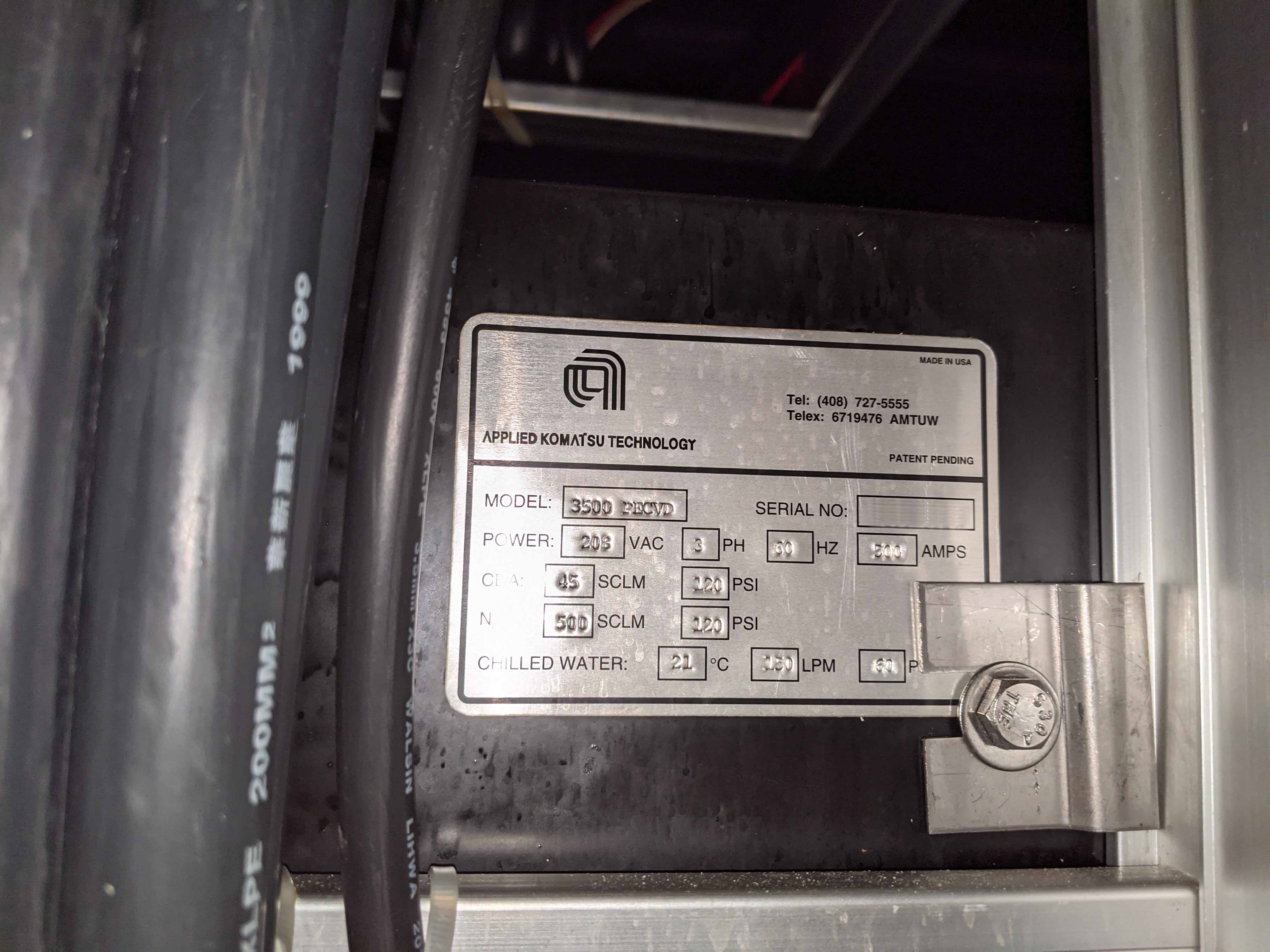

Used AMAT / APPLIED MATERIALS 3500 #9380520 for sale

URL successfully copied!

Tap to zoom

AKT/AMAT / APPLIED MATERIALS / AKT 3500 is a single-wafer spin-etch reactor designed specifically for etching large etched structures in aqueous media. The reactor is capable of producing intricate patterns and precise feature shapes. AKT 3500 has been optimized to etch small and large etched structures, as well as high-throughput uniform etching applications. This includes designs with both positive and negative photoresist features and micro-channeled structures. AMAT AKT-3500's unique design enables robust and repeatable uniform, consistent etching results. It offers great control over the etching rate and selectivity, as well as accurate feature definition and depth control. The process also has excellent electron-beam mask-edge definition and substrate temperature control during the etching process. The reactor uses an acid-based solution as the etchant. This can range from an aqueous solution of dilute HCl to a more complex solution. The etch process is initiated by applying the photoresist on the substrate, which is then spun onto the platen of AMAT / APPLIED MATERIALS / AKT AKT-3500. This is then exposed to high intensity ultra-violet light for a few seconds, allowing the photoresist to adhere to the substrate. The etchant is then added to the platen and the wafer is spun in this solution for a set period of time. During this period, the etchant reacts with the photoresist, developing the desired topography on the substrate. Once the desired process step has been completed, the platen is rinsed with DI water and the substrate is spun dry. After that, the dried photoresist is removed and the substrate is inspected for the desired results. The whole process is quite simple and can be completed with minimal operator intervention. AKT AKT-3500 reactor is a great tool for etching features on a variety of different substrates. It provides accurate and consistent etching times, allowing for highly precise results with excellent repeatability. The ability to change the etchant concentration and adjust the process parameters enables the user to etch different materials in different thicknesses, making it a great versatile tool for etching.

There are no reviews yet