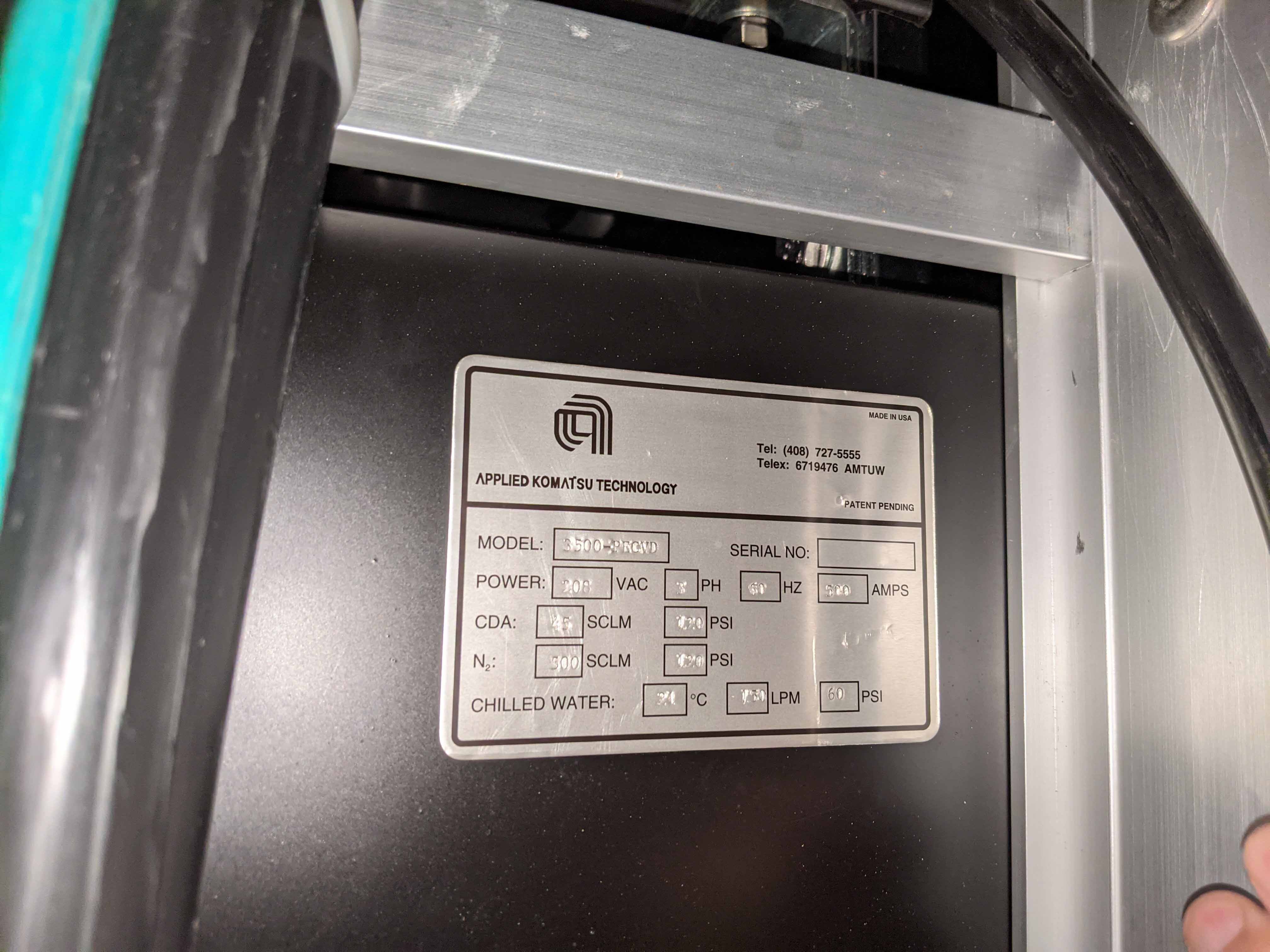

Used AMAT / APPLIED MATERIALS 3500 #9380518 for sale

URL successfully copied!

Tap to zoom

AMAT / APPLIED MATERIALS / AKT 3500 is a high-precision plasma reactor equipment designed for ion implantation processes. It features a programmable planning system that allows for precise control of dose and current distribution. This unit is widely used in the semiconductor industry for processing semiconductor wafers. AKT 3500 consists of a power supply, a plasma source, and a vacuum chamber. The power supply is responsible for controlling the power supply for the plasma source. It can be programmed to regulate the amount of power delivered to the process. The plasma source produces a high-energy plasma that is then ionized by the power supply. This results in a current of ionized particles that can be used to implant ions into the material being processed. The vacuum chamber is a sealed, air-tight container where the process occurs. The material to be processed is placed in the chamber and then heated to the desired temperature to facilitate the implantation of the ions. The implantation process typically requires a vacuum of 10-6 Torr. Once this pressure has been achieved, the power supply is activated and the ionization process begins. The particles are accelerated through the machine and then impact the material, resulting in implantation of the desired elements. The programmable planning tool of AMAT AKT-3500 allows for precise control over the process. The parameters such as current density and dose can be programmed to define the desired results. The asset is equipped with up to four separate processing channels, each with its own chamber, enabling multiple wafers or substrates to be processed simultaneously. AMAT 3500 is an efficient and accurate reactor model that can be used in a variety of industrial applications. It is designed with a user-friendly interface and provides precise control of dose and current during an ion implantation process. This makes it possible to tailor the implantation process to specific customer requirements and ensures process uniformity. This equipment is an invaluable tool in semiconductor wafer processing and is widely used in the industry.

There are no reviews yet