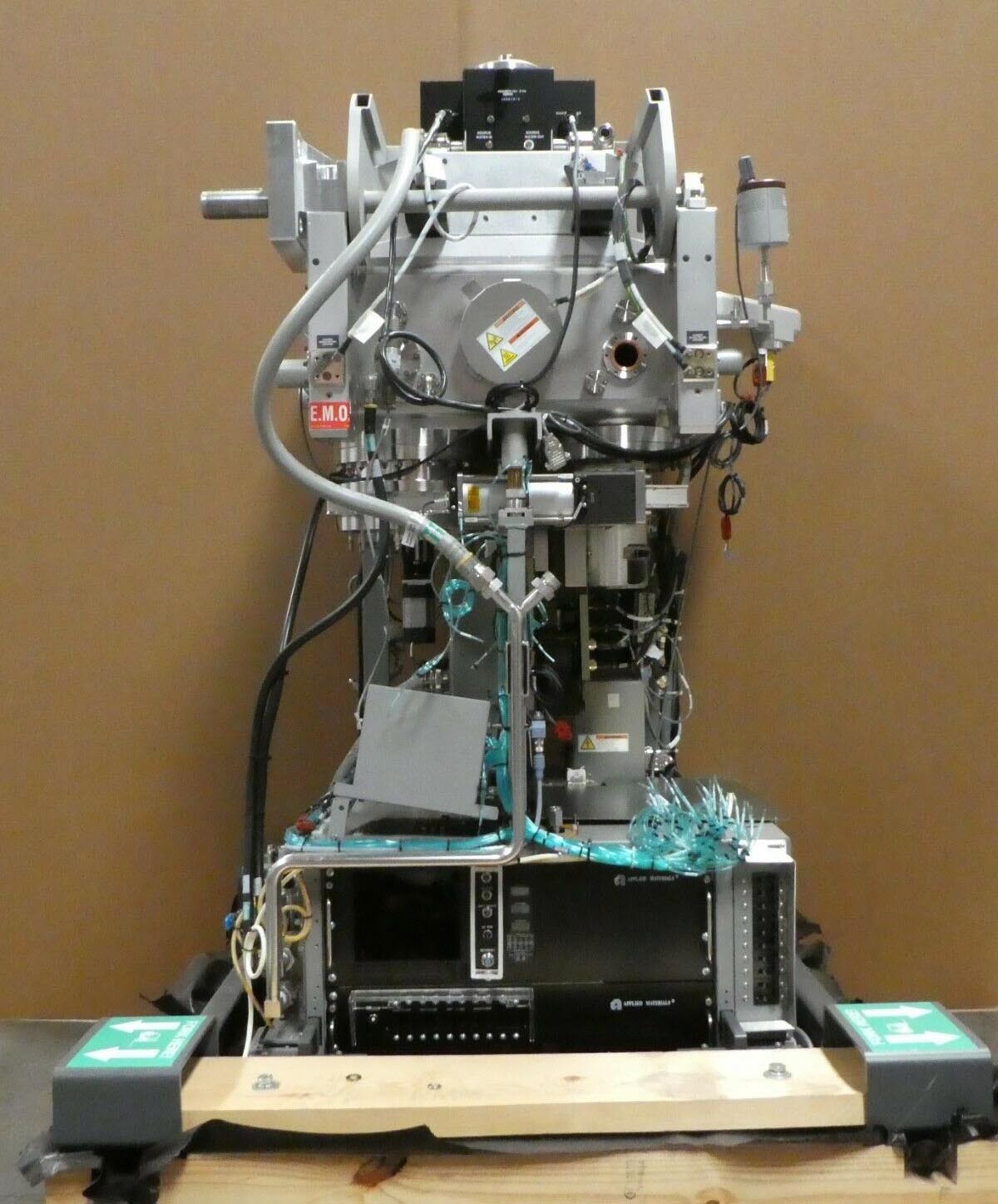

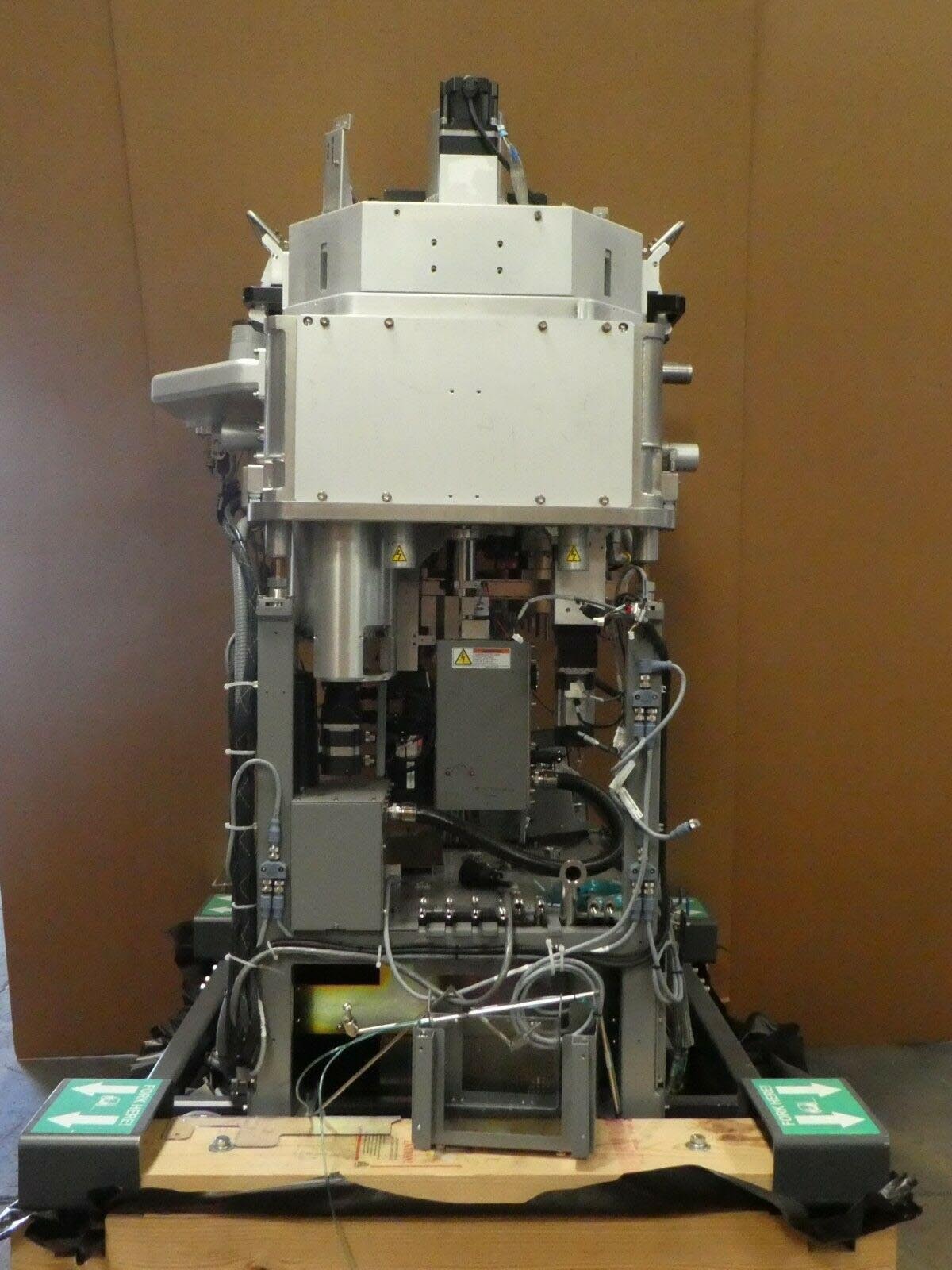

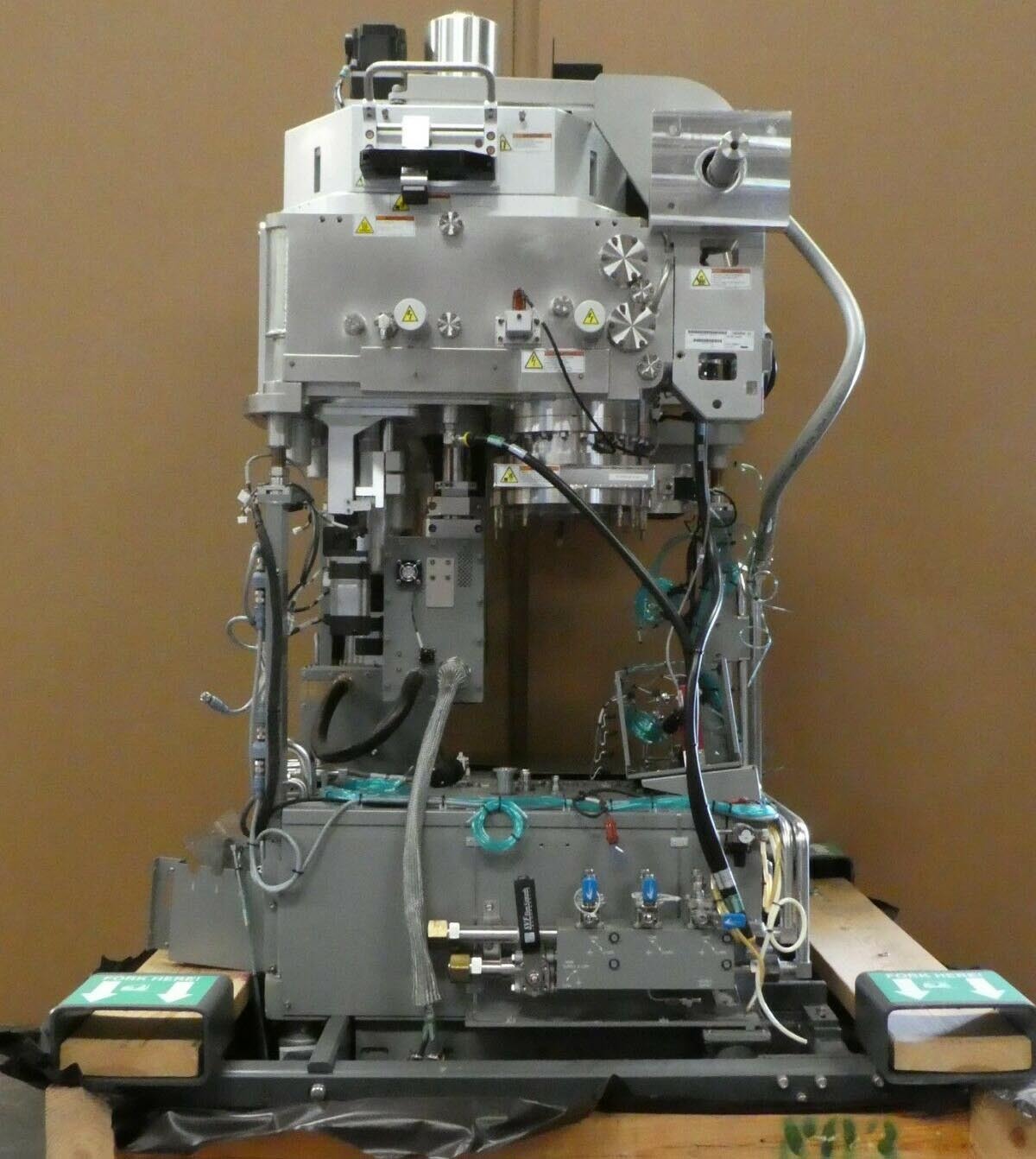

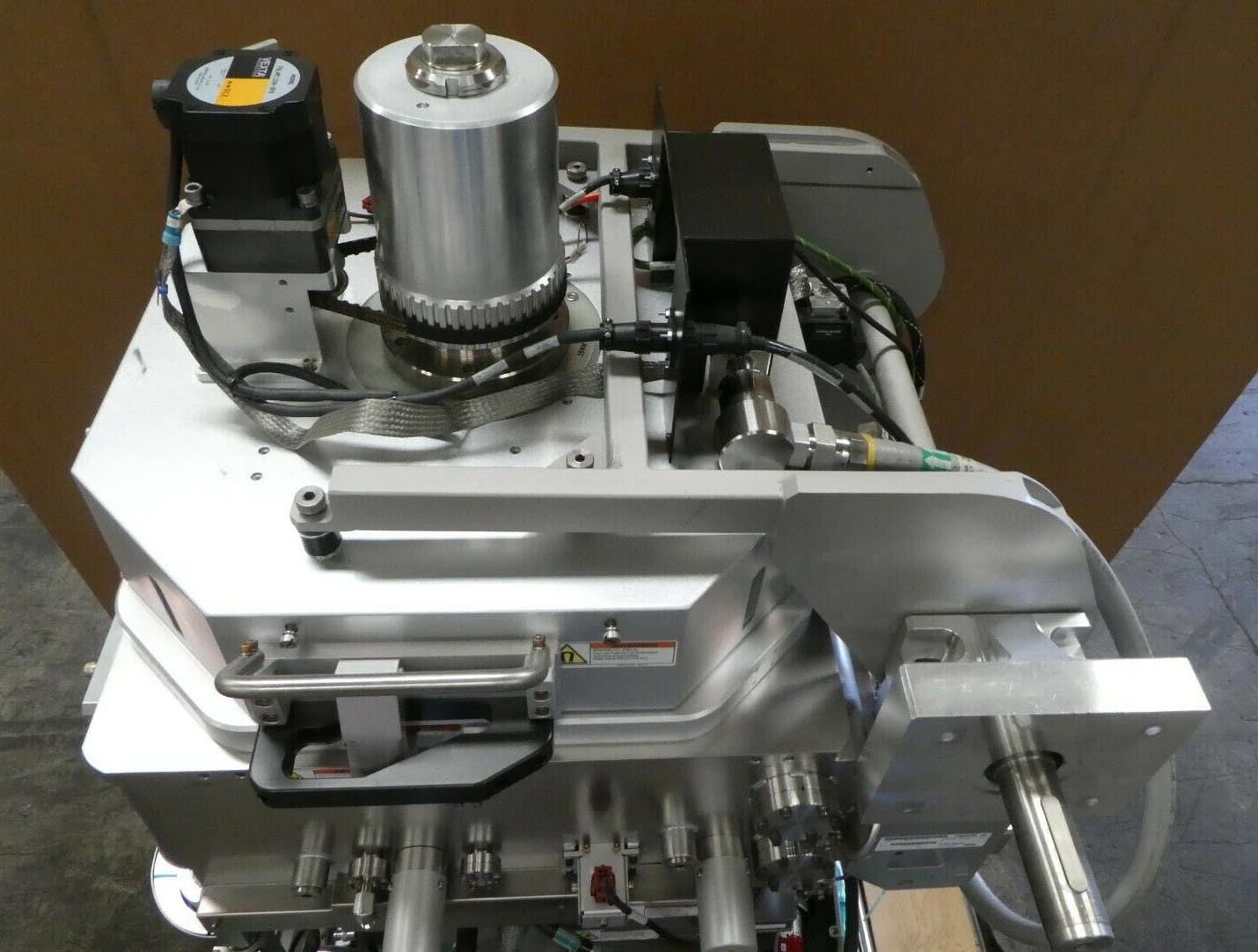

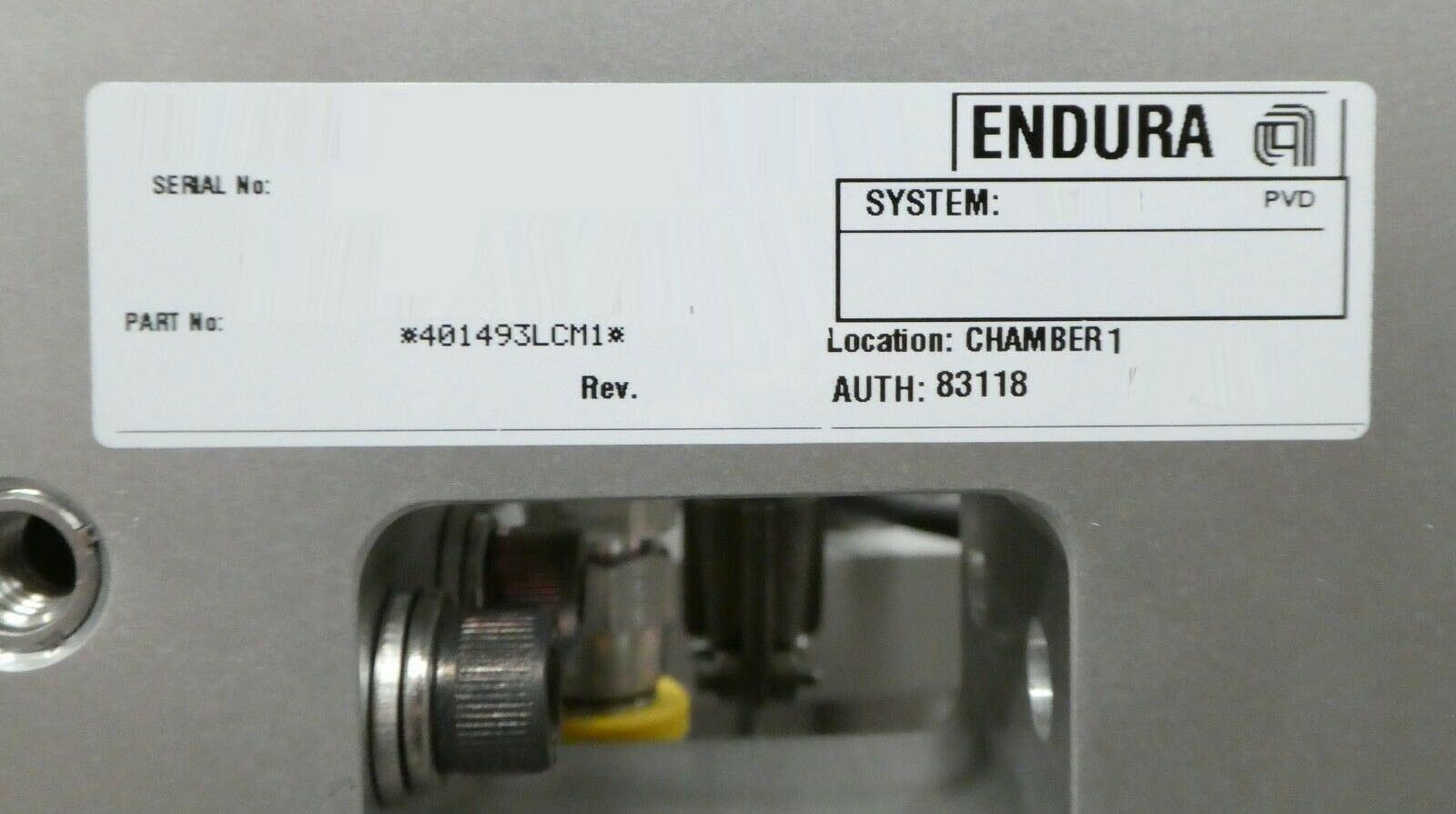

Used AMAT / APPLIED MATERIALS 401493LCM1 #9384031 for sale

URL successfully copied!

Tap to zoom

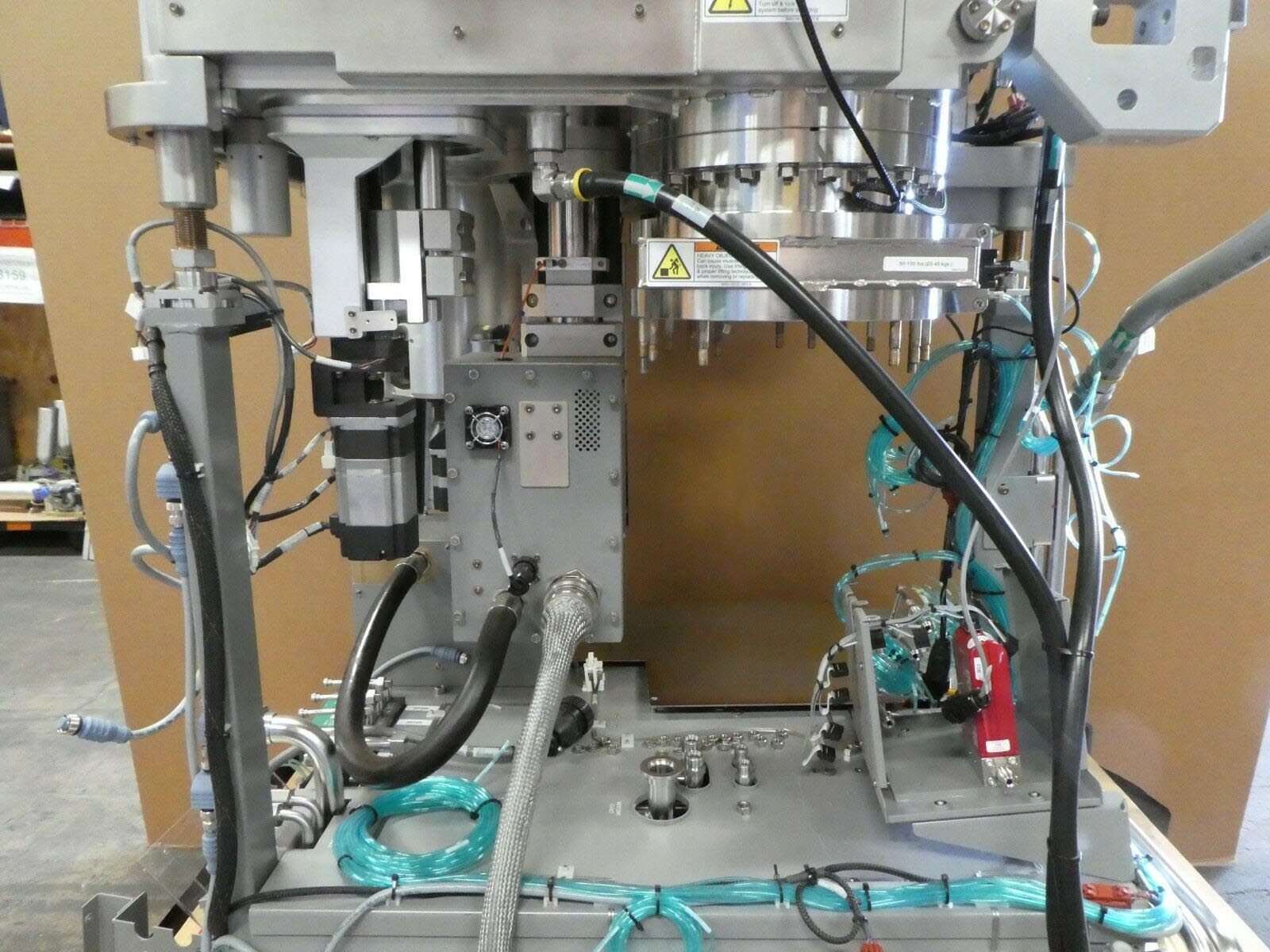

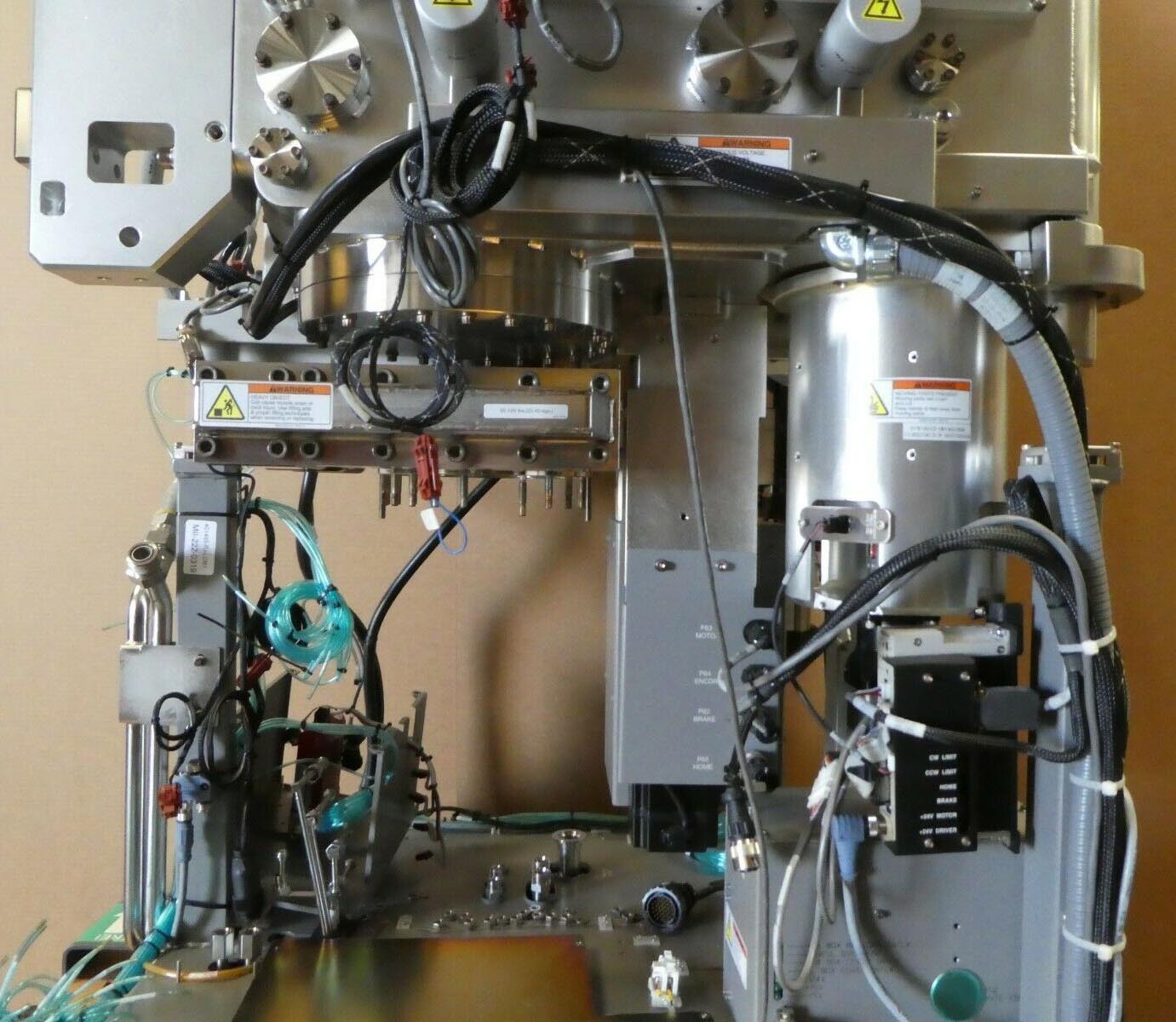

AMAT / APPLIED MATERIALS 401493LCM1 is a stationary metal chamber, designed to increase a specific species concentration in gas, liquid, and/or solid phases. It is comprised of an outer steel cylindrical housing, four stainless steel reaction tubes, and a ceramic tube, all contained within an oxygen-free, hot zone atmosphere. The approximately 7-foot tall chamber is connected to two temperature- and pressure-controlled hot zones, a thermal conductivity detector (TCD) for monitoring process gases, and a mass flow controller (MFC) for controlling process flow. The reaction tubes, made from stainless steel, are suspended within the cylindrical housing and are lined with inert ceramic. The ceramic-lined tubes reduce contamination and correct unwanted fluctuations in hot zone temperatures. Heaters embedded within the ceramic tube walls serve to maintain a homogenous vacuum and chamber temperature. AMAT 401493LCM1 utilizes an interface between the chamber and the heated zone that allows for the injection of the process gas. The process gas is distributed evenly throughout the chamber, ensuring an even concentration of the species for homogenous growth. The heated zones each achieve temperatures up to 700C, and are manipulated by the TCD. The MFC regulates the process gas through individual inlet controllers, and the pressure of the process gas is kept constant within a range of 10 to 15 psi. APPLIED MATERIALS 401493LCM1 is composed of materials that are corrosion and oxidation-resistant, making it an advantageous and reliable reactor for an extended range of continuous deposition processes. Type 304 stainless steel lines the interior of the reaction tube, providing for an efficiently maintained protective atmosphere. And the chamber is designed with pressure ratings up to 15 PSIG to ensure the desired product output. Overall, 401493LCM1 is a three-inch diameter, highly efficient reactor designed to improve reactor performance and ensure improved product quality. It is an ideal choice for depositing hard masks, thin films, multi-layer dies, Metallization, and a wide range of other related technologies. This reactor is simple to maintain, reducing downtime and allowing for a more responsive, productive, and cost-effective manufacturing process.

There are no reviews yet