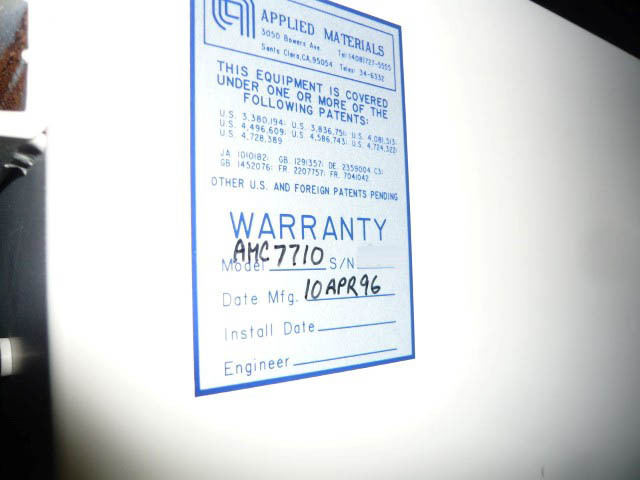

Used AMAT / APPLIED MATERIALS 7710 #9095871 for sale

URL successfully copied!

Tap to zoom

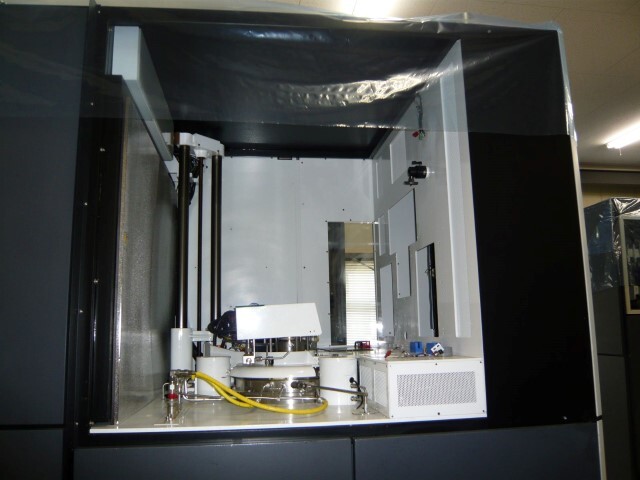

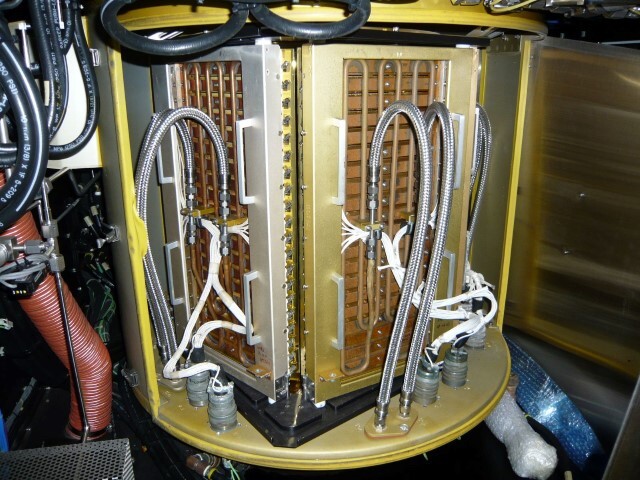

AMAT / APPLIED MATERIALS 7710 is a type of chemical vapor deposition (CVD) equipment used in the semiconductor industry for the growth of materials on substrates. AMAT 7710 is a single-wafer thermal CVD system designed to meet the most challenging deposition needs with precise control and repeatability of process parameters. The quality, uniformity and repeatability of the resulting films are unparalleled in the industry. The unit features a quartz reactor chamber that can accommodate a single 4" or 8" wafer and the Czochralski method can hold up to two 8" wafers. APPLIED MATERIALS 7710 CVD machine offers an integrated fluid flow control, with two independent gas lines, one line for carrier gas with a precision mass flow controller, and the other for dopant precursors with an independent flow controller. The tool is equipped with several process parameters including temperature, pressure, reactant flow rates, radiometers and HMDS for cleaning, as well as two pre-set user defined recipes. The process chamber temperature can be set to temperatures as low as 50°C for low temperature deposition needs and as high as 950°C. The quartz chamber of 7710 offers fast thermal recovery and a wide range of process recipes. An integrated wafer temperature control allows for tight control of wafer surface temperatures and ensures uniform films across the entire wafer. The asset can also be programmed to pause and resume deposition to reduce non-uniformity or saturation during film growth. Additionally, the proximity of the substrate to the source materials eliminates the need for additional plasma systems. The CVD model also features process control software that provides real-time process monitoring and control. AMAT / APPLIED MATERIALS 7710 is designed for reliability and maintenance is made easy with the repeatability of components for fast and easy replacement. Safety features like the fully automated door interlocks, alarms, and emergency shut off switches make sure the equipment remains safe and secure. The system is also extremely efficient with a low gas consumption rate and the quartz chamber captures gas after-effects to secure a high quality deposition. AMAT 7710 is ideal for research and development purposes and its reliability, quality, and repeatability make it an ideal choice for fabricating some of the most precise and sophisticated semiconductor devices.

There are no reviews yet