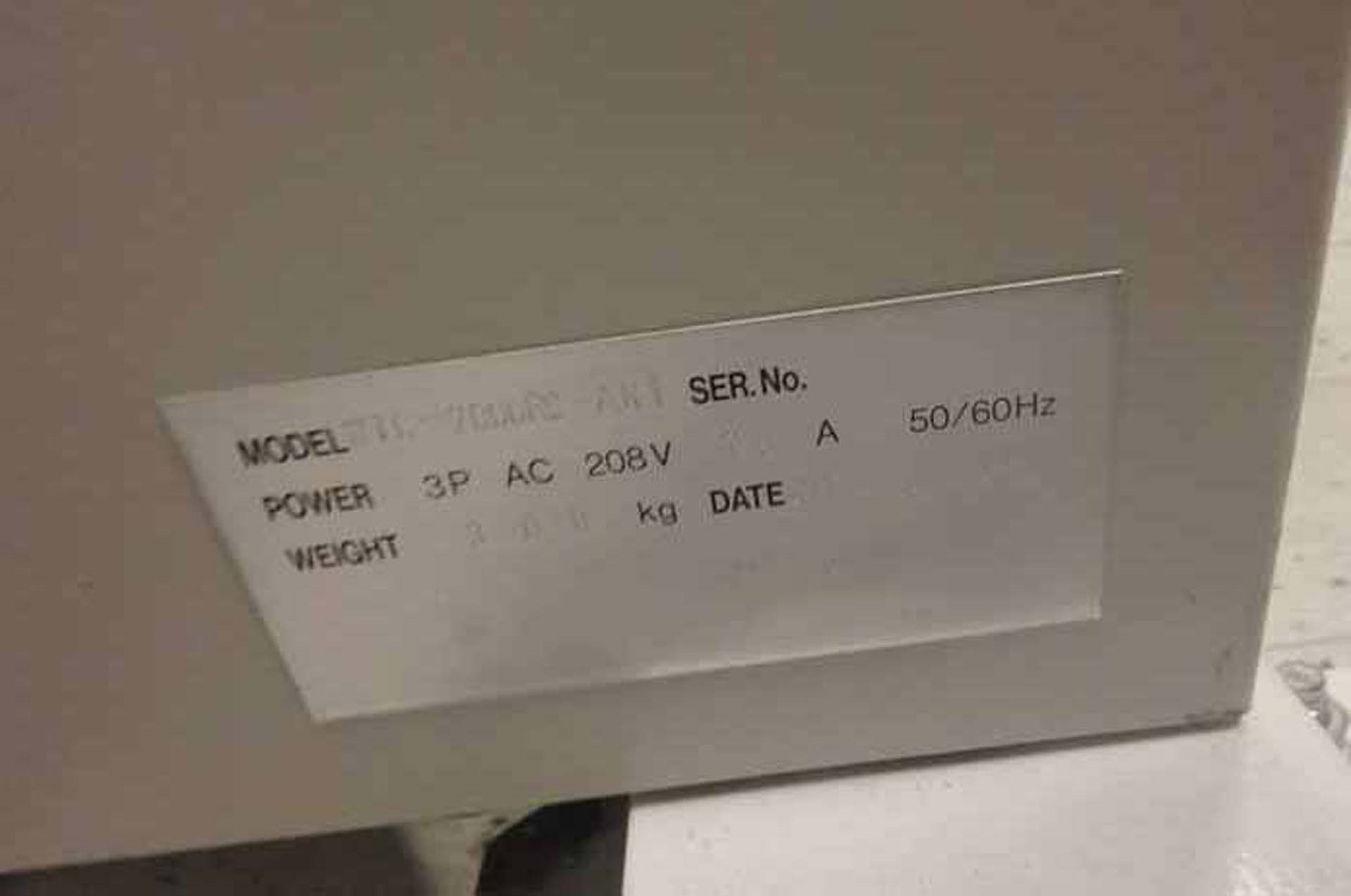

RASCO WTC-2000RS-AKT Water chiller

AMAT RFPP RF20 Power source / Supplies rack

Capable of transferring: 300x300 mm Square glass substrates

With single loader module to load lock chamber

13-Slots load lock chamber cassette

IMI Using chamber B

With RF power

Wafer handler

Spare parts

Manuals

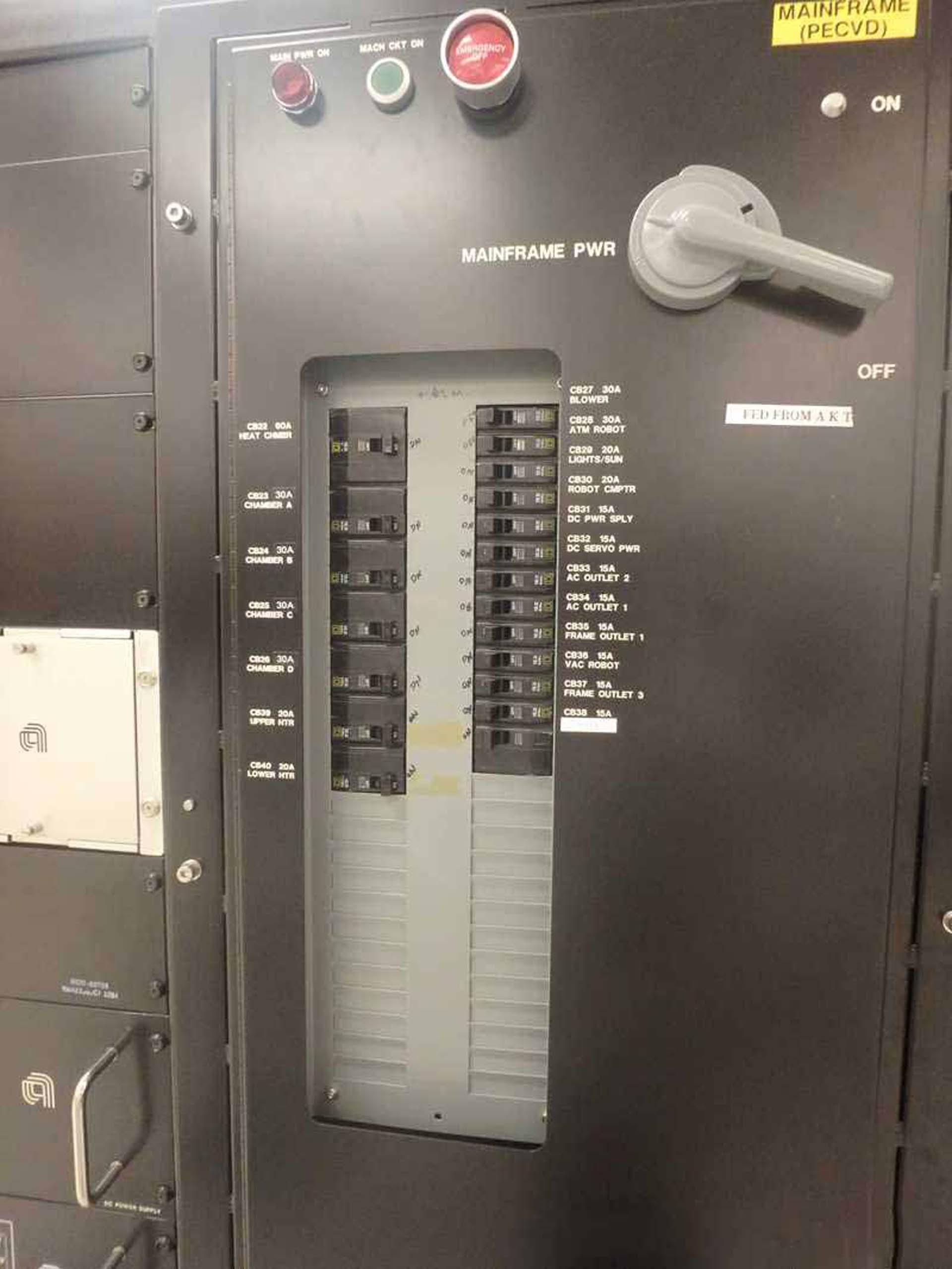

Power supply: 208 V, 60 Hz, 300 Amps, 3 Phase

1997 vintage.

AMAT / APPLIED MATERIALS / AKT 1600 is a plasma-enhanced chemical vapor deposition (PECVD) reactor equipment used for depositing thin films, such as dielectrics, conductive materials, and materials for optical applications. The system is designed to operate at up to 200 W of RF power, enabling deposition of thin films with excellent characteristics. The PECVD process is used to deposit thin films of polycrystalline silicon, amorphous silicon, silicon nitride, and silicon oxynitrides. The unit utilizes a RF-driven source gas module and combines both plasma and thermal processes to deposit uniform, highly conformal thin films over large substrate areas. The substrate size is capable of reaching up to 300 mm in diameter. Furthermore, the reactive gas fluxes are adjustable to enable precise control over the growth of the thin films. AKT 1600 contains an RF antenna that is used to generate the plasma used in the deposition process. The machine is powered by two high-power RF generators with ratings of 200 W. The external RF source is connected to the interior chamber by a RF coil that acts as a communication link between the RF generator and the plasma chamber. The tool's plasma chamber is designed to house multiple substrates for multi-zone deposition. The chamber is enclosed by a quartz bell jar that is used to provide an inert environment for the plasma deposition process. The bell jar has an adjustable gas inlet asset that is used to control the etching/deposition process by controlling the rate of flow of the source gases. For temperature control, the model is equipped with a high-temperature, dual-zone heating element. The low temperature zone is used to initiate and stabilize the deposition process, while the high-temperature zone is used to optimize the process. AMAT AKT1600 also has an adjustable gas exhaust equipment that is used to control the pressure inside the chamber and aid in the removal of by-products from the process. Overall, APPLIED MATERIALS AKT1600 is a robust PECVD system that provides users with a reliable, versatile, and efficient way to deposit quality thin films. With its adjustable gas inlet and exhaust unit, high-power RF generators, and two-zone heating element, users can easily control the deposition process in order to yield thin films with excellent characteristics for a wide range of applications.

There are no reviews yet