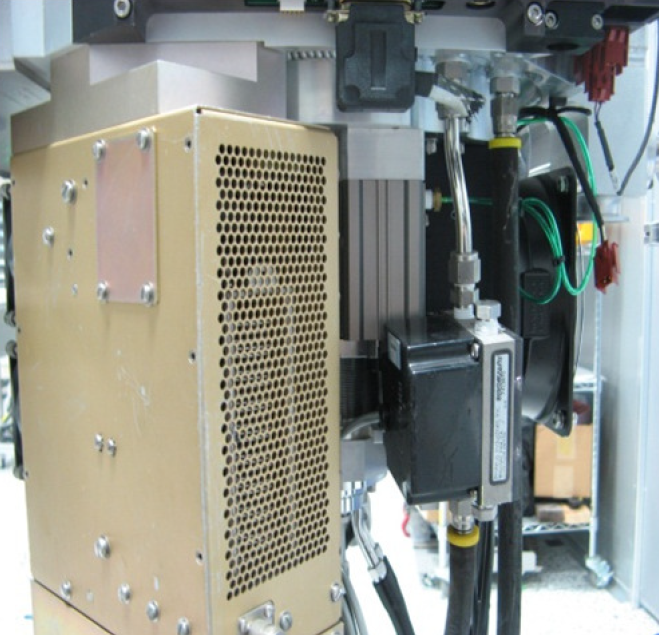

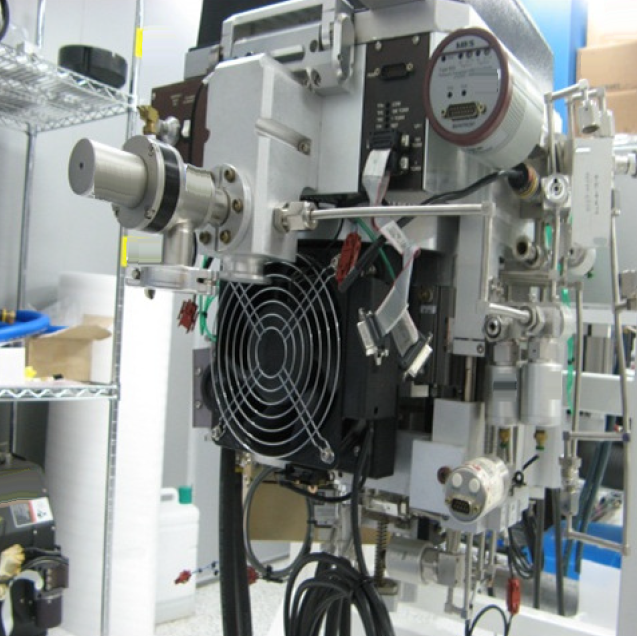

Used AMAT / APPLIED MATERIALS 5200 #170732 for sale

URL successfully copied!

Tap to zoom

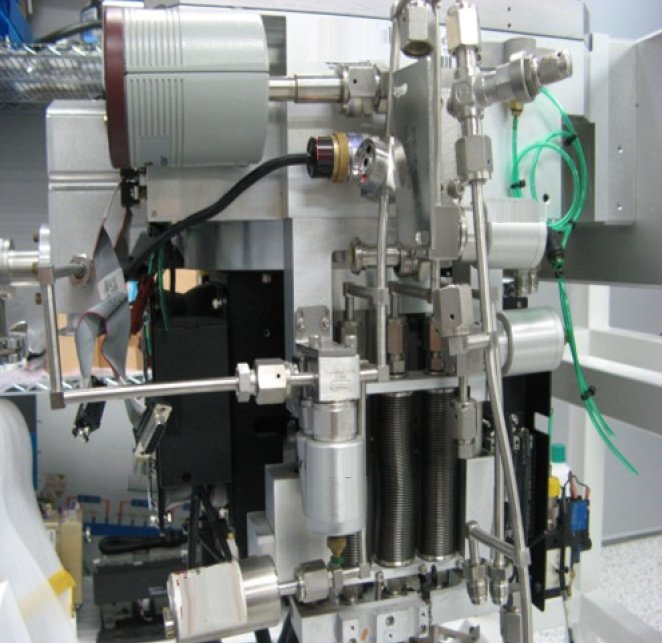

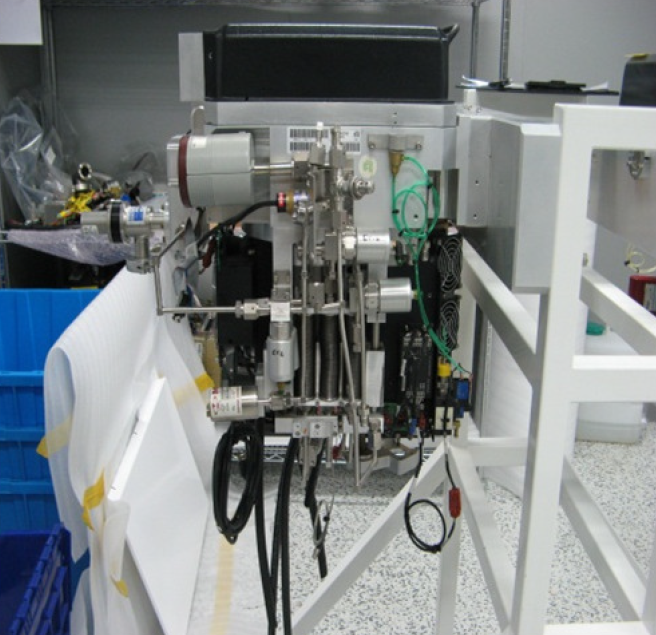

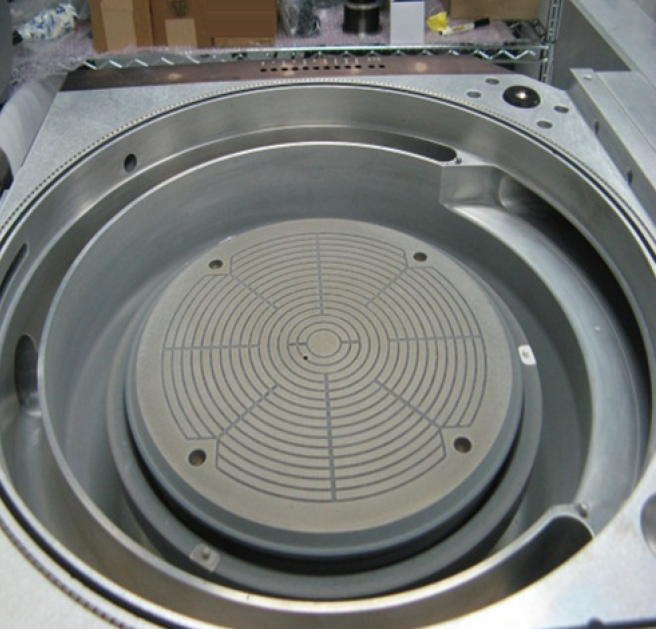

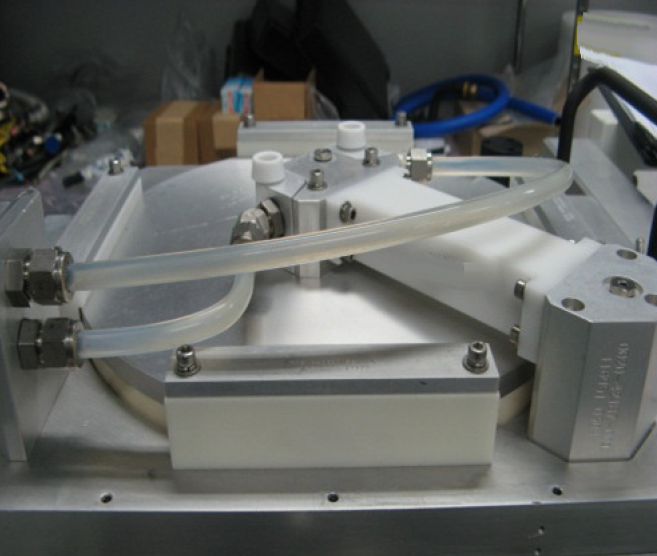

AMAT / APPLIED MATERIALS 5200 (AMAT 5200) is a reactive sputter deposition equipment designed to deposit thin film coatings with controlled characteristic on semiconductor and optoelectronic wafers. It is widely used for deposition of transparent conducting oxides (TCOs), compund semiconductors, metals, and dielectric materials. APPLIED MATERIALS 5200 is a versatile deposition tool with several operating modes and a wide range of process control. 5200 is a unique magnetron sputter deposition system. It consists of a vacuum chamber, a rotatable substrate holder, up to four cylindrical magnetron sputter sources and optional sources for electron beam evaporation, thermal evaporation and ion beam assist deposition (IBAD). The sputter sources are placed at the top of the chamber and the substrate rotates horizontally in an area defined by high power magnets. The substrate is mounted on a static or magnetically levitated rotating substrate holder. The substrate is heated by either a heated heater or resistive cartridges. Heat is controlled through a high-sensitivity proportional-integral-derivative (PID) heating control unit. By utilizing the rotary sputter source, the background pressure required for operation is kept within a very tight range while the layer thickness uniformity is increased. AMAT / APPLIED MATERIALS 5200 is capable of depositing many different types of materials with a very high deposition rate up to 45 Å/minute. The magnetron sputter sources can be operated in DC, dual frequency, and/or RF mode, allowing for a wider variability of material target selection and thickness control. In addition, the optional sources for electron beam evaporation, thermal evaporation, and ion beam assist deposition (IBAD) give the machine additional versatility in layer deposition. AMAT 5200 is equipped with various process monitoring capabilities. It features an ion gauge monitor and separate flow sensors that allow users to monitor the chamber background pressure in real-time during the deposition process. It also has a quad segment mass-flow controller that can throttle the gases to different pressure regions and gives the user the ability to precisely tune the process gas conditions. APPLIED MATERIALS 5200 utilizes advanced process control tool (APCS) to optimize the film deposition process. The APCS allows for accurate time-zero adjustment for precise layer thickness control and provides precise real-time monitoring of the layer deposition process. The APCS also includes a sensor asset for critical process parameters including power control, pressure and temperature. In conclusion, 5200 is a versatile thin-film deposition tool with many different applications in the field of optoelectronics, semiconductor and dielectric device fabrication. It features a range of operational modes and precise process control parameters to create precise layers with the desired characteristics. The tool is used in research in leading laboratories around the world and provides a reliable and cost-efficient alternative to other systems.

There are no reviews yet