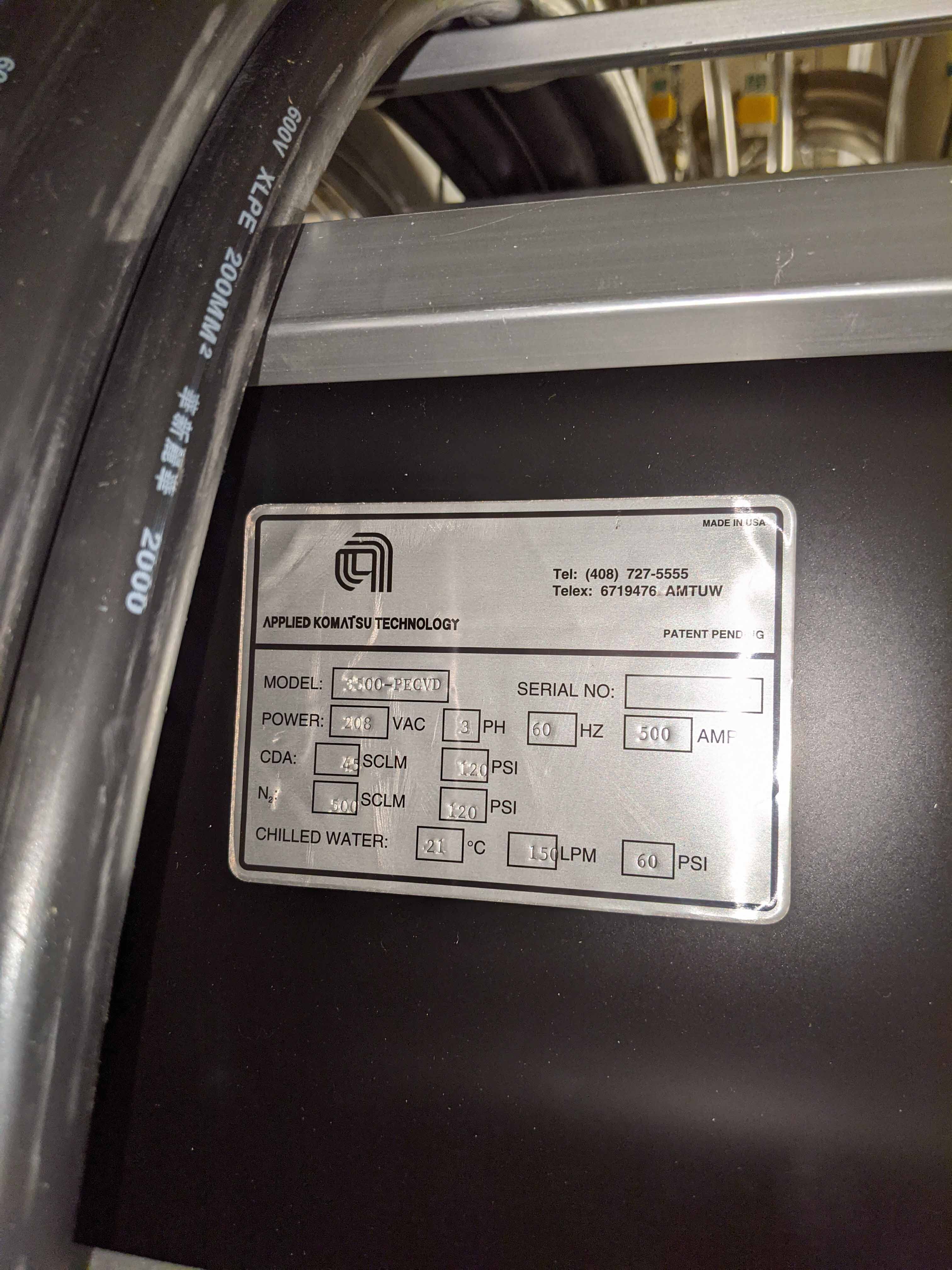

Used AMAT / APPLIED MATERIALS 3500 #9380507 for sale

URL successfully copied!

Tap to zoom

AMAT / APPLIED MATERIALS / AKT 3500 Reactor is a high-performance magnetically confined electron cyclotron resonance (ECR) plasma reactor used for the reliable, efficient and precise deposition of layers and coatings on a wide range of substrates. The reactor can achieve uniform plasma etching in a range of chamber geometries, with parametric flexibility enabling optimal process optimization. The in-situ plasma characterization capability provided by AKT 3500 Reactor provides powerful feedback control capability for process optimization and constant uniform deposition over area. AMAT AKT-3500 Reactor is capable of producing high-density, highly energetic plasmas that can be utilized for a wide range of deposition applications including diamond-like carbon (DLC) coatings, dielectric layers, multi-layer stacks and wide bandgap oxide layers. The reactor has a plc-driven C-V robot-feeder that is capable of controlling and monitoring all process parameters, such as heater power, gas flows and deposition rates, to ensure the reliability and uniformity of the deposition. The high-density plasmas and the uniform deposition rate are enabled by the use of dual magnetic field systems combined with an electron heating equipment. The dual-magnetic field systems of APPLIED MATERIALS 3500 Reactor is located inside a chamber that is cooled by a helium closed-loop cooling system to maintain a stable working environment. The magnetic field is generated by two helically wound planar inductors that form an ECR zone. This ECR zone allows for a wide dynamic range in electron temperature conditions that are highly conducive to the efficient production of a high-density, energetic plasma. The electron heating unit of 3500 Reactor is a microwave waveguide machine which is connected to the ECR zone. The microwaves are generated through the RF subsystem and strategically positioned inside the chamber which allows for maximum energy density for highly efficient plasma production. The remaining processing systems, such as the gas feed tool, are designed to ensure an uninterrupted and consistent process throughout the duration of the deposition process. AKT-3500 Reactor is a reliable, efficient and precise deposition asset that is capable of producing a wide range of high-quality layers and coatings. The reactor has in-situ plasma characterization for powerful feedback control and a closed-loop cooling model for a consistently stable deposition environment. With its parametric flexibility and advanced process control solutions, AKT AKT-3500 Reactor offers the highest level of process optimization and uniform deposition for any deposition application.

There are no reviews yet