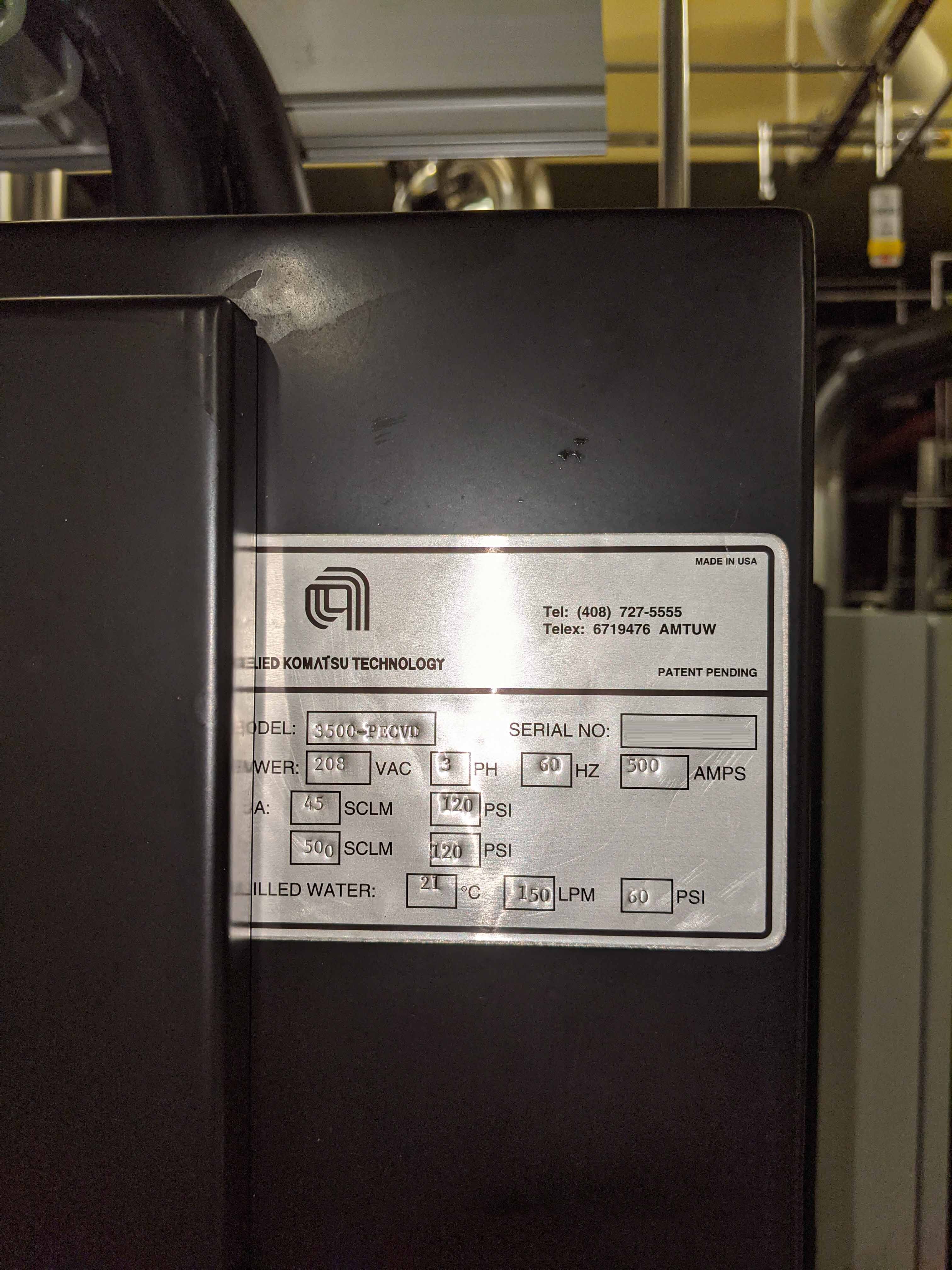

Used AMAT / APPLIED MATERIALS 3500 #9380511 for sale

URL successfully copied!

Tap to zoom

AMAT / APPLIED MATERIALS / AKT 3500 is a high-performance equipment that can be used to fabricate nanoscale devices through the reaction of substrates and dopants. This cutting-edge reactor is designed to provide exceptional process stability, efficiency, and repeatability. It employs an advanced process control system, allowing for precise control of chamber parameters, in-situ monitoring of chamber conditions during process execution. AKT 3500 features an advanced vacuum chamber, capable of achieving process pressures from low to high (10-4 to 10-2 torr). This chamber is equipped with both a tilt and rotate capability, enabling the device to be mounted at various angles. This capability provides greater control over the process, enhancing the control of tool tilt and rotation to create more uniform nanostructures. The reactor is also highly versatile, capable of conducting processes across a range of temperatures (down to -120°C) and wafer sizes (from 4" up to 8"). With its built-in gas mixing manifold, AMAT AKT-3500 can also mix gases at high precision (1 point calibration) to better control the process. AKT AKT-3500 is configured with an advanced cooling unit, giving the device an operational cooling capacity from -30°C up to 200°C. This cooling machine helps maintain stable temperatures that enhance the development of nanostructures with superior properties and performance. The device also boasts an improved uniformity performance, meaning that more uniform nanostructures can be produced with greater efficiency. 3500 also incorporates safety features such as an interlock tool that monitors the parameters of the process in order to ensure process stability. The device is also equipped with a self-check function that can identify minor equipment malfunctions to reduce the likelihood of major process disruptions. Overall, APPLIED MATERIALS AKT-3500 is an advanced asset capable of producing nanostructures with superior properties and performance. This model provides powerful temperature control, improved process uniformity, comprehensive monitoring, and various safety features that make it an invaluable tool in the production of nano-scale devices.

There are no reviews yet