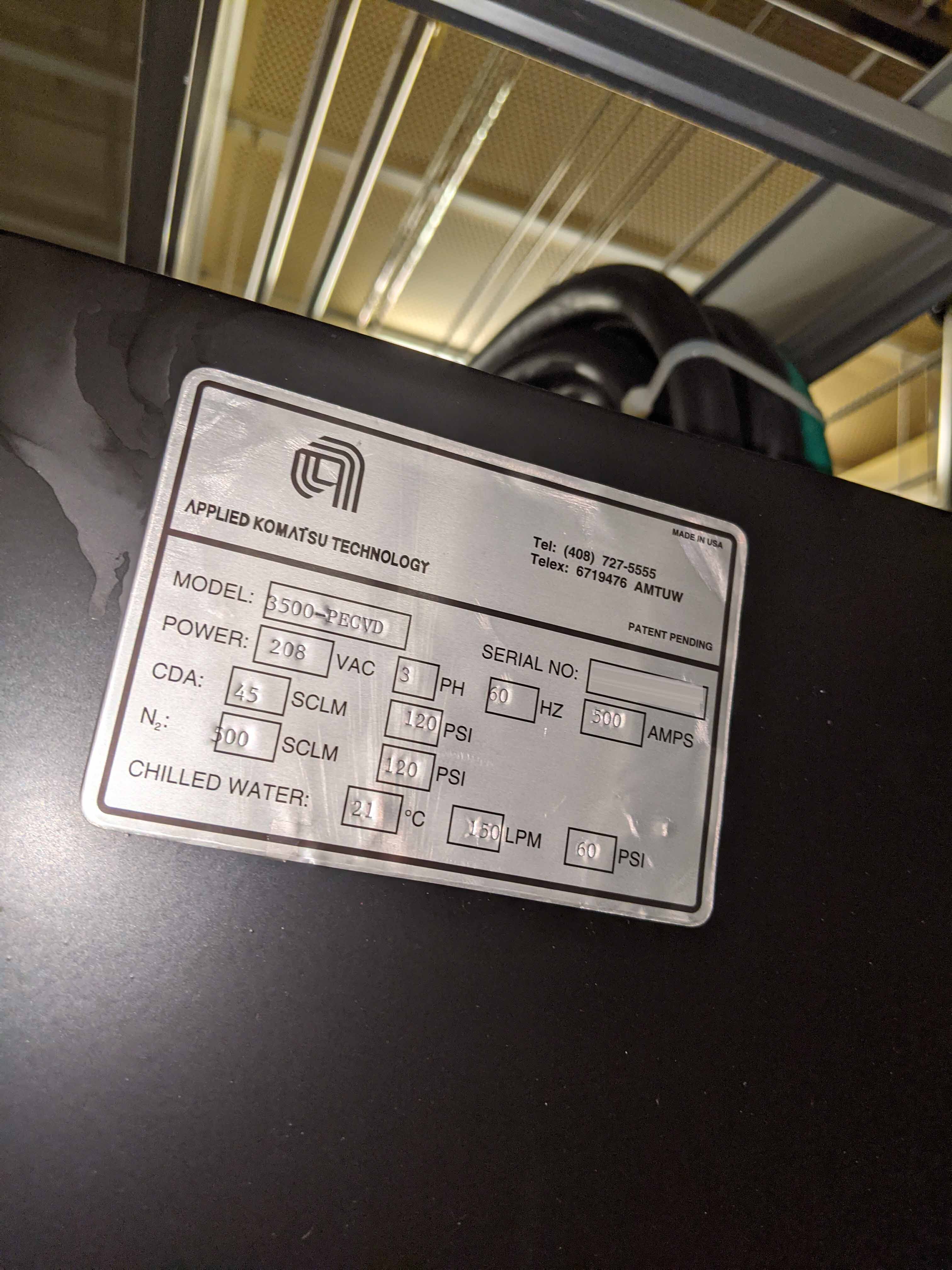

Used AMAT / APPLIED MATERIALS 3500 #9380510 for sale

URL successfully copied!

Tap to zoom

AMAT / APPLIED MATERIALS / AKT 3500 is a high-performance high-density plasma enhanced chemical vapor deposition (HD PECVD) reactor used for thin-film deposition. It is designed to deposit thin films onto wafers of up to six inches in size and is fully automated, allowing for the deposition of high quality films with high repeatability and reproducibility. The PECVD process enables the deposition of films through the activation and combination of gases. The PECVD process is conducted in the reactor's chamber, also known as the plasma chamber, a reaction chamber, or a deposition chamber. The materials used in the deposition are typically a precursors, introduced as a gas into the plasma chamber. The chamber contains an electrode system creating an electrical field that produces a high-density plasma which breaks down the precursors into active species allowing their deposition onto a wafer substrate placed at the chamber's bottom. The PECVD process can be performed with temperatures ranging from 25 to 500°C and at various pressures of both inert and reactive gas. The density of the plasma is measured in Watt/cm3 and is limited by the circuit's power capacity and by the material's susceptance. AKT 3500 is designed with eight electrode systems, allowing an excellent uniformity and step coverage across the wafer substrate. The combination of the electrode system and the variable gas pressure allows for precise control of the quality and thickness of the deposited film. The silicon-based VMOS capacitor is adopted in the construction of the PECVD reactor, and provides six volts at 50 kHz performance. The combination of an advanced cooling system and optimally designed electrodes ensures high plasma density and stability while the computational fluid dynamics (CFD) enables the optimization of the reactor's performance. Additionally, the PECVD reactor is also compatible with adaptive-controlled thickness uniformity (ACTURO) technology which employs a built-in algorithm for controlling the deposition process. This process helps in optimizing the deposition uniformity across the wafer and compensates for every individual deposition requirement like flow rate, pressure, and plasma power. AMAT AKT-3500 is a cutting-edge PECVD tool, which can be reprogrammed to adjust the temperature, pressure, gas flow, and plasma power to suit a variety of applications. Its ability to produce uniform and repeatable performance on various substrates enables them to be used widely for thin-film deposition in various industries including microelectronics, medical equipment, and products.

There are no reviews yet