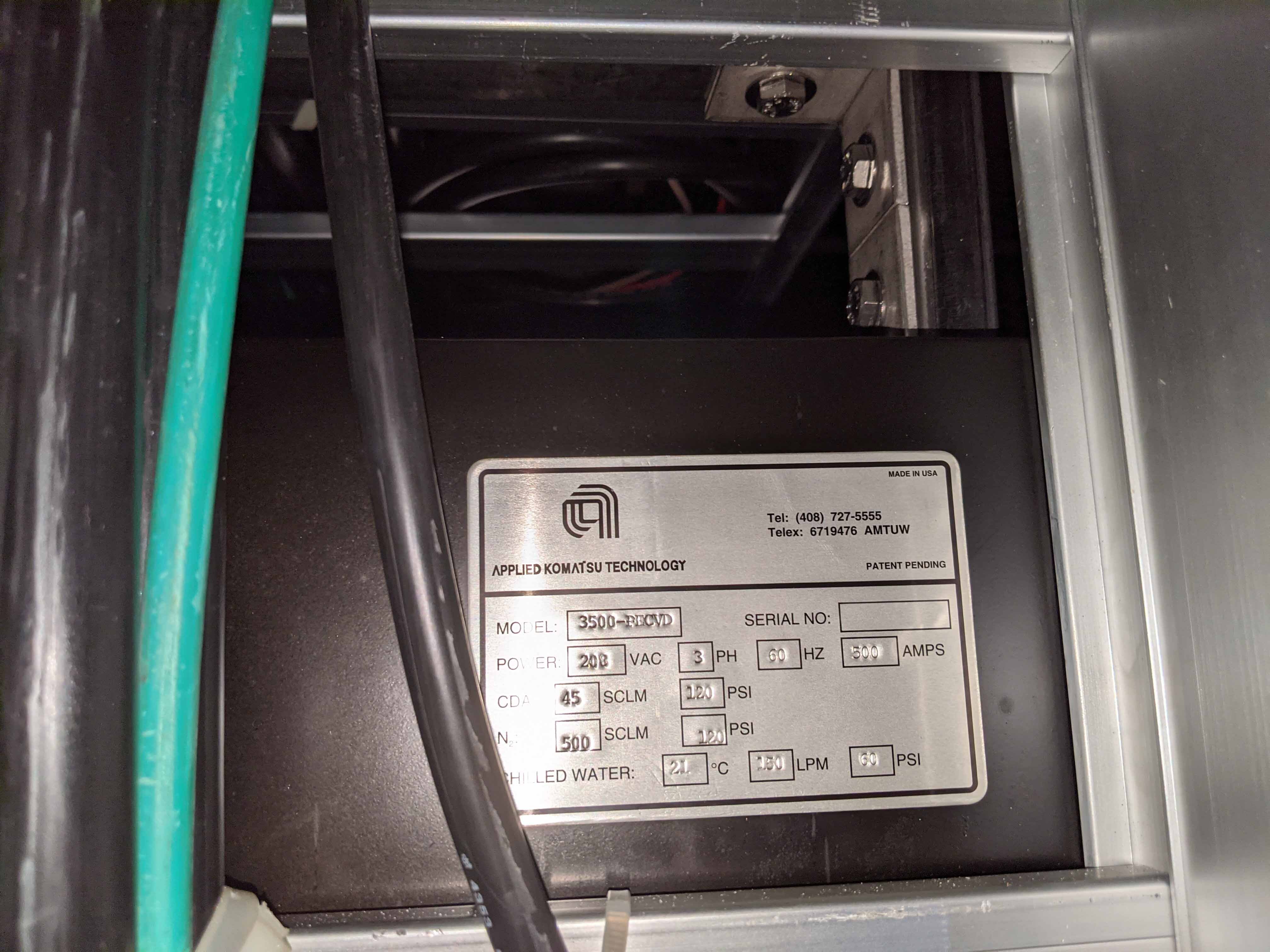

Used AMAT / APPLIED MATERIALS 3500 #9380517 for sale

URL successfully copied!

Tap to zoom

AKT, Inc. (AMAT) AMAT / APPLIED MATERIALS / AKT 3500 reactor is a versatile plasma etching and deposition equipment used for various semiconductor fabrication processes. This tool is typically used for reactive ion etching (RIE), ion milling, and chemical vapor deposition (CVD). This system is a high vacuum chamber which provides a cross-sectional area and a working volume of approximately 25 cm cubic, and operates under a vacuum of approximately 10-7 Torr. The whole unit is computer controlled and contains various process parameters such as pressure, temperature, molecule flux, time, ion energy, electron temperature, and gas species. In order to achieve high quality results, AKT 3500 reactor uses advanced isolation materials such as alumina and stainless steel to prevent contamination from the environment, and to ensure repeatable control and response. The chamber also includes a high power antenna which is used to generate a high power plasma beam. This antenna is controlled by the machine to enable precise plasma etching and sharp deposition of materials on the semiconductor wafer. Furthermore, the reactor can provide a temperature range from -25°C to 250°C. Its advanced gas heating tool helps to ensure fast and accurate processing. In addition, AMAT AKT-3500 offers various types of deposition, including low pressure chemical vapor deposition (LPCVD), sputtering, evaporation, and plasma enhanced chemical vapor deposition (PECVD). The asset is fully integrated with an automatic cassette-to-cassette model, which can be used for continuous without manual transfer. This feature can simplify loading and unloading process and help improve production efficiency. The impressive versatility and accuracy of 3500 make it especially suitable for use in fine line structure and advanced device fabrication. It is widely used in Integrated Circuits (ICs) development, and is a cost-effective solution for semiconductor manufacturers. Furthermore, the equipment is designed with robust safety standards and comes with several features such as over-temperature control, pressure sensor, and alarm system. All in all, APPLIED MATERIALS 3500 provides reliable and repeatable results, and is versatile enough for etching and deposition of a wide variety of materials.

There are no reviews yet